Transcription

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko MarkičBuilding Materials Reuse and RecycleDAVORIN KRALJ¹, MIRKO MARKIČ²ART-K, BusinessConsulting, Na gricu 47, 2000 Maribor, SLOVENIA¹,Faculty of Management, University of Primorska, Cankarjeva ul. 5, 6104 Koper,SLOVENIA¹,²davorin.kralj@amis.net, mirko.markic@fm-kp.siAbstract: The building industry has not only become a major consumer of materials; it ha salso become a sourceof polluttion. Environmental integrated production and reusing and recycling is of great importance for thecompetitev position in EU Member States. EU Member States shall ensure that the technical, environmental andeconomic feasibility of alternative systems is considered and is taken into account before construction starts . Thearticle focuses on Reuse Building Materials as a way for environment protection and sustainable development.Integrated environmental management integrates the requirements of sustainable development and LCA. There aremany methods used to reduce waste and increase profits through salvage, reuse, and the recycling of constructionwaste. Sustainable development as a tool to continual improvement cycle and with processes innovation the needto save money in the processes via reduced resources and utility costs. This article demonstrates that alternatives tomodern building materials are available.Key words: environment, management, reuse, salvage, sustainable developmentbuildings and for large existing buildings that aresubject to major renovation (EPBD Articles 4, 5 and6). Other tools will be energy certification of buildings(Article 7) and inspection of boilers and airconditioning systems (Articles 8 and 9).A basic requirement for measures in Articles 4, 5, 6and 7 is the existence of a general framework for amethodology of calculation of the total energyperformance of buildings, as set out in Article 3 andthe Annex to the Directive [1].Directive 2002/91/EC OF THE EUROPEANPARLIAMENT AND OF THE COUNCILof 16December 2002 on the energy performance ofbuildings in article 5 says:Member States shall take the necessary measures toensure that new buildings meet the minimum energyperformance requirements referred to in Article 4. Fornew buildings with a total useful floor area over 1 000m2, Member States shall ensure that the technical,environmental and economic feasibility of alternativesystems such as:1 IntroductionAll systems recycle. The biosphere is a network ofcontinually recycling materials and information inalternating cycles of convergence and divergence. Asmaterials converge or become more concentrated theygain in quality, increasing their potentials to driveuseful work in proportion to their concentrationsrelative to the environment. As their potentials areused, materials diverge, or become more dispersed inthe landscape, only to be concentrated again at anothertime and place. Fitting the patterns of humanity tothese material cycling pathways has becomeparamount in importance as our numbers and influenceon the biosphere increases [11].Directive 2002/91/EC on the energy performance ofbuildings (the EPBD) requires several differentmeasures to achieve prudent and rational use of energyresources and to reduce the environmental impact ofthe energy use for buildings. This is to beaccomplished by increased energy efficiency in bothnew and existing buildings. One tool for this will bethe application by Member States of minimumrequirements on the energy performance of newISSN: 1790-5079 409decentralised energy supply systems based onrenewable energy,Issue 5, Volume 4, April 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENT Davorin Kralj, Mirko MarkičStrategies include zero waste, integrated recycling,international approaches, reuse of materials, resourceoptimisation, waste reduction, and deconstruction.Examination of the waste management hierarchy andlife cycle management of material is used to improvethe understanding of reuse and recycle opportunities.Other considerations include cost, economic factors,social factors and environmental factors. All of theseassessments are needed to develop a comprehensivewaste management plan for a specific project [13].CHP,district or block heating or cooling, ifavailable,heat pumps, under certain conditions,is considered and is taken into account beforeconstruction starts [2].In order to stop the global warmth due to the CO2concentration, the energy use should be decreased. Theinvestment of building construction industry in Japanis about 20% of GDP. This fraction is much higherthan in most developed countries. That results theJapanese building construction industry includingresidential use consumes about one third of all energyand resources of the entire industrial sectors. In orderto save energy as well as resource, the recycle of thebuilding materials should be urgent to be carried out[12].2It is important to recognize that the sustained growth inreuse efforts, as well as the sustained interest of thereuse industry, derives in large measure from the solidwaste reduction hierarchy: Reduce, Reuse, thenRecycle. It is best to reduce first, reuse as a secondoption, then to resort to recycling. Reuse is recognizedas being distinct from recycling, both in doctrine, andin the handling of the materials this unique industrydiverts from the waste stream. Recyclers havesuccessfully kept materials out of the landfill bycollecting, segregating, processing and manufacturingtheir collected goods into new products. Reusers, onthe other hand, with little or no processing, keepmaterials out the waste stream by passing the goodsthey collect on to others. There are also forms ofmanaging materials that are not quite reuse and notquite recycling.Environmental Management andStrategies for building materialreuse and recycleLeaders of successful, high-growth companiesunderstand that innovation is what drives growth, andinnovation is achieved by awesome people with ashared relentless growth attitude and shared passionfor problem solving and for turning ideas into realities.Companies that continuously innovate will create andre-invent new markets, products, services, andbusiness models – which leads to more growth.Innovation is founded on your enterprise's ability torecognize market opportunities, your internalcapabilities to respond innovatively, and yourknowledge base. So, the best thing to do to guaranteegrowth is to build a sustainable innovationorganization around the following components:1. Vision and strategy for innovation2. Culture supporting innovation3. Processes, practices and systems supportinginnovation4. Top management team leading innovation5. Cross-functional teams mapping innovation road6. Empowered employees driving innovation [14].Repair is a method of taking an item, whichmay appear to have lived its useful life, andfixing it so that it can still be productive. Remanufacturing and refurbishing are waysof taking some used components and some newcomponents to "rebuild" an item. For instance,toner cartridges are often used, then sent to amanufacturer to be broken down and rebuiltusing some of the original parts that are reusable,and some new parts. Other items commonlyrepaired or rebuilt include engines, "single-use"cameras, appliances and electronic equipment[15].Reuse is a means to prevent solid waste from enteringthe landfill, improve our communities, and increase thematerial, educational and occupational wellbeing ofour citizens by taking useful products discarded bythose who no longer want them and providing them tothose who do. In many cases, reuse supports localcommunity and social programs while providingdonating businesses with tax benefits and reduceddisposal fees [15].Reuse and recycling of building material is a growingarea of interest and concern in many parts of the USA.Current practices and trends in the building materialwaste management area are examined from a buildinglife cycle standpoint or cradle to reincarnation concept.ISSN: 1790-5079 410Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičway for people of all socio-economic circles toacquire the items they need. From businessfurniture to household items, from cars toappliances, and just about anything else you couldthink of -- it is less expensive to buy used thannew[15].3Sustainable design and construction, or "greenbuilding," is a holistic approach that minimizesenvironmental impact, reduces maintenance, andcreates a more desirable workspace for the buildingoccupants. Green building focuses on siting issues,energy and water efficiency, recycled content buildingmaterials, minimizing local and global environmentaleffects caused by buildings, and indoor environmentalquality. The goal is to transform the market of publicfunded construction, so that all projects will bedesigned and constructed reflecting green buildingprinciples [3].Figure 1: Reuse in waste reduction hierarchy [15].Benefits of Reuse: Environmental BenefitsThe Directive 2002/91/EC (EPBD) was adopted by theEuropean Parliament on 16th December 2002 andentered into force on 4th January 2003. All MemberStates have had a period of three years in order to buildup relevant systems and measures to transpose andimplementtherequirements.The EPBD is set to promote the improvement ofenergy performance of buildings with fourrequirements to be implemented by the MemberStates:Many reuse programs have evolved from local solidwaste reduction goals because reuse requires fewerresources, less energy, and less labor, compared torecycling, disposal, or the manufacture of newproducts from virgin materials. Reuse provides anexcellent, environmentally-preferred alternative toother waste management methods, because it reducesair, water and land pollution, limits the need for newnatural resources, such as timber, petroleum, fibers andother materials. The US Environmental ProtectionAgency has recently identified waste reduction as animportant method of reducing greenhouse gasemissions, a contributing factor to global warming. Community BenefitsFor many years, reuse has been used as a critical wayof getting needed materials to the many disadvantagedpopulations that exist. Reuse continues to provide anexcellent way in which to get people the food,clothing, building materials, business equipment,medical supplies and other items that they desperatelyneed. There are other ways, however, that reusebenefits the community. Many reuse centers areengaged in job-training programs, programs for theEconomic BenefitsWhen reusing materials, instead of creating newproducts from virgin materials, there is lessburden on the economy. Reuse is an economicalISSN: 1790-50791.General framework for a methodology ofcalculation of the integrated performance ofbuildings2.Setting of minimum energy standards in new andexisting buildings3.Energy certification of buildings4.Inspection and assessment of heating andcooling installations.The EPBD is foremost a measure that concerns a verylarge number of actors on all levels and with differentimpacts and different motivations: designer, housingassociations, architects, providers of buildingappliances, installation companies, building experts,owners, tenants, essentially all energy consumers inthe European Union. On 4th January 2006, theminimum requirements for energy performance shouldbe legally binding in Member Sates, EnergyCertificates should be required and inspections forhandicapped or at-risk youth programs. Green Building411Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičmeasures, for average local market conditions, meetingcost-effectiveness criteria. Before construction starts,specific studies may be requested if the measure, ormeasures, are deemed feasible [2].heating and cooling devices should be organised underan established system. The most important componentof the EPBD is energy certification (labelling) ofbuildings. Member States are obliged to ensure thatwhen buildings are constructed, sold or rented out, anEnergy Performance Certificate is made available tothe owner or by the owner to the tenant or potentialbuyer. The certification shall also include advices andinformation on how to improve energy performance,and may, for larger public buildings, provide for thedisplay of the current temperature and of therecommended indoor temperature [23]. Table 1 showsthe energy efficiency trend for the sales refrigerators &freezers, washing machines and dishwashers after thecoming into force of the relevant implementinglabelling directive ebuilding materials in your project can reduce waste,pollution, and energy use. Some examples ofreusable/recyclable/biodegradable building materialsinclude:Wood (reusable/recyclable/biodegradable) Earthen Materials (reusable/biodegradable) Steel, Aluminum, Iron, Copper(reusable/recyclable) Bricks (reusable/recyclable) Concrete (may be crushed and recycled) Gypsum/Drywall (recyclable, sometimesbiodegradeable) Straw Bale Insulation (biodegradable) Wool Carpet (biodegradable) Linoleum Flooring (biodegradable) [16].Building materials composed of one substance (e.g,steel, concrete, wood, etc.), or that are readilydisassembled into individual materials, are generallyeasiest to reuse or recycle. Materials composed ofmany ingredients, such as vinyl siding or woodchipboard are generally not readily reusable,recyclable, or biodegradable. Evaluate materialscarefully. Are they the best choice for the application?Are they durable? Can they be readily disassembledfor reuse, recycling, or biodegrading at the end of theuseful life of the building [16]?Table 1: Energy efficiency trend of themainhousehold appliances sold in the EU in 19952003 [23]Buildings will have an impact on long-term energyconsumption and new buildings should therefore meetThe extraction, manufacture and transport, anddisposal of virgin building materials pollutes air andwater, depletes resources, and damages naturalhabitats. Construction and demolition are responsiblefor roughly 30% of the U.S. solid waste stream andreal-world case studies by the Alameda County WasteManagement Authority have demonstrated more than85% of that material, from flooring to roofing topackaging, is reusable or recyclable. The extraction,manufacture and transport, and disposal of virginbuilding materials pollutes air and water, depletesresources, and damages natural habitats. Constructionminimum energy performance requirements tailored tothe local climate. Best practice should in this respectbe geared to the optimum use of factors relevant toenhancing energy performance. As the application ofalternative energy supply systems is generally notexplored to its full potential, the technical,environmental and economic feasibility of alternativeenergy supply systems should be considered; this canbe carried out once, by the Member State, through astudy which produces a list of energy conservationISSN: 1790-5079 412Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičand demolition are responsible for roughly 30% of theU.S. solid waste stream and real-world case studies bythe Alameda County Waste Management Authorityhave demonstrated more than 85% of that material,from flooring to roofing to packaging, is reusable orrecyclable[16].Practice material storage and handling procedures toprevent loss or damage.E. Purchase to Prevent Waste.Purchase salvaged, recycled, or recycled-contentmaterials and equipment.Check to ensure the correct amount of each materialis delivered to site.Maintain an up-to-date material ordering anddelivery schedule to minimize the amount of timethat materials are on-site and reduce the chance ofdamage.Replace toxic materials with less toxic or non-toxicproducts to reduce hazardous packaging.Choose products with minimal or no packaging.Ask suppliers to deliver supplies using sturdy,returnable pallets and containers. Have supplierspick up pallets and empty containers.Require suppliers to take back or buy-backsubstandard, rejected, or unused items [3].4 Minimize Construction WasteImpactsThe following considerations can minimize wasteimpacts on any size project. From the broad influencesof design to the specific methods used on the job-site,all play a roll in the prevention of waste.A. Design to Prevent Waste.Design with standard sizes for building materials.Specify materials and assemblies that can be easilydisassembled at the end of their useful life.Design precast concrete members for concrete (Tiltup) construction.Choose durable non-toxic interior finishes ormaterials.Design spaces to be flexible for changing uses.Consider reusing materials (on-site) or installingsalvaged materials from off-site sources.How to recognized tips for Construction WasteReduction:B. Plan for Waste Prevention.Target specific waste producing practices for wasteprevention.Include waste prevention measures in a WasteManagement Plan. See Waste Management Planand Reporting Form.Communicate your waste management plan atmeetings, post it on-line, and promote the result.C. Use Construction Methods that Prevent Waste.For wood construction, use advanced framingtechniques (e.g. 24" on-center, and insulatedheaders), trusses for roof or floor framing, fingerjointed studs and trim, and engineered woodproducts.Consider using wood frame wall panelsprefabricated off-site.Walk through your local used building materialsstore to see what they carry and accept. Plan Ahead. Make a waste reduction or recyclingplan before starting work, and communicate it toall parties. Create a system of where things go soyou handle materials as little as possible to savelabor. Remove salvage items early in the process. Re-use scrap on the job. Use one centralizedwood-cutting station to promote reuse. Look for materials on the materials exchanges(VBMX, NH Materials Exchange). Use standard dimensions to reduce cut-off waste. Get a grant from the State to create your owninnovative project [17].What is a green building product or material? Greenbuilding materials are composed of renewable, ratherthan nonrenewable resources. Green materials areenvironmentally responsible because impacts areconsidered over the life of the product (Spiegel andMeadows, 1999). Depending upon project-specificgoals, an assessment of green materials may involve anD. Practice Job-Site Waste Prevention Methods.Set up central cutting areas for wood and othermaterials.Reuse concrete forms or choose reusable metal orfiberglass forms.Clearly mark areas key to waste prevention, such asthe material storage, central cutting, and recyclingstations.ISSN: 1790-5079 413Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičevaluation of one or more of the criteria listed below[18].warranties, source material characteristics, recycledcontent data, environmental statements, and durabilityinformation. In addition, this step may involveresearching other environmental issues, buildingcodes, government regulations, building industryarticles, model green building product specifications,and other sources of product data. Research helpsidentify the full range of the project’s building materialoptions.2. Evaluation. This step involves confirmation of thetechnical information, as well as filling in informationgaps. For example, the evaluator may request productcertifications from manufacturers to help sort outpossible exaggerated environmental product claims.Evaluation and assessment is relatively simple whencomparing similar types of building materials using theenvironmental criteria. For example, a recycledcontent assessment between various manufacturers ofmedium density fiberboard is a relativelystraightforward "apples to apples" comparison.However, the evaluation process is more complexwhen comparing different products with the samefunction. Then it may become necessary to processboth descriptive and quantitative forms of data.A life cycle assessment (LCA) is an evaluation of therelative "greenness" of building materials andproducts. LCA addresses the impacts of a productthrough all of its life stages. Although rather simple inprinciple, this approach has been difficult andexpensive in actual practice (although that appears tobe changing).One tool that uses the LCA methodology is BEES(Building for Environmental and EconomicSustainability) software. It allows users to balance theenvironmental and economic performance of buildingproducts. The software was developed by the NationalInstitute of Standards and Technology's Building andFire Research Laboratory.3. Selection. This step often involves the use of anevaluation matrix for scoring the project-specificenvironmental criteria. The total score of each productevaluation will indicate the product with the highestenvironmental attributes. Individual criteria includedin the rating system can be weighted to accommodateproject-specific goals and objectives [18].The ReEPNP 2005-2012 lays down that thecomponents of the Environment Protection NationalProgramme as regards waste shall be accounted for bythe following operational programmes (OPs): (i)Operational programme for waste disposal with theaim of reducing the quantities of disposedbiodegradable waste, (ii) Operational programme forhazardous wastemanagement (currentlyinResource Efficiency can be accomplished by utilizingmaterials that meet the following criteria: Recycled Content: Products with identifiablerecycled content, including postindustrial contentwith a preference for postconsumer content. Natural, plentiful or renewable: Materialsharvested from sustainably managed sources andpreferably have an independent certification (e.g.,certified wood) and are certified by an independentthird party. Resource efficient manufacturing process:Products manufactured with resource-efficientprocesses including reducing energy consumption,minimizing waste (recycled, recyclable and orsource reduced product packaging), and reducinggreenhouse gases. Locally available: Building materials, components,and systems found locally or regionally savingenergy and resources in transportation to theproject site. Salvaged, refurbished, or remanufactured: Includessaving a material from disposal and renovating,repairing, restoring, or generally improving theappearance, performance, quality, functionality, orvalue of a product. Reusable or recyclable: Select materials that can beeasily dismantled and reused or recycled at the endof their useful life. Recycled or recyclable product packaging:Products enclosed in recycled content orrecyclable packaging. Durable: Materials that are longer lasting or arecomparable to conventional products with long lifeexpectancies [18].Product selection can begin after the establishment tal assessment process for buildingproducts involves three basic steps. (Froeschle, 1999):1. Research. This step involves gathering all technicalinformation to be evaluated, including manufacturers'information such as Material Safety Data Sheets(MSDS), Indoor Air Quality (IAQ) test data, productISSN: 1790-5079414Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičpreparation), (iii) Operational programme forcollection of municipal waste (currently inpreparation), (iv) Operational programme forpackaging and waste packaging management, (v)Operational programme for waste oil management, (vi)Operational programme for battery and accumulatormanagement, (vii) Operational programme atedterphenyls,(viii)Operationalprogramme for construction waste management, (ix)Operational programme for reducing and preventingpollution due to titanium dioxide production waste,and (x) Operational programme for waste electric andelectronic equipment management [19].5Up until now, issues of modelling and improvementof heat protection and efficient use of energy inbuildings have not been adequately addressed as it isrequired bysustainable development approach.Ecological concerns provided the need for intensiveresearch of recycling of waste. Why is such kind ofstudy important? Because of environmental protection: Reuse Lightweight ConcreteA variety of raw materials are used to produceconcrete from lightweight aggregates. One of them isPoraver . The raw material for Poraver is glass or –to be more precise – recycled glass, of which millionsof tons are collected in the Federal Republic ofGermany every year employing – to all intents andpurpose – a perfect recycling system. Poraver makesuse of only the valuable raw material which fortechnical reasons cannot be utilised by the glassindustry to manufacture new glass products, e.g. fineglass shards. Poraver thus makes a decisivecontribution to perfecting the glass recycling process,at the same time protecting natural resources. Apartfrom its areas of use in the classic building materialsand additional building materials industry, Poraver is also gaining popularity in special applications [8].The objective of this study was to investigaterecycling of construction waste of concrete fromlightweight aggregates (density fromca 600 kg/m3 ).A commercially available concrete from lightweightaggregates Poraver was selected for thisinvestigation. Volume of the reactor, dimensions 150 x150 x 150 mm, was charged with rest, constructionwaste material of concrete from lightweight aggregatesPoraver and rest of volume with new raw materials ofconcrete from lightweight aggregates Poraver usedas binding. We made the new step as a recyclingcrushed construction waste from concrete fromlightweight aggregates Poraver and fresh concretefrom lightweight aggregates as a binding. Recyclingfollow next activity by normal room condition:The process of reusing and recycling begin by productdesign and development. Some of these benefits mayinclude: lower costs, stimulation of innovation, newbusiness opportunities, and improved product quality[21]. Strategies for recycling building materials: Set a goalSelect a contractor with proven recyclingexperienceUse a Construction Waste ManagementSpecificationMonitor the waste reduction program [22].If you look at the recycling facts, you will see thatsince 1990, the United States has improveddramatically in their recycling activities. Recyclingfacts report that fifteen years ago, the U.S. recycledroughly fifteen percent of our waste materials, whichtoday has doubled to thirty percent! The followingrecycling facts are both interesting and fun bits ofinformation to increase your knowledge on the art ofrecycling [4]. The process of recycling begin byproduct design and development. Some of thesebenefits may include: lower costs, stimulation ofinnovation, new business opportunities, and improvedproduct quality [5]. Strategies for recycling buildingmaterials: Set a goalSelect a contractor with proven recyclingexperienceUse a Construction Waste ManagementSpecificationMonitor the waste reduction program [6]ISSN: 1790-5079by minimizing waste,saving of fossil fuels due to recycling,to improving recycling process,optimized use of available resources,improved intellectual capital,optimized, effective and efficient processes,enhanced organizational performance, credibilityand sustainabilityreduced costs [7].a) assembling rest construction waste fromconcrete from lightweight aggregatesPoraver ,415Issue 5, Volume 4, May 2008

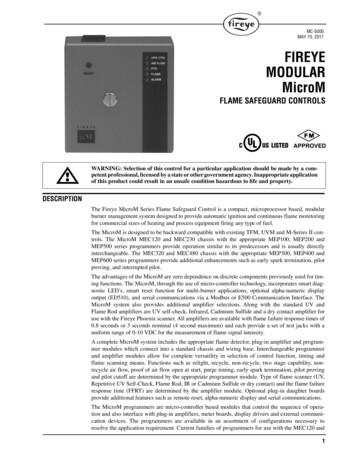

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markičb) crumbling into small pieces (Figure 2),100,0after that we took crumbled construction waste ofconcrete from lightweight aggregates Poraver (mechanical reprocessing), as a raw input material inthe processing line to the reactor,90,0c) charging of reactor volume with “new”raw material,d) binding reaction between new raw materials offresh concrete from lightweight aggregatesPoraver and rest material of constructionwaste from concrete from lightweightaggregates Poraver ,e) binding process,f) cooling,g) quality control.50,080,070,060,040,030,020,010,00/450/4 re 2: Granular size [mm] of crumbled fromwaste concrete from lightweight aggregates Poraver Prescription of raw materials of concrete fromlightweight aggregatesPoraver was used fromproducer. Granular size [mm] of crumbled wasteconcrete from lightweight aggregates Poraver presents figure 2. From the results it can be seen thatrecycled “new” recycled material, concrete fromlightweight aggregates Poraver has characteristics aspresents table 2.Testcube123456789-Mass 1,931,951,99Mass ,190,210,210,21Table 2: Characteristics of recycled material,concrete from lightweight aggregates Poraver Figure 3 and 4 present recycled material from concretefrom lightweight aggregates Poraver ISSN: 1790-5079416Issue 5, Volume 4, May 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko MarkičFigure 3: Recycled “new” material from lightweight aggregates Poraver Figure 4: Recycled material from concrete from lightweight aggregates Poraver scanning electron microscopeISSN: 1790-5079417Issue 5, Volume 4, April 2008

WSEAS TRANSACTIONS onENVIRONMENT and DEVELOPMENTDavorin Kralj, Mirko Markič(10.03.2007).[9] Kralj D.,: Environmental Waste Management inConstructions,Lecture Notes on Energy andEnvironment, WSEAS 07,Archanchon, France,Oct.2007.[10] ISO 1401:2004(E) Environmentalmanagement system – Requirements guidancefor use[11] Brown M.T., Buranakarn V.

3 Green Building Sustainable design and construction, or "green building," is a holistic approach that minimizes environmental impact, reduces maintenance, and creates a more desirable workspace for the building occupants. Green building focuses on siting issues, energy and wat