Transcription

Principles of MetallurgyIndustrial Metallurgists, LLCNorthbrook, IL 60062847.528.3467www.imetllc.comCopyright 2012 Industrial Metallurgists, LLC

IntroductionOverall goal: understand how manufacturing processes enable us to modifymechanical properties of metals.Cover fundamental metallurgical conceptsExplain methods for strengthening metals

Course Learning Objectives1.Explain the relationship between a metal’s properties and its composition,microscopic structure, and the manufacturing processes used to fabricate themetal.2.Describe three types of microscopic structures present in metals.3.Explain how cold working, alloying, and heat treating are used to strengthen ametal.4.Explain the microstructure and property changes that occur in cold workedmetals, steels, and precipitation hardened alloys when they are heat treated.5.Relate the heat treatment time and temperature to the microscopic structuresand properties of precipitation hardened alloys, steels, and cold worked metals.Click Next to continue

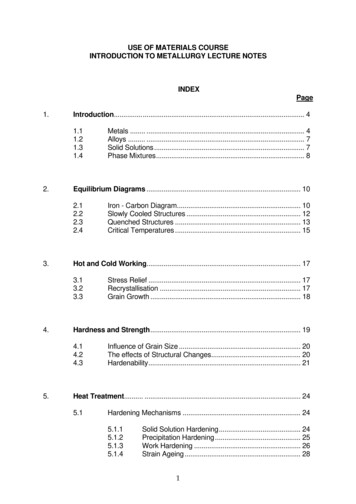

Course Content1. Material properties2. Composition3. Microscopic structuresa.b.c.d.Crystal structureGrains and grain boundariesMetallurgical phasesCrystal structure defects4. Diffusion5. Examplesa. Cold workingb. Annealing cold-worked metalsc. Solution hardeningd. Steel metallurgye. Precipitation hardening

Concepts applicable to components

Concepts applicable to Non-Mechanical JointsSolder and braze jointWeld joints

Materials Properties

Module learning objectiveExplain the relationship between properties, composition, microscopic structures, andprocessing.

ringdefectsClick Next to continue

Metal properties Density Thermal conductivity Melting pointPhysical Strength Hardness Ductility ToughnessMechanicalpropertiesElectricalProperties Conductivity Magnetic permeability Corrosion Fatigue Creep WearReliabilityJoiningEase of Welding BrazingFabricationEase of Forming Machining CastingClick Nextto continue

Composition refers to elements that make up a metalSteel - iron, carbon, manganese, and siliconBrass - copper and zinc

Microscopic structuresGrainsPhases10 mm0.0004”Courtesy of Aston Metallurgical ServicesArrangement of atoms(Courtesy of Aston Metallurgical Services)

Manufacturing defectsAlter metal propertiesTry to minimize defectsWhat manufacturing defects can be tolerated?How can the level of defects be controlled?No more discussion of manufacturing defects in this courseGas porosity in die casting0.5 mmForging lap0.125 mm

CompositionPropertiesMicroscopicstructure

Can process an alloy different ways Obtain different microscopic structures Obtain different eManufacturingProcesses

Can process a metal different ways Obtain different microscopic structures Obtain different propertiesHarder and strongerCourtesy of Aston Metallurgical ServicesCourtesy of Aston Metallurgical ServicesCritical concept Alloy and process selection Control variation

For any particular design, want to Select materials that have the desired properties Use manufacturing processes capable of transforming a material into desiredshape with desired reManufacturingProcesses

Questions for further thought1.What metals are used in your products?2.What are the desired properties of the metals?3.What manufacturing processes are used to obtain the desired properties in themetals?Click Next to continue

End of module

Introduction Overall goal: understand how manufacturing processes enable us to modify mechanical properties of metals. . Steel metallurgy e. Precipitation hardening. Concepts applicable to components.