Transcription

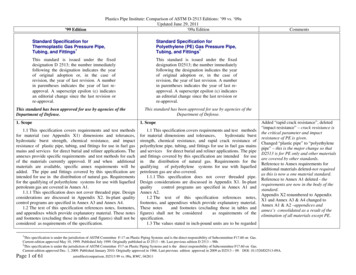

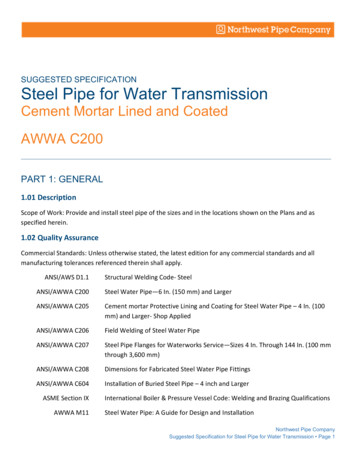

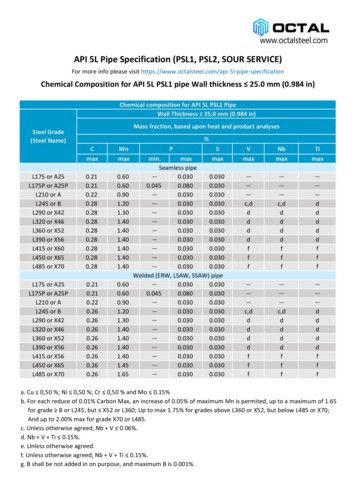

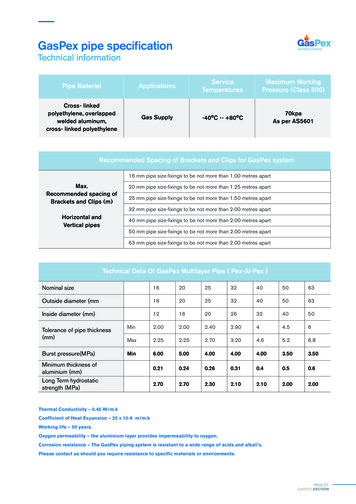

GasPex pipe specificationTechnical informationPipe MaterialApplicationsServiceTemperaturesMaximum WorkingPressure (Class 500)Cross- linkedpolyethylene, overlappedwelded aluminum,cross- linked polyethyleneGas Supply-40 C -- 80 C70kpaAs per AS5601Recommended Spacing of Brackets and Clips for GasPex system16 mm pipe size-fixings to be not more than 1.00 metres apartMax.Recommended spacing ofBrackets and Clips (m)20 mm pipe size-fixings to be not more than 1.25 metres apart25 mm pipe size-fixings to be not more than 1.50 metres apart32 mm pipe size-fixings to be not more than 2.00 metres apartHorizontal andVertical pipes40 mm pipe size-fixings to be not more than 2.00 metres apart50 mm pipe size-fixings to be not more than 2.00 metres apart63 mm pipe size-fixings to be not more than 2.00 metres apartTechnical Data Of GasPex Multilayer Pipe ( Pex-Al-Pex )Nominal size16202532405063Outside diameter (mm16202532405063Inside diameter (mm)12162026324050Tolerance of pipe 703.204.65.26.8Burst imum thickness ofaluminium (mm)Long Term hydrostaticstrength (MPa)Thermal Conductivity – 0.45 W/m.kCoefficient of Heat Expansion – 25 x 10-6 m/m.kWorking life – 50 years.Oxygen permeability – the aluminium layer provides impermeability to oxygen.Corrosion resistance – The GasPex piping system is resistant to a wide range of acids and alkali’s.Please contact us should you require resistance to specific materials or environments.PAGE 31GASPEX SECTION

GasPex F5 FittingsTechnical information(1) working media; working temperature/pressureApplicationCold water, hot water, gas and compressed airWorking Temperature-20 C 95 CStructure Drawing And Main ComponentsMaterial1. Main body: DZR Brass2. Isolating ring: Polyethylene3. Sleeve: Stainless Steel SleeveSS3044. O-ring NBR(2) Pressure lossF5 U-Profile Press Fittings For Gas SupplyNominal sizeZeta values § (-)/equivalent Pipe length eL [m]16202532405063§eL§eL§eL§eL§eL§eL§eLPress Elbow 0.912.32Equal Straight .000.461.17Straight at flow .100.51.29Branch at flow �––Equal Tee “Y” typeZeta Value and equivalent pipe length of F5 u-profile press fittings for gas supply.A water velocity of 2m/s has been used for the calculation of equivalent pipe lengthsPAGE 26GASPEX SECTION

GasPex F5 FittingsTechnical information(3) The torque resistance of threadThread Size1/2”3/4”1”1 1/4”1 1/2”2”2 1/2”Torque /N·m75100125160200250300(4) Fitting stress corrosion resistanceStress Corrosion resistanceSamplingTestingRequirementsThree test specimens selected atrandom shall be conditioned tostandard laboratory conditions priorto testing.Test specimens shall be testedaccording to ASTM B858 “StandardTest Method for Ammonia Vapour Testfor Determining Susceptibility to StressCorrosion Cracking in Copper Alloys”Ammonia test for stress corrosionresistance” in a test solution of PH 9.5There shall be no evidence of crackingwhen viewed with a microscope with aminimum magnification of 10X. Failureof one of the three specimens testedis cause for retest of three additionalspecimens. Failure of one specimen in theretest shall constitute failure in the testMinimum distance between pipe fixingsThe following detail has been extracted from AS5601 16mm pipe size-fixings to be not more than 1.00 metres apart 20mm pipe size-fixings to be not more than 1.25 metres apart 25mm pipe size-fixings to be not more than 1.50 metres apart 32mm pipe size and above – fixings to be not more than 2.00 metres apartPAGE 27GASPEX SECTION

GasPex Pipe Sizing ExampleThe following example demonstrates how to correctly size a GasPex installation to accommodate theenergy requirements of the appliances to be connected.A range of GasPex sizing tables is included in this manual as gas supply pressures vary in different regions of Australia. In this example we areusing a supply meter pressure of 2.75kPa with a pressure drop of 0.75kPa.The diagram below details the parameters for this installation.FDHot WaterService190Mj/hSpace Heater70Mj/hAGas Meter 2.75 kpaNatural Gas4m13mC10mB6m2m6mECooktop30MjhThe first step in the sizing calculationThe first step in the sizing calculation is to determine the index length of the run. The index length isthe distance from the gas meter to the farthest appliance. We can review the distances as follows:Appliance NameDistance from Gas MeterHot Water Service17 mCooktop29 mSpace Heater31 mThe Space Heater is furthest from the Gas meter – 31 metres is used as the Index length for this calculation.PAGE 42GASPEX SECTION

GasPex Pipe Sizing ExampleThe next step is to determine the gas flow/energy requirementsThe next step is to determine the gas flow/energy requirements of the GasPex pipe for each section inthe installation. The parameters for the spine and branches of the run is as follows:Pipe SectionGas Flow g to the GasPex sizing chart for 2.75kPa Meter Pressure and 0.75 kPa pressure drop, there is a column for 30 m length of pipe and thenext column is 35m. As the index length is 31 metres, we need to round up and use the 35 m column.Section A – B requires 290 MJ/h. Looking down the 35m column of the chart, we see that 25mm pipe will only deliver 270 MJ/h and this isinsufficient. 32mm pipe will deliver 543 MJ/h which more than covers our need. We therefore need to use 32mm pipe for section A – B. SectionB – F requires 190 MJ/h so reviewing the chart we need to use 25mm GasPex pipe. The following table summarises the sizing required for thisinstallation.Pipe SectionGas Flow (MJ/h)GasPex Pipe Size (DN)Section Length 0mm8C–E3016mm6A GasPex sizing calculator is also available in the Couta App available from the Apple or Google stores. Download the App and register. You canthen use the app to easily calculate job sizing.PAGE 43GASPEX SECTION

Pipe Sizing ChartsLPG Gas Sizing Charts(LP GAS ONLY)LPG Gas – 40 kPa Meter Pressure with a Pressure Drop of 10 kPaOD mm1620Length of PipeRun (metres)2532405063LPG GAS flow through GasPex Composite Pipe 02004267651,5232,6264,7178,472PAGE 44GASPEX SECTION

Pipe Sizing ChartsLPG Gas Sizing Charts(LP GAS ONLY)LPG 2.75kPa Meter Supply with 0.25kPa Pressure DropOD mm1620Length of PipeRun (metres)2532405063LPG GAS flow through GasPex Composite Pipe 01,024200245090179309554996PAGE 45GASPEX SECTION

Pipe Sizing ChartsNatural Gas Sizing Charts4032252016NormSize mm11834 03407204110095245013946833961991050100(NATURAL GAS ONLY)Meter Pressure 2.75 kPa with a Pressure Drop 0f 1.50 kPa5021988 15022 12008 10240 9046GAS flow through PE-X/AL/PE-X Composite Pipe Crimped Fittings (MJ/h)Length of straight pipe in metres63PAGE 46GASPEX SECTION

Pipe Sizing ChartsNatural Gas Sizing 748221275(NATURAL GAS ONLY)Meter Pressure 1.1 kPa with a Pressure Drop 0f 0.075 kPa503987NATURAL GAS flow through PE-X/AL/PE-X Composite Pipe Crimped Fittings (MJ/h)Length of straight pipe in 210n/a350Meter Pressure 1.1 kPa with a Pressure Drop 0f 0.075 kPa - (continued)63PAGE 47GASPEX SECTION

Pipe Sizing ChartsNatural Gas Sizing 9837018485437024981278672356177824275(NATURAL GAS ONLY)Meter Pressure 2.75 kPa - 5.0 kPa with a Pressure Drop 0f 0.75 kPa5015908NATURAL GAS flow through PE-X/AL/PE-X Composite Pipe Crimped Fittings (MJ/h)Length of straight pipe in 753417350Meter Pressure 2.75 kPa - 5.0 kPa with a Pressure Drop 0f 0.75 kPa - (continued)63PAGE 48GASPEX SECTION

A GasPex sizing calculator is also available in the Couta App available from the Apple or Google stores. Download the App and register. You can : then use the app to easily calculate job sizing. GasPex Pipe Sizing Example: PAGE : 44: GASPEX : SECTION: Pipe Sizing Charts: LPG Gas Sizing Charts (LP GAS ONLY) LPG Gas – 40 kPa Meter Pressure with a Pressure Drop of 10 kPa: OD mm