Transcription

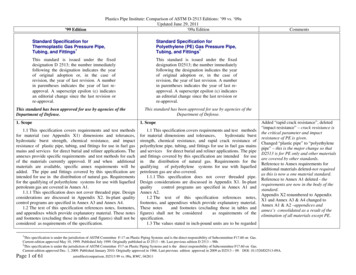

’99 EditionPlastics Pipe Institute: Comparison of ASTM D-2513 Editions: ’99 vs. ‘09aUpdated June 29, 2011‘09a EditionStandard Specification forThermoplastic Gas Pressure Pipe,1Tubing, and FittingsStandard Specification forPolyethylene (PE) Gas Pressure Pipe,1Tubing, and FittingsThis standard is issued under the fixeddesignation D 2513; the number immediatelyfollowing the designation indicates the yearof original adoption or, in the case ofrevision, the year of last revision. A numberin parentheses indicates the year of last reapproval. A superscript epsilon (ε) indicatesan editorial change since the last revision orre-approval.This standard is issued under the fixeddesignation D2513; the number immediatelyfollowing the designation indicates the yearof original adoption or, in the case ofrevision, the year of last revision. A numberin parentheses indicates the year of last reapproval. A superscript epsilon (ε) indicatesan editorial change since the last revision orre-approval.This standard has been approved for use by agencies of theDepartment of Defense.CommentsThis standard has been approved for use by agencies of theDepartment of Defense.1. Scope1. Scope1.1 This specification covers requirements and test methodsfor material (see Appendix X1) dimensions and tolerances,hydrostatic burst strength, chemical resistance, and impactresistance of plastic pipe, tubing, and fittings for use in fuel gasmains and services for direct burial and reliner applications. Theannexes provide specific requirements and test methods for eachof the materials currently approved. If and when additionalmaterials are available, specific annex requirements will beadded. The pipe and fittings covered by this specification areintended for use in the distribution of natural gas. Requirementsfor the qualifying of polyethylene systems for use with liquefiedpetroleum gas are covered in Annex A1.1.1.1 This specification does not cover threaded pipe. Designconsiderations are discussed in Appendix X2. In-plant qualitycontrol programs are specified in Annex A3 and Annex A4.1.2 The text of this specification references notes, footnotes,and appendixes which provide explanatory material. These notesand footnotes (excluding those in tables and figures) shall not beconsidered as requirements of the specification.1.1 This specification covers requirements and test methodsfor material dimensions and tolerances,hydrostatic burststrength, chemical resistance, and rapid crack resistance ofpolyethylene pipe, tubing, and fittings for use in fuel gas mainsand services for direct burial and reliner applications. The pipeand fittings covered by this specification are intended for usein the distribution of natural gas. Requirements for thequalifying of polyethylene systems for use with liquefiedpetroleum gas are also covered.1.1.1 This specification does not cover threaded pipe.Design considerations are discussed in Appendix X1. In-plantqualitycontrol programs are specified in Annex A1 andAnnex A2.1.2 The text of this specification references notes,footnotes, and appendixes which provide explanatory material.These notesand footnotes (excluding those in tables andfigures) shall not be consideredas requirements of thespecification.1.3 The values stated in inch-pound units are to be regarded1Added “rapid crack resistance”, deleted“impact resistance” – crack resistance isthe critical parameter and impactresistance of PE is given.Changed “plastic pipe” to “polyethylenepipe” – this is the major change so thatD2513 is for PE only and other materialsare covered by other standards.Reference to Annex requirements foradditional materials deleted-not requiredas this is now a one material standard.Reference to Annex A1 deleted - therequirements are now in the body of thestandard.Appendix X2 renumbered to AppendixX1 and Annex A3 & A4 changed toAnnex A1 & A2 –appendices andannex’s consolidated as a result of theelimination of all materials except PE.This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.Current edition approved May 10, 1999. Published July 1999. Originally published as D 2513 – 66. Last previous edition D 2513 – 98b.2This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.Current edition approved Dec. 1, 2009. Published January 2010. Originally approved in 1966. Last previous edition approved in 2009 as D2513 – 09. DOI: 10.1520/D2513-09A.Page 1 of 61astmfiles/comparison, D2513 99 vs. 09a, RWC, 042811

Plastics Pipe Institute: Comparison of ASTM D-2513 Editions: ’99 vs. ‘09aUpdated June 29, 2011‘09a Edition’99 Edition1.3 The values stated in inch-pound units are to be regarded as as standard. The values given in parentheses are mathematicalthe standard. The values given in parentheses are provided for conversions to SI units that are provided for information onlyand are not considered standard.information purposes only.1.4 The following is an index of the annexes and appendixes1.4 The following is an index of the annexes and appendix inin this specification:this Polyethylene (PE) Pipe andFittingsPoly (Vinyl Chloride) (PVC)Pipe and FittingsIn-Plant Quality Control for allmaterials up to 12 in.In-Plant Quality Control for PEmaterials between 14 and 24in.Polyamide (PA) Pipe andFittingsSubjectNew MaterialsDesign Consideration1.5 The following precautionary caveat pertains only to thetest method portion, Section 6, of this specification. Thisstandard does not purport to address all of the safety concerns, ifany, associated with its use. It is the responsibility of the user ofthis standard to establish appropriate safety and health practicesand determine the applicability of regulatory limitations prior touse.AnnexAnnex A1Annex A2AppendixesAppendix X1SubjectIn-Plant Quality Control for allmaterials up to 12 in.In-Plant Quality Control for PEmaterials between 14 and 24in.SubjectDesign Consideration1.5 The following precautionary caveat pertains only to thetest method portion, Section 6, ofthis specification. Thisstandard does not purport to address all of the safety concerns,if any, associated with its use. It is the responsibility of theuser of this standard to establish appropriatesafety andhealth practices and determine the applicability of regulatorylimitations prior to use.3. Terminology3. Terminology3.1 Definitions—Definitions are in accordance withTerminology F 412, and abbreviations are in accordance withTerminology D 1600, unless otherwise specified.3.2 The gas industry terminology used in this specification isin accordance with ANSI B31.8 or 49 CFR Part 192, unlessotherwise indicated.3.3 The term pipe used herein refers to both pipe and tubingunless specifically stated otherwise.3.4 re-rounding equipment—equipment used to reform thepipe and permanently reduce ovality to 5% or less.3.1 Definitions—Definitionsare in accordance withTerminology F412, and abbreviations are in accordance withTerminology D1600, unless otherwise specified.3.2 The gas industry terminology used in this specificationis in accordance with ANSI B31.8 or OPS 49 CFR Part 192,unless otherwise indicated.3.3 The term pipe used hereinrefers to both pipe andtubing unless specifically stated otherwise.3.4 re-rounding equipment—equipment used to reform thepipe and permanently reduce ovality to 5% or less.Page 2 of 61astmfiles/comparison, D2513 99 vs. 09a, RWC, 042811CommentsEliminated Annex’s A1, A2 & A5 andrenumbered A3 as A1 and A4 as A2-dueto elimination of all materials other thanPE.Eliminated Appendix X1 and renumberedX2 as X1-due to elimination of newmaterials.

Plastics Pipe Institute: Comparison of ASTM D-2513 Editions: ’99 vs. ‘09aUpdated June 29, 2011‘09a Edition’99 Edition3.5 rounding equipment—equipment, devices, clamps, etc.,3.5 rounding equipment—equipment, devices, clamps, andused to temporarily hold the pipe round while out-of-roundness so forth, used to temporarily hold the pipe round while out-ofmeasurements are made, or a joining procedure (heat fusion, roundnessmeasurements are made, or a joining procedureelectrofusion, or mechanical) is performed.(heat fusion, electrofusion, or mechanical) is performed.3.6 standard thermoplastic material designated code—the3.6 pipe material designated code—the pipe materialpipe material designation code shall consist of the abbreviation designation code shall consist of the abbreviation for the typefor the type of plastic (PE, PVC, or PA) followed by Arabic of plastic (PE) followed by Arabic numerals which describenumerals which describe the short term properties in accordance the short term properties in accordance with applicablewith applicable ASTM standards, the hydrostatic design stress Specification D3350, the hydrostatic design stress for water atfor water at 73.4 F (23 C) in units of 100 psi with any decimal 73.4 F (23 C) in unitsof 100 psi with any decimal figuresfigures dropped. Where the hydrostatic design stress code dropped. Where the hydrostatic designstress code containscontains less than two figures, a zero is used before the number. less than two figures, a zero is used before the number. Thus,Thus, a complete material designation code shall consist of two a complete material designation code shall consist of PE andor three letters and four figures for plastic pipe materials. For four figures for PE materials. For example, PE2708 is a gradeexample, PE 2406 is a grade P24 polyethylene with a 630 psi PE27 polyethylene with an 800psi design stress for water atdesign stress for water at 73.4 F (23 C). The hydrostatic design 73.4 F (23 C). The hydrostatic design stresses for gas are notstresses for gas are not used in this designation code.used in this designation code.3.7 thermoplastic pipe dimension ratio (DR)—the ratio of3.7 dimension ratio (DR)—the ratio of pipe diameter to wallpipe diameter to wall thickness. It is calculated by dividing the thickness. It is calculated by dividing the specified outsidespecified outside diameter of the pipe, in inches, by the minimum diameter of the pipe, in inches (mm), by the minimum specifiedspecified wall thickness, in inches. The standard dimension ratio wall thickness, in inches (mm). The standard dimension ratio(SDR) is a common numbering system which is derived from the (SDR) is a common numbering system which is derived fromthe ANSI preferred number series R 10.ANSI preferred number series R 10.3.8 toe-in—a small reduction of the outside diameter at the3.8 toe-in—a small reduction of the outside diameter at thecut end of a length of thermoplastic pipe.cut end of a length of thermoplastic pipe.4. Materials4. Materials4.1 General—The plastic used to make pipe and fittings shallbe virgin plastic or reworked plastic (see 4.2) as specified in theAnnexes and shall have a Plastics Pipe Institute (PPI) long-termhydrostatic design stress and hydrostatic design basis rating.4.2 Rework Material—Clean rework material of the samecommercial designation, generated from the manufacturer's ownpipe and fitting production shall not be used unless the pipe andfitting produced meet all the requirements of this specification.4.1 General—The PE used to make pipe and fittings shallbe PE or reworked PE (see 4.2 and 4.4) and shall have a PlasticsPipe Institute (PPI) long-term hydrostatic design stress andhydrostatic design basis rating.4.2 Rework Material—Clean rework material of the samecommercial designation, generated from the manufacturer's ownpipe and fitting production shall not be used unless the pipe andfittingproduced meet all the requirements of thisspecification. The use of these rework materials shall begoverned by the requirements of 4.3 and PPI TN-30/2006 Inpipe, rework materials shall be limited to a maximum of 30 %by weight.NOTE 1—References and material descriptions for ABS,CAB, PB, PE2306, PE3306 and PE3406 have been removed fromD 2513. Elimination of these materials does not affect thepipelines that are in service. They can still be used for gasdistribution. The main reason for removing these materials fromPage 3 of 61NOTE 1—The requirements for rework materials herein areastmfiles/comparison, D2513 99 vs. 09a, RWC, 042811CommentsChanged “standard thermoplasticmaterial” to “pipe material” – due tofocus on PE only.Eliminated example reference to PVC andPA-these materials no longer in thisspecification.Changed “applicable ASTM standards” toSpecification D3350-PE only so thespecific standard is referenced.Eliminated “two or three letters” – PEonly so this option is not needed.Changed reference material and stressfrom “PE 2406” and “ 630 psi” to “PE2708” and “ 800” psi – materialdesignations and reference stresschanged to reflect new, high performancePE material.“Thermoplastic pipe” eliminated-thiscomment was redundant.4.1Only change is to reference 4.4 for the PEmaterial classification codes4.2 and Note 1Based on a extensive project byNYSEARCH (with AGA PMC and PPIparticipation), the use of rework in gaspipes was limited to a maximum of 30%.This 30% limitation represents a“strengthening” of the gas pipe standard.The project was initiated in response to aPHMSA request and was fully supportedby such.

Plastics Pipe Institute: Comparison of ASTM D-2513 Editions: ’99 vs. ‘09aUpdated June 29, 2011‘09a Edition’99 Editionthis standard is to reflect the current state of the art in gas intended to incorporate prudent specifications to ensure that thedistribution plastic piping.potential for contamination in gas piping products, that meetthis specification, is reduced to the extent possible. It isimperative to emphasize that rework materials have not beenidentified as the cause of any field failures. The requirementsfor rework materials were developed by the consensus ofinterested parties including product manufacturers, gas utilitycompanies, and regulatory agencies

29.06.2011 · Plastics Pipe Institute: Comparison of ASTM D-2513 Editions: ’99 vs. ‘09a Updated June 29, 2011 ’99 Edition ‘09a Edition Comments Page 1 of 61 astmfiles/comparison, D2513 99 vs. 09a, RWC, 042811 Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings1