Transcription

Specification for Line PipeUpstream SegmentAPI SPECIFICATION 5LFORTY-THIRD EDITION, MARCH 2004EFFECTIVE DATE: OCTOBER 2004ERRATA DECEMBER 2004AmericanPetroleumInstituteHelping YouGet The JobDone Right M

SPECIAL NOTESAPI publications necessarily address problems of a general nature. With respect to particular circumstances, local, state, and federal laws and regulations should be reviewed.API is not undertaking to meet the duties of employers, manufacturers, or suppliers towarn and properly train and equip their employees, and others exposed, concerning healthand safety risks and precautions, nor undertaking their obligations under local, state, or federallaws.Information concerning safety and health risks and proper precautions with respect to particular materials and conditions should be obtained from the employer, the manufacturer orsupplier of that material, or the material safety data sheet.Nothing contained in any API publication is to be construed as granting any right, byimpl ication or otherwise, for the manufacture, sale, or use of any method, apparatus, or product covered by letters patent. Neither should anything contained in the publication be construed as insuring anyone against liability for infringement of letters patent.Generally, API standards are reviewed and revised, reaffirmed, or withdrawn at least everyfive years. Sometimes a one-time extension of up to two years will be added to this reviewcycle. This publication will no longer be in effect five years after its publication date as anoperative API standard or, where an extension has been granted, upon republication. Statusof the publication can be ascertained from the API Standards department telephone (202)682-8000. A catalog of API publications, programs and services is published annually andupdated biannually by API, and available through Global Engineering Documents, 15 Inverness Way East, MIS C303B, Englewood, CO 80112-5776.This document was produced under API standardization procedures that ensure appropriate notification and participation in the developmental process and is designated as an APIstandard. Questions concerning the interpretation of the content of this standard or comments and questions concerning the procedures under which this standard was developedshould be directed in writing to the Director of the Standards department, American Petroleum Institute, 1220 L Street, N.W., Washington, D.C. 20005. Requests for permission toreproduce or translate all or any part of the material published herein should be addressed tothe Director, Business Services.API standards are published to facilitate the broad availability of proven, sound engineering and operating practices. These standards are not intended to obviate the need for applying sound engineering judgment regarding when and where these standards should beutilized. The formulation and publication of API standards is not intended in any way toinhibit anyone from using any other practices.Any manufacturer marking equipment or materials in conformance with the markingrequirements of an API standard is solely responsible for complying with all the applicablerequirements of that standard. API does not represent, warrant, or guarantee that such products do in fact conform to the applicable API standard.All rights reserved. No part of this work may be reproduced, stored in a retrieval system, ortransmitted by any means, electronic, mechanical, photocopying, recording, or otherwise,wi/hout prior written permission from the publisher. Contact the Publisher,API Publishing Services, 1220 L Street, N. W, Washington, D.C. 20005.Copyright 2004 American Petroleum Institute

FOREWORDAPI publications may be used by anyone desiring to do so. Every effort has been made bythe Institute to assure the accuracy and reliability of the data contained in them; however, theInstitute makes no representation, warranty. or guarantee in connection with this publicationand hereby expressly disclaims any liability or responsibility for loss or damage resultingfrom its use or for the violation of any federal, state, or municipal regulation with which thispublication may conflict.Suggested revisions are invited and should be submitted to API, Standards department,1220 L Street, NW, Washington, DC 20005.iii

CONTENTSPageSCOPE .1.1 Purpose and Coverage .1.2 Product Specification Level (PSL) .1.3 Grades .1.4 Dimensions .1.5 Units .2REFERENCES . .3DEFINITIONS . 24INFORMATION TO BE SUPPLIED BY THE PURCHASER . 35PROCESS OF MANUFACTURE AND MATERIAL .5.1 Process of Manufacture .5.2 Cold Expansion .5.3 Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.4 Heat Treatment. .5.5 Skelp End Welds in Helical Seam Pipe .5.6 Traceability .66888886MATERIAL REQUIREMENTS . 86.1 Chemical Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.2 Mechanical Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97DIMENSIONS, WEIGHTS, LENGTHS, DEFECTS, AND END FINISHES .7.1 Specified Dimensions .7.2 Diameter. .7.3 Wall Thickness .7.4 Weight .7.5 Length .7.6 Straightness .7.7 Jointers .7.8 Workmanship and Defects .7.9 Pipe Ends .1010108COUPLINGS (PSL 1 ONLY) .8.1 Material .8.2 Tensile Tests .8.3 Dimensions .8.4 Inspection .15151515159INSPECTION AND TESTING .9.1 Test Equipment .9.2 Testing of Chemical Composition .9.3 Testing of Mechanical Properties .9.4 Hydrostatic Tests .9.5 Dimensional Testing .9.6 Surface Inspection .15151515171818vIIIIII12121214041 04104104

Page9.79.89.99.109.119.129.13Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Nondestructive Inspection .Disposition of Pipe Containing Defects .Test Methods . , .Invalidation of Tests .Retests .Reprocessing .1818222223232410 MARKING .10.1 General .10.2 Location of Markings .10.3 Sequence of Markings . , .10.4 Bundle Identification . , .10.5 Length . , . , .10.6 Couplings . , . , .10.7 Die Stamping . , . , .10.8 Thread Identification . , .10.9 Thread Certification . , .10. 10 Pipe Processor Markings . , .2424252526262626272727I I COATING AND PROTECTION . , . 27I 1.1 Coatings . 27t t.2 Thread Protectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2712 DOCUMENTS . 2712.1 Certification . 2712.2 Retention of Records . , . 2813 PIPE LOADING . , . 28SPECIFfCATION FOR WELDED JOINTERS (NORMATIVE) . 79REPAIR OF DEFECTS BY WELDING (NORMATIVE) . 81REPAIR WELDING PROCEDURE (NORMATiVE) . 83ELONGATION TABLE (NORMATIVE) . 89DIMENSIONS, WEIGHTS, AND TEST PRESSURES-Sf UNITS (NORMATIVE) . , . 93APPENDIX F SUPPLEMENTARY REQUIREMENTS (NORMATIVE) . 121APPENDIX G GUIDED-BEND TEST JIG DIMENSIONS (NORMATIVE) . 131APPENDIX H PURCHASER INSPECTION (NORMATIVE) . , . 143APPENDIX IMARKING INSTRUCTIONS FOR API LICENSEES(NORMATIVE) . , . 145APPENDIX JSUMMARY OF DIFFERENCES BETWEEN PSL 1 AND PSL 2(INFORMATIVE) . , . . . 149APPENDIX K END LOAD COMPENSATION FOR HYDROSTATICTEST PRESSURES IN EXCESS OF 90% OF SPECIFIEDMINIMUM YIELD STRENGTH (NORMATIVE) . . . . . . . . . . . . . . 151APPENDIX M CONVERSION PROCEDURES . , . I 04104

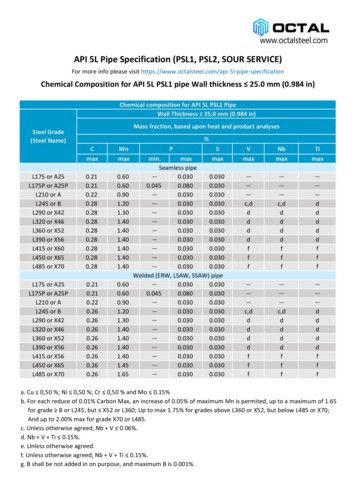

PageFiguresBelled End for Bell and Spigot Joint . 28ILine Pipe and Couplings . 282Orientation of Tensile Test Specimens . 293Tensile Test Specimens . 304Flattening Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 I5API Standard penetrameter . 316Examples of Maximum Distribution Patterns of Indicated7Circular Slag-inclusion and Gas-pocket-type Discontinuities . 32Examples of Maximum Distribution Patterns of Indicated8Elongated Slag-inclusion-type Discontinuities . 33Guided-bend Test Specimen . 33910 Jig for Guided-bend Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34B-1 Resultant Cavity for Undercut Repair (PSL 2 Only) . 82C-I Transverse Tensile Test Specimen . 85C-2 Guided-bend Test Specimen . 85C-3 Jig for Guided-bend Test . 86C-4 Nick-break Test Specimen . 87F-I Impact Test Specimen Tapered End Allowance. . . . . . . . . . . . . . . . . . . . . . . . . 126F-2 Charpy V-notch and Drop-weight Tear Test Specimen Locations . 127TablesI2AProcess of Manufacture and Product Specification Level (PSL) .PSL I Chemical Requirements for heat and Product Analysesby Percentage of Weight .2B PSL 2 Chemical Requirements for Heat and Product Analysesby Percentage of Weight .3A Tensile Requirements for PSL I .3B Tensile Requirements for PSL 2 .Standard-wall Threaded line Pipe Dimensions, Weights, and4Test Pressures (U.S. Customary and SI Units) .Heavy-wall Threaded Line Pipe Dimensions, Weights, and5Test Pressures (U.S. Customary and SI Units) .6A Plain-end Line Pipe Dimensions, Weights per Unit Length, andTest Pressures for Sizes 0.405 through 1.900 (U.S. Customary Units) .6B Plain-end Line Pipe Dimensions, Weights per Unit Length, andTest Pressures for Sizes 2 3/8 through 59/16 (U.S. Customary Units) .6C Plain-end Line Pipe Dimensions, Weights per Unit Length, andTest Pressures for Sizes 65/8 through 80 (U.S. Customary Units) .Tolemces for Diameter of Pipe Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7Tolerance for Diameter at Pipe Ends .8Tolerances for Wall Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .910 Tolerances for Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tolerances on Lengths .II12 Coupling Dimensions, Weights, and Tolerances .13 Maximum Inspection Lot Size for Tensile Testing .14 Relationship between Pipe Dimensions and Required Charpy Specimens .14A Relationship between Pipe Dimensions and Transverse Tensile Specimens .15 ASTM Hole-type IQI for F1uorscopic Inspection .16 ASTM Hole-type IQI for Radiographic Inspection .17 IS

API SPECIFICATION 5L FORTY-THIRD EDITION, MARCH 2004 EFFECTIVE DATE: OCTOBER 2004 ERRATA DECEMBER 2004 American Petroleum Institute Helping You Get The Job Done Right M . SPECIAL NOTES API publications necessarily address problems of a general nature. With respect to partic ular circumstances, local, state, and federal laws and regulations should be reviewed. API is not

![API Ballot: [Ballot ID] – API 510 & API 570, Deferrals, Rev05](/img/5/api510andapi570deferralsrev5.jpg)