Transcription

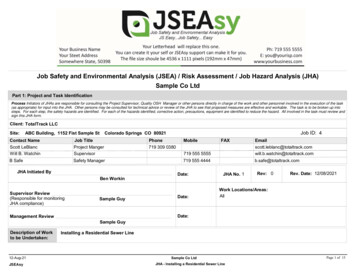

Job Safety and Environmental Analysis (JSEA) / Risk Assessment / Job Hazard Analysis (JHA)Sample Co LtdPart 1: Project and Task IdentificationProcess Initiators of JHAs are responsible for consulting the Project Supervisor, Quality OSH Manager or other persons directly in charge of the work and other personnel involved in the execution of the task(as appropriate) for input into the JHA. Other persons may be consulted for technical advice or review of the JHA to see that proposed measures are effective and workable. The task is to be broken up intosteps. For each step, the safety hazards are identified. For each of the hazards identified, corrective action, precautions, equipment are identified to reduce the hazard. All involved in the task must review andsign this JHA form.Client: TotalTrack LLCSite:ABC Building, 1152 Fist Sample StContact NameScott LeBlancWill B. WatchinJob TitleProject MangerSupervisorB SafeSafety ManagerJHA Initiated ByBen WorkinSupervisor Review(Responsible for monitoringJHA compliance)Job ID: 4Colorado Springs CO 80921Sample GuyPhone719 309 0380Mobile719 555 n@totaltrack.com719 555 4444b.safe@totaltrack.comDate:Date:FAXJHA No. 1Rev: 0Rev. Date: 12/08/2021Work Locations/Areas:AllDate:Management ReviewSample GuyDescription of Workto be Undertaken:12-Aug-21JSEAsyInstalling a Residential Sewer LineSample Co LtdJHA - Installing a Residential Sewer LinePage 1 of 15

High Risk Construction Work covered in this SWMSRisk of a person falling more than 2 metresWork on a telecommunication towerDemolition of load‐bearing structureLikely to involve disturbing asbestosTemporary load‐bearing suport for structural alterationsor repairsUse of ExplosivesWork in or near a confined spaceWork on or near chemical, fuel or refrigerantlinesTilt‐up precast concrete elementsWork on, in or adjacent to a road, railway, shipping lane orother traffic corridor in use by traffic other than pedestriansWork on or near energised electrical installations or servicesWork in any area that may have a contaminated orflammable atmosphereWork in a area with movement of powered mobile plantWork in areas with artificial extremes oftemperatureWork in or near water or other liquid that involves a risk ofdrowningDiving workWork in or near a shaft or trench deeper than1.5 m or a tunnelWork on or near pressurised gas mains or pipingWork PermitsNot RequiredHot WorkConfined spaceIsolationExcavationWork permits for this activity:DemolitionWork at HeightsPlant SetupRoad ClosureOther:12-Aug-21JSEAsySample Co LtdJHA - Installing a Residential Sewer LineCoringPage 2 of 15

First, identify and assess the risks, then decide the best way to control them by applying the Hierarchy of Control as follows:LEVELLevel 1Level 2Level Controlling the Hazard at sourceReplacing one substance or Activity with a less hazardous oneSeparating the hazard from the personEngineeringInstalling Guards on machineryAdministrationImplementing policies and procedures for safe work practicesPersonal Protective EquipmentUse of safety glasses, hardhats, protective clothing, etc.Hierarchy of ControlsSubstitute the hazardIsolate the hazardUse engineering controlsUse administrativecontrolsEffectivenessEliminate the hazardUse PPE12-Aug-21JSEAsySample Co LtdJHA - Installing a Residential Sewer LinePage 3 of 15

Part 2: Hazard Analysis, Control and Legislation WorksheetSample Co LtdJob Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.1List the steps needed to do the jobin the sequence to be done.RiskRatingAgainst each step list potential hazards thatcould cause injury when the job is done.Hazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByArrive at domestic site with truck and establish unloading area1.1Park truck on site of road1.22Potential Hazard(s) / RiskJob Hazard Analysis (JHA)Set up unloading areaObstructing traffic2Being hit by motor vehicles19Check for clearways and bike lanes1DriverDo not block people’s driveways1DriverWatch for oncoming traffic3AllAlways wear Hi visibility clothing1AllSet up hi visibility temporary bollards or cones1DriverSite Orientation/ Induction2.1Report to client’s receptionEntering restricted areas19Follow posted signs and go directly to reception1All2.2Undertake a site inductionUnfamiliarity with emergency procedures14Listen and ensure you obtain information andsite emergency and evacuation procedures1AllUnawareness of site specific hazards14Listen and ensure you obtain information aboutany and all site hazards1AllUnawareness of restricted areas18Listen and ensure you obtain information aboutany restricted areas1AllUnawareness of other operations orhazardous activities being undertaken on site9Listen and ensure you obtain information aboutany other activities being undertaken on site5AllBreaching minimum site PPE requirements13HI visibility clothing must be worn at all timeswhilst on siteSteel toe safety boots must be worn at all timeswhilst on siteSafety glasses must either be worn or carried atall times whilst on site1All1All1AllNO SMOKING on site-designated smoking areawill be available and ALL butts to be placed in binProgressive housekeeping clean as you go1All1AllControlled by Site Manager5Site SupervisorBunting or Caution tape shall define the workarea by providing a 3 meter barrier or denyingaccess whichever is more appropriate.3AllAll team members must wear Hi-Visibility vestsor clothingEnsure constant communication with all5All5Everyone working in3Claim Work Area3.1Access the siteBreaching site rules or requirements3.24Establish safe perimeter13People entering work area21Working where there is movement of powered mobile plant4.1Enter the work area where poweredmobile plant is or will be operating12-Aug-21JSEAsyBeing hit or runover by powered mobile plant22Sample Co LtdJHA - Installing a Residential Sewer LinePage 4 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.List the steps needed to do the jobin the sequence to be done.Potential Hazard(s) / RiskJob Hazard Analysis (JHA)RiskRatingAgainst each step list potential hazards thatcould cause injury when the job is done.Hazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.personnel in the immediate areaNever assume the plant operator has seen youor knows where you areEstablish eye contact with the operatorCrushing53the area of the plantEveryone working inthe area of the plantEveryone working inthe area of the plantEveryone working inthe area of the plant3Never stand or traverse between the machineand a fixed structure at any timeNever assume others have seen or are aware ofany impeding obstacle312Be aware of surroundings, risers and set downs3All13Ensure correct manual handling procedures3InstallerKeep Load close to body5AllEnsure a firm grip2AllWear safety boots3All6Everyone working inthe area of the plantEveryone working inthe area of the plantUnload skid steer excavator from trailer using aluminium ramps5.1Place ramps in positionMuscle strain - musculoskeletal disordersDropping components5.2Release machine restraints5.3Board the Machine5.4Unload and drive machine to ground5.565Action ByCommunicate your intentions with the plantoperator via radio or hand or head signals andensure an appropriate response23Tripping hazardNewRiskRatingMoving or driving the machine17Ramps may strike personnel7Ensure locating pins are securely in place3OperatorMachine may move4Ensure machine is stable before tie downtension is releasedEnsure truck is parked on level hard surfaceDue care by personnel1Driver15DriverAllGain access and egress from the manufacturedentry/ exit opening onlyKeep three points of contact during access andegress2Operator2OperatorEnsure firm ground3OperatorExperienced and competent operator with VOCto perform task5Operator13Only trained and authorised employees withVOC may operate this equipment3Driver14Check for dents, cracks and faulty welds3OperatorCheck all hydraulic rams and lines, controls forleaksCheck all safety devices3Driver3OperatorFalling from machine14Machine can tip, slip or fall down ramps9Injury to people, damage to product orequipment from running into or overSafety check and operation of Excavator for trenching and excavations6.1Safety check of unit. Fill out Pre-trip/Daily Inspection12-Aug-21JSEAsyFaulty equipment machine failureSample Co LtdJHA - Installing a Residential Sewer LinePage 5 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.List the steps needed to do the jobin the sequence to be done.Potential Hazard(s) / RiskJob Hazard Analysis (JHA)RiskRatingAgainst each step list potential hazards thatcould cause injury when the job is done.Hazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByCheck for leaking Fuids1OperatorCheck tracks for tightness and rollers, idlers, andsprockets for damage3Plant Operator6.2Boarding the machineFalling from Ladder23Ensure 3 points of contact3All6.3Operating / traveling with or withouta loadInjury to people, damage to product orequipment from running into or over13Only trained and authorised employees withVOC may operate this equipment3DriverThrown out of cab or against cab interior13Always wear seatbelt1Plant OperatorPersonal Injury20Allow no one to ride outside of the cab1Plant OperatorNever use the basket or other attachments as astaging platform for workers1Plant OperatorBe alert for trenches, open cuts, sump holes andpitsKeep the machine as level as possible whenoperating2Driver3OperatorTipping over6.4Dig19Electrocution25Always check for overhead power lines1DriverDigging up underground services18Any suspected services should be uncovered byhand digging and clearly marked so as to bevisible to plant operators on siteObtain service location from property ownerDial 811 before you dig2Site Supervisor33SupervisorSite ManagerAll stockpile materials must be “put out of thezone of influence”If excavations exceed 5 feet (1.5m) no personsshould work in the trench without supportIf excavations exceed 5 feet (1.5m) undertakebenching , battering or shoringPlant is not to travel up to 3 feet (1m) from edgeof trench unless the trench is only 3 feet (1m)deep (zone of influence)3Operator2All2Site Manager2Plant OperatorGround collapse6.5Load the truck12-Aug-21JSEAsy22Environmental - Disturb Cultural Heritage Sites9Stop all works if sub-surface archaeologicaldeposits are discovered1AllEnvironmental - Spreading of Weeds andpests4Contain weeds if present for disposal3AllEnvironmental - Dust16Wet down area in dry dusty conditions1AllRunning over someone15Be aware of everyone’s location in the work area5Plant OperatorDropping material on cab and driver9Do not move bucket near cab of truck.3Plat OperatorUneven loading may affect control of truck13Load truck evenly5Plat OperatorSample Co LtdJHA - Installing a Residential Sewer LinePage 6 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.List the steps needed to do the jobin the sequence to be done.6.67Backing upPotential Hazard(s) / RiskAgainst each step list potential hazards thatcould cause injury when the job is done.RiskRatingHazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByReversing/ Running over people andequipment and not very good visual22Make sure that your back up alarm is working5Plant OperatorGround collapse22Inspect excavation daily for water, groundmovement, undermining collapses and any otherchanges from previous day.Ensure all team members have read andunderstand the Trench and Excavations IncidentEmergency Response ProcedureIf excavations exceed 5 feet (1.5m) no personsshould work in the trench without supportIf excavations exceed 1.5m undertake benching ,battering or shoring3All trench workers6Site Manager2All2Site ManagerEnsure firm ground support3InstallerEnsure correct slope of ladder (4m up - 1m out)Do not face away from the ladder when going upor downMaterials or tools must not be carried whileclimbing the ladder—use a tool belt or side pouch16AllUser3UserWorking in open trench7.1Gain access to trench via a ladderFalling from Ladder7.28Job Hazard Analysis (JHA)Working in trench23Restricted entry or exit22Provide ladder access points required every 32feet (10m)2Site ManagerUnauthorized access18Remove ladder if no one is working in excavation1All persons workingon or in trenchDigging up underground services18Dial 1100 before you dig5SupervisorObtain service location from facillity manager5SupervisorDo not over reach with shovel3OperatorStand firmly in braced position before exertingforce5LaborerDig/ clean trench by hand8.1Dig into ground with ShovelMuscle strain - musculoskeletal disorders8.2Check gradient by laying pipe intotrench and setting levelEnvironmental - Disturbance to Plants oranimals - removal of vegitation17Ensure fragile vegetation is removed carefully forreinstatement1AllEnvironmental - Dust16Wet down area in dry dusty conditions1AllEnvironmental - Spreading of Weeds andpests4Contain weeds if present for disposal3AllMoving Machinery21Ensure constant communication with co-workers5OperatorWear Hi visibility clothing1AllBe aware of loose edges2AllFalling into trench12-Aug-21JSEAsy1313Sample Co LtdJHA - Installing a Residential Sewer LinePage 7 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.9List the steps needed to do the jobin the sequence to be done.Potential Hazard(s) / RiskJob Hazard Analysis (JHA)RiskRatingAgainst each step list potential hazards thatcould cause injury when the job is done.Hazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByInstallation of UPVC Pipe9.1Cut pipe to length with hand saw9.2Apply Cleaning Fuid to Pipes9.3Apply glue to pipe endsCut through body parts18Ensure the user has been inducted with SOP2Site SupervisorEnsure opposite hand is well clear of cutting area5PlumberEnvironmental - Waste Generation11Measure twice and cut once3AllInhalation of toxic and noxious fumes25Provide adequate fan forced ventilation3OperatorRead SDS to know the specific hazards of thesubstance you are using1AllSkin irritation7Wash hands immediately if contact with skinoccurs1AllInhalation of toxic and noxious fumes25Ensure adequate ventilation1AllRead SDS to know the specific hazards of thesubstance you are using1AllRefer to manufacturers Safety Data Sheet (SDS)prior to commencementWash hands immediately if contact with skinoccurs1All1AllSkin irritation7Environmental - Spills to land contamination8Immediately clean up any spillage1AllSkin irritation7Wash hands immediately if contact with skinoccurs1All9.4Fit pipes together10Back Fill trench using excavator with sand and original spoil10.1Boarding the machineFalling from Ladder23Ensure 3 points of contact3All10.2Operating / traveling with or withouta loadInjury to people, damage to product orequipment from running into or over13Only trained and authorised employees withVOC may operate this equipment3DriverThrown out of cab or against cab interior13Always wear seatbelt1Plat OperatorPersonal Injury20Allow no one to ride outside of the cab1Plant OperatorNever use the basket or other attachments as astaging platform for workers1Plant OperatorBe alert for trenches, open cuts, sump holes andpitsKeep the machine as level as possible whenoperating2Driver3OperatorTipping over10.3Fill the trenchElectrocution25Always check for overhead power lines1DriverRunning over someone15Be aware of everyone’s location in the work area5Plant OperatorStop work immediately if the exclusion zone hasbeen breached5Plant OperatorCheck for services (tap stands, stormwater pipes1AllCrushing12-Aug-21JSEAsy1923Sample Co LtdJHA - Installing a Residential Sewer LinePage 8 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.List the steps needed to do the jobin the sequence to be done.Potential Hazard(s) / RiskAgainst each step list potential hazards thatcould cause injury when the job is done.Job Hazard Analysis (JHA)RiskRatingHazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.etc)Ensure rocks and sharp objects are not incontact with pipes10.411Backing upNewRiskRatingAction By2Plant OperatorDigging up underground services18Ensure warnng tape is placed in the trench whenit is halfway back filled2Plant OperatorReversing/ Running over people andequipment and not very good visual22Make sure that your back up alarm is working5Driver13Inspect rake or shovel for defects or damage(e.g., splintered, loose, bent, or cracked toolhandles, loose connections, and damaged tinesor blade)If a rake or shovel fails your inspection, remove itfrom use3All3AllDo not over reach3OperatorUse a rake or shovel that is comfortable for yourheight and strengthDo not use a rake or shovel that is too long orheavy for youNever twist your trunk when raking or moving ashovel load. Always turn your feet and body inthe direction where you wish to pile leaves orspread or drop the shovel load.Never overextend your arms or shoulders to loada shovelShovel loads should not be thrown above about1200mm or further than about 900mm3Operator3Operator3All3All3AllAll personnel are to be trained in the safeoperating procedure of hand toolsBe on the lookout for signs of repetitive stress.Early detection might prevent a serious injuryWhen raking, stand upright and use the rake topull leaves or dirt towards youBefore shoveling, inspect the area forobstructions such as cables and pipesWhen shoveling, stand upright and bend yourknees so your legs carry most of the loadPush the shovel blade into the soil or material toobtain a shovel loadKeep your arms and elbows close to your bodywhen handling a shovel llSpreading soil with Shovel and Rake11.1Spread with rake or shovelFaulty or unsafe hand toolsMuscle strain - musculoskeletal disordersInjury from using hand tools12-Aug-21JSEAsy1313Sample Co LtdJHA - Installing a Residential Sewer LinePage 9 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentProcess StepsStepNo.12List the steps needed to do the jobin the sequence to be done.Against each step list potential hazards thatcould cause injury when the job is done.RiskRatingHazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByWhen digging, use the ball of your foot to pushthe shovel blade into the groundWhen raking or shoveling for long periods, varyyour arm and leg positions and movementsNever lay a garden rake down with the teethpointing up – the teeth should always be pointingdown3All6All3AllBack injury13Lift the shovel load by straightening your legs5Allhand injury18Wear gloves1AllStriking foot8Wear safety boots1All13Ensure correct manual handling procedures3InstallerEnsure adequate personnel is utilised todistribute the load3AllCheck for dents, cracks and faulty welds3OperatorCheck and top up fuel levelsCheck all hoses for cracks and leaks11OperatorOperatorCheck for leaking FuidsCheck oil levels11OperatorOperatorDo not operate unit that has faulty parts orequipment. If a problem is found, contactsupervisor to initiate repairs of any damage orabnormalities2OperatorEnsure adequate ventilation1AllNever start the machine indoors. Exhaust fumescan be dangerous if inhaled.1OperatorCompact area using a gasoline powered leg rammer12.1Carry the machine to the work area12.2Perform prestart inspection12.3Start the machine12.413Potential Hazard(s) / RiskJob Hazard Analysis (JHA)Operate the machineMuscle strain - musculoskeletal disordersFaulty equipment machine failure14Inhalation of toxic and noxious fumes25Damage to machinery and personal injuryfrom incorrect operation21The operator must have received instruction andtraining in the safe operation of the equipment1OperatorHearing damage18Use correct PPE - Ear Muffs / Ear Plugs2OperatorRunaway machinery13Do not let go of the handle1OperatorStriking foot8Wear safety boots1AllVibration13Do not exceed the maximum hours of dailyexposure as per the manufacturersrecommendations1OperatorIneffective JHA13Review the JHA at a minimum of 3 monthlyintervals2SupervisorMonitoring and review of JHA13.1Monitor the JHA12-Aug-21JSEAsySample Co LtdJHA - Installing a Residential Sewer LinePage 10 of 15

Job Safety and Environmental Analysis (JSEA) / Risk AssessmentStepNo.Process StepsList the steps needed to do the jobin the sequence to be done.Potential Hazard(s) / RiskAgainst each step list potential hazards thatcould cause injury when the job is done.JHA Failure12-Aug-21JSEAsyJob Hazard Analysis (JHA)RiskRating18Hazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.NewRiskRatingAction ByMonitor and complete an inspection of aminimum of 2 task observations3SupervisorStop Work1AllIn conjunction with workers and all involved,review and formulate a new JHAImplement new controls1Supervisor1AllConduct a toolbox meeting with all personnelinvolved with work activity1SupervisorSample Co LtdJHA - Installing a Residential Sewer LinePage 11 of 15

Part 3: Hazard Analysis, Control and Legislation Worksheet - Site modifications, additions or alterationsJob Safety and Environmental Analysis (JSEA) / Risk AssessmentStepNo.12-Aug-21JSEAsyProcess StepsPotential Hazard(s) / RiskList the steps needed to do the jobin the sequence to be done.Against each step list potential hazards thatcould cause injury when the job is done.Sample Co LtdJob Hazard Analysis (JHA)RiskRatingHazard Control MeasuresFor each hazard, identify control measuresto eliminate or minimise the risk of injury.Sample Co LtdJHA - Installing a Residential Sewer LineNewRiskRatingAction ByPage 12 of 15

Sample Co LtdPart 4: Worker Qualifications and Induction RecordDuties and Responsibilities of PersonnelCompleting the Task:Personal Qualifications and ExperienceRequired To Carry Out the Works:The ability to work unsupervised and part of a teamPlant OperatorPlumber (Preferred) or a competency level of workingwith UPVC and allied materialsMaintain adequate house-keeping on siteReporting of any injuries / incidents to your ProjectSupervisorTake reasonable care for your own health and safetyTake reasonable care for the health and safety ofothersOperate safely and perform daily pre-shift inspectionsAdherence to company's and the site's OSH policiesand proceduresFormal or Specialized Training orLicenses Required to Complete Work orOperate Specific Plant or Equipment:Commercial Drivers LicenseJHA Sign Off – Your signature below indicates that you have been consulted in development ofthe JHA and accept and will implement the requirements of the JHA and control measuresNo. NameClassificationSignatureEmployed ByDate123456Reference and Detail Applicable Sections of:LegislationCodes Of PracticeProject WHSSite WHSManufacturer Or Supplier RecommendationsANSI/ASSP A10.12-1998 Safety Requirements For ExcavationCode of Federal Regulations (CFR): 1926 For Construction Subpart C - General Safety and Health ProvisionsCode of Federal Regulations (CFR): 1926 For Construction Subpart P - ExcavationsOccupational Safety and Health Regulation under the US Occupational Safety and Health Act of 1970Plant and Equipment to be used for task:Hi-visibility temporary bollards or conesWarning signs and bunting as requiredExcavatorLadderShovel12-Aug-21JSEAsyPlant, Equipment and Area Safety Inspections:Excavator Pre Operational ChecksGasoline Powered Tools Pre- Operational ChecksHand Tools Pre Operation CheckHand Tools Pre- Operational ChecksSkid Steer Pre Operational ChecksSample Co LtdJHA - Installing a Residential Sewer LinePage 13 of 15

Hand ToolsShovel and RakeGasoline powered Leg Rammer12-Aug-21JSEAsySample Co LtdJHA - Installing a Residential Sewer LinePage 14 of 15

PPE Requirements for Task:GlovesHearing ProtectionSample Co LtdElectrical Tool Tag Hi Visibility Vests or ClothingSafety BootsAcronyms and Abbreviations:LTI - Lost Time InjuryPPE - Personal Protection EquipmentPTD - Permanent and Total Disability12-Aug-21JSEAsySample Co LtdJHA - Installing a Residential Sewer LinePage 15 of 15

Part 2: Hazard Analysis, Control and Legislation Worksheet Sample Co Ltd Job Safety and Environmental Analysis (JSEA) / Risk Assessment Risk Rating Step No. Process Steps Potential Hazard(s) / Risk Hazard Control Measures New Risk Rating List the steps n