Transcription

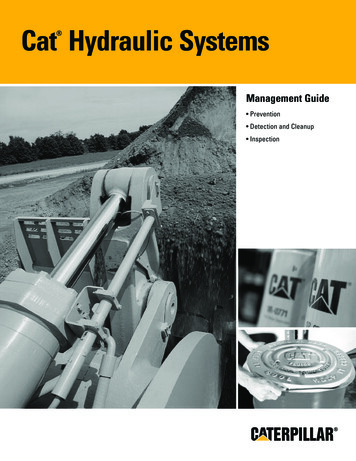

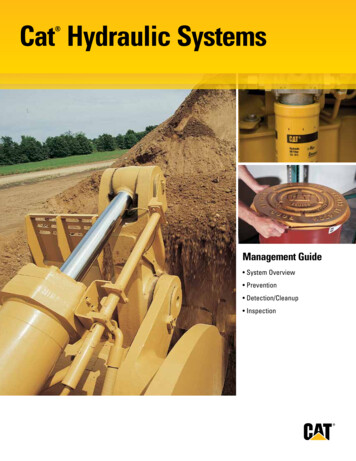

Cat Hydraulic Systems Management Guide System Overview Prevention Detection/Cleanup Inspection

ContentsCustomer demand for more powerful andeasier-to-operate equipment has elevatedthe importance of proper hydraulic systemSystem OverviewPrevention45-13management. The condition of a machine’sDetection/Cleanup14-15hydraulic system can make a big differenceInspection16-17in the amount of work that gets done andat what price. Fluid contamination is theleading cause of hydraulic system failures.By learning to control contamination, youcan help maintain system efficiency, extendcomponent life, and correct problemsbefore they lead to costly repairs andunscheduled downtime.This management guide offersinformation, tips, and ideas butis not intended as a technicalmanual or a substitute for theadvice and recommendationsof our parts and serviceexperts. By referencing thismanual and following therecommendations in yourOperations and MaintenanceManual, you can maximize theproductivity, service life, andvalue of your Cat machines.

Manage it well. Make it last.This guide gives you the tools to get maximum value from your Cat hydraulic system.Understanding the elements of hydraulic system management can help you maintain systemefficiency, extend component life, and correct problems to avoid unnecessary repairs andunscheduled downtime.Daily inspections and preventive maintenance puts you in control of the life and performanceof your investment. And your Cat dealer is always available to answer questions and providewhatever help you need, such as S O SSM fluid analysis and periodic inspections.

System OverviewPreventionInspectionMany hydraulic system problems can be prevented withattention to the system’s number-one enemy: fluid contamination.By learning to control contamination, you can help maintainsystem efficiency, extend component life and correct problemsbefore they lead to costly repairs and unscheduled downtime.Daily hydraulic system inspections performed by you and youroperators can catch leaks and other small problems before theyresult in unscheduled downtime. Efficiency loss is not easilydetected and silently robs your machine of performance. That’swhy we also recommend technical inspections performed by ourtrained technicians. These periodic inspections include checksof system pressures, cycle times and more—which can identifyproblems and help us recommend corrective actions.Detection/CleanupHydraulic systems are closed systems, which means muchof what you need to know is happening internally. To detectwear and other problems that can occur inside the system, werecommend regular use of our S O S Fluid Analysis Services.One of these services, particle counting, is especially importantfor hydraulics. It identifies excessive contamination levels thatcan be brought under control through high-efficiency filtration,“kidney looping” and other means.4

PreventionKnow What Contaminants ArePreventing hydraulic system problems begins by addressing fluidcontamination. Contaminated oil is the primary threat to today’shydraulic systems. Understanding what contamination is, why it’sharmful, how it gets in, and how to control it can go a long way inimproving machine performance, extending component life andlowering your costs.Particulate ContaminantsChemical ContaminantsParticulate contaminants are the most common, measurable,and controllable. They can be built in at the factory, transferredin through new oil, generated internally or taken in duringmaintenance, attachment changes and machine operation.Examples of particulate contaminants include dirt, sand, paintand metal or rubber wear particles.Chemical contaminants include heat, water and air. Thesecombine to break down the oil’s chemical composition, producingcontamination in the form of oxidation and acids. Like particulatecontaminants, chemical contaminants can originate inside oroutside the system.Contamination is anything foreign in the hydraulic system. Thereare two types of contaminants: particulate and chemical.5

PreventionAbrasive WearKnow the Effects of ContaminationAbrasive particles scrape metal fromhydraulic components. Wear metal iscreated, multiplies and travels to otherparts of the system to do more damage.Fluid contamination damages a hydraulic system in two ways.First, it reduces system efficiency. Machine productivity andefficient hydraulics go hand in hand. If a hydraulic systemisn’t performing at peak efficiency, it’s robbing the machineof performance. Efficiency losses usually occur slowly andcan reach 16 to 20 percent before the operator detects a lossin performance. These “invisible” efficiency losses also canincrease fuel consumption.Contamination also accelerates component wear—75 to 85percent of hydraulic pump, motor, cylinder, and valve failurescan be traced to contamination. Due to the extremely smallclearances in today’s hydraulic systems, even particles youcannot see can damage pumps, motors, cylinders, and valves inthe form of abrasive, adhesive, and fatigue wear.Fatigue WearRepeated high-pressure stress loadscause metal to chip or break fromcomponents and contaminate thehydraulic system.Adhesive Wear (Silting)Typical metal-to-metal clearances in Cat hydraulic systems are3-5 microns (one micron is one millionth of a meter). Therefore, evenparticles too small to see can do big damage.6Small particles build up on metalsurfaces and clog the flow of fluids.The result is jamming and stickingof valves and reduced systemefficiency.

PreventionKnow When Your Systems Are Exposed to ContaminationBecause contamination can have many sources throughout thelife of a machine, controlling it must be a joint effort.dealers and customers on ways to keep Cat products clean oncethey leave the factory.Caterpillar is committed to shipping clean machines andcomponents. As a result, in-plant process reviews and employeeeducation are ongoing efforts. Caterpillar also is working withLet’s look closely at some of the things you can do to minimizecontamination. You’ll be surprised how many are simplycommon sense.CaterpillarCat dealer7

PreventionControl Contamination During HousekeepingIf you have a service shop, housekeeping is the best place to initiate contamination control. Each technician needs to understand theimportance of contamination control and practice it daily. Here are some tips:Keep Floors and Work AreasCleanSweeping floors daily and maintaininguncluttered work benches withsurfaces that won’t mar parts or addcontaminants are good ways to jumpstart contamination control efforts.Put Someone in ChargeMaking someone responsible and accountablefor results will help ensure contaminationcontrol becomes an ongoing effort.Manage Spills CorrectlyProtect Work “In Progress”Oil spills should be cleaned up promptlyand properly. Absorbent pads, mopsand scrubbers are recommended overgranular methods that tend to pollute theair with contaminants.When possible and at the end ofeach shift, make sure in-processrepairs are protected from airbornecontaminants.Ask your dealer about other repairprocesses that can be implemented tocontrol contamination.8

PreventionControl Contamination During Hose AssemblyPrecautions you take when assembling and storing hoses can go a long way in minimizing fluid contamination.Clean Hoses Properly During AssemblyThe cutting and assembly of hoses introduce many contaminantsthat need to be removed before installation. We recommend useof the Cat Hose Cleaner Group, which fires a foam projectilethrough hoses, tubes and couplings. This air-powered tooltakes only seconds to strip out metal and rubber contaminantstraditional cleaning methods leave behind.Protect Stored Hose and AssembliesBulk hose in storage and assemblies that have been properlycleaned should be protected from airborne contaminants.Installation of caps and plugs is a low-cost means of deliveringthis protection.9

PreventionControl Contamination During Oil and Filter Changes and Oil StorageBesides maintaining a clean facility, paying attention to the hydraulic oil is important. The oil you select and how you store andtransfer it all have an impact on contamination and component life. Filter and fluid changes also present contamination controlopportunities. Here are a few tips:Select the Right OilCat Hydraulic Oil contains the neededadditives, like oxidation and foaminhibitors, to help prevent contamination.It also has more than twice as much zincas standard industrial oils to providemaximum protection to pumps, motors,cylinders and valves. Be familiar withthe additives in your oil, and don’tcompromise quality to save a smallamount of money.10Change Oil Regularly and AlwaysFilter Oil Stored in BulkWe have extended the oil changeinterval for hydraulic systems to 6,000hours, providing certain conditions formonitoring the oil are met. We alsorecommend changing oil when it’s warmand agitated, and always filtering new oilfrom barrels or other bulk systems beforeinstallation.Use Tight-fitting Barrel CoversTight-fitting covers, such as our 1U6156,can help prevent dirt, water, airborneparticles and other contaminants fromentering oil barrels. It’s also wise to storebarrels inside.

PreventionChange Filters Regularlyand CarefullyUse Quality Filters BetweenSystem InvasionsUse High Efficiency Filters AfterMaintenance and ServiceHydraulic filters should be changed atleast every 500 hours. It’s also importantto keep new filters and other partspackaged until they’re ready to install andto remove old filters carefully.Using inadequate filters can compromiseperformance. To maintain the highestlevels of cleanliness and performance,we recommend installing genuine CatFluid Filters.Contaminants invade the hydraulicsystem any time it’s open for maintenanceor repair. We recommend Cat HighEfficiency Filters at 250 service meterhours following any system invasion. Besure to change High Efficiency Filtersbefore 250 hours if the bypass indicatorgoes on.11

PreventionControl ContaminationDuring GeneralMaintenancePerform Daily InspectionsWhen performing the daily inspections,check for leaks and promptly fix any youfind. Look especially for worn cylinderwiper seals and pitted rods that may begiving dirt and other contaminants a freepass into the system.Earlier we discussed the importance offollowing recommended oil and filterchange intervals. A few other preventiontips include:Keep Hydraulic Tanks FilledAlways keep the hydraulic tank between“Full” and “Add.” Insufficient fluid levelsare the leading cause of pump cavitation,leading to pump failure and contaminationof the entire system. Low fluid levelscan also result in high oil temperatures,causing oil to degrade.Maintain ValvesMaintain oil cooler and relief valvesproperly. Relief valve settings should beadjusted only by our trained technicians.If a pressure loss is detected, it’simportant to find its source and repair it.1Replace Worn Fan BeltsInspect fan belts, radiators, and oilcoolers regularly. Maintaining fan speedand cleaning debris from radiators andoil coolers will help keep the systemoperating at acceptable temperatures.12

PreventionControl Contamination During Equipment OperationHere are a few ways to guard against contamination on the job site:Monitor Hydraulic System TemperaturesExcessive heat in hydraulic systems thins the oil, increases fluid oxidation, bakes sealsand blisters hoses. It is important to monitor system temperatures and, if equipped,watch temperature gauges and sensor lights.Use Care When Changing Work ToolsWith today’s machines, operators frequently change work tools that are hydraulicallydriven. If not maintained, these tools can contaminate each machine they’re attachedto. Always inspect quick couplers and wipe off dirt from flush-face disconnects beforecoupling. Protect nipples and couplers with caps and plugs.Listen to Your OperatorsAn often-overlooked opportunity for contamination control is listening to your operators.Day in and day out, these individuals live with your machines and can alert you toexcessive drift, noises, and other signs of possible contamination.13

Detection/CleanupKnow What’s Happening Inside Your Hydraulic SystemsHelping to prevent contamination is important, but you alsomust know what is occurring inside your hydraulic systems.Regular use of our S O S Services is the best way to detectcomponent wear and contamination so you can head offproblems early.Take Samples RegularlyTaking hydraulic oil samples regularly—when recommended—iscritical because it allows for accurate interpretation. Whensamples are taken regularly, a baseline is established so trendscan emerge. This information helps us make proper servicerecommendations. How you take a sample is also important. Formore information, please reference https://dealer.cat.com/SOS.The Cleaner the System, the Better!Caterpillar recommends a cleanliness target for optimizingcomponent life in Cat hydraulic systems of ISO 18/15 or cleaner.Understand Our S O S ServicesS O S Services for hydraulic systems is composed of four tests: Component Wear Rate Analysis evaluates the wear takingplace inside the lubricated compartment. Oil Condition Analysis determines if the oil has degraded. Oil Contamination Tests determine if anything harmful hasentered the oil. Oil Identification confirms use of the correct oil.S O S analysis interpreters use these tests to evaluate hydraulicsystem health and, if needed, recommend maintenance.14

Detection/CleanupUse the Correct Method to Take SamplesUsing an Oil Valve ProbeFilling Out Label AccuratelyUsing Vacuum Extraction Set the engine at low idle after itreaches normal operating temperature.Remove the dust cap from the valve andwipe the valve with a clean cloth.Providing complete information on thesample label makes processing yoursample easier. Make sure you includeimportant information like: Insert the probe into the valve andcollect about 100 ml (4 fl oz) of oil into awaste container. Dispose of the wasteoil and tube properly. Machine model and serial number Turn off the engine after it reachesnormal operating temperature. Measureand cut new tubing to the length ofthe dipstick. If the compartment youare sampling does not have a dipstick,cut the tubing so that it reaches abouthalfway into the oil depth. Insert the probe with a new piece oftube into the valve again and fill thesample bottle about three-quarters full—do not fill to the top. Withdraw the probe and secure the capon the bottle. Place the bottle withthe completed label into the shippingcylinder.Note: Oil valve probe should be used onpressurized compartments only. Retrofitvalve kits are available for models notequipped with valves. Service meter units on equipment and oil Whether or not the oil was changedwhen the sample was taken Insert the tubing through the head of thevacuum pump and tighten the retainingnut. The tubing should extend about4 cm (1 in) beyond the base of thevacuum pump head. Install a new sampling bottle onto thevacuum pump head and insert the endof the tubing into the oil—do not allowthe tube to touch the bottom of thecompartment. Pump the vacuum pump handle to createa vacuum. Fill the bottle about threequarters full—do not fill to the top. Withdraw the tubing, remove the bottlefrom the vacuum pump and secure thecap on the bottle. Place the bottle with thecompleted label into the shipping cylinder.Address Elevated Contamination Levels PromptlyWhen interpretation of S O S analysis data verifies you havea contaminated system, it’s important to respond promptly.The longer you operate a contaminated system, the fastercomponents wear, system efficiency erodes, and oil propertiesbreak down.Besides identifying and correcting the cause of elevatedcontamination levels, it’s important to clean up the system.High Efficiency Filters, “kidney loop” filtration, oil changes orcomplete system flushing may be appropriate, depending oncontamination levels.15

InspectionPerform System InspectionsRecommended Service Intervals10-hour or daily inspection Check hydraulic fluid level Check hydraulic cylinders and pumpsfor leaks Check hoses, lines and hydraulic tankarea for leaks or damage250-hour or monthly inspection Perform 10-hour preventivemaintenance checks Check hydraulic oil coolerfor leaks or plugging Check all hydraulic lines for damaged,missing or loose connections500-hour or quarterly inspection Perform 10- and 250-hour preventivemaintenance checksThe final element in hydraulic system management involves inspecting and “listeningto” your equipment. You can help maintain system performance and catch problemsearly by: Perform S O S sampling of hydraulic oil Following the inspection and maintenance schedule shown on this page Change hydraulic filter Paying attention to the repair indicators listed on pages 17 and 18 Check hydraulic pumps and mountingsfor loose or missing hardwareMachine Inspection1,000-hour or six-month inspection Perform 10-, 250- and 500-hourpreventive maintenance checks Check pump weep holes for leaks2,000-hour or annual inspection Perform 10-, 250-, 500- and 1,000-hourpreventive maintenance checks Check hydraulic system pressure Check hydraulic system cycle times anddrift rates16Once a year or every 2,000 hours, we recommend having your hydraulic systemsinspected by our trained service professionals. During these inspections we: Conduct a detailed visual walkaround inspection of the hydraulics, enginecompartment, cab, power train and ground engaging tools Drift test all hydraulic cylinders Perform complete checks of cycle times and system pressures Stall test the hydraulic system Take a sample of the hydraulic oil and perform S O S ServicesAfter interpreting the inspection and fluid analysis results, we’ll meet with you to delivera complete report. If service is necessary, we’ll also provide a quote. We offer a varietyof repair options and can help you decide on the one best for you.

InspectionPay Attention to Repair Indicators!Repair IndicatorsPossible CausesCat Dealer Service OptionsLeaksSystem pressure too highScored or bent cylinder rodFailed or incorrect sealsImproperly torqued hose connectionWorn or damaged hoses, tubes and fittingsMissing guardsHose serviceThorough visual machine inspectionMaintenance and diagnostic servicesS O S ServicesExcessive Cylinder DriftValve adjustment neededScored cylinderFailed seal or sealsScored valveContaminated oilIdentification and measurementDiagnostic servicesS O S ServicesSlow Cycle TimesEngine performanceFaulty valveLow fluid levelWorn system componentsContaminated oilMachine measurements compared tospecsDiagnostic servicesS O S ServicesNoisy OperationEngine performanceLow fluid levelRestriction in systemAerationWorn system componentsFaulty relief valveThorough visual machine inspectionS O S ServicesSystem OverheatingFaulty oil coolerLow fluid levelPlugged filterWorn system componentsFaulty relief valveWrong viscosity or contaminated oilRestriction in systemPoor operator habitsThorough visual machine inspectionMaintenance and diagnostic servicesS O S ServicesLoose Cylinder JointsWorn rod or cylinder eye/trunnionPoor lubricationImproper preventive maintenance scheduleComponent inspection/repairBlisters or Abrasions in HosePinhole leaks in liner materialPoor hose routingExternal damageSystem overheatingThorough visual machine inspectionHose serviceExcessive Hose MovementImproper clamping or routing of hoseAeration/cavitationHose serviceS O S ServicesHigh levels of wear elements, dirt andother contaminants in oil will acceleratecomponent wear and erode system efficiencyPreventive maintenance scheduleconsultationHigh Service Meter HoursTalk with us to determine what high-hourservice is appropriate for your systemsConsult with dealer17

Notes18

Notes19

Expect more from the expertsMore and more of your operating costs are tied to hydraulic systems. Following the information andmaintenance practices outlined in this guide can greatly extend service life and lower costs. Your Catdealer is committed to helping you maximize efficiency, productivity, and machine availability with aneffective management control system incorporated into a Customer Support Agreement. We’re builtto put you in control.For more information about our hydraulic products and services, call your dealer today orvisit www.cat.comPEGP6028-06 2014 Caterpillar All Rights Reserved Printed in USACAT, CATERPILLAR, BUILT FOR IT, their respective logos, S O S, “Caterpillar Yellow” and the “Power Edge” trade dress, aswell as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Fluid contamination damages a hydraulic system in two ways. First, it reduces system efficiency. Machine productivity and efficient hydraulics go hand in hand. If a hydraulic system isn’t performing at peak efficiency, it’s robbing the machine o