Transcription

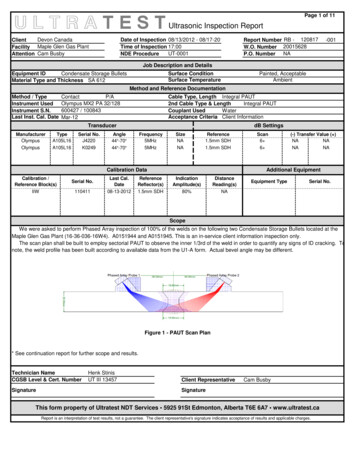

Page 1 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-201Time of Inspection 17:00UT-0001NDE ProcedureReport Number RB - 120817W.O. Number 20015628NAP.O. Number-001Job Description and DetailsEquipment IDCondensate Storage BulletsMaterial Type and Thickness SA 612Surface ConditionSurface TemperaturePainted, AcceptableAmbientMethod and Reference DocumentationMethod / TypeInstrument UsedInstrument S.N.Last Inst. Cal. DateContactP/AOlympus MX2 PA 32/128600427 / 100843Mar-12Cable Type, Length Integral PAUT2nd Cable Type & LengthIntegral PAUTCouplant UsedWaterAcceptance Criteria Client eA105L16A105L16Serial No.J4220K0249dB SettingsAngle44 -70 44 -70 Frequency5MHz5MHzSizeNANAReference1.5mm SDH1.5mm SDHCalibration DataScan6 6 (-) Transfer Value ( )NANANANAAdditional EquipmentCalibration /Reference Block(s)Serial No.Last )DistanceReading(s)IIW11041108-13-20121.5mm SDH80%NAEquipment TypeSerial No.ScopeWe were asked to perform Phased Array inspection of 100% of the welds on the following two Condensate Storage Bullets located at theMaple Glen Gas Plant (16-36-036-16W4). A0151944 and A0151945. This is an in-service client information inspection only.The scan plan shall be built to employ sectorial PAUT to observe the inner 1/3rd of the weld in order to quantify any signs of ID cracking. Tonote, the weld profile has been built according to available data from the U1-A form. Actual bevel angle may be different.Figure 1 - PAUT Scan Plan* See continuation report for further scope and results.Technician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 2 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberScope - ContinuedWhen discontinuities are encountered that may be indicative of ID connected cracking, they shall be imaged with TOFD to determineextent and only whether the indication is crack like or not. Due to the original joint efficiency requirements, this inspection shall not be utilizedto determine acceptability of the weld in accordance to code of construction.The Bullet on the North side of the plant is called tank north, the Bullet on the South side is called tank south. The ‘direction of flow’ of thetanks is assumed to be from west to east, naming the outer most circular weld on the west side number 1. All circular welds are scanned infour sections, 12 to 3 o-clock, 3 to 6 o-clock, 9 to 6 o-clock and 12 to 9 o-clock. The longitudinal welds on the heads are scanned clockwise,naming the 12 o-clock position ‘zero’.Summary Report146 data sets were captured, giving 100% coverage of all welds for each vessel. 19 relevant indications were detected, 2 of which areinterpreted as crack like. As a cautionary note the other 17 indications may pose a risk to develop into cracks in the future. A monitoringprotocol may be wise until such time that a visual internal can be completed. Refer to Figures A and B for crack like indication detail.Detail Report - PAUT Data sets and description.Technician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 3 of 4Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberDetail Report - PAUT Data sets and description - Continued.Technician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 4 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberDetail Report - Discontinuity IdentificationFigure A - Indication number 10Technician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 5 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberDetail Report - Discontinuity IdentificationFigure B - Indication number 12Comments on Figures A and B (Indications 10 and 12)Indication 10 measures Length: 46mm (1129 to 1175) Height: 3mm (17 to 20). Indication 12 measures Length: 103mm (100 to 203)Height: 1.5mm (18.5 to 20). While these indications certainly appear to be ID connected, without full knowledge of the weld bevel andinternal weld profile (caps ground flush?) these has to be some caution in analysis. These indications may turn out to be undercut or smallareas of cold lap. Future monitoring to look for signs of growth would be prudent, however these indications may be easily classified withthe next internal inspection by visual or magnetic particle methods.Images of Relevant IndicationsThe following pages contain the images of both the PAUT and TOFD for the 19 relevant indications detected during the inspection.Technician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 6 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 7 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 8 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 9 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 10 of 11Ultrasonic Inspection ReportDevon CanadaClientFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628NAP.O. NumberImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

Page 11 of 11Ultrasonic Inspection ReportClientDevon CanadaFacility Maple Glen Gas PlantAttention Cam BusbyDate of Inspection 08/13/2012 - 08/17-2012Time of Inspection 17:00NDE ProcedureUT-0001Report Number RB - 120817 -001W.O. Number 20015628P.O. NumberNAImages of Relavant Indications - ContinuedTechnician NameCGSB Level & Cert. NumberSignatureHenk StinisUT III 13457Client RepresentativeCam BusbySignatureThis form property of Ultratest NDT Services 5925 91St Edmonton, Alberta T6E 6A7 www.ultratest.caReport is an interpretation of test results, not a guarantee. The client representative's signature indicates acceptance of results and applicable charges.

note, the weld profile has been built according to available data from the U1-A form. Actual bevel angle may be different. The scan plan shall be built to employ sectorial PAUT to observe the inner 1/3rd of the weld in order to quantify any signs of ID cracking. To Maple Glen Gas Plant (16-36-036-16W4). A0151944 and A0151945. This is an in-service client information inspection only. We were .