Transcription

USING STABILITYTESTING TO DETERMINESHELF LIFE

CONTENTSWhat is Shelf Life? . 1How Do You Determine the Shelf Life of a Product? . 2Real-Time Stability Tests . 2Accelerated Aging or Accelerated Shelf Life Testing . 3Is an Accelerated Shelf Life Testing a Good Fit for Your Product? . 3-4ASTM-F1980 Time vs. Temperature . 4Tenney / Lunaire Environmental Test Chambers and Rooms OfferSuperior Shelf Life Testing for a Number of Industries . 5

WHAT IS SHELF LIFE?Products change over time as they sit in storage,but as long as their performance characteristicsremain within the manufacturer’s specifications,the products are considered stable. The phrase“shelf life” refers to the length of time aproduct remains stable when stored under themanufacturer’s recommended conditions. Foodmanufacturers need to accurately determine theuse by or best before dates for their products inorder to meet strict regulations and to keep theirbrand and consumers safe.Shelf life is a product of physical, microbiological,and chemical processes, triggered by any one of amultitude of contributing factors. Manufacturersuse real time stability tests to establish aproduct’s shelf life. According to the Instituteof Food Technologists (IFT) and the NationalAdvisory Committee on Microbiological Criteriafor Foods (NACMCF), shelf-life is “the amount oftime that a food product is considered acceptablefor consumption when stored at the appropriatestorage conditions.” When determining if a foodproduct is acceptable for consumption, severalfactors – including organoleptic properties(taste, order, texture, appearance), microbialspoilage, and chemical changes to the productduring storage – must be considered. Almostall food, drug, and other consumed productsrequire a stated expiration date in the USA. Inaddition, many other consumer and industrialproduct manufacturers define shelf life to provideconsumers an understanding of a productsusable life at time of purchase. Also, thesemanufacturers use various packaging to extendstorage conditions. This can be identified andverified using shelf life testing and acceleratedshelf life testing.1

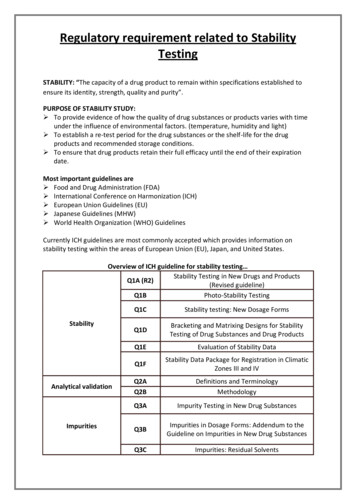

HOW DO YOU DETERMINE THE SHELFLIFE OF A PRODUCT?The shelf life of a product begins from thetime the product is finished processing and ispackaged. The time depends on factors likeingredients, manufacturing process, packaging,and typical storage conditions.There are two main types of tests to establishshelf life: real-time stability tests and acceleratedshelf life testing. It should be noted that, inthe food and drug industries, accelerated agingdata is recognized by regulatory bodies as anacceptable means to generate data quickly, butthis data is only accepted until those tests canbe correlated to “real time” samples. In otherindustries, accelerated aging is a tool that isvery useful in product testing and understandingproduct limitations.REAL-TIME STABILITY TESTSManufacturers typically use real-time stabilitytests to determine the duration of time that theproduct will be effective for their customer’s use.This provides consumers with what is known asthe “expiration date” of a given product. Realtime stability testing to determine shelf life israther straight forward – store the product ina particular defined environment and note thepoint in time at which the product breaks downand becomes ineffective. This is done by takinga subset of the product samples in a stabilitychamber and methodically testing for efficacyat pre-determined intervals until the product nolonger exhibits its desired properties. This clearlydefines the products usable life.The storage temperature and humidity parametersare defined by different organizations dependingon the type of product. For example, food anddrug manufacturers have guidelines (ICH) toprovide consistency. Testing in this way ensuresthe product continues to meet the stringentquality, safety, and efficacy standards of thepharmaceutical industry, even after sitting on theshelf for a long time or when exposed to variousenvironments. Manufacturers of other productshave other standards either defined by an industrygroup or that are company specific definedstorage conditions. It should be noted that whendoing this type of testing, often in addition to theproduct itself being tested, the packaging is alsotested. This is especially true when the packagingis designed to enhance the products efficacy,longevity, or if the contents need to remain sterile.“Use real-time stability tests todetermine the duration of timethat the product will be effectivefor [the] customer’s use.2”

ACCELERATED AGING OR ACCELERATEDSHELF LIFE TESTINGAccelerated shelf life takes the climaticconditions to more extreme levels in order tocompress required test time. This is done byapplying the Arrhenius equation to determine therate of acceleration of time based on increasedtemperatures.stimuli to help determine the long-term effects ofexpected levels of stress in a much shorter timeframe. These tests cycle through stages of appliedstresses, causing materials to react as they wouldover a long period of storage or shipment to helpverify shelf-life and storage performance.Accelerated aging uses aggravated conditions ofheat, humidity, vibration, and other environmentalIS AN ACCELERATED SHELF LIFE TESTINGA GOOD FIT FOR YOUR PRODUCT?Shelf stable and frozen products with a shelf-lifeof six months or more are good candidates foraccelerated shelf life studies. Accelerated shelflife studies are not recommended for all products,such as refrigerated products that spoil due tomicrobial growth. Each product has a specificmode of spoilage (i.e. rancidity, moisture loss/gain, organoleptic changes), so applicable testsneed to be tailored to the specific product. Mostother products or durable goods can benefit fromaccelerated testing.3

Accelerated aging tests help determine productstorage requirements as well as establishacceptable parameters for products and packageexpiration dates. Accelerated aging can also helpdetermine the expected lifecycle of products andassemblies.Accelerated aging, oftentimes referred to asaccelerated shelf-life testing, is commonly usedin the medical device industry to accelerate theeffects of time on a sterile barrier packagingsystem to establish shelf life parameters. It is alsocommonly used for many other types of products.The accelerated aging process is based on therelationship of temperature and reaction ratewhere an increase in temperature increases thereaction rate.Reference ASTM F1980-16ASTM-F1980 TIME VS. TEMPERATUREProperly applied in a package validation test plan(and within ANSI/AAMI/ISO 11607 guidelines),accelerated aging can result in a decreased timeto-market for a new product. For example, perthe Arrhenius equation, a polymer product or oneprotected by polymer packaging that is subjectedto 5.3 weeks of Accelerated Aging at 55 Chas similar aging characteristics as a 42.2-weeksample aged at 25 C. One thing to be awareof is the limit of the product aging temperature.For polymer packaging, it is typically limitedto 60 C or less due to the polymer materialchanges/breakdown at temperatures higher than60 C. This maximum temperature or point ofdegradation needs to be taken into considerationfor other materials, as well.4

TENNEY / LUNAIRE ENVIRONMENTAL TESTCHAMBERS AND ROOMS OFFER SUPERIORSHELF LIFE TESTING FOR A NUMBER OFINDUSTRIESAccurate predictions of shelf life rely on accuratetesting results. Lunaire Stability EnvironmentalTest Chambers and Rooms provide innovativeengineering and design, robust construction, andsuperior performance that is needed to meet andexceed these requirements.The Lunaire steady state stability reach inchambers include the CEO series, which offers avariety of temperature and humidity combinationsin a number of workspace sizes, while the LunaireSS series of steady state testing chambers offershigh performance in workspaces of 10, 20, and30 cubic feet. Lunaire also offers Steady StateEnvironmental Walk-In Rooms for stability testing,shelf life testing, and accelerated life testing.In addition to shelf life testing and acceleratedshelf life testing, Tenney and Lunaire manufacturehigh quality test chambers that can consistentlymeet nearly every temperature, humidity,altitude, and vacuum testing and processingrequirements. Tenney and Lunaire offer a numberof environmental test chambers and rooms tomeet a variety of testing, such as reliabilitytesting, package testing, incubation, controlledwalk-in and reach in cycling chambers, controlledtemperature storage, accelerated aging, drying,burn in, and cold room applications for a numberof pharmaceutical, medical, personal care,electronics, automotive, defense, industrial,research & development, and consumer productsapplications.Contact www.tenney.com for more information.5

accelerated shelf-life testing, is commonly used in the medical device industry to accelerate the effects of time on a sterile barrier packaging system to establish shelf life parameters. It is also commonly used for many other types of products. The accelerated aging process is based on the relationship of temperature and reaction rate