Transcription

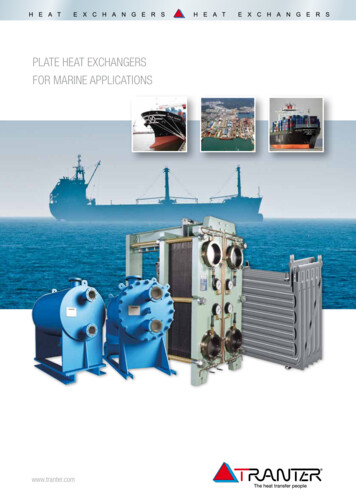

PLATE HEAT EXCHANGERSFOR MARINE APPLICATIONSwww.tranter.com

There are times when thereliability of your equipmentis crucial!When conditions are tough, crew and equipment are reallyput to the test. The main engine oil cooler and centralfreshwater cooler simply have to work. There is no room forcompromise when the sea is rough and the harbour far away.That’s why Tranter offers you the very best. Reliable, compact,and efficient plate heat exchangers that are easy to serviceand maintain. So, it's no wonder they can be found on boardcountless vessels all around the world – from luxury yachts tohuge container vessels, supertankers and offshore rigs.Tranter offers an extensive range of gasketed plate heatexchangers specially designed for marine applications. This,combined with our extensive experience and solid technicalexpertise within marine and industrial applications, makes usa reliable partner.For many decades our plate heat exchangers have proved to bethe perfect solution for various closed-circuit cooling systemsat sea. They are also frequently found in other applications onboard, such as tap-water production systems and HVAC systems.

Our experts will guide youto the right solutionTranter is a global supplier of plate heat exchangers. We haveextensive experience of heat transfer solutions for marine, offshore, HVAC and industrial applications around the world.Our mission is to help you achieve the optimum solution withregard to performance efficiency, payback and energy conservation.Our marine programme encompasses plate heat exchangersthat fulfil any capacity requirement. Our patented Ultra flexdesign means that we can closely match precise heat exchangerrequirements with just a few plate designs. Plates are providedin stainless steel, and titanium as standard, but are also available in other materials. We can also offer frames constructedfrom aluminium etc. when it is important to keep the weight low.Quality all the wayAt Tranter we enlist cutting-edge technology in our manu facturing processes. Raw materials are subject to rigorousquality speci fi cations. Exact measurements and metall urgicalanalyses are performed in accordance with our Total QualityManagement System. Fully-automated plate presses ensureconsistent high quality and plate uniformity time after time.After assembly each plate heat exchanger is tested, and theresults are incorporated into a data bank. Before packing andshipping, we carry out a final check. Nothing is left to chance!

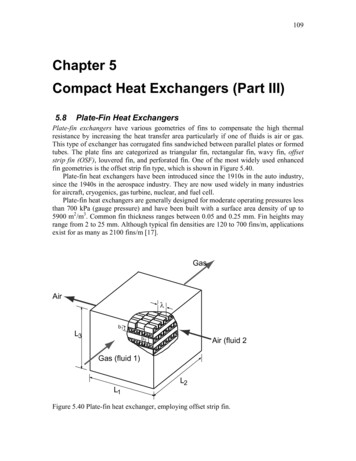

Keep cool for smoothand reliable operationCentral cooling systemsA central cooling system consists of central coolers that use seawater to cool a secondary circuit with fresh water. This circuitpasses through a battery of other coolers, such as lubricationoil cooler, jacket water cooler, turbo-charging air cooler etc.Using fresh water in the secondary circuit, minimizes corrosion,scaling and redundancy in machines and equipment and ensuressmooth operation. At the same time the cost for repair andreplacement will be kept to a minimum.Sea WaterHigh Temp. Fresh WaterMain EngineMGO CoolerFresh WaterMain EngineLube Oil CoolerLube OilMGOStern TubeLube Oil CoolerCentr

Central fresh water coolersMain engine lube oil coolerM/E T/C.L.O CoolerM/E J. F. W. CoolerGenerator EngineMGO Cooler/Boiler MGO CoolerJacket water coolerral Freshwater CoolersStern tube lube oil cooler

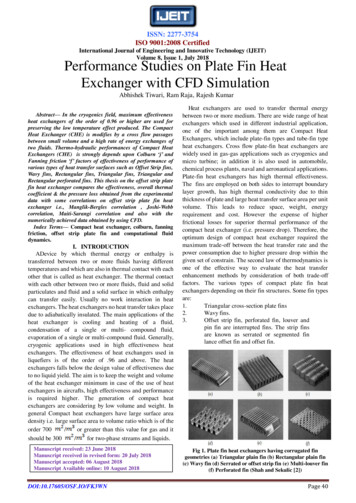

Marine plate heat exchangersGX-26GC-26GL-13GC-16Connection sizeØ50/65 mmGX-42Connection sizeØ100 C-60GX-100GX-140Connection sizeØ200 mmConnection sizeØ150 mmGL-152GX-205GL-218GL-284Connection sizeØ350 mmConnection sizeØ300 mmFrame type N/PGL-230GL-330Connection sizeØ400/450/500 mmGL-430

X-26 NGC-26 N100450226GX-42 N100450GX-51 NGC-51 N150GX-64 PDmmEmmChannel plate materialsAISI 15062628519103001320GX-91 P15062628523903001800GasketsGX-60 PGC-60 P2008254201700350910NBRGX-100 P20082542022803501490FKMGX-140 P20082542028603502070Viton GL-85 PGX-85 P300106057019853601140GL-145 PGX-145 P300106057025653601720GX-205 P300106057032153602300GL-230 N450151070031724502090GL-330 N450151070037824502700GL-430 N450151070043924503310AISI 316TitaniumMax working pressureN10 barP16 barS25 barEPDMMax working temperatureNBR140 CEPDM160 CFKM180 CApprovalsABS, GL, LRS, NK, BV, DNV, RINA,KR, CCS, RSInstrument flangesCIP – Cleaning-in-PlaceRoller assemblyMovable coverPlate packGasketGuide barFixed coverLinersBack flushHydraulic tightening toolStrainers

Conventional plates (GC)The corrugated plates have a gasket along the periphery. Thereare also gaskets around two of the four ports, which meansthat only one of the two fluids has access to the heatingsurface. The next plate has gaskets around the other twoports. Thus a channel system is created where two fluids passthrough every other channel respectively. Leakage betweenthe two fluids is not possible thanks to double gaskets aroundthe ports. The pressure drop and heat transfer are dependenton factors such as the arrow angle of the plate pattern. Anobtuse arrow angle (high-theta plate) means high resistanceand a high thermal driving force. An acute angle (low-thetaplate) means a low pressure drop but a lower thermaldriving force.High-theta plateLow-theta plateUltraflex plates (GX)Our unique, patented Ultraflex plate design features two anglesfor each plate size. The plates are available with a herringbone pattern with either an acute or obtuse angle, making itpossible to achieve six combinations of channels. An obtuseangle (high-theta plate) gives high resistance, and an acuteangle (low-theta plate) a low pressure drop. This allows ourheat exchangers to be optimized for the characteristics of eachindividual application. If you have different flow rates in theprimary and secondary circuits, your plate heat exchangers canbe designed with asymmetrical channels for maximum heattransfer efficiency and economy.Our unique Ultraflex designallows the two plates to beturned and rotated, givingsix combinations of high- andlow-theta plate pairs, matching the performance parameters of your application.Ultraflex allows asymmetrical designs, with each circuit individuallyoptimized for heat transfer.High-theta plateLow-theta plateHS High-theta,same directionHD High-theta,different directionsMS Medium-theta,same directionLS Low-theta,same directionLD Low-theta,different directionsMD Medium-theta,different directions

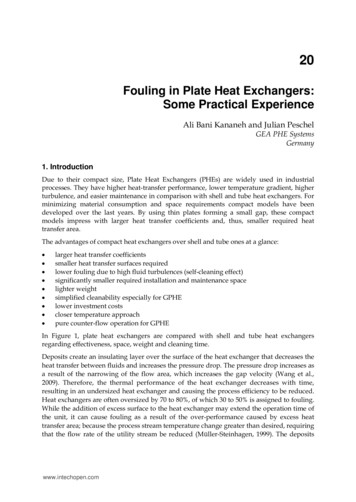

No unnecessary ballastWhy fill up your engine room with heavy, bulky equipment,when efficiency and economy are vital factors?A plate heat exchanger from Tranter is only about 1/3 of thesize and 1/6 of the weight of a shell-&-tube exchanger ofcomparable performance. Even if it may seem reasonable toinvest in a tube exchanger, this would have a much higher lifecycle cost than a plate heat exchanger.One reason is that the heat transfer properties of a plate heatexchanger are 3 to 5 times higher. Another is the close temperature approach which is as low as 1 C.Efficiency pays off!A plate heat exchanger offers many advantages comparedwith conventional shell-and-tube exchangers Up to 50% more efficient Up to 90% more compact 3-5 times higher k-values Unique turbulent flow design Closer temperature approach – as low as 1 C Far less material needed– less use of exotic alloys or titaniumService and maintenancemade easyWith regular service and maintenance you keep control ofyour heat exchanger’s condition so that you can maintainoptimum performance.With a Tranter service program you get a grip on things beforethey become a problem. Every program is tailor-made to yourspecific requirements and can include anything from regularinspection to full annual overhaul.This is a condition in wich you could find your plate heat exchanger withoutregular maintenance.Tranter provides safe, fast and customised service for all yourplate heat exchangers, no matter the brand.Dirty plates effect heat transfer and reduce the overall performance.A global service networkFactoryOfficeService centerFactoryOfficeService centerOur service network of representatives and engineers in Europe,Asia, Australia, Middle East, North & South America will backyou up with support and services. They can also train your staffin handling day-to-day maintenance themselves.Contact us for more information.

Improve thermal systemsefficiency and reliabilityShell & plate heat exchanger and prime surface heat exchanger banks.Plate heat exchangers save energy,space and weightTranter shell & plate heat exchanger and prime surface heatthese and other strategies to improve your your offshorethermal systems. Let us put the efficiency and reliability ofplate heat exchangers to work for you!exchanger banks are both designed for optimum efficiencyin compact packages. Shell & plate exchangers consistentlyoutperform shell & tube deck heaters, while heat exchangerbanks make pipe coil obsolete for bulk cargo heating banksand box coolers.Both products offer: Much smaller footprints Lighter weight Easier installation Removable heat exchange surfaces for effective cleaning Faster heating or cooling with less energy fluid Turbulent flow for better scaling resistance, greater reliability Less steel, lower purchase price, shorter lead time and lessexpensive deliveryTopside and below, take advantage of all the benefits plateheat exchangers provide. Contact us today for details onPlate heat exchangers on-board optimise your thermal systemefficiency with less - for less.

Tank Cargo HeatingIncrease efficiency and reduceinstallation cost with Platecoil Tranter manufacture tailor made PLATECOIL solutions for anycargo and tank design. PLATECOIL follow all major class societyrequirements and are made in materials such as carbon and stainlesssteel, titanium or other special alloys.Conventional marine cargo heating systems are known to beexpensive and time consuming to fabricate, install as well asvery energy inefficient. With Tranter PLATECOIL installed youwill reduce the total cost of installation, the heating footprintand installed total weight. It is also easy to access for cleaningand maintenance. The response time in temperature variancesis superior compared to conventional pipe coil. PLATECOILinstallations reduce the energy consumption by adapting a higherheat transfer efficiency compared to pipe coil. The overall heatingmedia holdup volume will be reduced by using PLATECOIL.Cargo heating bank fabricated from PLATECOIL panels.Tranter PLATECOIL can be tailor made to any shape required.PLATECOIL based cargo heating system in articulated tug barges. Please notethe drawing is not to scale; banks and piping are enlarged for clarity.

At the forefront of heat exchangertechnology for more than 80 yearsWichita Falls, TX USACotia, BrazilTel: 1 940 723 7125Tel: 55 11 360 841 54Fax: 1 940 723 5131E-mail: marine@se.tranter.comE-mail: marine@se.tranter.comwww.tranter.comPune, IndiaTel: 91 2137 392300Fax: 91 2137 392354E-mail: marine@se.tranter.comChina/Southeast AsiaTranter ChinaBeijing, ChinaTel: 86 10 8049 1790Fax: 86 10 643 79 490E-mail: marine@se.tranter.comENGVänersborg, SwedenTel: 46 521 799 800Fax: 46 521 673 93E-mail: marine@se.tranter.comSouth AmericaMiddle East/Africa/AsiaTranter Ind e Com de Equip. Ltda Tranter India Pvt. Ltd.95100-9520EuropeNorth AmericaTranter International AB Tranter, Inc.2014-08Tranter top quality, high-performance, proprietaryproducts are on the job in demanding industrial andcommercial installations around the world. Backed byour comprehensive experience and worldwide presence,Tranter offers you exceptional system performance,applications assistance and local service. Tranter is closeto its customers, with subsidiary companies, agents,distributors and representatives located worldwide.Contact us for a qualified discussion of your needs.

A plate heat exchanger from Tranter is only about 1/3 of the size and 1/6 of the weight of a shell-&-tube exchanger of comparable performance. Even if it may seem reasonable to invest in a tube exchanger, this would have a much higher life cycle cost than a plate heat exchanger. One reason is that the heat