Transcription

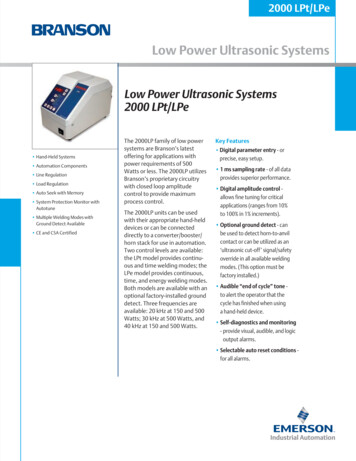

2000 LPt/LPeLow Power Ultrasonic SystemsLow Power Ultrasonic Systems2000 LPt/LPe Hand-Held Systems Automation Components Line Regulation Load Regulation Auto Seek with Memory System Protection Monitor withAutotune Multiple Welding Modes withGround Detect Available CE and CSA CertifiedThe 2000LP family of low powersystems are Branson’s latestoffering for applications withpower requirements of 500Watts or less. The 2000LP utilizesBranson’s proprietary circuitrywith closed loop amplitudecontrol to provide maximumprocess control.The 2000LP units can be usedwith their appropriate hand-helddevices or can be connecteddirectly to a converter/booster/horn stack for use in automation.Two control levels are available:the LPt model provides continuous and time welding modes; theLPe model provides continuous,time, and energy welding modes.Both models are available with anoptional factory-installed grounddetect. Three frequencies areavailable: 20 kHz at 150 and 500Watts; 30 kHz at 500 Watts, and40 kHz at 150 and 500 Watts.Key Features Digital parameter entry - orprecise, easy setup. 1 ms sampling rate - of all dataprovides superior performance. Digital amplitude control allows fine tuning for criticalapplications (ranges from 10%to 100% in 1% increments). Optional ground detect - canbe used to detect horn-to-anvilcontact or can be utilized as an‘ultrasonic cut-off’ signal/safetyoverride in all available weldingmodes. (This option must befactory installed.) Audible “end of cycle” tone to alert the operator that thecycle has finished when usinga hand-held device. Self-diagnostics and monitoring- provide visual, audible, and logicoutput alarms. Selectable auto reset conditions for all alarms.

Power Supply Line / Load Regulation Branson’s proprietary closedloop amplitude control correctsfor variations due to power linefluctuations and varying loadconditions. Output amplitudeis maintained with a variation ofonly 2% with line voltage fluctuations of 10%, regardless ofload. It ensures constant powerin welding and provides greaterweld consistency and reliability. Autotune plus Memory (AT/M) Provides fully-automatic tuningin a range of 500 Hz centeredaround 19.950 kHz for 20 kHzhorns, 750 at 30 kHz for 30 kHzhorns, and 1000 around 39.900kHz for 40 kHz horns, and storeshorn frequency at the end ofeach weld. Auto Seek - tracks the operatingfrequency when the systemis idle. It automatically measureshorn frequency by running thehorn at a low level amplitude(5%) to find and lock on to thehorn operating frequency andstore it in memory. System Protection Monitor(SPM) - Five levels of powersupply protection are provided:1) phasing, 2) over voltage,3) over current, 4) over temperature, and 5) power. The benefitsof this feature are to avoidequipment failures and toprovide greater weld accuracyand repeatability. Sequence of operation is displayed in the digitalLED window during thewelding cycle. Visual and audible alarms, andexternal outputs - identifyoverload, machine faults, andsetup errors. LED readouts display parameter settings - during setup andoperation for easy reference andmonitoring. LEDs are large andeasy to read in most light conditions. Nonvolatile storage of cycleparameters - provides storage oflast-used cycle parameters evenif the system is shut off or a powerinterruption occurs. High Cycle Rate - The powersupply is capable of in excess of200 welds per minute. Actualcycle rate is dependent upon theapplication and controls. Real Power Measurement Power measurement includesboth RF voltage and current, andis corrected for any amplitudesetting. Seven-segment LEDsdisplay the peak power achievedduring the weld cycle. Peak power reading - from thelast welding cycle is availableon the digital LED display bydepressing the “reset” switch.Similarly, power in the tuningmode is digitally displayed whenthe “test” switch is depressed. User I/O interface - providedfor direct hook-up with programmable controllers. Overload andWeld On outputs and externalreset input are available forcustomer access, through 24VDC logic interfaces. Externalreset input available in 24V.(Requires J911 start cable.)Hand-Held Welding ToolsThe 2000 Series hand-held ultrasonic welders are compact, lightweight tools usedto spot weld or stake large, complex parts and those with hard-to-reach joint areas.With pistol grip (PT) models, the trigger switch is located on the grip; barrel grip (HT) modelshave the trigger switch located on the side of the barrel. All units may be operated in anuntimed mode with the 2000LPt or 2000LPe set for continuous operation, utilizing thetrigger switch; or in a timed or energy mode using the 2000LPe power supply controller. Withtime or energy modes, the trigger switch initiates the cycle, which is then controlled by thepower supply.On the HT-215 unit, the operator grips a sliding, spring-loaded sleeve, and by applyingpressure against the parts to be welded, automatically triggers the ultrasonic welding cycle.Welding duration is controlled by the power supply either in time or energy welding modes.An adjustment screw is used to vary the force required before ultrasonic triggering occurs.

Basic ConfigurationsAutomation ComponentsPower SupplyPower OutputConverterRF CablesStart Cables150 Watts2CH1J934C (8’)J9132CH2J934C (8’)J911 (PLA* req’d)2CH3J934C (8’)20 kHz20:0.15.2CH20:0.50.902500 WattsTW-1J935 (8’)J913TW-2J935 (8’)J911 (PLA* req’d)TW-3J935 (8’)J931J913902RJ931CJ11 (PLA* req’d)CR30J934C30 kH30:0.50.CR500 WattsCH30J934CJ913CS30J934CJ911 (PLA* req’d)CP30J934C4C8’ built-in40 kHz40:0.15.4C40:0.15.4T40:0.50.4THand Held SystemsPower Supply150 Watts150 Watts500 WattsPower OutputJ913KTRJ936 (8’)J911 (PLA* req’d)4TRJ934J9134THJ934CJ911 (PLA* req’d)4TPJ934C4TRJ934J9134THJ934CJ911 (PLA* req’d)4TPJ934CHand HeldConverter RequiredReplaces20 kHz20:0.15.2CH150 WattsHT-215TW-1HK-215TW-2HG-152TW-320:0.50.902500 WattsPT-250402GK-5500 WattsPT-350Built-in—40:0.15.4C150 WattsPT-415KTJKG-1HT-415KTJKG-140:0.15.4T150 0Built-inGK-470HT-480Built-inHG-47030 kHz30:0.50.CR40 kHz40:0.50.4T500 Watts

Ordering Information20 kHz, 150 Watt System Components30 kHz, 500 Watt System ComponentsPower SuppliesPower SuppliesBranson EDP No.Branson EDP No.LPt, 100-120 V100-132-931LPt, 100-120 V100-132-967LPt, 200-240 V100-132-932LPt, 200-240 V100-132-968LPt, 200-240 V, CE100-132-933LPt, 200-240 V, CE100-132-969LPe, 100-120 V100-132-928LPe, 100-120 V100-132-964LPe, 200-240 V100-132-929LPe, 200-240 V100-132-965LPe, 200-240 V, CE100-132-930LPe, 200-240 V, CE100-132-966ConvertersConverters2CH1 (33μ), SHV, CE101-135-1274C, 8’ RF cable built-in, CE101-135-1262CH2 (75μ), SHV, CE101-135-128KTR, MS connector101-135-0452CH3 (125μ), SHV, CE101-135-129KTJ, acorn contact, CE101-135-046TW-1 (75μ), BNC101-135-015TW-2 (125μ), BNC101-135-016TW-2 pinned (125μ),TW-3 (33μ), BNCBNC 159-023-313101-135-031HT-415, barrel grip, CE101-136-011PT-415, pistol grip, CE101-136-01540 kHz, 150/500 Watt System ComponentsHT-215, barrel grip101-136-010Power SuppliesHK-215, pistol grip (trim knife)159-136-009LPt, 150 W, 100-120 V149-132-943LPt, 150 W, 200-240 V149-132-94420 kHz, 500 Watt System ComponentsLPt, 150 W, 200-240 V, CE149-132-945Power SuppliesBranson EDP No.LPe, 150 W, 100-120 V149-132-940149-132-1026LPe, 150 W, 200-240 V149-132-941LPt, 200-240 V149-132-1027LPe, 150 W, 200-240 V, CE149-132-942LPt, 200-240 V, CE149-132-1028LPt, 500 W, 100-120 V149-132-955LPe, 100-120 V149-132-1023LPt, 500 W, 200-240 V149-132-956LPe, 200-240 V149-132-1024LPt, 500 W, 200-240 V, CE149-132-957LPe, 200-240 V, CE149-132-1025LPe, 500 W, 100-120 V149-132-952LPe, 500 W, 200-240 V149-132-953LPe, 500 W, 200-240 V, CE149-132-954Converters402 (used in PT-250 Hand-held)101-135-014902R (used in automation)101-135-048Hand-held Welder (requires 402 converter)PT-250, pistol grip, CE101-136-014HK-215Hand-held Welders (require KTJ converter)Hand-held Welders (require TW-1, -2, or-3 converter)LPt, 100-120 VHT-215PT-250Branson EDP No.PT-350PT-415Converters4TR, MS connector101-135-0424TH, SHV connector, CE101-135-0674TP, SHV connector, CE101-135-068HT-415Hand-held Welders (converter built in)PT-480, pistol grip, CE159-135-133HT-480, barrel grip, CE159-135-134PT-480HT-480product2000 LPt/LPename

Ordering Information (continued)CablesRF, J934 (4TR converter)RF, J934C (for all SHV), ’101-240-181RF, J937 (all TW converters)8’100-246-1218RF, J938 (KTR converter)8’100-246-1219Start, J911, 9-pin (requires product liability agreement)Start, J913, 1025’101-240-072AccessoriesGround Detect (must be factory installed)225-029-866Fan filter kit (for use in dusty environments)101-063-614UTK and HG-152 adaptor cable (allows use of UTK or HG-152)125-240-29215’ RF/start extension cable (do not use with PT-415 or HT-415)125-240-281BoostersBooster/Gain20 kHz30 kHzPurple (Al) 1:0.6101-149-055—101-149-087Green (Al) 1:1101-149-051—101-149-079Gold (Al) 1:1.5101-149-052—101-149-080Silver (Al) 1:2101-149-053—101-149-081Black (Al) 1:2.5——101-149-082Purple (Ti) 1:0.6101-149-060——Green (Ti) 1:1101-149-056101-149-106101-149-085Gold (Ti) 1:1.5101-149-057101-149-105101-149-086Silver (Ti) 1:2101-149-058101-149-104101-149-083Black (Ti) 1:2.5101-149-059101-149-103101-149-084Note: Boosters are not used with TW and 2CH converters.40 kHz

2000 LPt/LPeSpecifications2000LP Power 40:0.50.4T30:0.5.CR20 kHz20 kHz40 kHz40 kHz40 kHz30 kHzElectrical SpecificationsFrequency:Output power:150 watts500 watts150 watts150 watts500 watts500 wattsLine voltage:FCC, CSA Certified100-120 V AC,50/60 Hz, 1Ø,2 amps100-120 V AC,50/60 Hz, 1Ø,7 amps100-120 V AC,50/60 Hz, 1Ø,2 amps100-120 V AC,50/60 Hz, 1Ø,2 amps.100-120 V AC,50/60 Hz, 1Ø,7 amps100-120 V AC,50/60 Hz, 1Ø,7 ampsLine voltage FCC,CSA Certified200-240 V AC,50/60 Hz, 1Ø,1 amp200-240 V AC,50/60 Hz, 1Ø,6 amps200-240 V AC,50/60 Hz, 1Ø,1 amp200-240 V AC,50/60 Hz, 1Ø,1 amp200-240V AC,50/60 Hz, 1Ø,6 amps200-240 V AC,50/60 Hz, 1Ø,6 ampsLine voltage:CE Certified200-240 V AC,50/60 Hz, 1Ø,1 amp200-240 V AC,50/60 Hz, 1Ø,6 amps200-240 V AC,50/60 Hz, 1Ø,1 amp200-240 V AC,50/60 Hz, 1Ø,1 amp200-240V AC,50/60 Hz, 1Ø,6 amps200-240 V AC,50/60 Hz, 1Ø,6 ampsReceptacle required:100-120 V AC models: NEMA 5-15R; 200-240V AC models: *NEMA 6-15R or equivalent; 200-240V AC, CE Certified: *CEE 7/7Mechanical SpecificationsHeight:9” (229 mm)Width:7.75” (197 mm)Depth:13.3” (338 mm) (depth: plus 3” [76 mm] cable clearance)Weight:15.5 lbs. (7 kg)*User must supply power cord ends for all 200-240 V systems.Regional Technical CentersHeadquarters:Toll free: 888-BUC-JOIN(888-282-5646)Fax: 203-796-9838Boston:978-262-9040Fax: 978-262-1494Chicago:847-229-0800Fax: 847-229-0861Atlanta:770-962-2111Fax: 770-962-3720Los Angeles:909-305-2080Fax: 909-305-2060Dallas:972-484-9228Fax: 972-484-9976Detroit (automotive):248-299-0400Fax: 248-299-9343Rochester, NY:585-624-8000Fax: 585-624-1262Toronto, Canada:905-201-4633Fax: 905-201-4637Monterrey, MX:52-811-332-0261Fax: 52-555-670-7885wBransonAddress UltrasonicsWeoiosid wkeoijsdonCorporation41AddressEagle Road,WeoiosidDanbury,wkeoijsdonCT 06813-1961(203)Address796-0400Weoiosid Fax:wkeoijsdon(203) 796-9838www.bransonultrasonics.come-mail: old 7.5pt subject to change without notice. All dimensions are nominal. All units are CEcompliantcomplywkeoijsdonwith FCC rulesand regulationsgoverning radiointerference.Notes nfrequencycwle joic osijeofnkeoijsdonNote:All sales shallbe subjecttocsdkncwthe Supplier’sterms andconditionsof sale as describedcsd kncwlejoicosijeofnkeoijsdonlejoic osijeofnkeoijsdoncsdkncwlejoicc osijeofnkineoijsBranson’squotationsand salescontracts.don csd kncwlejoicosijeofnkeoijsdoncsd kncwlejoic osijeofn keoijsdon .All Branson 2000 LPt/LPe Series ultrasonic power supplies are CSA approved and FCC compliant.CEcompliantmodels are indicated.Notesbold 7.5ptNotes nkeoijsdon csdkn cwle joic osijeofn keoijsdonHand-heldincludean appropriatetool kit.csdkncwlejoiccsdkncwlejoic osijeofnkeoijsdon csdkncwlejoicc on2000LP PowerSuppliescarry a three-yearwarranty on materialsworkdon csd kncwlejoicosijeofn n hand-heldwelderscsdcarrya one-yearwarrantyon materials and workmanship.csdkncwlejoicosij. applies to equipment purchased and operated in North America. ForNote:This warrantywarranty information on units purchased and/or operated outside the U.S. contact your localrepresentative.ISO Certifications2000LptLe BransonUltrasonicsCorporation1999Copyright info6pt sonlogojoicis aosijeofntrademarkand servicemark of Emersonjsdoncsdkn cwlekeoijsdoncsd kncwlejoicosijeofn on csdkncw lejoic osijeofn keoijsdon csdkncwlejoic c osijeofnk.

both RF voltage and current, and is corrected for any amplitude setting. Seven-segment LEDs display the peak power achieved during the weld cycle. . Hand-held Welder (requires 402 converter) 4TH, SHV connector, CE 101-135-067 PT-250, pistol