Transcription

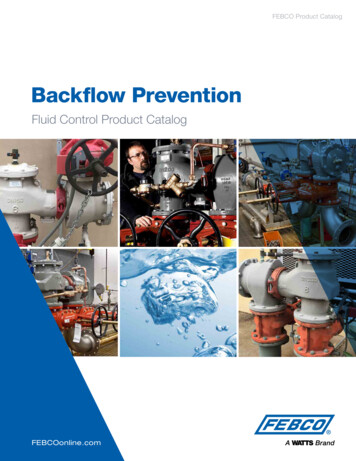

FEBCO Product CatalogBackflow PreventionFluid Control Product CatalogFEBCOonline.com

FEBCO is an ISO 9001 Certified manufacturer ofhigh quality fluid control products. For over 80 yearsFEBCO has been committed to manufacturing excellence and innovative design and dedicated to theimprovement of our industry.This catalog is presented to assist our customers,design engineers, municipal officials, contractors andinstallers with the dimensional and technical dataneeded to use and specify FEBCO. Due to our commitment to product refinement and improvement,specific details of our products may change. We makeevery effort to ensure that our dimensions and technical data are as accurate as possible. Please contactyour local FEBCO representative for our latest productinformation. A list of representatives as well as helpful,in-depth information about our products can be foundat our web site: www.FEBCOonline.comWe thank you, our customers, for your continuedsupport and for making our success possible. Theemployees and representatives of FEBCO look forward to serving you.ISO 9001 Certified

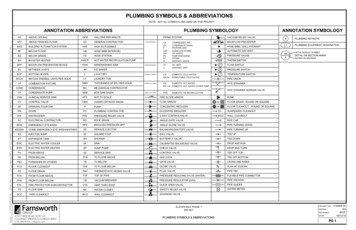

Tab l e o f C on t en t sSection 1 — Single Check ValvesSeries 800. . . . . . . . . . . . . 4" – 10" Detector Check for Automatic Fire Sprinkler Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Series 406. . . . . . . . . . . . . 2" Detector Check for Automatic Fire Sprinkler Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Section 2 — Double Check Valve AssembliesSeries 850, LF850. . . . . . . 1 2" – 2" Double Check Valve Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11Series LF850. . . . . . . . . . . 21 2" – 10" Double Check Valve Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 13Series 850U, LF850U. . . . . 1 2" – 2" Double Check Valve Assemblies w/Union End Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 15Series LF870V. . . . . . . . . . 21 2" – 8" Double Check Valve Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 - 17Section 3 — Double Check Detector AssembliesSeries 856ST. . . . . . . . . . . 21 2" – 10" Double Check Detector Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19Series 876VST. . . . . . . . . . 21 2" – 10" Double Check Detector Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 21Section 4 — Reduced Pressure Zone AssembliesSeries 825Y, LF825Y. . . . . 3 4" – 2" Reduced Pressure Zone Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 23Series 825YA, LF825YA. . . 3 4" – 2" Reduced Pressure Zone Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 - 27Series 860, LF860. . . . . . . 1 2" – 2" Reduced Pressure Zone Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 - 29Series LF860. . . . . . . . . . . 21 2" – 10" Reduced Pressure Zone Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 - 31Series 860U, LF860U. . . . . 1 2" – 2" Reduced Pressure Zone Assemblies w/Union End Ball Valves . . . . . . . . . . . . . . . . . . . . . . 32 - 33Series LF880V. . . . . . . . . . 21 2" – 10" Reduced Pressure Zone Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 - 35Section 5 — Reduced Pressure Detector AssembliesSeries 826YD. . . . . . . . . . . 21 2" – 10" Reduced Pressure Detector Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 - 37Section 6 — Vacuum BreakersSeries 710/715. . . . . . . . . . 1 2" – 2" Atmospheric Vacuum Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 - 39Series 765. . . . . . . . . . . . . 1 2" – 2" Pressure Vacuum Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 - 41Series LF767FR. . . . . . . . . 1 2" – 2" Freeze Resistant Pressure Vacuum Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 - 43

Ta b l e o f C on t en t sSection 7 — AccessoriesSeries 601-P . . . . . . . . . . . 1 2" – 2" Air Gap Drains for Use with 860, 860U, LF860, LF860U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44Series 601-M. . . . . . . . . . . 1 2" – 2" Air Gap Drains for Use with 860, 860U, LF860, LF860U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45Series 601-M. . . . . . . . . . . 21 2" – 10" Air Gap Drain Kits for Use with the MasterSeries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46Series AGD . . . . . . . . . . . . 3 4" – 2" and 21 2" – 10" Air Gap Drains for Use with Reduced Pressure Devices . . . . . . . . . . . . . . . . . . . 47Series 611. . . . . . . . . . . . . 21 2" – 10" Valve Setter Used with the MasterSeries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 - 50Series FPTC-1. . . . . . . . . . 1 8" – 3 4" Thermostatic Freeze Relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51Series LF650A. . . . . . . . . . 1 2" – 2" “Y” Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52Series 758A. . . . . . . . . . . . 21 2" – 10" “Y” Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53Spool Adapter . . . . . . . . . . 4" – 8" DuraCheck to MasterSeries‚ Spacer Spool Adapter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Series LFTC-1 . . . . . . . . . . Full Port Test Cock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55TK-1. . . . . . . . . . . . . . . . . . Backflow Preventer Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56Section 8 — Irrigation SpecialtiesSeries FPHB-1. . . . . . . . . . 3 4" – 1" Key Operated Wall Hydrants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Series LF622. . . . . . . . . . . 1 2" – 2" Full Port Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 - 59Section 9 — Flow Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 - 71Note: FEBCO product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,please contact FEBCO Technical Service. FEBCO reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on FEBCO products previously or subsequently sold.

Wh y Wo rk w i t h F E B C O?Safeguarding the drinking water supply is critical to protecting human health. For 50 years FEBCO has designed and manufacturedinnovative and patented assemblies for this critical purpose. FEBCO’s backflow prevention assemblies, which prevent the backwardflow of contaminated water into the potable water supply, are reliable and easily serviced. What’s more, they offer one of the lowesttotal installed costs in the industry.From FEBCO’s earliest days, experienced engineers have combined expert knowledge, technological advances, industry innovation,and broad manufacturing experience to design and manufacture one of the widest lines of top-quality backflow prevention assemblies available.FEBCO works closely with municipalities, engineers, architects, and contractors to solve their unique backflow prevention issues, andprovides educational materials to the general public for building awareness around the importance of safeguarding potable water.Why work with FEBCO? Simple. Superior designs, innovative technology, state-of-the-art manufacturing facilities, and acommitment to keeping all drinking water clean and safe with reliable and trusted backflow prevention assemblies.Lead Free TransitionWith the changeover to lead free in the United States that became effective January 4, 2014, lead free backflow preventiondevices are required in certain applications and/or settings. The FEBCO backflow preventer line includes top-quality, fully-tested LeadFree* versions of our standard backflow products.Standard Material Products (not Lead Free*) CONTAIN MORE THAN 0.25% LEAD.Effective January 4, 2014, it is illegal to use this product in any plumbing system providing water for human consumption,such as drinking or dishwashing, in the United States.Before installing standard material product, consult your local water authority, building and plumbing codes.Industry TermsBackpressure: Pressure, higher than the supply pressure, caused by a pump, elevated tank, boiler, or other means that cancause backflow.Backsiphonage: Backflow caused by negative or reduced pressure in the supply piping.Cross-connection: A connection or potential connection between any part of the potable water system and another environmentwhere undesirable substances could enter the potable water system. Contaminated or undesirable substances can include gases,liquids, or solids, such as chemicals, waste products, steam, water from other sources (potable or non-potable), or any other matter that can change the color of or add odor to the water. Bypass arrangements, jumper connections, removable sections, swivel orchangeover assemblies, or any other temporary or permanent connecting arrangement where backflow can occur are consideredcross-connections.* The wetted surface of this product contacted by consumable watercontains less than 0.25% of lead by weight.

Degrees of Health HazardHealth hazard: A cross-connection or potential cross-connection where any substance that could cause death, illness,or spread disease, or have a high probability of causing such effects, could be introduced into the potable water supply.Non-health hazard: A cross-connection or potential cross-connection where any substance introduced into the potable watersupply would generally not be considered a health hazard, but would constitute a nuisance or be aesthetically AZARD Reduced PressureDetector Assemblies LF870VLF850850/850ULF850/LF850UDouble Check ValveAssemblies 876VST856STDouble CheckDetector Assemblies 765/765ULF767FRPressure VacuumBreaker Assemblies 710/715Atmospheric Vacuum Breaker LF880VLF860860/860U/ LF860/LF860UReduced Pressure Zone825/LF825Assemblies825YA/LF825YA826YD! WARNINGYou are required to consult the local building and plumbingcodes prior to installation. If the information in this manualis not consistent with local building or plumbing codes,the local codes should be followed. Inquire with governingauthorities for additional local requirements.

S er i e s 8 0 0Detector Check for Automatic Fire Sprinkler SystemsSize: 4" – 10" (100 – 250mm)1Single Check Valves800 with optional by-passFeaturesThe FEBCO Series 800 is used in the protection of water supplies from unauthorizedusage. This requires installation of the proper valving to measure water loss. The Series800 Detector check is not a backflow prevention assembly and should not be used assuch. UL listed and FM approved forhorizontal or vertical installation. Spring-loaded swing check forreliability and minimum head loss 250psi (17.2 bar) working pressurefor superior strength DuraCast ductile iron body for superior strength andlighter weight Fully rubber encapsulated ductileiron disc for strength Fusion epoxy coated, inside andout, for corrosion protection Simple service procedures Cast lifting ring for ease ofinstallation 4", 6", 8", and 10" Sizes3 4" standard bypass; optional sizes 1", 11 2", 2" End Connections – Flanged ANSIB16.42, Class 150 Pressure – TemperatureMaterialsMax. Working Pressure: 250psi(17.2 bar)Hydrostatic Test Pressure: 500psi(34.5 bar)Temperature range: 32ºF to 110ºF(0ºC to 60ºC)Main valve body: Ductile iron Grade65-45-12, Fusion Epoxy coated,Internal and External, AWWAC550-90Trim: BronzeElastomers: NitrileSpring: Stainless SteelBypass: Copper alloy tube andfittingsBypass meter: Totalizing typeGPM/CFMSize: 5 8" x 3 4"Approvals4", 6", 8" and 10"Dimensions — WeightsBYPASS SIZESSTANDARDOPTIONALFCin.mm41006150820010 250DBin.mmin.mmin.mm 20 1 25 11 2 402 34in.mm50 AESeries 800SIZE (DN)DIMENSIONSWEIGHT(Standard Bypass only)ABCDEFin.mmin.mmin.mmin.mmin.mmin.mmin.410016 6150221 28200261 210250361 4Dimensions shown are nominal.1241957267392112 172128123184325337119 135 8163 420342483464255084 51 263 48121141401712038 For additional information, reference literature ES-F-800. Flow Charts on p. 60.10 115 8125 8133 21537034.571.297.5167.8

S e ri e s 4 0 6Detector Check for Automatic Fire Sprinkler SystemsSingle Check Valves1Size: 2" (50mm)406Features Meter detects leakage and/ortheft of water from Automatic FireSprinkler Systems Can be installed horizontally or vertically (up or down) Center-stem-guided, spring-loadedcheck for morepositive seating Replaceable bronze seat ring Reversible seat disc for ease of service Bronze body and cover End Detail – 2 Bolt Meter FlangePressure – TemperatureThe FEBCO Series 406 Detector Check is designed for automatic fire sprinklersystems (non-potable applications).MaterialsOperationMain Valve Body: BronzeSeat Ring: BronzeDisc Holder: DelrinSpring: Stainless SteelBy-pass Meter: Bronze TotalizingWater MeterOptional (gpm or cfm)In a non-flowing condition, the mainlinecheck and by-pass check are closedand the meter is stopped. When waterbegins to flow, the bypass check opensand the meter begins to register. Whenthe pressure drop across the valveapproximates 1.5psi (10.3 kPa), themainline check opens and allows full flowof water.The bypass meter and check remainoperating and open at all flow rates.DimensionsSizes: Mainline: 2" (50mm)Bypass: ¾" (20mm) IPSMaximum Working Pressure: 175psi(12.1 bar)Hydrostatic Test Pressure: 350psi(24.1 bar)Temperature Range: 32ºF to 110ºF(0ºC - 43ºC) " (19mm) IPS(TWO PLACES)34(2) 3 4" DIA. HOLES(19mm)81 2"(216mm)21 2"(64mm)133 8"(340mm)17"(432mm)41 2"(114mm)6"(152mm)9"(230mm)NOTICEInquire with governing authorities for local installation requirements.For additional information, reference literature ES-F-406. Flow Chart on p. 60.9

S er i e s 8 5 0 / L F 8 5 0Double Check Valve AssembliesSize: 1 2" – 2" (15 – 50mm)2850/LF850Double Check Valve AssembliesThe FEBCO Series 850 Double Check Valve Assemblies are designed for non-healthhazard applications. End Connections – NPT ANSI/ASME B1.20.1. They are designedto protect drinking water supplies from dangerous cross connections in accordancewith national plumbing codes and water authority requirements fornon-potable service applications such as irrigation, fireline, or industrial processing.MaterialsApprovals – StandardsValve Body: BronzeElastomers: SiliconeSprings: Stainless Steel ANSI/AWWA Conformance(C510-92) Approved by the Foundation for CrossConnection Control and HydraulicResearch at the University of SouthernCalifornia.Models Wye - Strainer1015Pressure – TemperatureMax. Working Pressure: 175psi(12.1 bar)Hydrostatic Test Press: 350psi(24.1 bar)Temperature Range: 32 F to 140 F(0 C to 60 C)B64.5FEBCO Series LF850 Double Check ValveLEAD FREE* TheAssembliesare designed for non-health hazard applications. TheLF850S features Lead Free* construction to comply with Lead Free* installationrequirements. End Connections – NPT ANSI / ASME B1.20.1. The Lead Free* DoubleCheck Valve Assemblies shall comply with state codes and standards, where applicable, requiring reduced lead content.MaterialsApprovalsModels ANSI/AWWA Conformance(C510-92) Approved by the Foundation forCross-Connection Control andHydraulic Research at the Universityof Southern California.Valve Body: Lead Free* cast coppersilicon alloyElastomers: SiliconeSprings: Stainless Steel LF850 - Standard Assembly with BallValves1015B64.5* The wetted surface of this productcontacted by consumable water containsless than 0.25% of lead by weight.10 For additional information, reference literature ES-F-850S and ES-LF-850S. Flow Charts on p. 60.

Dimensions — WeightsDouble Check Valve Assemblies2DEACBSeries 850/LF850SIZE in.mmlbs.kgs. 111 411 2215202532405010103 4121 2157 8163 8175 82542733184034164501 11 217 83331 23838487676891 11 215 821 221 221 23838416464643 31 833 841 441 441 47979861081081081 11 411 221 421 421 .6123412121814Dimensions are nominal.NOTICEInquire with governing authorities for local installation requirements.11

Ma st e r S er i e s L F 8 5 0Double Check Valve AssembliesSize: 21 2" – 10" (65 – 250mm)2850 Double Check AssemblyDouble Check Valve AssembliesFeatures Inline Serviceable Assembly No Special Tools Required forServicing Captured Modular Spring Assembly Reversible & Replaceable Discs Field Replaceable Seats Ductile Iron Valve Body Design Stainless Steel Check Components Winterization feature with discretainers and valve body drain ports Clapper Check Assembly Commonality between 1st & 2ndCheck Components Captured O-ring DesignPressure-TemperatureMax. Working Pressure: 175psi(12.1 bar)Min. Working Pressure: 10psi(0.7 bar)Hydrostatic Test Pressure: 350psi(24.1 bar)Hydrostatic Safety Pressure: 700psi(48.3 bar)Temperature Range: 33 F - 140 F(0.5 C - 60 C)ContinuousFEBCO Master Series 850 Double Check ValveLEAD FREE* TheAssemblies are designed for non-health hazard applications. End Connections – Flanged ANSI B16.1 Class 125. The FEBCO MasterSeriesLF850 Double Check Assembly is specifically designed to protect against possiblebackpressure and backsiphonage conditions for non-health hazard (i.e., pollutant)application in accordance with Local Governing Water Utility Code. This BackflowAssembly is primarily used on potable drinking water systems where Local GoverningCode mandates protection from non-potable quality water being pumped or siphonedback into the potable water system.The LF850 features Lead Free* construction to comply with low lead installationrequirements. The Lead Free* Double Check Assemblies shall comply with statecodes and standards, where applicable, requiring reduced lead content.OptionsApprovalsOSY: UL/FM Approved OS&Y GateValves(ANSI/AWWA C515 Compliant) Approved by the Foundation forCross-Connection Control andHydraulic Research at The Universityof Southern California (FCCCHRUSC) ASSE 1015 Listed UL Classified (US & Canada)† FM Approved†NRS: Non-Rising Stem Gate Valves(ANSI/AWWA C509 Compliant)LG: Less Shut-off valves; This is NOTan APPROVED ASSEMBLYExample Ordering Descriptions:4” LF850-OSY - Valve Assembly fittedwith OS&Y Shutoff Valves4” LF850-NRS - V alve Assembly fittedwith NRS Shutoff ValvesMaterialsBelow is a general materials list of theModel LF850. All assemblies size 21 2"through 10" is similar in materials andconstruction. Please contact your localFEBCO Representative if you require further information.Main Valve Body: Ductile iron Grade65-45-12Coating: Fusion epoxy coated internaland external AWWA C550Shutoff Valves: NRS resilient wedge gatevalves AWWA C509 (Standard) OSYresilient wedge gate valves AWWA C515(UL/FM)Check Seats: Stainless SteelDisc Holder: Stainless SteelElastomer Disc: SiliconeSpring: Stainless Steel* The wetted surface of this productcontacted by consumable water containsless than 0.25% of lead by weight.Clamp: AWWA C606 (10" Only)12 For additional information, reference literature ES-F-850L Flow Charts on p. 61. IAPMO CSA Listed AWWA Standard C510 Compliant End Connections: Compliant toASME B16.1 Class 125 & AWWAClass D Flange† Assembly configured with UL/FMApproved OS&Y RW Gate Valves.Less gate valve assemblies are notUL/FM approved configurations.†1015†B64.5

E***CDouble Check Valve Assemblies2Dimensions — WeightsD**CCDBBAAGHHMasterSeries LF850SIZE n.mmin.mmin.mmin.mmlbs.kgs.lbs.kgs.2 346810658010015020025040 417 8461 45665725 810351064117514221651184525 255 828343 4413 4463 86486517118831061117812 127 8143 8187 8231 2271 23213273654795976991010101 8123 4155 8155 82542542573243973974 41 251 261 2791141141401651782297 73 881 897 8111 8123 Dimensions are nominal.** Indicates nominal dimensions with NRS Gate Valves*** Indicates nominal dimensions**** Indicates weight of complete Backflow Assemblies with specified Gate Valveswith OSY Gate Valves (Full Open Position)NOTICEInquire with governing authorities for local installation requirements.13

S er i e s 8 5 0 U / L F 8 5 0 UDouble Check Valve Assemblies with Union End Ball ValvesSize: 1 2" – 2" (15 – 50mm)2850U/LF850UDouble Check Valve AssembliesThe FEBCO Series 850U Double Check Valve Assemblies are designed for non-healthhazard applications. Series 850U are designed to protect drinking water supplies fromdangerous cross-connections in accordance with national plumbing codes and waterauthority requirements for non-potable service applications such as irrigation, fireline,or industrial processing. End Connections – NPT ANSI/ASME B1.20.1.MaterialsApprovals – StandardsValve Body: BronzeElastomers: SiliconeSprings: Stainless Steel ANSI/AWWA Conformance(C510-92) Approved by the Foundationfor Cross-Connection Controland Hydraulic Research at theUniversity of Southern California.Pressure – TemperatureMax. Working Pressure: 175psi(12.1 bar)1015B64.5Hydrostatic Test Press: 350psi(24.1 bar)Temperature Range: 32 F to 140 F(0 C to 60 C)FEBCO Series LF850U Double Check ValveLEAD FREE* TheAssemblies are designed for non-health hazardapplications. End Connections – NPT ANSI/ASME B1.20.1. The LF850U featuresLead Free* construction to comply with Lead Free* installation requirements. EndConnections – NPT ANSI/ASME B1.20.1. The Lead Free* Double Check ValveAssemblies with Union End Ball Valves shall comply with state codes and standards,where applicable, requiring reduced lead content.MaterialsApprovals – StandardsValve Body: BronzeElastomers: SiliconeSprings: Stainless Steel ANSI/AWWA Conformance(C510-92) Approved by the Foundationfor Cross-Connection Controland Hydraulic Research at theUniversity of Southern California.1015B64.5* The wetted surface of this productcontacted by consumable water containsless than 0.25% of lead by weight.14 For additional information, reference literature ES-F-850U and ES-F-LF850U. Flow Charts on p. 61.

Dimensions — WeightsDouble Check Valve Assemblies2DEACBSERIES 850U/LF850USIZE (DN)DIMENSIONSAin.mm 15 2012511 43211 240250Dimensions are .kgs.11121 2145 8181 4187 8201 22993183724644795211 11 217 83331 23838487676891 11 215 821 221 221 23838416464643 31 833 841 441 441 47979861081081081 11 411 221 421 421 0.912121814NOTICEInquire with governing authorities for local installation requirements.15

Ma st e r S er i e s L F 8 7 0 VDouble Check Valve AssembliesSize: 21 2" – 8" (65 – 200mm)2Double Check Valve AssembliesStandard OrientationFeatures Inline Serviceable Assembly Horizontal “N-Pattern” Installations Vertical-Up “Z-Pattern” Installations No Special Tools Required for Servicing Captured Modular Spring Assembly Reversible & Replaceable Discs Field Replaceable Seats Ductile Iron Valve Body Design Stainless Steel Check ComponentsVertical OrientationLF870VTheFEBCO MasterSeries LF870V Double Check ValveLEAD FREE* Assembliesare designed for non-health hazard applications.Standard orientation is inlet flow vertical up, outlet flow vertical down. Vertical orientation is inlet and outlet flow vertical up. The FEBCO MasterSeries LF870V Double CheckAssembly is specifically designed to protect against possible backpressure and backsiphonage conditions for non-health hazard (i.e., pollutant) application in accordancewith Local Governing Water Utility Code. This Backflow Assembly is primarily used onpotable drinking water systems where Local Governing Code mandates protection fromnon-potable quality water being pumped or siphoned back into the potable water system.The LF870V features Lead Free* construction to comply with Lead Free* installationrequirements. The Lead Free* Double Check Assembly shall comply with state codesand standards, where applicable, requiring reduced lead content. Winterization feature with disc retainersand valve body drain portsOptions - SuffixMaterials Clapper Check AssemblyOSY: UL/FM Approved OS&Y Gate Valves[ANSI/AWWA C515 Compliant]Shutoff Valves: NRS resilient wedge gatevalve AWWA C509 (Standard)NRS: Non-Rising Stem Gate Valves[ANSI/AWWA C509 Compliant]OSY resilient wedge gate valve AWWAC515 (UL/FM)LG: Less Shut-off valves; This is NOT anAPPROVED ASSEMBLYCheck Seats: Stainless SteelExample Ordering Description:Elastomer Disc: Silicone Commonality between 1st & 2nd CheckComponents Captured O-ring DesignPressure — TemperatureMax. Working Pressure: 175 psi(12.1 bar)Min. Working Pressure: 10 psi(0.7 bar)Hydrostatic Test Pressure: 350 psi(24.1 bar)Hydrostatic Safety Pressure: 700 psi(48.3 bar)Temperature Range: 33 F - 140 F(0.5 C- 60 C)ContinuousAssembly FlowOrientationHorizontal (N-Pattern 2 ” – 8”) 12Approved by FCCCHR-USC, ASSE, cULus,FM, IAPMOVertical Up (Z-Pattern 21 2” – 8”) Approved by FCCCHR-USC, ASSE, cULus,FM, IAPMO4” LF870V-OSY - Valve Assembly fitted withOS&Y Shutoff ValvesAvailable Components(cont.)Disc Holder: Stainless SteelSpring: Stainless SteelClamp: AWWA C606Wye Strainer: FDA Approved [ASME B16.1 Class125 & AWWA Class D Flange]Series 611 Valve Setter: MJ x MJ Mechanical Joint x Mechanical Joint[AWWA C111/A21.11]Approvals: StandardMJ x FL - Mechanical Joint x Flange[AWWA C111/A21.11; ASME B16.1Class 125/AWWA Class D Flange] ASSE 1015 Listed Approved by the Foundation for CrossConnection Control and HydraulicResearch at The University of SouthernCalifornia [FCCCHR-USC] UL Classified [US & Canada]†FL x FL – Flange x Flange [ASME B16.1 Class 125 & AWWAClass D Flange] FM Approved†Materials End Connections: Compliant to ASMEB16.1 Class 125 & AWWA Class DFlangeBelow is a general materials list of the ModelLF870V. All assemblies size 21 2” through 8”is similar in materials and construction. Pleasecontact your local FEBCO Representative if yourequire further information. IAPMO AWWA Standard C510 Compliant† Assembly configured with UL/FM Approved OS&Y RWGate Valves. Less gate valve assemblies are not UL/FM approved configurations.Main Valve Body: Ductile ironGrade 65-45-12* The wetted surface of this productcontacted by consumable water containsless than 0.25% of lead by weight.†Coating: Fusion epoxy coatedinternal and external AWWA C550-9016 For additional information, reference literature ES-LF-870V. Flow Charts on p. 62.1015B64.5†

Dimensions — WeightsModel LF870V Standard OrientationModel LF870V Vertical Orientation2KFDouble Check Valve AssembliesFCCKMGABGBEJE1SERIES LF870VSIZE lbs.kg.lbs.kg.21 265253 4654121 231861 4159241 4616165 8422135 8346271 469231 289125 8321163 84161978920191380253 4 654121 2 318146 1591424 629165 8 422141 8 35928 71833 4 95127 8 3271422 5652231012271034100277 8708143567178263 4680173 4451151 23943178741 2114143 8365231 45913201453321516150321 4819164068203321 4819215 8 548185 8 473371 494651 2140187 8 479301 8 765492223512232820037 95318 4709 235363 8 324247 8 632203 4 527411 2 105463 4 172231 2 597373 4 95978235581036712121414Dimensions are nominal.** Indicates nominal dimensions with NRS Gate Valves*** Indicates nominal dimensions with OSY Gate Valves (Full Open Position)**** Indicates weight of complete Backflow Assemblies with specified Gate Valves10" sizes are available in standard materials. Consult factory.NOTICEInquire with governing authorities for local installation requirements.17

Ma st e r S er i e s 8 5 6 S TDouble Check Detector Backflow Prevention AssembliesSize: 21 2" – 10" (65 – 250mm)Features3Double Check Detector AssembliesMain Valve: Inline Serviceable Assembly No Special Tools Required forServicing Captured Modular Spring Assembly Reversible & Replaceable Discs Field Replaceable Seats Ductile Iron Valve Body Design Stainless Steel Check Components Winterization feature with discretainers and valve body drain ports Clapper Check Assembly Commonality between 1st & 2ndCheck Components Captured O-ring DesignAuxiliary Bypass: Compact Bypass Design; Remainswithin Main Valve Assembly Profile Inline Serviceable 3 4" BackflowAssembly No Special Tools Required forServicing Field Replaceable Seats & Discs Detect Potential Underground WaterLeaks Detect Unauthorized Water UsagePressure – TemperatureMax. Working Pressure: 175psi(12.1 bar)Min. Working Pressure: 10psi(0.7 bar)Hydrostatic Test Pressure: 350psi(24.1 bar)856STThe FEBCO MasterSeries 856ST Double Check Detector Assembly is specificallydesigned to protect against possible backpressure and backsiphonage conditionsf

Free* versions of our standard backflow products. Standard Material Products (not Lead Free*) CONTAIN MORE THAN 0.25% LEAD. Effective January 4, 2014, it is illegal to use this product in any plumbing system providing water for human consumptio