Transcription

UniclassJT20 JV50 L75624EPICL634 L2242 L511CI/SfB(56.3)April 2006Underfloor HeatingAvailable Through MerchantsUF417Design andInstallation GuideSTANDARD UNDERFLOOR HEATINGCOMPONENTS FOR SMALLNEW-BUILD RESIDENTIAL PROJECTSIntelligent Solutions forHeating Projects

UNDERFLOOR HEATINGStandard Product Range: Design and Installation GuideAbout OSMA UFHA partnership of experienceOSMA Underfloor Heating combines thespecialist skills and experience of twocompanies:Wavin is Europe’s largest supplier ofVersatility, Consistency and ReliabilityWhat’s different aboutOSMA Underfloor HeatingGiving you a choiceOSMA UFH products have been designedproduct choice including floor panels withto provide the highest possible heatingpre-cut channels in the insulation toperformance while using materials that willindicate the positioning and spacing forlast throughout the life of the building.installation of the pipe on siteThe products combine easy installationAlternatively, you can opt for a basic systemwith consistent performance. They ensurewhich allows the installer to set the pipethat the power output from the floor iscentres and layout during installation.plastic pipe systems in terms of productrange, innovation, logistical servicesand geographical presenceThermoBoard is one of the UK’s majorsuppliers of underfloor heating systems.OSMA plumbed systems offer you adetermined by the product rather than bythe skills or experience of the installer.The company has pioneered thedevelopment of product-based solutionsOSMA innovationto underfloor heating for more than aOSMA UFH products are as easy to usedecadeas conventional radiators. They requirelittle or no previous underfloor heatingThe UK’s most advancedUFH technologyexperience. No specialist tools areOSMA UFH technology has beenThey enable any installer to work moredeveloped to suit all building constructionquickly to achieve a high quality result.types typically used in the UK – bothOSMA UFH systems for domesticconcrete-based floors and timber floors.applications include plumbed systems forIt provides innovative, cost-efficientall types of floor construction, including:solutions for all types of environment,including residential, commercial andpublic buildings.For residential projectsThis publication provides guidance onthe design and installation of underfloorheating using OSMA UFH componentsavailable through Merchant Stockists.These products are primarily designed foruse in new-build residential applicationsup to four circuits.2needed for successful installation.SALES AND TECHNICAL ENQUIRIES01392 444122Sand/cement and liquid screedsTimber battens and timber joistsFully floating timber floorsThe range available through Merchants isspecifically designed to offer efficient andeffective solutions for small and mediumsized heating projects. These may include:extensions, refurbishment of individualrooms, conservatories or single dwellinginstallations.FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGStandard Product Range: Design and Installation GuideContentsFurther InformationTimber FloorsINTRODUCING UFHOSMA Underfloor Heating products2-4Timber Joist Products17Fully Floating Floor Products18Battened Floor Products19are available for OSMA UnderfloorDESIGNDesign Principles5-6Design Procedures7-10System ControlsGeneral ConsiderationsMixing Control UnitsPressure Testing23-24Sales and TechnicalEnquiriesTel: 01392 444122Fax: 01392 444135Design PlannerScreeded FloorsBasic Products for Screeded FloorsSystem PlatesTo obtain copies, please contact:REFERENCESITEWORK1415-16Product Guide20-22System Verification12-13Heating Standard Products Range:Trade Price List10-11OSMA UFH SYSTEMS/PRODUCTSProduct RangeThe following related publications25General Information /Technical Assistance27The OSMA UFH GuaranteeOSMA Underfloor Heating is the only UFHsupplier in the UK which engineers andmanufactures its products. Each systemuses the highest specification components.All systems described in this Design andInstallation Guide are directly backed by a fullproduct guarantee provided that installationhas been in accordance with the instructionsprovided. Unlike some other UFH suppliers,this guarantee is independently underwrittenby insurance. For full details/terms, contact OSMAUnderfloor Heating.NOTE: For plumbed systems, this Guaranteepresumes the use of OSMA Flexible PlumbingPipe (OsmaGold). The Guarantee may NOTapply if pipe from another manufactureris used.OSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingIntroduction . Contents3

UNDERFLOOR HEATINGIntroduction / Standard Product RangeIntroductionUNDERFLOOR HEATINGRADIANT HEATThe maximum floor temperature shouldUnderfloor heating is the most comfortableAs soon as the floor surface becomesnot normally exceed 29 C (althoughform of heating. It is unobtrusive,warmer than the air in the room, it begins34 C is acceptable in bathrooms).economical, safe, hygienic and virtuallyto radiate. Radiant energy emitted frommaintenance-free. It offers the bestthe floor is absorbed by all the otherlong-term method of heating a buildingsurfaces in the room. These surfacesbecause it uses low-temperature water,warm up and begin to radiate, therebywhich in future can be provided withoutproviding an all-round comfortablehaving to burn fossil fuels.warmth in the room. The air in theA UFH system is easily formed. Insteadof hanging conventional radiators onroom only becomes warm because itis in contact with these warm surfaces.THE OSMA STANDARDPRODUCT RANGEThe OSMA Standard Product Range hasbeen designed to enable anyone who isfamiliar with radiator heating to confidentlydesign and install underfloor heatingwithin standard concrete and screed ortimber floor types.the wall, you simply make the floor itselfENERGY EFFICIENTa large-surface heat emitter byFor product range and selection,Most new-build constructions can beincorporating warm water pipe withinsee pages 12-19.kept warm with heating power in thethe floor construction.range 35-75W/m2. This power outputcan be achieved with floor surfacetemperatures of just 24-27 C.Larger projectsFor larger and more complex underfloorheating (and cooling) projects, OSMAUFH has a range of alternative productsavailable. OSMA UFH has extensiveexperience of partnering with thelargest contractors on the mosttechnically demanding projects and canprovide a bespoke design service, withdirect-to-site delivery.4SALES AND TECHNICAL ENQUIRIES01392 444122FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGDesign PrinciplesDesign PrinciplesAn underfloor heating system consists of:In-floor components and heating pipeFlow controls of the water into the floorRoom temperature controlMINIMISING HEAT LOSSIf you use a boiler designed to heat theWith any form of underfloor heating it iswater to a higher temperature, it isimportant to minimise the amount of heatnecessary to add a water mixing controlthat is lost to the underside of the floor.unit to reduce the temperature of theInsulating ground floors to BuildingThese are very similar to the elementsRegulation standards is generally sufficientof any radiator system. The principleto restrict the heat transfer downwards.difference is that the heat emitter is builtHowever, consideration should be giveninto the floor rather than hung on theto installing higher levels of insulation,wall.in line with the trend for increases inThe same form of Heating Primary isregulatory requirements.used to distribute warm water aroundOn upper floors, Building Regulationsthe building. Where a spur would bePart E now require that acoustictaken off the Primary to a radiator, theinsulation must be incorporated betweensame kind of spur is taken instead to ajoists or within the make up of a solidwater flow controller, and through thisfloor. This also provides effective thermalto the pipe circuits in the floor.insulation.The temperature of each room isWATER TEMPERATUREcontrolled using a room thermostat andIf you are designing an underfloor heatinga valve to turn ON/OFF the flow of watersystem to heat an entire building, someinto the floor.modern combi and condensing boilersLOWER WATERTEMPERATUREare able to supply water, at the requiredAn underfloor heating system uses waterunderfloor heating system. Such aat a much lower temperature than isboiler’s internal pump can be used torequired by radiators.circulate the water around the pipeTo achieve the necessary heat output, awater entering the underfloor heatingsystem (see pages 20-22).lower temperature, directly to ancircuits.floor surface temperature of maximum29 C is generally required. Depending onthe conductivity of the floor and the floorfinish, this may be achieved with a watertemperature in the underfloor pipes ofbetween 40 C and 60 C. Suchtemperatures can be easily producedfrom a heat pump or from solar heating.By contrast, to generate sufficient airconvection, radiators generally requirewater at 70-80 C, and this can only beproduced easily by burning fossil fuels.OSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingIntroduction . Design Principles5

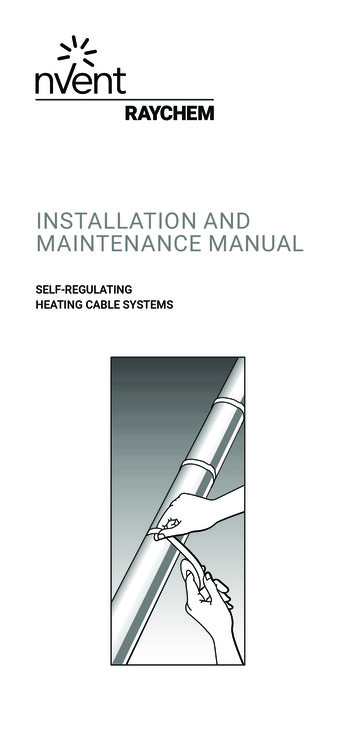

UNDERFLOOR HEATINGDesign PrinciplesDesign Principles continuedControl Pack with ManifoldWATER FLOW CONTROLWhichever type of boiler is used, forprojects larger than 20m2 the heated wateris generally distributed to separate pipecircuits via a manifold. Electricallyoperated actuators on each branch of themanifold, linked to a room thermostat, canbe used to control the flow of water intothe separate circuits/zones.Where necessary, a Water Mixing ControlUnit can be added to the front of themanifold (see pages 20-22).COMBINED SYSTEMSIt is possible to add a section of underfloorheating to a radiator system, provided:the boiler has sufficient spare capacitythe diameter of the spur from thePrimary to the water mixing controlleris large enough to deliver the quantitySingle Port Manifoldof heat required by the underfloorheatingThere are two ways to ensure that the hightemperature water from a radiator systemdoes not cause the floor to become toohot:In small projects that involve justone zone and a maximum area ofabout 20m2, it is possible to use Singleport manifold and control pack:If individual room control is requiredWater Mixing Control Unit for One or Two Circuitsand water is to be taken from the boilerprimary pipework, this unit allows asmall area to be run independently ofan existing central heating system. Itwil require a simple by-pass and athermostat which must be purchasedseparately.Mixing Control is used:High temperature water from theradiator Primary is mixed with waterreturning from the floor to produce astream of water into the floor at atemperature that can be adjusted toa level which will not result in the flooroverheating.6SALES AND TECHNICAL ENQUIRIES01392 444122FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGDesign Procedures1How Much Heating Power Do I Need ?Experience shows that in most new orrefurbished buildings complying to April2002 Part L Building Regulations, heatingpower of 35-75W/m2 is sufficient tomaintain internal temperature of 20ºC.Provided the floor finish thermal resistanceis not greater than 0.150 m2 K/W (1.5 Tog),this amount of power output can begenerated by any of the forms of UFHdescribed in this Guide, using pipe at200mm centres. Consequently, it maynot be necessary to make detailed heatloss calculations.Where a space is to be heated thatmay have higher heat losses, the powerrequirement should be calculated, usingthe calculation method outlined onpage 11. Use this calculation method for:rooms with large areas of glazingUnderfloor heating is an effective way ofform of heating may be required toheating a conservatory. However, the highmaintain an internal temperature of 20 Cbuildings constructed to pre-Aprilrate of heat loss through the extensiveon occasions when the external2002 Part L Building Regulationsareas of glazing means a supplementarytemperature falls below 7-8 C.rooms with more than 2 external walls2CONSERVATORIESWhat Heating Power Will UFH Provide ?The power output equation for UFH is:Occasionally, detailed heat lossThe type of floor finish – for example,(calculations – as prepared in accordancetiles, timber or carpet – or the spacingwith the calculation method outlined onof the heating pipe can affect the transferpage 11 – show that 95W/m2 powerof heat from the floor through to theoutput is insufficient. This can sometimesfloor surface.)floor surface room airx 10.6 W/m2–temperaturetemperatureAs a consequence, it can be seen that witha floor surface of 29 C and airtemperature of 20 C, power output will2be 95W/m . In most projects, this willbe sufficient.happen in bathrooms, for example, wherethe available floor area is small bycomparison with the heat loss. In suchcases, the underfloor heating can be29ºC is the maximum design surfacesupplemented by installing a toweltemperature (above that the floor mayradiator perhaps plumbed in as part ofbecome uncomfortable, although inthe UFH circuit.Use these Tables not only to confirm thatthe power output will be sufficient but alsoto determine the Flow/Return temperaturesthat will be required.Bathrooms the design temperaturemay be increased to 34 C).OSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingDesign Principles . Design Procedures7

UNDERFLOOR HEATINGDesign ProceduresUFH System Output (W/m2)Screeded FloorsResistanceof Floor Finishm2 K/W200 mm300 mm200 mm300 mm200 mm300 mm10mm Timber0.07012310110788917520mm Timber0.14090797869665810mm Carpet/Hard Tile0.100113949882837010mm Carpet & Underlay0.1509180797067604mm Vinyl – Linoleum0.018150114131991128510mm Ceramic Tiles0.0121511181321031128725mm Marble0.0111401111229710382Floor FinishFlow/Return Temperatures & UFH Pipe Centres (mm)65-55 CFloor Finish55-45 CUFH System Output (W/m2)Floating & Battened/Joisted FloorResistanceof Floor Finishm2 K/W60-50 CFlow/Return Temperatures & UFH Pipe Centres (mm)65-55 C60-50 C55-45 C200 mm200 mm200 mm10mm Timber0.07079755620mm Timber0.14086656410mm Carpet/Hard Tile0.10075705210mm Carpet & Underlay0.1506361474mm Vinyl – Linoleum0.01886556410mm Ceramic Tiles0.01287756525mm Marble0.011797659EN1264 Theoretical Heat Output for Screed, Floating & Batten/Joisted OSMA UFH systems8SALES AND TECHNICAL ENQUIRIES01392 444122FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGDesign Procedures3What Type Of Floor Do I Have?Generally, the options include –2. Screw Clipsgrooved panels of chipboard or plywood.If the insulation is soft – for example,The floor deck is held in place purely by itsstandard density or high density expandedown weight.polystyrene such as Jablite or mineralThe Standard Product Range includesTimber battenswool such as Rockwool – staples will50mm thick Floating Floor Panels thatSoftwood joistnot grip the pipe sufficiently tightly.incorporate pre-cut pipe channels withScrew Clips should be used.factory-fitted aluminium heat diffusers, and3. System Platesa polythene film fixed over the top of these.These are vacuum-formed plastic panelsThey are used in place of plain insulationwith moulded pipe grippers that are laidpanels to support a fully-floating deck.over the top of whatever insulation youThe conductivity of OSMA Floating Floorpurchase. System Plates hold the pipePanels is much lower than expandedSCREEDsecurely, and at regular spacings.polystyrene, and this helps minimiseMost screeded floors are formed by layingOSMA System Plates allow the pipe todownward heat loss.sand/cement mix 65-75mm thick overbe set as close as 50mm centres, whichinsulation. Before the screed is laid, edgeis very useful when taking pipe throughinsulation should be set all round theTimber Battens, Joistsand I-Beamscorridors to several separate rooms.periphery of the room to allow for thermalBattens are used either where the floorThe pipe can also be held diagonally.loadings are to be higher than can beWhatever the method chosen, attentionsupported by a fully-floating floor or whereshould be paid –the floor deck is to be formed from planksScreedFully-floating timberManufactured timber I-beamsOnce the type of floor construction hasbeen determined, the appropriateproducts may be selected from theStandard Product Range (see pages 12-13).movement in the screed during the year.When creating an underfloor heatingsystem, heating pipe is fixed to the topof the insulation, just before the screedis laid, so that the heating pipe ends upwithin the thickness of the screed.where the ends of the pipe circuit(s)come together below the site of theWater Flow Controller/ManifoldWe recommend that the heating pipeat the junction between floor and wall,is set at 200mm spacing, which iswhere the pipe changes from runningsufficiently close to enable the full heatinghorizontally to verticallyrather than be allowed to fully float.Softwood joists are commonly used inIntermediate Floors althoughmanufactured I-Beams are often usedinstead because they can be stronger andare more stable dimensionally.performance to be achieved, whilstIn most underfloor heating systems, theseminimising the amount of pipe used.details are the only parts that are visible.The Standard Product Range provides 3The OSMA Standard Product Rangedifferent ways of securing the pipe to theincludes accessories such as Sweeptop of the insulation:Bends and Clamps to ensure that these1. Staplesthat must be nailed down to a support,details can be achieved neatly.The Standard Product Range includes50mm thick Batten/Joist panels, similar toFloating Floor Panels but 340mm wide,which are intended to fit between 50mmthick battens and automatically spacethese at nominal 400mm centres, or to befitted between softwood joists at similarfor example, extruded polystyrene suchFULLY-FLOATINGTIMBER FLOORSas Polyfoam or Styrofoam, or polyurethaneThese are floors where panels of insulationbe fitted up from below between I-Beams.such as Celotex – staples will provide aare used to support a timber floor decksecure fix for the pipe.that is normally formed from tongued andIf the insulation you purchase is firm –4centres, either from above or below, or toFor Product Range, see pages 12–13Pressure TestingUnderfloor heating pipe is arranged inCONTINUOUS PIPE LENGTHSor Heating Panels have been installed in anseparate pipe circuits within the floorIf the pipe circuit is a continuous pipeI-Beam joisted floor, each circuit shouldconstruction and terminated at the waterlength, the test pressure should be 3 bar.be tested to at least 18 bar.flow controller. Prior to connection to theThis will be sufficient to determine whetherAfter each pipe circuit has been pressure-water flow controller, each pipe circuitthe pipe has been punctured duringtested, connect the pipe ends to the Watershould be pressure-tested, using aninstallation, by a nail for example.Flow Controller. Do not pressure test pipePIPE LENGTHS WITH FITTINGScircuits AFTER connection to the WaterIf the circuit includes OsmaGold fittings, asFlow Controller.OsmaGold Pressure-Tester. The pressuretest should be dated and recorded as apermanent record (see pages 23-24).it may when Chipboard Modules are usedOSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingDesign Procedures9

UNDERFLOOR HEATINGDesign Procedures General Considerations 5Water Flow ControlSMALL PROJECTSOr:so that it cannot operate if there is noIn small projects, covering areas less thanIt is recommended that the supply to theheated water in the Primary. The pipe20m2, either Single Port Manifold andWater Mixing Controller should be takenproviding water to the Controller shouldControl Pack, or Water Mixing Control canfrom the heating Primary, either beforehave sufficient capacity to supply thebe used.or after any timed Diverter Valve, whichquantity of heat required by the section ofcontrols the supply to radiators forUFH attached to it.AREAS GREATER THAN 20m2In larger projects a manifold should be usedup to a maximum of four ports.example, as required. The electrical supplyto the Water Mixing Controller can betimed or otherwise, as required, althoughin general the wiring should be arranged6Room Temperature ControlEither standard or programmable room(generally the Boiler Live) is fed through thethermostats may be used (purchasedroom thermostat to the controller.separately).In projects having more than onetemperature zone, the flow of water intoeach circuit is controlled by a 2Wire Actuator on each circuit branch,In small projects, where there is a singlezone, the electrical feed that is used toenable/disable the Water Mixing Controller7which is opened/closed under the controlof its associated room thermostat. TheOSMA UH1-M Wiring Centre connectseach room thermostat to the appropriateactuator. The operation of any oneactuator will turn on the Water MixingController and boiler and initiate the flowof heated water to it.Project DesignOnce the most appropriate products haveImportant Notesbeen selected, a dimensioned design/Never bend 15mm OsmaGold pipeGENERALCONSIDERATIONSinstallation drawing should be produced. Amore tightly than a radius of 120mm.Response times:Design Planning Grid is produced on pageIf you have bent the pipe too tightly andSetting pipe within a 65-75mm screed30 of this brochure to help withit has kinked the pipe needs towill form an underfloor heating systemproject design.be replacedwith quite high thermal mass. FromThe drawing should show where eachAlways cut OsmaGold pipe using ancold, it will have to warm up the massfloor component and the Water MixingOsmaGold cutter or sharp secateurs.of the screed before the top surfaceController is to be sited. This will alsoNever use a saw bladecan begin to radiate. Once warm,assist in producing a full schedule of thematerials required.INSTALLATIONPROCEDURESGenerally, products should be installedin the following stages:1. Clear the space to be heatedAlways use pipe inserts whenever ajoint is formedNever use joints in pipe if pipe isgoing to be placed in screedit will continue to produce heat forseveral hours even after the boilerhas turned offUnderfloor heating in a timber floor hasa smaller thermal mass to warm upAlways allow screeds to dry naturally.before it starts to work but it will coolDon’t use UFH pipe as a way ofdown more quickly after the boiler hasspeeding up the drying processturned off2. Install Floor Components and PipeAdditives:3. Conduct pressure-testGenerally, the additives that the boiler4. Install Water Mixing Controls andor radiator manufacturers specify willhave no effect on the OsmaGold pipe.connect circuitsIf in doubt contact OSMA UFH5. Connect up Electrics6. Commission10SALES AND TECHNICAL ENQUIRIES01392 444122FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGGeneral ConsiderationsProject Design continuedHEAT LOSS CALCULATIONTo calculate the actual heat losses froma room do the following sum:Next, calculate the area (m2) of the exposedVolume of room (m3)xfloor space that may be heated.Difference between design internal2Area of surface (m )xDivide total heat required (Watts) by availableand external temperaturesxTemperature difference between thefloor area (m2) to calculate Power required(W/m2) (see example below).U-value equivalent two sides of the surface ( C)xAir Change Loss (Watts)U-value for the surface 2000mmThe U-value equivalent to use is:3Surface Loss (Watts)AC / hrAdd up the amounts for each surface1.00.33BedroomsTotal Surface Loss (Watts)1.50.50Living RoomsAdd to this figure the energy needed to2.00.66BathroomsNext sum together Surface Loss andAir Change Loss 800mm2400mm1200mmTypical for1200mmheat any incoming cold air as follows:U-valuemm000mm0012Total Loss (Watts)ExampleINPUT DATARoomSTUDY2SURFACEU-valueExterior Walls0.30Floor Area6.00mWindows & Doors2.30Height2.40m2Internal Walls0.90Exterior Wall9.60m2Ceiling/Roof0.50Interior Wall12.00m2Air Changes per Hour1.502.402GlazingmDESIRED ROOM TEMPERATURE20 CROOM TEMPERATURESUBTRACTOUTSIDE TEMPERATURE-2 CAVERAGE INTERNAL ROOM TEMPEQUALSTEMPERATURE DIFFERENCE20 C15 C5 CSUBTRACTEQUALS22 CINTERIOR ROOM DIFFERENCEEXTERNAL WALLArea (Minus) Glazing9.60m2U-valueMULTIPLY0.30Temp DiffMULTIPLY22Watts Loss CEQUALS CEQUALS CEQUALS CEQUALS63.36WINDOW & DOORArea2.40U-valuem2MULTIPLY2.30Temp DiffMULTIPLY22Watts Loss121.44INTERNAL WALLU-valueArea12.00m2MULTIPLY0.90Temp DiffMULTIPLY5Watts Loss54.00CEILING / 0.50Temp DiffMULTIPLYAIR CHANGE LOSSESTemp DiffMULTIPLY22 C22Watts LossPer Hour0.5066.00Watts LossEQUALSTOTAL LOSSES158.40463.20DIVIDE BYUSABLE AREA6EQUALSTOTAL REQUIRED OUTPUT W/m 2 (USEABLE AREA ONLY)77.20This figure may now be checked against the Power Output tables on page 8OSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingDesign Procedures . General Considerations11

UNDERFLOOR HEATINGProduct RangeScreed RTCODEPACKQUANTITY1200 x 600 x 50mmPlain Insulation25UH050125m x 150mmMulti Height Edge Expansion Foam15UH15381500 x 800mm System Plate15UH19618Screw Clips(Bag of 50)15UH2331Staples for 15mm OsmaGold Pipe(Box of 300)15UH2301Staple Gun15UH3231Insulation Joint Tape15UH4001OSMA Plate Clips(Pack of 25)15UH2341OSMA Plate Tack Clips(Pack of 25)15UH2351PARTCODEPACKQUANTITY1200 x 340 x 50mmStraight Joist Panel30UH059201200 x 600 x 50mmStraight Batten Panel25UH05351200 x 340 x 50mm(3) Loop Return Panel25UH056101200 x 50 x 50mmPlastic ‘L’ Bracket15UH70030PARTCODEPACKQUANTITY15mm x 50m Coil15HC160115mm x 100m Coil15HC180115mm x 15mm Straight Connector15HC5105Branch Tee 15 x 15 x 15mm15HC5425Elbow 90 15mm15HC53010Blanking Caps 15mm15HC7401015UH235Floating/Batten/Joisted Floor30UH05925UH05325UH05615UH700OsmaGold Pipe & Fittings*15HC16015HC18015HC542* OsmaGold Pipe & Fittings are available from yourlocal OsmaGold stockist15HC53015HC74015HC51012SALES AND TECHNICAL ENQUIRIES01392 444122FAX01392 444135EMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGProduct RangeSingle Room Controls48UH585PARTCODEPACKQUANTITY1-2 Circuit Control Pack(For Connection to Heating Primary)48UH58511-2 Circuit Control Pack(For Connection to Radiator Branch)48UH5501PARTCODEPACKQUANTITYManifold Mixing Unit (inc. Pump)48UH58012 Port Manifold67UH87213 Port Manifold67UH87314 Port Manifold67UH8741Port Thermometer47UH88811" Isolation Ball Valve47UH58522 Wire Actuator (240V)52UH8021Wiring CentreUH1-M1Programmable LCDThermostat (240V)PRT-M148UH550System Controls48UH58067UH87447UH88847UH585Programmable LCD Thermostat withDomestic Hot Water Timer ipe Clamps15UH2362Curved Pipe Supports15UH2392Y Connectors for 48UH55047UH55021/2" Isolation Ball Valve for 48UH55047UH5552Circular Saw Blade15UH3051OSMA Infrared Thermometer15UH5001OSMA Installation/Service Pack15UH6911OSMA UFH Design and Installation Guide 2006LITERATURE01249 766333Underfloor HeatingProduct Range13

UNDERFLOOR HEATINGFor Screeded FloorsBasic Products For Screeded FloorsSupplied as:PartNumbereither: OSMA Screw Clips15UH233optionScrew Clip Handle15UH300or: OSMA StapleswithStaple Gun15UH23015UH323Also required: Edge InsulationMulti-Height 25m x 125mm15UH153 OSMA 15mm Heating Pipe(OsmaGold)see page 12 Control Unit, Manifold andRoom Thermostat orSingle Room ControllerBAsee page 13 Sand/cement screed– Insulation–DCEProcedure1 Ensure flat and level sub-floor.2 Place edge insulation around theperimeter of the room (see A).3 Lay plain insulation, with staggeredjoints, to cover the required areaRecommendation: tape joints between5 Feed the pipe from the centre oflaid (so that, if the pipe is damagedthe coil. DO NOT REMOVE THEduring screeding, any fault can bePACKAGING FROM THE PIPE COIL.detected immediately and rectified).insulation panels to prevent ingress ofscreed (see C).6 Secure the pipe to the insulation inaccordance with the layout design,4 Mark out proposed pipe layout onthe surface of the insulation panelsusing Staples or Screw Clips asappropriate (see above).200mm in from the wall.Recommendation: follow a serpentinepattern, with pipe at 200mm centres,preferably running in the longestdirection of the room (see D).Alternatively, follow a spiral pattern at146 At point below where the Water MixingController is to be installed, use CurvedPipe Supports and Pipe Clamps to holdthe pipe neatly in place. Insulation type and thickness shouldbe chosen to satisfy Part L BuildingRegulations Staples or Screw Clips to securepipe to insulation. Use Staples for7 Once the pipe is installed, pressure200mm centres. This will put less forcetest PRIOR to screeding. Keep pipeonto the staples (see page 16, image F).under pressure, while screed is beingSALES AND TECHNICAL ENQUIRIES01392 444122RequirementsFAX01392 444135rigid insulation, Screw Clips for softinsulationEMAILinfo@osmaufh.co.uk

UNDERFLOOR HEATINGFor Screeded FloorsSystem PlatesSupplied as:PartNumberIndividual OSMA System Plates:– 1500 x 800mm 1.2m215UH196Also required: Edge InsulationMulti-Height 25m x 125mm15UH153 OSMA 15mm Heating Pipe(OsmaGold)see page 12 Control Unit, Manifold andRoom Thermostat orSingle Room ControllerAsee page 13 Sand/cement screed– Building adhesive–CBProcedureDE1 Ensure flat and level sub-floor.ABCD12 Place edge insulation around theperimeter of the room (see A).D2EFG13 Lay plain insulation over the sub-floor.4 Position first System Plate so that theG2Hsquare corner of the plate with a singlenodule is placed into the corner of theroom (see B).5 Lay and fix subsequent plates in thesame orientation, locking neighbouring7 Once the System Plates are in place,plates together by overlapping onefix them down locally to the top of therow of castellations (see C).insulation, in each corner and in theNOTE: Locking the Plates togethercentre of the room, using either Plateprevents movement and ingress ofAnchor Clips 15UH234 or Plate Tacksscreed

UNDERFLOOR HEATING Introduction/Standard Product Range 4 Introduction UNDERFLOOR HEATING Underfloor heating is the most comfortable form of heating. It is unobtrusive, economical, safe, hygienic and virtually maintenance-free. It offers the best long-term method of heating