Transcription

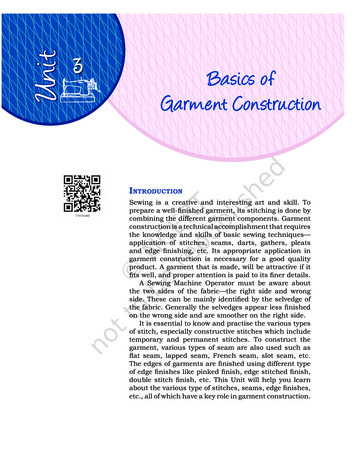

3Basics ofGarment ConstructionIntroductionSewing is a creative and interesting art and skill. Toprepare a well-finished garment, its stitching is done bycombining the different garment components. Garmentconstruction is a technical accomplishment that requiresthe knowledge and skills of basic sewing techniques—application of stitches, seams, darts, gathers, pleatsand edge finishing, etc. Its appropriate application ingarment construction is necessary for a good qualityproduct. A garment that is made, will be attractive if itfits well, and proper attention is paid to its finer details.A Sewing Machine Operator must be aware aboutthe two sides of the fabric—the right side and wrongside. These can be mainly identified by the selvedge ofthe fabric. Generally the selvedges appear less finishedon the wrong side and are smoother on the right side.It is essential to know and practise the various typesof stitch, especially constructive stitches which includetemporary and permanent stitches. To construct thegarment, various types of seam are also used such asflat seam, lapped seam, French seam, slot seam, etc.The edges of garments are finished using different typeof edge finishes like pinked finish, edge stitched finish,double stitch finish, etc. This Unit will help you learnabout the various type of stitches, seams, edge finishes,etc., all of which have a key role in garment construction.Unit 3.indd 7217-Mar-21 12:08:11 PM

Session 1: Various TypesofStitchNotesThis session will help provide the student with a throughunderstanding of the various kinds of stitch.StitchesAlmost every garment or other stitched articles we sew,needs some hand stitches. Thus, we should be able tohandle the needle and thread to carry out hand stitchescompetently. Before learning stitching on the sewingmachine, one should learn the basic hand stitcheswhich are very commonly used in the manufacturingof garments and other articles. A stitch may be definedas one unit of conformation resulting from one or morestrands or loops of thread intralooping, interlooping orpassing into or through the material. Intralooping is thepassing of a loop of thread through another loop formedby the same thread, while interlooping is the passingof a loop of thread through another loop formed by adifferent thread.The basic hand stitches are divided into two typesdepending on their use.Constructive stitchesIt is a line made by a portion of sewing thread passedover and under an equal or unequal number of threadsfor construction purpose. Such stitches can be classifiedas temporary and permanent stitches.1. Temporary stitchesSuch stitches are used to hold the garment or fabricpieces together before permanent stitches are made.These stitches are also known as tacking or bastingstitches. Usually this stitch is horizontal and it is workedfrom the right to the left side with a knot.Various kind of tacking/basting stitches are asfollows.(i) Even bastingIt is used to hold the fabric together temporarily, butmore securely than in uneven basting. Make evenstitches of about ¼ inch to ⅜ inch long. When easingBasicsofGarment Construction73Unit 3.indd 7329-Mar-2019 02:48:06 PM

one layer of the fabric to another layer, hold the layerto be eased on top and gather this top layer to stitch(Fig. 3.1).Fig. 3.1: Even bastingFig. 3.2: Uneven bastingFig. 3.3: Diagonal bastingFig. 3.4: Slip basting(ii) Uneven bastingThis is used to mark or to hold fabrics together, onlywhere there is no strain on the stitches. Use this type ofbasting, as the guideline on the upper side of the fabricis at least twice than that on the underside of the fabric.Make a long stitch, about ½ inch on one side of thefabric and then a short stitch ¼ inch on the other sideof the fabric (Fig. 3.2).(iii) Diagonal bastingThis is used to hold two pieces of fabric together whenmore than one row of tacking is required. For example,when you are attaching interfacing to a collar ormounting a fabric on to an underlining, etc. It may bedone vertically or horizontally (Fig. 3.3).(iv) Slip bastingAlso called invisible hand basting, it is used whenworking from the right side of the fabric, and to markfitting alterations, or on occasions where patterns haveto be joined accurately. For example, strips, checks, etc.Turn under one edge of the material on the seam line.Pin the folded edge carefully to the seam line on theother edge with pins at right angles to the seam. Takeeven tacking stitches alternately through the fold andthrough the single edge on the seam line (Fig. 3.4).2. Permanent stitchesThe stitches that form a part of the stitched garment arecalled permanent stitches.(i) Running stitchThis is the simplest form of hand stitch which is usedmainly for gathering and shirring fabrics. When it isused for both gathering and shirring, make sure thatenough thread should be left to make an unbrokenline of stitches. It is similar to the even basting, butthe stitches are much smaller. The stitches shouldbe straight, fine and evenly spaced and mostly aboutSewing Machine Operator – Class IX74Unit 3.indd 7406-Mar-2019 03:23:46 PM

inch to ⅛ inch in length. To carry out the runningstitch, take several very small stitches on to the point ofthe needle before drawing the thread through the fabric.The stitches should be as small as the thickness of thefabric to allow less than 2mm on fine fabrics (Fig. 3.5).1/16(ii) Back stitchIt is considered to be very strong and is many a timesused as a substitute for machine stitching. It is mainlyapplied when extra strength is needed. Back stitch is veryuseful for making strong seams and for finishingoff a line of stitching. The stitches on the frontof the work are small and appear continuous. Towork the back stitch, make a small stitch backfrom left to right. Then make a double lengthstitch forward on the wrong side of the fabric. Sothe needle emerges a stitch’s length in front of thefirst one. Repeat this way, keeping the stitchesuniform in size and fairly firm (Fig. 3.6).Fig. 3.5: Running stitchFig. 3.6: Back stitch(iii) Run and back or combination stitchIn this combination, a back stitch and three or fourrunning stitches are combined and can be used forworking plain seams done by hand. This stitch isworked faster than the back stitch and stronger thanthe running stitch.(iv) Hem stitchIt is used for hems on medium weight or lightweightfabrics. It is mainly used to fasten a raw edge whichshould be turned in or to flatten a seam. It appears assmall slanting stitches on the wrong side of the fabric.The stitch size will depend on the fabric. The threadshould not be pulled taut or the fabric will pucker(Fig. 3.7).(v) Half back stitchThis stitch is quite similar to the back stitch, but with alonger stitch at the back side of the fabric. To carry outthe stitch, make a small stitch back from left to rightand then make a stitch forwards, two and a half timesas long, on the wrong side of the work. Make anothersmall stitch from left to right on the right side.BasicsofFig. 3.7: Hem stitchGarment Construction75Unit 3.indd 7506-Mar-2019 03:23:47 PM

(vi) OversewingIt is used to finish seam edges on fabrics which frayeasily. To carry out the stitch, hold the fabric with theedge to be worked away from the worker. Insert theneedle ⅛ to ¼ inch from the edge, and bring the threadover the edge of the fabric. Make the next stitch ¼ inchfurther on.Fig. 3.8: Half back stitchFig. 3.9: Oversewing stitch(vii) Blind hemming stitchThis stitch is worked on the inside fold of the hem sothat the stitches are almost invisible; thus, the name‘blind’. The thread should not be pulled tightly. To carryout the stitch, hold the work with the fold of the hemtowards you, take a very small stitch inside the hemfold edge, picking up a thread of the single fabric on thepoint of the needle before taking another stitch on theinside hem fold of the garment.(viii) Buttonhole stitchThis stitch is worked with the needlepointing towards you, and the fabricedge away from you. To carry out thestitch, insert the needle in the rightside of the edge of the buttonhole.Bring it out ⅛ inch below. Loop thethread hanging from the eye of theneedle from right to left under thepoint of the needle and draw theneedle upwards to knot the threadat the buttonhole edge.Fig. 3.11: ButtonholestitchDecorative stitchesFig. 3.10: Blind hemming stitchThese stitches are also known as embroidery stitches.This art is practised on all kinds of pliable materialwith different types of threads, precious and semiprecious stones, pearls, shells, beads, etc. There aredifferent kind of hand embroidery stitches. Someof the common hand embroidery stitches are stemstitch, chain stitch, herringbone stitch, featherstitch, lazy-daisy, satin stitch, cross stitch, Bullionstitch, etc., which are used to decorate garments, homeSewing Machine Operator – Class IX76Unit 3.indd 7606-Mar-2019 03:23:47 PM

furnishing items and other articles. As these stitchesare mainly used to decorate the garment or material,hence, not discussed in detail in this book as shown inFigs. 3.12(a–i).(a) Stem stitch(d) Herringbone stitch(g) Satin stitch(b) Chain stitch(e) Feather stitch(h) Blanket stitch(c) Cross stitch(f) Lazy-daisy stitch(i) Bullion stitchFig. 3.12 (a–i) Decorative stitchesBasicsofGarment Construction77Unit 3.indd 7706-Mar-2019 03:23:48 PM

NotesPractical ExercisesActivity 1Make a scrapbook of the constructive and decorative stitchesand label them.Material Required1.2.3.4.5.Coloured pens/pencilsScrapbookPictures of constructive and decorative stitchesScissorsAdhesive/glueProcedure1. Search and collect the pictures of different types ofconstructive and decorative stitches.2. Cut the pictures very neatly with scissors.3. Paste them in a scrapbook.4. Label them.Activity 2Prepare samples of hand stitches as given in this session.Material Required1.2.3.4.5.6.7.8.9.10.Cotton fabric to prepare samples (12" x 12")NeedleThreadFramePenPencilEraserA3-sized chart sheetGlueMarkers/coloured pensProcedure1. Use slip basting, running stitch, back stitch and hem stitchto finish four sides of the sample fabric.2. Make different constructive (temporary and permanent)stitches on the sample.3. Paste them on the chart sheet and write where they are used.4. Label them.5. Place the chart in the classroom/practical lab.Sewing Machine Operator – Class IX78Unit 3.indd 7806-Mar-2019 03:23:49 PM

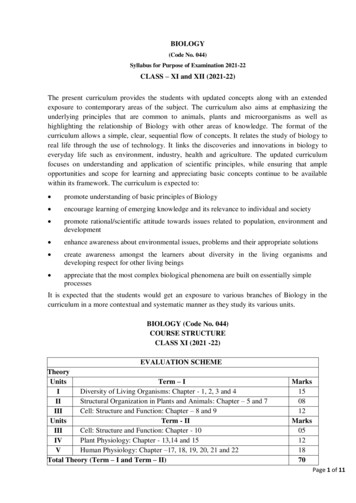

Check Your ProgressNotesA. Fill in the blanks with the most appropriate answer fromthe choices given below1. stitch forms part of a stitched garment.(a) Temporary(b) Permanent(c) Constructive(d) Hem2. stitch is of equal length about ¼ inch on bothsides of the fabric.(a) Uneven basting(b) Slip basting(c) Diagonal basting(d) Even basting3. stitch is used for hems on medium or lightweightfabrics.(a) Hem(b) Back(c) Run and back(d) DecorativeB. Short answer questions1. Write short notes on the following(a) Decorative stitches(b) Buttonhole stitchC. Long answer questions1. Describe how to make temporary stitches.2. Describe how to make permanent stitches.Session 2: Different TypeofSeamsSeams refer to the stitching line where two pieces offabric are stitched together. It is the basic building unitof any garment or stitched article. It is an applicationof a series of stitches or stitch types to one or severalthickness of material. Seams mainly construct thestructure of the garment or stitched article. It is alsoused for decorative purpose. Decorative seams aremainly used for decorative purposes while functionalseams are used mainly for the purpose of construction.An example of decorative seams is a tucked seam, andexample of functional seam is flat seam, French seam,BasicsofGarment Construction79Unit 3.indd 7906-Mar-2019 03:23:49 PM

Notesetc. Good appearance in a seam normally means smoothfabric joins with no missed or uneven stitches and nodamage to the material being sewn. Alternatively, itmeans regular gathering to form a style feature, or avarying but controlled amount of ease to ensure a goodfit of the garment to the body. With the wide variety offibre types and fabric construction available, good seamappearance during manufacturing requires differenttechniques. Once it has been achieved, it should bemaintained throughout the lifetime of the garment,despite the many problems that arise during wearing,washing and dry-cleaning. Performance of the seamsmeans the achievement of strength, comfort, durabilityand elasticity. Seams should be as strong as the fabric.Following are the points to be considered while makingseams. Seams are commonly machine stitched but onecan hand stitch a seam using back stitch. Before makinga seam, ensure that the needle and thread used areappropriate for the fabric weight and texture. Becausethe seams of a garment must withstand wear and tear,the beginning and the end of the line of stitching shouldbe secured with a few back stitches. To prevent fraying,enough quantity of fabric should always be left betweenthe line of stitching and the fabric edge.There are different type of seams, and the type offabric and garment should determine the one you select.Some commonly used seams are given below.Flat seamIt is the basic seam (functional seam), joining the edgesof two pieces of fabric. This seam is used on mediumweight fabrics where there is no special strain on theseam. Mostly, plain straight stitch is used to stitch theseam. Flat seam can be used on most of the garmentsand the seam edges should always be finished asappropriate for the type of fabric. Although a flat seamis always made with the right side of the fabric facing,some other seams will require to be initiated with thewrong sides of the fabric facing. With the right sidesof the fabric facing, pin the fabric together at both theends of the seam line and at intervals along the seamSewing Machine Operator – Class IX80Unit 3.indd 8006-Mar-2019 03:23:49 PM

line leaving an allowance of about ¾ inches properly,close to the seam line. Then stitch along the seam line,back stitching a couple of stitches at each end to securethe seam, and remove the pins. After removing the pins,finish the seam edge by pinking it or as necessary forthe fabric. Press the seam as stitched and then pressit open, using a pressing cloth between the iron andthe fabric.(a)Channel seamThis is a decorative seam mostly used in trousers,pockets of jeans, jackets, etc. It has a strip of fabricbehind it which is visible through the seam fold. It canbe made of contrasting fabric, if desired. With the rightsides of the fabric together, pin and tack along the seamline. Press the seam open and cut an underlay of thesame or contrasting fabric 1 inch wider than the twoseam edges. With the wrong side of the work facingyou, centre the right side of the underlay on the seamand pin in the position. Pin and then stitch an equaldistance, each side from the seam depression. Removethe pins and tacking, then press as stitched.(b)(c)(a) Tacked fabric together(b) Underlay pinned to seam(d)Fig.3.13 (a, b, c, d) Flat seam(c) Completed seamFig. 3.14 (a, b, c) Channel seamBasicsofGarment Construction81Unit 3.indd 8106-Mar-2019 03:23:49 PM

Lapped seamFig. 3.15: Lapped seamThis seam is used for joining sections of interfacingto avoid bulking, that is a mass of fabric gettingthick. Lap one edge of the fabric over the otherwith the seam lines directly over each other. Tackand then stitch along the seam line with a widezigzag stitch or a straight stitch. Trim the seamedges (Fig. 3.15).Flat felled seam(a)(b)Fig. 3.16 (a, b) Flat felled seamThis is a flat, durable and strong seam used mainlyon men’s sports shirts, work clothes, children’sclothes and pyjamas. It is time consuming anddifficult to make on curved edges and on bulkyfabrics. Place the fabric pieces to be joined at thewrong side facing, and then stitch on the seam line.Press both seam allowances together in the samedirection and trim the under seam allowance to ⅛inch and the upper one to ⅜ inch (Fig. 3.16 a). Turnunder the raw edge of the wide seam allowance soas to make a smooth fold of ¼ inch wide. Stitchclose to the folded edge on the right side of thegarment. The right side of the seam shows two rowsof stitching and wrong side shows only one row ofstitching (Fig. 3.16 b).French seam(a)(b)Fig.3.17 (a, b) French seamIt is a narrow seam generally used for fine fabricsor for those fabrics which fray easily. It is a seamwithin a seam. When finished, it should be about¼ inch or less in width. To make the Frenchseam, place the wrong sides of the fabric together(Fig. 3.17 a). Pin and tack in position close to theseam line. Stitch ¼ inch to the right of the seam lineto the end of the seam. Press as stitched. Pressingcan be done using hands to form a crease or usinga heat pressing iron. Then trim the seam allowanceto ⅛ inch. Press the seam open. Then turn the rightsides of the fabric together. Fold on the stitch lineand press. Tack in position. Stitch along the seamline and press as stitched (Fig. 3.17 b).Sewing Machine Operator – Class IX82Unit 3.indd 8206-Mar-2019 03:23:50 PM

Mantua maker’s seamIt is used to attach a frill to a straight piece of fabric.With the right sides of the fabric together, tack alongthe seam line and stitch. Trim the frill seam allowanceto ¼ inch. Double fold the other seam allowance overthe raw edge down to the seam line. Stitch very close tothe seam line then remove tacking and press the seamupwards, keeping away from the frill.(a)Double stitch seamIt is used mainly for sheer fabrics. To make this seam,take the right sides of the fabric together, tack andstitch along the seam line and press as stitched. Makeanother line of stitching in the seam allowance ¼ inchfrom the first line, using a fine multi stitch zigzag orstraight stitch. Then trim the raw edge using a scissorsor a pinking shear to prevent the fabric from fraying.(b)Fig. 3.18 (a, b) Mantuamaker’s seamLingerie seamIt is used mainly for making very fine seams. It is sonamed because of its use in lingerie. To make the seam,take the right sides of the fabric facing; pin, tack andthen stitch along the seam line. Then press as stitched.Finish the seam edges with pinking scissors and pressboth seam allowances to one side. Stitch seam edges onthe right side with small stitches of zigzag.Fig. 3.19: Double stitch seamTucked seamIt is a decorative seam and generally used as a designfeature on a garment. If a tucked seam is used on afabric which frays easily, the seam edges should befinished by oversewing. To make a tucked seam, takethe right side of the fabric facing you, turn under theseam allowance on one piece of fabric, and then pinFig. 3.20: Lingerie seam(a)Basicsof(b)Fig. 3.21 (a, b, c) Tucked seam(c)Garment Construction83Unit 3.indd 8306-Mar-2019 03:23:51 PM

Notesinto place. Place the folded edge of the seam line onthe right side of the second piece of fabric, putting theedges together. Tack and stitch the desired width fromthe folded edge. Remove tacking threads and trim offthe seam edge underneath the seam. Press as stitched.Practical ExercisesActivity 1To identify the various seams used on a pair of denim jeans,pillow covers, shirt, skirt, frock, bloomer and blouse.Material Required1.2.3.4.5.6.7.8.9.10.11.A pair of denim jeansPillow d chart sheetEraserProcedure1. Place each of the above items in front of you.2. Begin by observing and identifying the seams used in eachof these. Make a note of your observations.3. Now take an A3-sized chart sheet and draw out a table.4. While preparing the chart, remember to refer to the notesyou made earlier.5. List the names of the items you observed such as frock,shirt, blouse, etc., on the left side. Now write yourobservations on the kind of seams used in each of these onthe right side of the table.Activity 2Prepare samples of different seams as given in this session.Material Required1. Cotton fabric to prepare samples (12" x 12")2. Needle, thread and scissors3. PenSewing Machine Operator – Class IX84Unit 3.indd 8406-Mar-2019 03:23:51 PM

Practical Exercises4.5.6.7.8.9.10.EraserPencilPractical fileAdhesive/glueMarkers/coloured pensSewing machineBobbin/bobbin caseNotesProcedure1.2.3.4.Prepare samples of different seams.Finish the edges of the samples.Attach them in the practical file and write where they are used.Label them.Check Your ProgressA. Fill in the blanks with the most appropriate answer fromthe choices given below.1. Channel seam is a seam.(a) decorative(b) functional(c) Both (a) and (b)(d) None of the above2. seam is used for joining section or parts ofinterfacing to avoid bulk.(a) Welt(b) Lapped(c) Channel(d) French3. Tucked seam is a seam.(a) functional(b) decorative(c) Both (a) and (b)(d) None of the above4. is a seam within a seam.(a) Flat(b) French(c) Lapped(d) ChannelB. Short answer questions1. Write short notes on the following(a) Double stitch seam(b) Lapped seam(c) Lingerie seamC. Long answer question1. Describe the various type of seams in detail along witha diagram.BasicsofGarment Construction85Unit 3.indd 8506-Mar-2019 03:23:51 PM

Session 3: Edge FinishesEdge finishes are made to prevent fraying of the rawedges of the fabric or garment and thus, make the fabricedge more durable and attractive. They also providea neat appearance to the inner side of the garment.Although edge finishes are not essential for completionof the garment, it can add durability to a garment’s life.There are various types of edge finishes. They may becarried out by hand stitches or by sewing machine.Some of the common edge finishes are described inthis session.Different type of edge finishesPinked finishThis is a quick method of finishing done with pinkingshears (a kind of fabric cutting scissors). After stitching,trim the edges, preferably at a distance of ⅛ inch byusing pinking scissors (also called pinking shears).This technique is not used on fabrics that ravel badly(Fig. 3.22).Fig. 3.22: Pinked finishFig. 3.23: Edge stitched finishEdge stitched finishThis is a neat finish for light to medium-weight, nonbulky fabrics. In this finish, the seam is stitched andpressed open. Then turn under ¼ inch on each seamedge. Stitch close to the fold without catching thegarment (Fig. 3.23). This is a bulky type of finish andis not suitable for deeply curved seams. This finish ismostly used on unlined coats and jackets where theseam allowance is wide.Double stitch finishFig. 3.24: Double stitch finishAfter making a plain seam, to carry out double stitchfinish work, an extra line of stitching is made about¼ inch from the raw edge of the fabric or garment(Fig. 3.24). This is done for a plain unfinished seam orpinked seam. It is not suitable for bulky fabrics. Thistype of finish is commonly used on sheer fabrics.Sewing Machine Operator – Class IX86Unit 3.indd 8629-Mar-2019 02:56:44 PM

Herringbone finishThis finish neatens the raw edges of heavy materiallike flannel, brocade, tweed, etc. It also holds down theturning, making the seam flat, avoiding the bulkiness.After pressing the seam open, herringbone stitches areworked on the two raw edges (Fig. 3.25).Bound seam edge finishFig. 3.25: Herringbone finishIn this method, the seam is pressed open and a separatepiece of binding (a double folded bias strip) is attachedto both the seam edges (Fig. 3.26) and tacked. It is oftenused on lightweight fabrics like silk, chiffon, etc.Practical ExercisesActivity 1Fig. 3.26: Bound seam edgefinishDraw pictures of various types of edge finishes and preparea scrapbook.Material pbookRulerMarkers/coloured pensProcedure1. Draw edge finishes on the scrapbook and write where theyare used.2. Label them.Activity 2Prepare samples of edge finishes as given in this session.Material Required1.2.3.4.5.Cotton fabric to prepare samples (12"X12")Needle and threadA3-sized chart sheetAdhesive/gluePenBasicsofGarment Construction87Unit 3.indd 8729-Mar-2019 02:56:45 PM

Practical Coloured pensPinking scissorsSewing machineBobbin/bobbin caseProcedure1.2.3.4.Prepare samples of edge finishes.Paste them on a chart sheet.Label them.Place the chart in the classroom or practical lab.Check Your ProgressA. Fill in the blanks with the most appropriate answer fromthe choices given below.1. seam edge is trimmed with pinking shearsand gives a zigzag appearance.(a) Pinked finish(b) Herringbone(c) Double-stitch finish(d) None of the above2. In , a separate piece of binding is attached toboth seam edges.(a) pinked edge(b) bound seam edge finish(c) herringbone finish(d) double stitch3. finish is suitable for heavy fabrics.(a) Pinked edge(b) Edge stitch(c) Herringbone(d) None of the above4. finish is commonly used on sheer fabrics.(a) Herringbone(b) Double stitch(c) Bound seam edge(d) Edge stitch5. Edge finishes are made to prevent of the rawedges of the fabric/garment.(a) Basting(b) Hemming(c) Fraying(d) None of the aboveSewing Machine Operator – Class IX88Unit 3.indd 8807-Mar-2019 02:48:59 PM

B. Short answer questionsNotes1. Write short notes on the following(a) Bound seam edge finish(b) Herringbone finish(c) Pinked seam(d) Edge stitch finish2. Explain the double stitch finish.C. Long answer question1. Describe various type of edge finishes and their use in detailalong with diagrams.BasicsofGarment Construction89Unit 3.indd 8906-Mar-2019 03:23:52 PM

fabric and then a short stitch ¼ inch on the other side of the fabric (Fig. 3.2). (iii) Diagonal basting. This is used to hold two pieces of fabric together when . more than one row of tacking is required. For example, when you are attaching interfacing to a collar or mounting a