Transcription

The Complete Guide toBuilt-insSecond EditionUpdated with New Products & TechniquesMINNEAPOLIS, Minnesotawww.creativepub.com

ContentsThe Complete Guide to Built-InsIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47Portfolio of Built-In & Shelving Projects . . . . . . . . . . . . . . . . . . . . 7Techniques & Design . . . . . . . . . . . . . . . . . . . . 18Copyright 2010Creative Publishing international, Inc.400 First Avenue North, Suite 300Minneapolis, Minnesota 554011‑800‑328‑0590www.creativepub.comAll rights reservedPrinted in ChinaPresident/CEO: Ken FundHome Improvement GroupPublisher: Bryan TrandemManaging Editor: Tracy StanleySenior Editor: Mark JohansonCreative Director: Michele Lanci-AltomareArt Direction/Design: Brad Springer, Jon Simpson, James Kegley10 9 8 7 6 5 4 3 2 1Library of Congress Cataloging-in-Publication DataLead Photographer: Joel SchnellSet Builder: James ParmeterProduction Managers: Linda Halls, Laura HokkanenPage Layout Artist: Danielle SmithShop Help: Charles BoldtEdition Editor: Charles PetersonTechnical Editor: Betsy MathesonProofreader: Drew SiqvelandThe Complete Guide to Built-InsCreated by: The Editors of Creative Publishing international, Inc., in cooperation with Black & Decker.Black & Decker is a trademark of The Black & Decker Corporation and is used under license.NOTICE TO READERSFor safety, use caution, care, and good judgment when following the procedures described in this book. The publisherand Black & Decker cannot assume responsibility for any damage to property or injury to persons as a result of misuseof the information provided.The techniques shown in this book are general techniques for various applications. In some instances, additionaltechniques not shown in this book may be required. Always follow manufacturers’ instructions included with products,since deviating from the directions may void warranties. The projects in this book vary widely as to skill levels required:some may not be appropriate for all do-it-yourselfers, and some may require professional help.Consult your local building department for information on building permits, codes, and other laws as they apply toyour project.Tools & Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Planning a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Jobsite Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Project Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cutting & Fitting Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adding Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Basic Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Preparing for the Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203034353638404230Installing Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46Built-In Projects . . . . . . . . . . . . . . . . . . . . . . . . 52Vertical Cabinet Dividers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54Home Office in Closet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58Banquette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62Pull Out Pantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66Window Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Bed Surround . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78Loft Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84Country Diner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92Wall Niche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102Understairs Bookcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108Entryway Room Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114Built in Closet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120Laundry Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128Towel Tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136Undersink Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142Foyer Bench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144Hobby Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150Bath Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156Kneewall Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162Club Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168Refrigerator Surround . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180Formal Bookcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188Utility Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194Cube Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198Closet Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204Joist Shelving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206Entryway Cubbies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210Basement Storage Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214Trimwork Wall Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218Box Beam Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222Floor-to-Ceiling Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . .Credits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Metric Conversions . . . . . . . . . . . . . . . . . . . .Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2342352362375446108188218

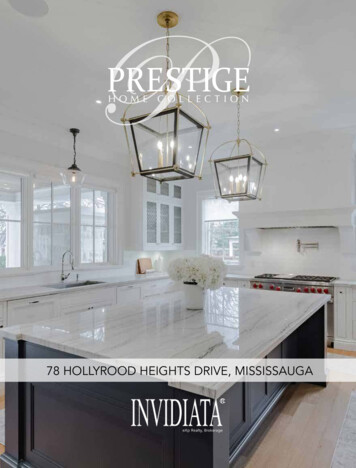

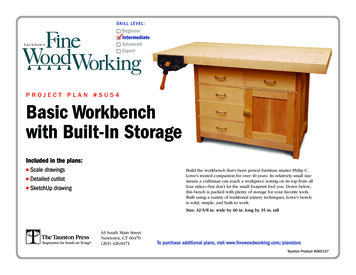

Understairs BookcasesIf your home has a staircase with open space below,chances are you’ve wondered how to make the mostof that oddly configured square footage. This bookcaseproject could be the answer. Behind the two pairs ofgently rising birch-frame doors you’ll find a bank ofbirch plywood shelves that are designed for use as aformal bookcase. Because the door panels are createdwith Plexiglas, the shelves are also quite suitable fordisplay purposes.While the bookcase cabinets must be custom-fitto your space, the basic design of the individual unitsis quite simple. Each cabinet is essentially a plywoodbox with an angled top. The boxes fit side by side inthe understairs area, flush with the wall surfaces. Theshelves in each unit incorporate birch 1 2 shelf edge toimprove their appearance and stiffen the shelf boards.A birch face frame is wrapped around the perimeterof the project, concealing the plywood edges. TheTools & Materials swinging doors are also made of birch. The secretto building the face frames and the door frames is aclever woodworking technique known as the pocketscrew joint made with angled screws driven into theback sides of the mating pieces.Understairs storage units are often made withslide-out shelving or pull-out drawers. This strategyallows for efficient use of space since the pullout units can be nearly as deep as the total stairwidth. The drawback is that the drawers or slideout shelves can be a bit rickety, especially if you’renot an experienced cabinetmaker. When designingyour project, you can increase the storage space bydeepening the shelves and using them as storagecubbies. If your staircase is bounded by anotherinterior wall, you can add a bookcase on the otherside, with the two bookcases sharing a divided panelor wall.ToolsWork glovesEye protectionRespiratorStud finderLevelPencilUtility knife or wallboard sawPry barDrillRouter (and rabbet bit)Pilot bitsChiselLarge pipe clampsFraming squareTable sawPneumatic brad nailerHVLP sprayer (optional)HammerNail setMaterials2 4 lumberPlywood stock (¼", ¾")Wood glueBrads150- or 220-grit sandpaperDesired finishPocket screws6d finish nails1¼" drywall screwsCoarse-thread drywall screwsWood putty; frosted glassPlexiglas108 The Complete Guide to BUILT-INSUnit 2Clear panelinsertsUnit 1A rich formal bookcase inhabits the previously wasted space underneath a staircase. The books are protected by birch doorswith Plexiglas panels that have a soft, contemporary design feeling.Glazier’s pointsLatchesPulls1 2 hardwoodShimsHingesFace frameDoor framesBuilt-In Projects 109

How to Build the Understairs Bookcase1Lay out the planned project on the walls. Be sure to identifyand label all stud locations as well as any wiring, plumbing orductwork in the project area. Try to plan the opening in thewall so it will be bordered by existing studs, and with the wallcovering cut up to the studs but not beyond.3Install 2 4 sleepers on the floor after you’ve thoroughlycleaned up the project area and disposed of all debris properly.Sleepers should butt against the wall’s sole plate and run backin a perpendicular fashion slightly further than the plannedproject depth. Install a sleeper at the end of the project area,beneath the midpoint, and at 16" intervals.562Cut and remove the wall covering with electrical service.First shut off electricity at the main service panel. To minimizedust, use a utility knife or wallboard saw to cut the wallcovering along the cutting lines. Pry off the wall covering,taking care not to damage surrounding walls surfaces.4Rip plywood stock into strips for making the cabinet frameand shelves. We used ¾" birch-veneer plywood to match thebirch that is used for the face frame and door frames. Thecabinet frame pieces are ripped to 12" wide but the shelvesshould be only 11¼" wide to allow for the ¾"-thick shelf edgestrips. Cut all parts to length.Assemble the unit frames with wood glue and coarsethread drywall screws driven through the outer faces and intothe edges of the mating boards. Drill countersunk pilot holesfor the screws. Work on a flat surface and check the joint witha framing square to make sure they are square. If you havelarge pipe clamps, use them to clamp the workpieces beforedriving the screws. Make both the Unit 1 and Unit 2 frames(tops, sides, and bottom panels).7Attach hardwood shelf edge to the shelves and the dividersupport edges. The tops of the 1 2 edge boards should beflush with the top surfaces of the shelves. The vertical edgingpieces should be flush with the outside edges of the dividers.Install shelf boards in the cabinet frame. The shelves shouldbe flush with the back edges of the frame, leaving a ¾" revealin the front. Draw shelf layout lines on both faces of the framepieces so you can center the screws. Install the full-widthshelves first. Assemble the shorter shelves and their dividersupports into L shapes, and then install them as a unit. Cutback panels from ¼" plywood and attach them with brads.8Apply a finish to the cabinet units. Sand all wood surfaces with150- or 220-grit sand paper, wipe down with mineral spirits, andthen apply two to three light coats of water-based polyurethane.We used an HVLP sprayer to apply the finish, but wipe-onpolyurethane works just fine if you don’t have spraying equipment.(continued)110 The Complete Guide to Built-insBuilt-In Projects 111

9Install the first unit in the project opening. The front edgesshould be flush with the room-side surface of the wall. Checkwith a level and shim between the frames and sleepers asneeded. Attach by driving 6d finish nails through the basepanel and into the sleepers and also through the side paneland into the wall stud.11Make the face frame. It’s possible to cut the pieces of theface frame and nail them individually to the cabinet units, butyou’ll get more professional-looking results with cleaner joints ifyou assemble the face frame, finish it, and then attach it to thecabinet as one piece. We used pocket screws to make the joints,but you can use dowels or biscuits instead. Apply a finish.112 The Complete Guide to Built-ins10Install the second unit in the project opening, shimming asneeded to make sure it is level and the top panel continuesin alignment with the top of the first unit. Before securing thepanels to the sleepers and stud, drive 1¼" drywall screws tojoin the units’ side panels at each corner where they meet.Countersink the pilot holes and cover with tinted wood putty.Attach the other side panel to the wall stud and nail thebottom panel to the sleepers with 6d finish nails.12Attach the face frame to the cabinet frame edges withbrads or pneumatic finish nails. Use plenty of nails, since theface frame will support the swinging door hinges. Set all nailheads and conceal with tinted wood putty.13Make the door frames. The frames will look best withthe vertical stiles running full height and capturing the railsbetween them. As you work, lay each completed frame on aflat surface next to the previous one and make sure the lineformed by the top rails follows the same angle as the top faceframe rails. The joint options are the same for the door framesas for the face frames (we again used pocket screws). Makesure to leave at least 1" of clear stock on each corner so therouter won’t cut into any fasteners when cutting rabbets.15Install the door panels. You can use frosted glass (temperedis best), ¼" plywood, or Plexiglas. We used Plexiglas because ofthe risk of breakage. It is possible to cut both glass and Plexiglasto size yourself, but given the high cost of materials and relativelylow cost of custom cutting, you’ll be glad you chose to have thepieces cut to size at the store. Panels should be about ¼" smallerthan the opening (including the rabbet widths) in each direction.Use glazier’s points to secure the panels.14Cut rabbet recesses for the door panel inserts. Use a pilotedrabbet bit and router. The rabbets should be 3 8" deep and ½"wide. Make the cuts in multiple passes of increasing depth—don’t try to remove all the material in a single pass. Once allrabbets have been cut around the perimeter of each doorframe back, square off the corners of the cuts with a sharpwood chisel. Note: In most cases, to create clearance you willneed to cut a ½" chamfer on the top inside edge of the twodoor frames where the hinges are on the side with the point.16Hang the doors and attach latches and pulls. Take great carewhen hanging the cabinet doors to make sure that the linecreated by the door tops is straight and parallel to the faceframe, with a consistent reveal. Orient the cabinet door pairs sothey close together in the center of each unit. Attach the doorpulls roughly midway up each cabinet door. Add latches orcatches so doors will stay closed. Note: You may need to bevelthe inside faces of the frames on the hinge side.Built-In Projects 113

108 The Comple Te Guide o BuilT-iNS Built-In Projects . side, with the two bookcases sharing a divided panel or wall. I f your home has a staircase with open space below, . While the bookcase cabinets must be custom-fi