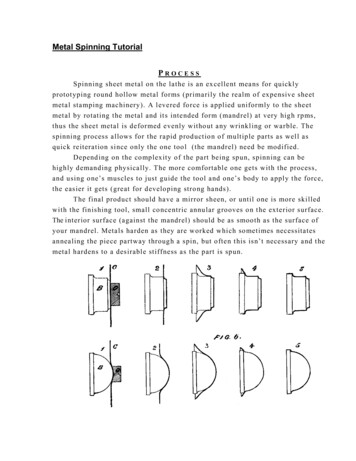

Transcription

HVAC Rollforming and Sheet Metal EquipmentManufactured in the U.S.A.

Where superior duct work begins. The Vicon line of HVAC Rollforming and Sheet Metal Equipment is the industry proven solution for all of your duct shopneeds. Backed by the Vicon name and over 40 years of engineering experience, you can be assured that every Viconmachine is designed and built to provide years of quality service and customer satisfaction. All Vicon machinery is100% manufactured in the USA in our 50,000 square foot manufacturing facility located in Pevely, MO. Every memberof the Vicon team is committed to delivering American made quality equipment and superior customer service tothe industry – bearing in mind the necessary components for complete customer success. Innovative technology,impeccable workmanship, and unrivaled support – we pride ourselves as the leader in complete turn-key solutions.Our commitment.Keep manufacturing where it belongs.1

IndexVicon V8 Pittsburgh Rollformer. 3Vicon V8 Snaplock Rollformer. 4Vicon V8 Slip & Drive Rollformer. 5Vicon V8 Outboard Optional Tooling. 6Vicon TDX Rollformer. 7Vicon TDX II Rollformer. 8V12 Rollformer & Optional Tooling. 9Vicon Coil Strip Feed Line.10Vicon Plasma Feeder.11Vicon Seam Closer.12Vicon Duct Brake.13Vicon Duct Beader.13Vicon Cheek Bender.14Vicon Edge Notcher.142

V8 Pittsburgh Rollforming MachinesThe Vicon V8 Eight-Station Pittsburgh Rollformer canbe optionally tooled with either Right Angle Flange,4-in-1 or Acme Lock Rolls. All V8 rollformers produceseams that exceed the standards set by SMACNA.ModelLeft Outboard (Female)Speedo p t i o n s Right Angle Flange RollsV8-P20Small Pittsburgh 20-28 Ga (5/16” pocket), 1” Notch90 FPMV8-P18Large Pittsburgh 18-24 Ga (7/16” pocket), 1-3/8” Notch90 FPMV8-P16Large Pittsburgh 16-20 Ga (7/16” pocket), 1-3/8” Notch45 FPM20-28 Ga. (1/4” - 7/16”)16-24 Ga. (1/4” - 7/16”) 4-in-1 Rolls (22 Ga. - 28 Ga.) to produceclinch, small standing seam, 7/16” flangeand male 1/4 edgefe at u re s&b e n e f i t s Quietest machine in the industry Eight forming stations for all roll sets - no opening roll on any roll set Acme Lock (Double Seam) Rolls(20 Ga.-28 Ga.) or (16 Ga.-22 Ga.) Large, heavy duty bearings with inner races and grease fittings protectroll shafts and extend bearing life of the machine Slide out shaft design allows for easy maintenance Heavy duty 1” diameter stress proof roller shafts Woodruff shaft keys for added strength and precise alignment 5 HP motor coupled to an industrial oil bath worm gear drive forlongevity Heavy duty roller chain drive, no belts Heavy duty motor starter with thermal protection overloads3 5 Gallon Sealant System for sealingPittsburgh Lock (1 Gun) 5 HP Single Phase Motor (90 FPM) 3 HP Single Phase Motor (60 FPM)(18 gauge and lighter) Additional options available

V8 Snaplock Rollforming MachinesModelV8-SL20TypeButton Punch SnaplockV8-RPSL Round Pipe SnaplockLeft Outboard (Female)Right Outboard (Male)SpeedSnaplock 20-28 Gauge, 1-3/8” Notch Male Button Punch 20-28 Gauge, 7/16” Notch 90 FPMModified Reeves Lock 24-30 GaugeModified Reeves Lock 24-30 Gauge90 FPMThe VICON V8 Eight-Station Snaplock Rollformer can betooled with either Button Punch Snaplock or Round PipeSnaplock. All V8 rollformers produce seams that exceedthe standards set by SMACNA.fe atu re s&V8 Button Punch Snaplockb e n e f i t s Quietest machine in the industry Eight forming stations for all roll sets - no opening roll onany roll setV8 Round Pipe Snaplock Large, heavy duty bearings with inner races and greasefittings protect roll shafts and extend bearing life of themachine Slide out shaft design allows for easy maintenance Heavy duty 1” diameter stress proof roller shafts Woodruff shaft keys for added strength and precisealignmento p t i o n s 5 HP motor coupled to an industrial oil bath worm geardrive for longevity Crossover System: Heavy duty roller chain drive, no belts Heavy duty motor starter with thermal protection overloads(Pittsburgh & Snaplock)Two machines tooled and positioned to allow forfaster production rates of Pittsburgh & Snaplock4

V8 Slip & Drive Rollforming MachinesV8 Slip & DriveModel V8-SDReinforced Flat “S” Cleat(22-28 Gauge, 3-3/4” strip)V8 Flat “S”V8 Drive CleatModel V8-SModel V8-DDrive Cleat(20-28 Gauge, 2-1/8” strip)The Vicon V8 Slip & Drive Rollformer producesconnections that exceed the standards set bySMACNA. This eight station rollformer is equippedShown with optional slitterwith Flat “S” and Drive Cleat tooling inboard and canbe equipped with your choice of outboard toolingsuch as Pittsburgh, Snaplock, 4-in-1, or Acme Lock rollsdepending on shop requirements. An optional highspeed slitter is available to produce slips and drivesfrom scrap metal, saving labor and material.o p t i o n s Slitter Attachment 5 Gallon Sealant System for sealing Pittsburgh Lock(1 Gun) 5 HP Single Phase Motor (90 FPM) 3 HP Single Phase Motor (60 FPM) Additional options availablefe at u re s&b e n e f i t s Quietest machine in the industry Eight forming stations for all roll sets - no openingroll on any roll set Large, heavy duty bearings with inner races andgrease fittings protect roll shafts and extendbearing life of the machine Slide out shaft design allows for easymaintenance Heavy duty 1” diameter stress proof roller shafts Woodruff shaft keys for added strength andprecise alignment 5 HP/3 Phase motor coupled to an industrial oilbath worm gear drive for longevity Heavy duty roller chain drive, no belts Heavy duty motor starter with thermal protectionoverloads 90 FPM Pitch Speed5

V8 Outboard Optional ToolingOutboard Tooling OptionsLocationFemale Snaplock20-30 Gauge, 5/8” Pocket, 1-3/8” NotchProfileLeftMale Snaplock20-30 Gauge, 7/16” NotchRightSmall Pittsburgh20-28 Gauge, 5/16” Pocket, 1” NotchLeftLarge Pittsburgh18-24 Gauge, 7/16” Pocket, 1-3/8” NotchLeftLarge Pittsburgh16-20 Gauge, 7/16” Pocket, 1-3/8” NotchLeftRight Angle Flange20-28 Gauge 1/4” - 7/16”RightRight Angle Flange16-24 Gauge 1/4” - 7/16”Right4-in-1 Rolls - 22-28 Gauge,5/8” Tap-In, 5/8” Standing Seam, 9/16” Male Seam, 1/4” Male PittsburghRightAcme Lock (Double Seam)20-28 GaugeRightAcme Lock (Double Seam)16-22 GaugeRightNote: Additional profiles are available, inquire within.6

TDX RollformerT-25bThe Vicon TDX 16 Station Rollformer is tooled toproduce the T-25b transverse flange (four-bolt)connection. This profile has been evaluated by theSMACNA Testing and Research Institute and meetstesting criteria as called for in SMACNA’s HVAC DuctConstruction Standards.The TDX Rollformer is equipped with one set TDX toolingmounted left outboard and has one inboard and oneoutboard roll space available for optional tooling basedon shop requirements.Location1-1/8” 20-24 Gauge StandardStanding “S”InboardTDX Clip 2-1/4” Material 20-22 ga16 Station12 StationInboardOutboard1-5/8” 16-20 Gauge 2-in-1Standing SeamOutboard1-1/8” 18-24 Gauge 3-in-1,Tap-In-Lock, Standing Seam &Right Angle Flange (10 Stations)Outboard2” x 2” Angle,16 Gauge CapacityOutboard Large, heavy duty bearings with inner races andgrease fittings protect roll shafts and extendbearing life of the machine16-20 Gauge 7/16”Pittsburgh (8 Stations),1-3/8” NotchOutboard Slide out shaft design allows for easy maintenance Heavy duty 1-1/4” diameter stress proof rollershafts Woodruff shaft keys for added strength and precisealignment Hardened infeed guides reduce wear from plasmacut edge 7.5 HP Motor coupled to industrial oil bath gearreducer for quiet longevity Heavy duty roller chain drive, no belts18-26 Gauge 7/16”Pittsburgh (8 Stations),1-3/8”NotchOutboardSpecial Option AvailableTDX 16-24 Gauge Capacity50 FPMOutboardTDX “C” 18-26 Gauge (T-25a)Outboardfeat u re s&b e n e f i t s Sixteen (16) Forming Stations for superior quality 18 – 26 Ga. Material Capacity – no adjustmentsnecessary between gauges (16 ga option available) 70 FPM Forming Speed Independent adjustment at each forming stationwith pre-set spring tension7Tooling OptionsProfile

TDX-II RollformerT-25aThe Vicon TDX-II 12 Station Rollformer is tooledto produce the T-25a transverse flange (four-bolt)connection. This profile has been evaluated by theSMACNA Testing and Research Institute and meetstesting criteria as called for in SMACNA’s HVAC DuctConstruction Standards.The TDX-II Rollformer is equipped with one set TDX-IItooling mounted left outboard standard and has oneinboard and one outboard roll space available for optionaltooling based on shop requirements.Tooling OptionsLocation1-5/8” 20-22 Gauge Standing “S”Inboard1-1/8” 20-22 Gauge StandardStanding “S”InboardTDX Clip 20-22 Gauge2-1/4” MaterialInboard orOutboardTDX-II “C” Style 18-26 Gauge(T-25a)Outboard1-5/8” 16-20 Gauge 2-in-1Standing SeamOutboardOutboard Slide out shaft design allows for easy maintenance1-1/8” 18-24 Gauge 3-in-1,Tap-In-Lock, Standing Seam &Right Angle Flange(10 Stations) Heavy duty 1-1/4” diameter stress proof rollershafts2” x 2” Angle16 Gauge CapacityOutboard16-20 Gauge 7/16”Pittsburgh (8 Stations),1-3/8” NotchOutboard18-26 Gauge 7/16”Pittsburgh (8 Stations),1-3/8” NotchOutboardfe at u re s&b e n e f i t s Twelve (12) Forming Stations 18 – 26 Ga. Material Capacity – no adjustmentsnecessary between gauges 50 FPM Forming Speed Large, heavy duty bearings with inner races andgrease fittings protect roll shafts and extend bearing life of the machine Woodruff shaft keys for added strength and precisealignment Hardened infeed guides reduce wear from plasmacut edge 5 HP Motor coupled to industrial oil bath gearreducer for quiet longevity Heavy duty roller chain drive, no beltsProfile8

V12 Rollformer & Optional ToolingModel V12The Vicon V12 Rollformer is a twelve stationbase machine and can be custom configuredbased on shop requirements.fe at u re s&b e n e f i t s Twelve (12) Forming StationsTooling OptionsLocation1-5/8” 20-22 Gauge Standing “S”Inboard1-1/8” 20-24 Gauge StandardStanding “S”Inboard1/2” 22-26 Gauge Standing “S”Inboard 50 FPM Forming Speed Large, heavy duty bearings with inner races andgrease fittings protect roll shafts and extend bearing life of the machine Slide out shaft design allows for easy maintenance Heavy duty 1-1/4” diameter stress proof rollershafts Woodruff shaft keys for added strength andprecise alignment Hardened infeed guides reduce wear from plasmacut edge 5 HP Motor coupled to industrial oil bath gearreducer for quiet longevityTDX Clip 20-22 GaugeInboard orOutboard1-5/8” 16-20 Gauge 2-in-1Standing SeamOutboard1-1/8” 18-24 Gauge 3-in-1,Tap-In-Lock, Standing Seam &Right Angle Flange (10 Stations)Outboard2” x 2” Angle,16 Gauge CapacityOutboard Heavy duty roller chain drive, no beltsOther standard tooling options are availablewith custom tooling profiles.9Profile

Coil Strip Feed LineThe Vicon Coil Strip Feed Line can be configured inseveral ways for production of various profiles. Coilfe at u re s&b e n e f i t seither before or after the rollform machine depending Dual Drop in style Uncoiler shown. Other types ofdecoilers available.on the application. The line is controlled by the Vicon Vicon PC Cut-to-Length Controlmetal stock is uncoiled, straightened and cut to lengthPC Control to ensure accurate finished parts and canbe synchronized to the Vicon office program. Hydraulically driven three (3) roll straightener withadditional entrance and exit pinch rollsThe coil cradles and machine guides are configured so thatthe material to be processed is pre-aligned. This addedfeature minimizes your set-up time. Hydraulic Press with straight shear or contoureddiesVicon can also manufacture coil strip feed lines to producesingle wall turning vanes for elbows. Hole Punch available Hydraulic Power Unit Length tolerance of 1/16” 60” Dual Transfer Conveyor supports blanks duringthe shearing process and feeds blanks up to 60”long into the rollformero p t i o n s 120” Dual Transfer System Tooling profile will determine the requiredrollformer and processing speeds Micro processor multi-batch controllerS&DTDX Clip1/2”Standing “S”1-1/8”Standing “S”1-5/8”Standing “S”2” x 2” Angle10

Plasma FeederWith VICON patented style coil spools,coils can be loaded in under 5 ating labor through the use of the VICON PlasmaFeeding System. Uncoils, straightens, beads and feedsyour various material gauges to your plasma cuttings p e cif ic at ion s&b e n e f i t s Capable of handling up to 6 underfed coil cradlesmachine. 16 ga. to 28 ga. mild steel capacityWith the VICON style drum mandrel, the VICON PlasmaFeeder is an innovative solution for the easy loadingunderfed coils. Convenient removable coil keeper endplate is light enough for just one person to attach it tothe drum mandrel. A coil can be changed in under fiveminutes. Coil widths from 48” to 60” standardCoils will be spooled on VICON’s exclusive patented CoilDrum Assemblies for the fastest coil loading possible.The underfed unit is designed with pneumatic “backup”wheels at each coil station for positive feed-up of each coiland safe band removal on new coils. Roller track system Powered infeed guide ramp for safe, hands-free coilfeedingsupports the material of the desired coil up to the infeedguide ramp on the plasma feed unit.Overall Length*UnderfedCradle SystemOverfedCradle SystemOne Cradle17’10”12’4”Two Cradles22’2”16’8”Three Cradles26’6”21’0”Four Cradles30’10”25’4”Five Cradles35’2”Six Cradles39’6” 12,000 lbs coil capacity Hydraulic coil drive for smoother acceleration anddeceleration of coils, utilizing auto coil reversal rewindtechnology Pneumatic backup wheels at each coil station for safeband removal and positive coil feeding Choice of beading either up or down to suit shopstandards Will feed other existing plasma cutting systemso p t i o n s Individual coil drives on each cradle Overfed coil cradles available to reduce floor space 72” coil width*Not including Plasma machine11fe at u re s

Pittsburgh Seam CloserModel V-PSC-V516The Vicon Pittsburgh Seam Closer reliably closes thePittsburgh seam on duct work ranging from 16 – 26Ga. and 12” to 60” in length. The heavy-duty “SingleV” forming roll closes the Pittsburgh seam from eitherside, eliminating the need to turn the duct section overto align the Pittsburgh edge with the forming wheelsthus saving time and labor.fe at u re s&b e n e f i t s 16 to 26 Gauge material capacity 12” to 60” duct length “Single V” Forming Roll with heavy duty bearingsand shafts will close the Pittsburgh seam fromeither side eliminating the need to turn ductsection over to align the Pittsburgh edge with theforming wheels Grease fittings on the forming roll for longevity Easy to clean sealant from forming roll Counter balanced top clamp head for easy set-up(no tools required) Large, heavy-duty removable clamp pads for easyclean up of duct sealant Large, heavy-duty roller chain drive (no cables) Easy operation with manual or automatic PushButton Control Hydraulic Power Unit (not shown) 3 HP Motor (Single or 3-Phase Voltage)Replaces most existing seam closers without pit modifications.Pit dimensions provided upon request.12

Duct Brakefe at u re sModel V-TDX-BThe Vicon Duct Brake forms TDX flanged duct work withquick and easy positioning and 90 degree bending ofL-Duct Section, Full Wrapper Duct, and Fittings.&b e n e f i t s 16 Gauge x 5’ Bending Capacity Maximum 2” Liner Capacity when forming lined duct 6” x 6” minimum full wrapped, unlined duct size Pneumatic forming cycle, single foot switchoperation for TDX or S&D Manual or push button controls Timer to control bend sequences Precision heavy duty construction Adjustable height table for TDX, S&D and Raw Slip & Drive capability Front support apron Retractable notch positioning guide for self-aligningbend location and easier part removal 80 PSI / 5 CFM 115 Volt / Single Phaseo p t i o n s 36” Manual BackgaugeDuct BeaderModel V-2060-BD (20 Ga)Model V-1860-BD (18 Ga)fe at u re s&b e n e f i t sModel V-2060-BD 20 Gauge Mild Steel Capacity, 60” wide 12 inch bead increments Chain Drive 30 FPM ¼ HP Motor, 115 volt single phaseModel V-1860-BD 18 Gauge Mild Steel Capacity, 60” wide 12 inch bead increments Chain Drive 40 FPM ½ HP Motor, 115 volt single phase13o p t i o n s Foot pedal

Pneumatic CheekbenderModel V2418CBfe at u re s&b e n e f i t s Designed to form a 90 flange on either side of the unit(Optional Button Punch available) 18 Gauge mild steel maximum capacity 24” wide bending capacity Foot pedal control Inclined face for ease of use & better ergonomics Open ended allowing formation on either side as well aslonger flanges with additional cycles Welded tubular frame Replaceable, hardened wear plate for use with plasmacut edge Slide out gauge allows for 1/4” or 7/16” bendEdge NotcherModel V-EN-20 (20 Ga)Model V-EN-18 (18 Ga)fe at u re s&b e n e f i t s 18 or 20 Gauge mild steel capacities available Variable notch depth up to 1-1/4” Variable notch spacing (Factory set at 3/4”) Automatically progresses flat parts or roundpipe Voltage – 110/1/60; 1 HP Motor (20 ga model)– 220/1/60; 2 HP Motor (18 ga model) Bench mounting recommended14

ViStreamWaterjet Liner Cutting SystemSpiral PipePlasma Cutting SystemFull Coil LineModel HVAC 510 SLLiner Cutting SystemModel HVAC 510Plasma Cutting SystemVicon’s full line of HVAC manufacturing systems are specially engineered to help duct shops compete in today’s highly competitive environment.Manufacturing & Service/Vicon Machinery LLC1180 Mason Circle NorthPevely, MO 63070Tel. 636.349.8999Fax 636.326.2097Corporate Headquarters & SalesPlasma Automation Inc.Vicon Machinery LLC1801 Arctic AvenueBohemia, NY 11716Tel. 800.563.8510Fax 631.563.7239Member ofManufacturing & Software Development/Plasma Automation Inc.10346 Mercer PikeMeadville, PA 16335Tel. 814.333.2181Fax 814.333.2353www.viconmachinery.com sales@viconmachinery.com15

The Vicon line of HVAC Rollforming and Sheet Metal Equipment is the industry proven solution for all of your duct shop needs. Backed by the Vicon name and over 40 years of engineering experience, you can be assured that every Vicon machine is designed and built to provide years of quality