Transcription

Gas Shielded Welding ProcessesGas Metal Arc Welding(GMAW)Lecture 4p1

(Gas Metal Arc WeldingProcess Fundamentals In GMAW the welding heat sour is an arc maintainedbetween a consumable wire electrode and the workpiece The weld is formed by melting and solidification of thejoint edges together with filler material transferred fromthe electrode An flow of inert gas shields the high-temperature arc andweld pool from reactions with the surroundingatmosphere4p2

GMAW Process FundamentalsElectrodeShielding Gas In Directionof TravelCONSUMABLEELECTRODE/GaSNOZZleGAS , / SHIELDA P BaseMetal Lecture 4Metalp:

(GMAW Metal Transfer Modes Short Circuiting or "Dip" Transfer Globular Transfer Spray Transfer Pulsed or Synergic TransferI,p4

GMAW Short Circuiting TransferII(.) ZE Rn O --- ::: ------ - 'zoEIIARCING PERIOD Io ---rTTl'-.--.---.-i:: ------n7ize'iiRLecture 4- Timep

(GMAW Globular Transfer ModeGAS NOZZLEp ELECTRODE(IIIr '"R-Anode reactionP-Electromagnetic"pinch" forceI-II(AIRI\.I( L{ ( IIgIjVIB)(p6

GMAW Spray TransferVariation in volume and rate of drop transfer with welding current15.10·'300., "-§0.0I200I 1/16 in. (1.6 mm)II MILD STEELDROPVOLUMEII:0a!w.'"z. 0i20TRANSITIO CURRENT100 .SWIELECTRODE. DCRP::EIARGON-I% OXYGENSHIELDING GAS1/4 in. (6.4 mm)ARC LENGTH0I 10155 a.10001002003004006000600 0II:c 0.0WW::E3 EE5 0CURRENT, ALecture 4p

(GMAW Spray Transfer-p8 --- ----

GMAW Pulsed TransferPULSE PEAK NT3- --------1:JuSPRAY TRANSFERCURRENT RANGEBACKGROUND CURRENT4GLOBULAR .5 TRANSFj;R.CURRENTRANGE1 2 3 4 5 U UTIME Pulse frequency and amplitude determine wire melting rate "Synergic" control automatically gives the optimum pulseconditions for a given wire feed rateLecture 4p'

GMAW Welding Procedures( Process Variables-4Welding current (electrode melting rate)PolarityArc voltage (length)Travel speedElectrode extensionElectrode sizeShielding gas compositionp10

GMAW Electrode Melting RateC.-800c700EcLLI20-- EE-15 C600WLLI 500wa.enC.-0-300encWLLI200I&.W 3a:::0WELDING CURRENT (A)Lecture 4pl

GMAW Torch Geometry(NozzleContact Tube toWork DistanceElectrode ExtensionI \.---'--,;I\,\Arc Length'rL------,\p12

GMAW Consumables Electrode composition is usually similar todesired weld metal composition with ad9itionaldeoxidizers e.g. Si, AI, Ti Electrodes are covered by AWS and otherspecifications- Carbon steel electrodes AWS A 5.18. Shielding Gases- Various shielding gases are used depending on metalbeing welded and desired transfer mode- Principally Ar, C02 and mixtures of Ar-G02, 02 or He- Several commercial "brand-name" compositionsLecture 4pt

(GMAW TlPical Welding ProceduresCarbon Steel'QRpz?zzJl/flA?zzl T eM FB RCp14

GMAW Welding EquipmentELECTRODE SuPPLYShielding asSupplyWelding GunWorkpiece(j) WOAK WoO(i) WA1eATOQU.I i CABLEA&SEMIM.Y8HElDING OM FROM cvt.HJER()WATERFAONQUN@ WELlllNO OOHTACl'OA CONTflOlGUNSWfTCH CIACUT'" ! Lecture 4@SHfElDlNG GAS TO GUN PCMEA CAaE""""""'H'UTPOWERP 1!

(GMAW Welding GunWIRE CONOUITSHIELDING GAS PATHELECTRODEINPUT WATER LINEQoWATERCHAMBER '-- CONTACT TIPGAS NOZZLE4POWER BLOCKCONTROLSWITCHPOWER CABlE!RETURN WATERp16

GMAW Applications Aluminum alloys, copper/bronze, magnesium.titanium, austenitic stainless steels, nickelalloys Sheet metal fabrication (short circuit mode)- eg automotive, appliance, light structures General structural fabrication (spray/pulsedmode) High production, mechanised and roboticweldingLecture 4p17

(GMAW Mechanized ApplicationField welds in oil/gas transmission pipelinesWeld preparationand bead sequenceP 18

. . . . . . --. .-----. .;.,;,0;Uk----------""J----------'- "' .c .U;6lJ.1Mf; Iii!CI : .GMAW: Mechanized ApplicationsShielded WorkstationTransfer Flaskr.w,: -Welding guns & seam trackefSpent Fuel BayFuel cominerCover seal weldedafter loading .,.,oi.JUndelwalerloading stationA/i '"X:. '""''''",52"'X Fuel Bundles '. j-,/, .,.- '-{".Lecture 4p19

(GMAW: Mechanized applicationsShielded station wallWelding guns mounted onautomatic seam trackersTV CameraI'" IIr ---f: ----"- ,- 1-----.!::, J--' fl"----'1. 1II11I",1WirefeederShieldingGasI" IL---liI--- I Control"'-1 Panel1 --,IlopL-----1r----'IC""L------ft----t-".lI\1 oVideomon orp20

. . . . . . .nl"il"" · "Process ControlComponent Status,Cycle startWeld overlapSEAMTRACKERWeld Cycle TIme,Cycle endTrackingDrive g CurrentShield gas flowIdleLecture 4P21

(GMAW Capabilities & Limitations Applicable to range ofmetals andthicknesses Higher productionrates than SMAW orGTAW No flux or slagresidues Adaptable to manualor mechanized/roboticapplications- Complex equipmentand set up Wire feeding canbe temperamental- Less portable thanSMAW- Gas shield sensitive toair currents(p22

WELDING PROCESSESGAS TUNGSTEN ARCWELDING(GTAW)Lecture 4p23

(GTAW: Process Fundamentals In GTAW the welding heat source is an arcmaintained between a non-consumabletungsten electrode and the workpiece Inert gas shields the arc and weld zone fromatmospheric contamination Filler need not always be added (autogenouswelding) Filler if required is added to the weld pool in theform of wire or rod.4p24

GTAW: Process Fundamentals DIRECTION OFWELDINGSHIELDINGGAS INIARCLecture 4NON-CONSUMABLETUNGSTEN ELECTRODESOUDIFIEDWELD METALp25,

(GTAW: Process Variables Welding current- DC, pulsed DC, high frequency pulsation, AC, variablepolarity AC Arc length (Voltage) Weld travel speed Oscillation Filler addition Shielding gas composition & flow rate- generally Ar or He or mixtures.P 26

GTAW: Current Polarity DCEP is mostly used- approx 70% of heat produced at anode (workpiece) DCEN used to disperse tenacious surfaceoxides when welding AI, Mg AC also used in AI welding- variable polarity pulsed ACLecture 4

GTAW: Effect of Polarity(p28e4---- -

-.- .-.-- .------------------ . ----- .-,GTAW: Arc VoltageTUNGSTEN ARC.ALUMINUM30ARC LENGTH- - 0.08 in. (2 mm)0.16 in. (4 mm) - 25w·C) { ,200'. 15ua: {HELIUM.--!lo-"' d" 100050100 150 200 250 300 350 400ARC CURRENT, ALecture 4P 2

(Pulsed GTAW (PGTAW)pulse duration 0.1 - 1sec -r--'--- ooIt. ".I' "O.ILI "'.'-- --l::-.J- -' .--L.PeakcurrentBackgroundcurrentTIMEPulsed DC advantages:Greater penetration for given average current,f Minimizes heat affected zone & distortion,f Improved capability to weld in all positions,f,4P 30

GTAW: Gas backingLecture 4p3'

GTAW: Pipe internal purgeGAS INLET(PURGE GASOUTLET!!:: --BAFFLEPIPE,4WELD JOINTP 32

GTAW Equipment SchematicTORCHARCLecture 4ELECTRICALCONDUCTORPOWERSOURCEp3::

GTAWTorch(POWER CONDUCTORCOOLING WATER IN/OUT. 1Sl'"SHIELDING GAS INLETHANDLE/SHIELDING GAS OUTLETTUNGSTEN ELECTRODE:-4---.p34

Mechanized GTAW Applications Mechanization of- weld head travel motions- wire feed (if required)- process controls: start/stop sequence, weld current profile,shielding gas flow, etc Typical applications: Pipe, tube, tube-tubesheetwelding, longitudinal welds in formed tubes. Advantages of mechanization-Increased productivity- reduced weld defect rates- shorter joint completion times- reduced need for skilled labourLecture 4p35

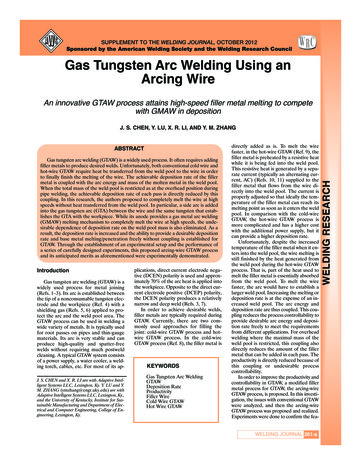

Hot Wire GTAWAUX.SHIELDING "-. GAS CON \TUBE--- AC HOTWIREPOWER(HIGH SPEED FILLERWIRE FEEDERGTAWTORCHDCGTAW .: - . POWERHEATEDWIRE4P 36

GTAW Deposition Rates20'C.c18OSCILLATION ,/ / .16:0:::::;.W Z0I-1412860a.w40,,,10(/)209HOT WIRE WITH,II"--2,",,,,765 .HOTWlRECOLD WIRE\4868-.c4 321010ARC ENERGY (kW)Lecture 4P 37

(Narrow-Gap GTAWSpecial Narrow-Gap.v.::::.-. TorchNarrow-Gap Joint .Lh4- Preparation4p38

GTAW Capabilities & Limitations Superior qualitywelds free from fluxresidues or spatter Excellent control ofpenetration Applicable to almostall metals Adaptable to manualor precisionmechanizedapplicationsLecture 4- Low deposition rates- Higher welder skillrequired in manualprocesses- Gas shieldingsensitive to aircurrentsp39

Gas Metal Arc Welding Process Fundamentals In GMAWthe welding heat sour is an arc maintained between a consumable wire electrode and the workpiece The weld is formed by melting and solidification ofthe joint edges togetherwith filler material transferred from the electrod