Transcription

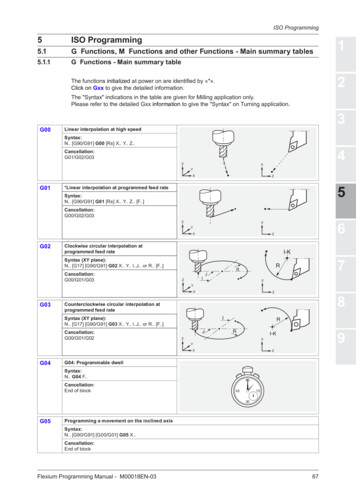

ISO Programming5ISO Programming5.1G Functions, M Functions and other Functions - Main summary tables5.1.1G Functions - Main summary table12The functions initialized at power on are identified by «*».Click on Gxx to give the detailed information.The "Syntax" indications in the table are given for Milling application only.Please refer to the detailed Gxx information to give the "Syntax" on Turning application.G003Linear interpolation at high speedSyntax:N. [G90/G91] G00 [R ] X. Y. Z.4Cancellation:G01/G02/G03ZXYXG01Z5*Linear interpolation at programmed feed rateSyntax:N. [G90/G91] G01 [R ] X. Y. Z. [F.]Cancellation:G00/G02/G03Z6XYXG02ZClockwise circular interpolation atprogrammed feed rateI-KSyntax (XY plane):N. [G17] [G90/G91] G02 X. Y. I.J. or R. lockwise circular interpolation atprogrammed feed rateSyntax (XY plane):N. [G17] [G90/G91] G03 X. Y. I.J. or R. [F.]Cancellation:G00/G01/G02IJRR9I-KZXYXG04ZG04: Programmable dwellSyntax:N. G04 F.Cancellation:End of block60451530G05Programming a movement on the inclined axisSyntax:N. [G90/G91] [G00/G01] G05 X.Cancellation:End of blockFlexium Programming Manual - M00018EN-0367

G06Spline curve execution commandSyntax:N. G06 NC.CancellationEnd of blockG07Initial tool positioning before machining along an inclined axisSyntax:N. [G90] [G00/G01] G07 X. Z.CancellationEnd of blockG09Deceleration at end of block beforecontinuation on next blockCancellationEnd of blockG10Programmedpoint reachedwith G09εpSyntax:N. G09 [G00/G01/G02/G03] X. Y. Z. [F.]With G09Without G09εpWithout G09Interruptible blockSyntax:N. [G40] [G04] [G00/G01/G02/G03] X. Y. Z. G10 [:n] [ X. or F.] [@n Value] N. [ Number] [EF.]Cancellation:End of blockG12Overspeed by handwheelSyntax:N. [G01/G02/G03] G12 X. Y. Z. [F.] [ 0 .]FeededFeCancellation:End of blockG16*Definition of the tool axis orientation withaddresses P, Q, RSyntax:N. G16 P /Q /R R Q P P-ZCancellation:G16 P /Q /R .YP XXR ZQR-G17*XY plane selectionZSyntax:N. G17Cancellation:G18/G19XYG 17XG18ZX plane selectionZSyntax:N. G18Cancellation:G17/G19GX68Y18ZXYFlexium Programming Manual - M00018EN-03

ISO ProgrammingG19YZ plane selectionZSyntax:N. G19GCancellation:G17/G18YZ119G202YX*Programming in polar coordinates (X, Z, C)Syntax:N. [G40] G20 [G00/G01] [X. Z. C.] [F.]3Cancellation:G21 and G22G21Programming in cartesian coordinates (X, Y, Z)XSyntax:N. [G40] G21 [G00/G01] [G41/G42] [X. Y. Z.][G94 F.]Cancellation:G20 and G22G224C5Programming in cylindrical coordinates (X, Y, Z)Syntax:N. [G40] G22 [G00/G01] [G41/G42] [X. Y. Z.][G94 F.]ZCancellation:G20 and G21G236CCircular interpolation defined by three points7Syntax: (XY plane)N. [G17] [G90/G91] G23 X. Y. I. J. [F.]Cancellation:End of blockTridimentional tool correction with 3 or 5 axesZSyntax:N. [D.] [G01] G29 X. Y. Z. P. Q. R.[I. J. K.] [A. /B. /C.]YZYXThread chasing cycleSyntax (XY plane):N. [G17] [M03/M04] [S.] G31 [X. Y.]Z. [ER.] [EH.] K. P. [F.] [EF.] [EC.]Cancellation:G80 to G89Flexium Programming Manual - PQR9XChaserZOPWork KG29P69

Constant lead thread cuttingSyntax:N. G33 X. Z. K. [EA.] [EB.] P. [Q.] [R.] [F.] [S.]KCancellation:End of blockXZPG33RQXZG38Sequenced thread cuttingPitchPitchSyntax:N. G38 X. Z. K.Cancellation:G00/G01/G02/G03XZG38 Resume Thread CuttingSyntax:G38 J delta posX EC posB appris K pas Z Xfin KZJCancellation:End of blockXZG39 Rigid Tap RemovalSyntax:G39 M3/4 S. K. Z. /OPCancellation:End of blockG40*Radius offset cancelTool pathSyntax:N. [G00/G01] G40 X. Y. Z.Tool centreCancellation:G29/G41/G42YXTool centreXLeft radius offsetTool pathSyntax (XY plane):N. [G17] [D.] [G00/G01/G02/G03] G41 X. Y.Cancellation:G29/G40/G42RProfileto bemachinedLEFT direction of(correction)Tool pathRYXXZRight radius offsetTool pathSyntax (XY plane):N. [G17] [D.] [G00/G01/G02/G03] G42 X. Y.Cancellation:G29/G40/G41Profileto bemachinedRYRIGHTdirection of( correction )Tool pathRXX70RIGHT(direction ofthe correction)G42Theoreticalcutting pointLEFT(direction ofthe correction)G41ZZProfile to be machinedFlexium Programming Manual - M00018EN-03

ISO ProgrammingG431Tridimensional tool correction with cylindrical toolSyntax:N. [D.] [G01] G43 X. Y. Z. P. Q. R.[I. J. K.] [A. / B. / C.]Cancellation:G40Simple pocket cycle2EXSyntax:N. G45 X. Y. Z. [ER.] EX. EY. [EB.]P. Q. [I.] [J.] [EG2/EG3] EP. EQ. EI. EJ.EBEBEXCancellation:End of blockEX3EBEYYEBEYG45XG48Spline curve interpolationSyntax:N. G48 NC. H. /N. N.4Cancellation:End of blockG49Spline curve deletion5Syntax:N. G49 NC.Cancellation:End of blockG51Mirror functionSyntax:N. G51 X- Y- Z-6G51 X –Cancellation:G51 X- Y- Z- cancelled by G51 X Y Z G51 X–YOP7G51 Y –G52Programming movements in absolutedimensions with reference to themeasurement originSyntax:N. [G40] [G90] [G00/G01] G52 X. Y. Z. A. B.C. [F.]Cancellation:End of blockG53XProgrammed pointOMZG52 . . .852GZOMYXProgrammed point9Cancellation of shifts DAT1 and DAT2Syntax:N. G53Cancellation:G54G54*Enabling of shifts DAT1 and DAT2Syntax:N. G54Cancellation:G53Flexium Programming Manual - M00018EN-0371

G59Program origin offsetOffsetSyntax:N. [G90/G91] G59 X. Y. Z. U. V. W. A. B. C.[I. J. K.]Cancellation:Cancelled by different G59 X. Y. Z.OffsetOP1OP1G5959GZOPYXXOPZOrigin ProgramG63Roughing cycle with groove(EZ)ProgrammedblankXZSyntax:N. G63 N. N. X. Z. EX. / EZ. P. / R. EA. /EU. EW. [EB.] [EC.] [ER.] [Q.] [EQ.] [EF.]Cancellation:End of blockXFinishedprofileERZG64Turn/Face roughing cycleKProgrammedblankSyntax:N. G64 N. N. [I. K.] P. / R.N. BLANK DEFINITIONICancellation:G80XFinished profileZG65Groove roughing cycleN.Syntax:N. G65 N. N. X. / Z. [I. K.] [EA.] P. / R. [Q.][EF.]Cancellation:End of blockKN.XIFinishedprofileZG66Plunging cycleSyntax:N. G66 D. X. Z. [EA.] P. / R. [EF.]D2D1Cancellation:End of blockXZRXZG70Inch data inputSyntax:N. c data inputSyntax:N. G71Cancellation:G70)mm(G71mmmm721100,2 m203040Flexium Programming Manual - M00018EN-03

ISO ProgrammingG731*Scaling factor cancelSyntax:N. [G40] G73Cancellation:G74G742Scaling factor enableSyntax:N. [G40] G74Cancellation:G73EnlargeReduceZ3YXG75Emergency retraction subroutine declarationPart programSyntax:N. G75 N.Cancellation:Cancelled by G75 N0 or different G75 N.G76PLC%30N10 G75 N300N.N.N.N . . M02N300N.N.4Emergencyretractactivation areaEmergencyretractsubroutine5Transfer of the current values of L and E parameters into the part programSyntax:N. G76 [H.] [N. N.]Cancellation :End of blockG76 /-6ISO program or block creation/deletionThe syntax specific to each function is described belowCancellation :End of blockG76 Syntax:N. G76 H.Note.G76 H bin is used to create binary files.Detailed information can be found in the FlexiumExtended Programming manual M00020.G76-%350.N110N120 G76 H123.1N130.PROGRAM AREA IN RAM%233 .%45 .%345 .%123.1 .8Program deletionSyntax:N. G76- H.G777Program creationUnconditional branch to a subroutine orsequence of blocks with returnSyntax:N. G77 [H.] [N. N.] [S.]Cancellation :End of blockFlexium Programming Manual - M00018EN-03%1050.N190N200 G76- H10.1N210.9PROGRAM AREA IN RAM%459%423%336%10.1.Main program%10N.N.N . . G77 . . .N.N.Subroutine%N.N.N.73

G77 -iCall of the subroutine return blockSyntax:N. G77 -iCancellation :End of blockG78Channel synchronisation with markersSyntax:N. G78 Q. Pj.i Pk.l .Please refer to example on page 409.Cancellation :Other G78End of programG79Conditional or unconditional jump to asequence without returnCurrent program%100N.N.N . . G79 N350N.N.N350N.N.Syntax:N. G79 [L./E. Number] N.Cancellation :End of blockG79 /-Temporary suspension of next block preparation in a sequence with movementsSyntax (XY plane)N. [G00/G01/G02/G03] X. Y. Z. G79 /- X. /F.Cancellation :End of blockG80*Machining cycle cancelSyntax:N. G80Cancellation:G31/G81-G89G81Drilling/centre drilling cycleSyntax (XY plane):N. [G17] G81 [X. Y.] Z. [ER.] [EH.] 1/G80/G81/G83-G89ZZOPXOPZPeck drilling cycleSyntax (XY plane):N. [G17] G83 [X. Y.] Z. [ER.] [EH.][P.]/[ES.] [Q.] [EP.] [F.] [EF.]Cancellation:G31/G80-G82, G84-G8974XOPCounterboring cycleSyntax (XY plane):N. [G17] G82 [X. Y.] Z. [ER.] [EH.] EF. [F.]G83ZOPZOPXZOPFlexium Programming Manual - M00018EN-03

ISO ProgrammingG841Tapping cycleSyntax (XY plane):N. [G17] G84 [X. Y.] Z. [ER.] [EH.] EF. [F.]ZCancellation:G31/G80-G83, G85-G89G84XOPOPZ2Rigid tapping cycleSyntax (XY Plane):N. [G17] [M03/M04] [M04-M05] G84 [X. Y.]Z. [ER.] [EH.] K. [EK.]3ZCancellationG31/G80-G83, G85-G89OPXX/ZOPG85Syntax (XY plane):N. [G17] G85 [X. Y.] Z. [ER.] [EH.] [F.] [EF.]Cancellation:G31/G80/G81-G84, G86-G89G864Reaming cycleZOPXBoring cycle with indexed stop and clearanceat hole bottomSyntax (XY plane):N. [G17] G86 [X. Y.] Z. [ER.] [EH.] [EC.][EA.] [EP.] [F.]6ZOPCancellation:G31/G80-G85, G87-G89YOPG877XDrilling cycle with chip breakingSyntax (XY plane):N. [G17] G87 [X. Y.] Z. [ER.] [EH.][P.]/[ES.] [Q.] [EP.] [EF.] [F.]Cancellation:G31/G80-G86, G88/G89G885ZOPZOPX8ZOP9Boring and facing cycleSyntax (XY plane):N. [G17] G88 [X. Y.] Z. [ER.] [EH.] [F.]Cancellation:G31/G80-G87/G89ZOPG89Boring cycle with Dwell at the Bottom of theholeSyntax (XY plane):N. [G17] G89 [X. Y.] Z. [ER.] [EH.] [EF.] [F.]Cancellation:G31/G80-G88Flexium Programming Manual - M00018EN-03ZOPXOPZ75

G90*Absolute dimensions with respect to theprogram originXYZSyntax:N. G90 X. Y. Z. A. B. C.XYZCancellation:G91OPG91Incremental dimensions with respect to thestart of the blockXYZSyntax:N. G91 X. Y. Z. A. B. C.XYZCancellation:G90OPG92Program origin presetCurrent pointZSyntax:N. G92 X. Y. Z.Cancellation:End of blockCurrent pointG92 . .XOP1ZXYG92 . .OP1YXOP0ZXOP0G92 S. Spindle Speed LimitingNDN. G92 S.ZCancellation:Cancelled by G92 S0 or G92 with different S.VcVcstN constantVc variableG92 R. Programming the tangential feed rateF.RininiMF.Cancellation:Cancelled by G92 R0 or by different G92 RRmSyntax:N. G92 R.Tangentialfeed rateG92Setting feed rate per axisSyntax:G92F. list of axes Cancellation:G92 F. or M02Zmm/minYXG93Feed rate in inverted of time (V/L)ZSyntax:N. G93 F. G01 X. Y. Z. A. B. C.XYY76V/DFCancellation:G94/G95ZisC axXFlexium Programming Manual - M00018EN-03

ISO ProgrammingG94inSyntax:N. G94 F. G01/G02/G03 X. Y. Z. A. B. C.Cancellation:G93/G95mm/mF (mm/min)XZYG951*Feed rate expressed in millimetres, inches ordegrees per minute2ZXFeed rate expressed in millimetres or inchesper revolutionSyntax:N. G95 F. G01/G02/G03 X. Y. Z.3FXCancellation:G93/G94mm/revZmm/revG964Constant surface speed is expressed inmeters per minuteN easesdecrXSyntax:N. G96 [X.] S.N saseincreCancellation:G94G975*Spindle speed Control (RPM)Syntax:N. G97 S. [M03/M04]6SCancellation:G96 (combined machine)7SG98Definition of the Start X for Interpolation on theC AxisX.Syntax:N. G98 X.C-G104C Tridimensional curve smoothingGeneral syntax:N. X. . Y. Z. (first point on the curve)N. [G01] G104 X.Y. Z. [F.][Intermediate points on the curve]N.G80 X. Y. Z. (last point on the curve)Cancellation:G808XCancellation:End of block9Xf Yf ZfXe Ye ZeXd Yd ZdXb Yb ZbXc Yc ZcXa Ya ZaG153 to Functions reserved for measuring cyclesG159These functions are parameterised by the machine builder.Please refer to the measuring cycles documentation.Flexium Programming Manual - M00018EN-0377

G199Programmed homingSyntax:G199 list of axes to home Cancellation:End of blockRemarkThis function is parameterised by the machine builder. Refer to the machine user's documentation.G997Enabling and execution of all functions stored in state G999Syntax:N. G997Cancellation:G998/G999G998Enabling of execution of the blocks and part of the functions processed in state G999Syntax:N. G998Cancellation:G997/G999G999Suspension of execution and forcing of block concatenationSyntax:N. G999Cancellation:G997/G99878Flexium Programming Manual - M00018EN-03

ISO Programming5.1.2M Functions - Main summary table1The functions initialized at power on are identified by «*».The miscellaneous functions listed in the table are decoded functions. Several decoded M functionscan be programmed in the same block, e.g. N. S100 M03 M40 M08.Click on Mxx to give the detailed information.The "Syntax" indications in the table are given for Milling application only.Please refer to the detailed Mxx informations to give the "Syntax" on Turning application.MSubroutine Branch by M FunctionN. M.M003Current program%50N.N.N.N . . M55N.N.Program stopSyntax:N. [G40] M01 [ 0 .]M01Program78End of programSyntax:N. M02M036%12N.N.N.N . . M01N.Cancellation:Action on the machine panel CYCLE keyM025%25N.N.N . .M00N.N.Cancellation:Action on the machine panel CYCLE keyOptional stop4Subroutine%255N.N.N.ProgramSyntax:N. [G40] M00 [ 0 .]M01%50N.N.N.N.N . . M029Spindle clockwise rotationSyntax:N. M03Cancellation:M04/M05/M00/M19M03M03Flexium Programming Manual - M00018EN-03279

M04Spindle counterclockwise rotationSyntax:N. M04M04Cancellation:M03/M05/M00/M19M04M05*Spindle offSyntax:N. M05Cancellation:M03/M04M06Tool changeSyntax:N. T. [D.] M06 [ 0. / (.)]T.M06Cancellation:M function report (CRM).M06T.M07T.T.Coolant 2 onSyntax:N. M07Cancellation:M09.M08M07M08Coolant 1 onM08M07See figure above.Syntax:N. M08Cancellation:M09M09*Coolant offSyntax:N. M09Cancellation:M07/M08M102112ClampSyntax:N. [G00/G01/ G02/ G03] M10 X. Y. Z. A. B.C.Cancellation:M11M11UnclampSyntax:N. M11Cancellation:M1080Flexium Programming Manual - M00018EN-03

ISO ProgrammingM12Programmed feed stop1M12Syntax:N. M12 [ 0.]FEED STOPCancellation:Press CYCLE on the machine panel2M19Indexed Spindle StopFixed indexing pointSyntax:N. [S.] [M03/M04] EC . 0/M41/M42/M43/M44/M45Spindle speed rangesM48*Spindle speed and feed rate potentiometerenable4Syntax:N. [S.] [ M03/M04] M40 to M45Cancellation:Cancel one another5100%100%Syntax:N. M486Cancellation:M49Spindle speedM49Spindle speed and feed rate potentiometerenable inhibitFeed rate7See figure above.Syntax:N. M49Cancellation:M48M618Release the current spindle in the channelSyntax:N. M61Cancellation:M62-M65M64/M65/M62/M63Control of spindles 1 to 4 (*M64)M66/M67/M68/M69Spindle 1 to 4 measurement (*M66)9Syntax:N. [S.] M62/M63/M64/M65 [M40-M45] M03/M04Cancellation:Cancel one anotherSyntax:N. [S.] M66/M67/M68/M69Cancellation:Cancel one another.Flexium Programming Manual - M00018EN-0381

M997Forced block consecutive executionProgramSyntax:N. 70 M997N80N90N100N.*Reactivation of MDI mode and subroutine calls by the automatic control functionSyntax:N. M998Cancellation:M997/M999M999Programmed cancellation of MDI mode and subroutine calls by the automatic control functionSyntax:N. M999Cancellation:M997/M998/M0282Flexium Programming Manual - M00018EN-03

ISO ProgrammingD.Other Functions - Main summary table1Tool Offset activationXSyntax:N. [G17] [G16 R ] D. [G40/G41/G42] X. Y. Z.XSpindledatumLength L . .Cancellation:D0 , M02 or new tool offset2ZTool tipradius @.Radius R . .DAT3TurretreferenceZDimension X . .5.1.3DimensionZ .Radius R . .3Milling Table offsetRotaryaxisB, C)DAT3OP0,(AXYZ4XYZDAT3OpPart zero pointEA.Angle element of a lineEA-EA YXEB 5X or ZX or YEA EA-XX or ZZX or Y6Fillet between two interpolationsSyntax:N. G01/G02/G03 X. Y. I. J. / R. [F.] EB . [EF.]EBCancellation:End of blockEB7EBEBYX (Z)Chamfer between two linearinterpolationsEBEB YXXED.Programmed angular offsetSyntax:N. [G90/G91] ED.Cancellation:Programming of a new value, M02, reset.Flexium Programming Manual - M00018EN-039 Cancellation:End of block8 Syntax:N. G01 X. Y. [F.] EB-. [EF.]EB EB-EBZYED . .OPX83

EF100EB EB EB –F200Cancellation:Programming of a new value, M02, reset.EF0.08F150YEB –XXEG.EF0.1F0.2F0.3EF80Syntax:N. Interpolation EB . / EB-. EF.1F0Feed rate specific to fillets EB andchamfers EB-.F100EFZProgrammed acceleration reductionSyntax:N. EG.Cancellation:Programming of a new value, M02, reset.EG . .ESSecant elementLine / CircleESLine/circleESESYLine/lineXETESXTangent elementLine / CircleETLine/circleETYXETCircle/circleXE /E- E EAE-XYEAXZCoordinates of the centre of a circleYI-JXIKZXSubroutine branch by M functionSyntax:N. M.84 (D)(D)E-M.ETCircle / CircleZDiscriminantE I. J.K.Line / LineZCurrent program%50N.N.N.N . . M55N.N.Subroutine%255N.N.N.Flexium Programming Manual - M00018EN-03

ISO ProgrammingR.1Radius of a circleRYRXX./Y.,Z. orX. Y.,Z.Coordinates of the end point of a lineXYX or YYMessage Transmission to the displaySyntax:N. EG.Cancellation:Programming end program, M02, reset./Block skipSyntax:/ N. (Contents unimportant)3XZX or ZXX 02ZXZ4Program%56N. 0 MessageN.5MessageProgram6%50N.N./N . ./N . ./N . .N.789Flexium Programming Manual - M00018EN-0385

5.1.4Word Format - Main summary tableThe formats of the axis words specified in the table are expressed as follows:- For linear axes: 5 digits to the left and 3 to the right of the decimal point are allowed when theinternal system unit (see chapter 3.1) is µm.- For rotary axes: 3 digits to the left and 4 to the right of the decimal point are allowed when theinternal system unit is 0.0001 degree.For instance, for linear axes: if the system is set to 0.1µ (internal unit), the formats are expressedwith 4 decimal digits; for the X axis, the format is X 044.For instance, for rotary axes: if the system is set to 0.001 degree (internal unit), the formats areexpressed with 3 decimal digits; for the B axis, the format is B 033.For the words related to the machining feed rate with no assigned formats (F., EF.), refer to themachine manufacturer’s manual for the maximum and minimum feed rates (maximum 8 digits anddecimal point).86FormatDescription%051Program number (1 to 99999.9)N05Sequence number (1 to 2147483647)G02G03Preparatory functions (0 to 99)Preparatory functions (100 to 250 and 997 to 999)H05Subroutine number (with G77, G76 and G48)X 053Movement on the X axis. In a cycle, end point on the machining axis (. plane)Y 053Movement on the Y axis. In a cycle, end point on the machining axis (. plane)Z 053Movement on the Z axis. In a cycle, end point on the machining axis (. plane)I 053J 053K 053For circular/helical interpolation (G02, G03), centre of the circle and pitch of the helixWith programmed origin offset (G59), centre of rotation and angular offset (ED)For thread chasing cycle (G31), thread pitch I, J or K depending on the interpolation planeI053For pocket cycle (G45), axial finishing passJ053For pocket cycle (G45), lateral finishing passK053For leadscrew tapping cycle (G84), tap pitchU 053Movement on the U axisV 053Movement on the V axisW 053Movement on the W axisA 034Movement on the A axisB 034Movement on the B axisC 034Movement on the C axisE /E-For profile geometry programming (PGP), discriminantEA 033EA 033EA 033For profile geometry programming (PGP), line angleIn a boring cycle with indexed spindle stop (G86), angle between EC. and tool cutting edgeIn polar programming, angle of the lineEB 053EB-053EB053For contour definition and PGP, radius or fillet between two interpolationsFor contour definition and PGP, chamfer between two linear interpolationsFor profile Geometry Programming (PGP), chamfer between 2 linesEC 033EC 033EC 033For spindle indexing (M19), indexing angleFor thread chasing cycle (G31), tool orientation in the hole bottomFor boring cycles (G86), indexing positionED 034Programmed angular offsetEF022EF.EF.EF.For cycles (G82, G84, G87, G89 or G31), dwell timeIn a reaming cycle (G85), retraction rateFeed rate specific to fillets (EB ) or chamfers (EB-)Maximum feed rate after an interrpt (G10)EG01Pocket cutting direction (EG02: clockwise; EG03: counterclockwise)Flexium Programming Manual - M00018EN-03

ISO Programming1EG03For interpolation, acceleration modulationEH 053In (G8x) cycles, dimension of the impact plane on the machining axisEI 053EI.In polar programming, length of the line (start/circle center)In a pocket cycle (G45), axial finishing feed rateEJ.In a pocket cycle (G45), lateral finishing feed rateEK01For rigid tapping cycle (G84), retraction/penetration speed ratioES /ES-For profile geometry programming (PGP), secant elementET /ET-For profile geometry programming (PGP), tangent elementEP053EP053EP053EP.In a boring cycle with indexed spindle stop (G86), lateral backoff in hole bottomIn a peck drilling cycle (G83), backoff clearance after each peckIn a drilling cycle with chip breaking (G87), backoff between two infeedsIn a pocket cycle (G45), axial roughing feed rateEQ053For pocket cycle (G45), lateral roughing feed rateER 053In cycles, infeed or retraction dimension on the machining axisES02In cycles G83 and G87, number of infeeds at constant valueEX 053EX053In polar programming, angle of the line (start/end)For pocket cycle (G45), dimension along X (or U)EY053For pocket cycle (G45), dimension along Y (or V)EZ053For pocket cycle (G45), dimension along Z (or W)5P 053P 043P053P043P041P / P-For thread chasing cycles (G31), withdrawal of toolFor 3D correction (G29), X component of the normal vectorFor cycle (G83 or G87), value of the first penetrationFor pocket cycles (G45), axial roughing pathWith axis channel synchronisation (G78), wait for a markerTool axis orientation (G16), along X (or U)6Q 053Q 043Q043Q04Q / Q-For cycles (G83 or G87), value of the last penetrationFor correction in space (G29), Y component of the normal vectorFor pocket cycle (G45), lateral roughing passWith channel synchronisation (G78), declaration of a markerTool axis orientation (G16), along Y or V7R 053R053R 043R / RR / R-For circular/helical interpolation (G02, G03), radius of the circleFor tangential feed rate programming (G92), value of the curve radiusFor space correction (G29), Z component of the normal vectorFor linear interpolation (G00, G01), positioning at programmed distanceTool axis orientation (G16), along Z or W8F.F.F.F.F.F022F01Feed rate in mm/min and degrees/min (G94)Feed rate in inches/min (G94)Feed rate in mm/rev (G95)Feed rate in V/L (G93)Feed rate in inches/revolution (G95)Dwell in seconds (G04)For thread chasing cycles (G31), number of threads (1 to 9)M02M03Miscellaneous functions 0 to 99Miscellaneous functions 100 to 899NC04For spline curve interpolation (with G06, G48, G49), curve number (1 to 9999)S05 orS032S02Spindle rotation speed in rpm (G97)T08Tool number (0 to 99999999)D03Correction number (0 to 255)L03Program variables L (0 to 19, 100 to 199 and 900 to 959)E5External parameters E2349In a subroutine branch (G77), number of subroutine iterations (1 to 99)Flexium Programming Manual - M00018EN-0387

5.2Programming with Reference to Diameter or RadiusThe part program and certain data related tomachining along the X (or U) axis are directly affectedby whether programming is with reference to diameteror radius.XPoint a5.2.1XaIn both cases, certain functions are always expressedwith respect to diameter and others with respect toradius.XaProgramming with reference to diameter or radius isselected by the machine builder.OPSystem Programmed with Reference to DiameterProgrammed values expressed with reference to diameter: values programmed in absolute dimensions (G90): coordinates of a movement along X. andposition I. of the centre of a circle, value of the starting diameter with constant surface speed (G96), value programmed with function G98.Programmed values expressed with reference to radius: values programmed in incremental dimensions (G91): value of a movement along X. andposition I. of the centre of a circle, circle radius with circular interpolation (R), fillet or chamfer (EB , EB-), pass depth for roughing cycle (P or R), machining allowance for roughing cycles (I or K), (ER), positioning clearance for roughing cycle (Q), minimum depth of cut for roughing cycle (EQ), thread depth (P) and last pass for thread cutting (Q), pass depth for drilling cycle (P and Q), offsets programmed with functions G59 and G52.Tool dimensions: Entry of values with respect to radius.Dynamic tool corrections: Entry of values with respect to diameter, but display of radial change on the «context "Tools"»page.Value of offset DAT2: Entry of the value with reference to radius.Movements related to the manual controls: Movements on the X axis with reference to radius, but display with reference to diameter on the«context "production"» page.5.2.2System Programmed with Reference to RadiusValues expressed with reference to radius: All the programmed movements applied to the X axis and all the values entered related tomachining along X.Values expressed with reference to diameter: Only the dynamic tool corrections on X are entered with reference to diameter.88Flexium Programming Manual - M00018EN-03

5 ISO Programming 5.1 G Functions, M Functions and other Functions - Main summary tables 5.1.1 G Functions - Main summary table The function. s initialized at power on are identified by «*». Click on Gxx to give the detailed information. The "Syntax" indicat