Transcription

Sheet Moulding CompoundBulk Moulding Compoud

SMC, The process

Equipment Mixer (type cowles dissolver) with vessel 400-1000 liter withdrain

Equipment Meetering pump to dose thickening agent (MgO paste) Pump and piping to connect mixing vessel to SMC machine SMC machine Glass roving rack and guiding tubes

Raw materials Glass rovingPe/Nylon/PE foilUnsaturated polyester resin (thickenable with MgO)Low shrink addive (e.g.solution of polystyrene in styrene)Low profile additive (PVAc solution or saturated polyester)Catalyst (TBPB)Internal release agent (Zinc stearate)Filler (Calcium carbonate, Dolomite, ATH, Talcum,Colour pasteThickening agent (Magnesium oxide)

Starting formulation general purpose SMCIngredientpbwOrtho phthalic resinStyreneTrigonox. CPoly ethylene powderZn stearatePigmentpasteCa carbonateMgO paste10051,55551603Glass 25 mm25% on paste

Starting formulation for Electrical boxesIngredientPbwPolyester resinPolystyrene solutioBYK W 996PBQ 10%Trigonox CPigment pastePolyethylene powdZn stearateATH courseATH fineMgO paste Luvatol MK 3565352,30,31,21045Glass roving 25 mm27% on paste1002,150

Starting formulation car body panelsIngredientpbwPure Maleic resin65,5Saturated polyester solution28PVAC solution2Styrene4,5BYK W 9962,9PBQ 10%0,7Co octoate 1%1,1Trigonox C1Ca stearate5,5Ca carbonate145Ca carbonate BLR380MgO paste2,6Glass roving 25 mm28% on paste

Thickening with MgO

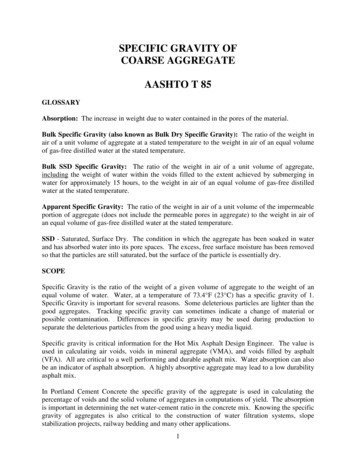

Thickening of SMC paste with MgO200 x 10E6Viscosity 23 C [mPa.s]160 x 10E6120 x 10E680 x 10E640 x 10E60 x 10E6051015Time [days]202530

Influence of MoistureMoisture:The moisture content of the UP resin,or filler can play an important role inthe final thickening level(hydrogen bonds)Moisture accelerates the thickeningin the initial stage, but stops thethickening (too) earlyNot enough moisture causes higherplateau viscosity .

Special requirements for UP resin High reactivityLow OH valueSmall limits for Acid valueReproducible thickening with MgOLow water contentResin has to be adapted for use in SMC.Selection in close co operation with resin supplierThe thickening of each batch has to be checked by thesupplier.The thickening figures have to be mentioned on the batchreport.

Resin specifications example

Special requirement for fillers Controlled particle size distribution Average particle size 20 micron Low humidity ( 0.2%) Equal whiteness from batch to batch

Requirements MgO paste Supplier have to check every new batch with an approvedstandard resin.Fgures have to be on the certificate of analysisStandard resin have to be refreshed every 6 month afterchecking the thickening efficiency compared with theprevious resin.

Capacity Hydraulic press For simple flat partsFor complicated partsFor Class A parts30-50 kg/square cm50- 80 kg/square cm60-100 kg/square cmPressure on projected surface ofthe mould!!

Moulds Material: SteelTreatments : Female mould: hardened edgesBoth moulds have to be chrome plated Placed on hot plate or provided with heating elements Clearance at working temperature : 0,05 – 0,2 mm Isolation plates between press table surface and heatingplates or heated moulds.

Appearence of ready made SMC

Mould for kitchen sinks

BMC Bulk Moulding Compound

BMC Kneader

BMC Kneader

Comparison SMC BMC formulationsIngredientSMCBMCPolyester resinLS additiveCatalystrelease agentpigment pasteFillerThickening agent65351.25101502.570 *)301.2510300--Glass fiber 25 mmGlass fiber 12 mm*) Thickenability not required27% on paste---12% on paste

Processing BMC Hydraulic Press Injection Machine

Head lamp reflectors

Optical engine chasis

Iron foot

Advantages of BMC Short cycle times Integration of functions Electric isolation Pigmented Excellent processable

Special requirements for UP resin High reactivity Low OH value Small limits for Acid value Reproducible thickening with MgO Low water content Resin has to be adapted for use in SMC. Selection in close co operation with resin supplier The thickening of each batch has to be checked by the supplier.