Transcription

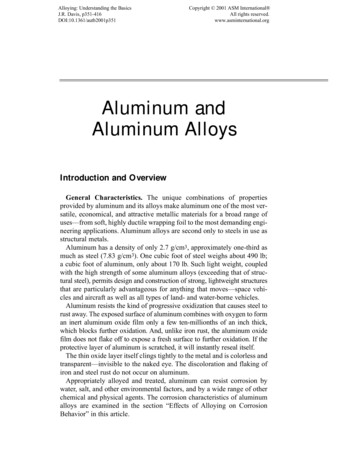

Alloying: Understanding the BasicsJ.R. Davis, p351-416DOI:10.1361/autb2001p351Copyright 2001 ASM International All rights reserved.www.asminternational.orgAluminum andAluminum AlloysIntroduction and OverviewGeneral Characteristics. The unique combinations of propertiesprovided by aluminum and its alloys make aluminum one of the most versatile, economical, and attractive metallic materials for a broad range ofuses—from soft, highly ductile wrapping foil to the most demanding engineering applications. Aluminum alloys are second only to steels in use asstructural metals.Aluminum has a density of only 2.7 g/cm3, approximately one-third asmuch as steel (7.83 g/cm3). One cubic foot of steel weighs about 490 lb;a cubic foot of aluminum, only about 170 lb. Such light weight, coupledwith the high strength of some aluminum alloys (exceeding that of structural steel), permits design and construction of strong, lightweight structuresthat are particularly advantageous for anything that moves—space vehicles and aircraft as well as all types of land- and water-borne vehicles.Aluminum resists the kind of progressive oxidization that causes steel torust away. The exposed surface of aluminum combines with oxygen to forman inert aluminum oxide film only a few ten-millionths of an inch thick,which blocks further oxidation. And, unlike iron rust, the aluminum oxidefilm does not flake off to expose a fresh surface to further oxidation. If theprotective layer of aluminum is scratched, it will instantly reseal itself.The thin oxide layer itself clings tightly to the metal and is colorless andtransparent—invisible to the naked eye. The discoloration and flaking ofiron and steel rust do not occur on aluminum.Appropriately alloyed and treated, aluminum can resist corrosion bywater, salt, and other environmental factors, and by a wide range of otherchemical and physical agents. The corrosion characteristics of aluminumalloys are examined in the section “Effects of Alloying on CorrosionBehavior” in this article.

352 / Light Metals and AlloysAluminum surfaces can be highly reflective. Radiant energy, visiblelight, radiant heat, and electromagnetic waves are efficiently reflected,while anodized and dark anodized surfaces can be reflective or absorbent.The reflectance of polished aluminum, over a broad range of wavelengths, leads to its selection for a variety of decorative and functionaluses.Aluminum typically displays excellent electrical and thermal conductivity, but specific alloys have been developed with high degrees of electrical resistivity. These alloys are useful, for example, in high-torqueelectric motors. Aluminum is often selected for its electrical conductivity,which is nearly twice that of copper on an equivalent weight basis. Therequirements of high conductivity and mechanical strength can be met byuse of long-line, high-voltage, aluminum steel-cored reinforced transmission cable. The thermal conductivity of aluminum alloys, about 50 to 60%that of copper, is advantageous in heat exchangers, evaporators, electrically heated appliances and utensils, and automotive cylinder heads andradiators.Aluminum is nonferromagnetic, a property of importance in the electrical and electronics industries. It is nonpyrophoric, which is important inapplications involving inflammable or explosive-materials handling orexposure. Aluminum is also non-toxic and is routinely used in containersfor food and beverages. It has an attractive appearance in its natural finish,which can be soft and lustrous or bright and shiny. It can be virtually anycolor or texture.The ease with which aluminum may be fabricated into any form is oneof its most important assets. Often it can compete successfully withcheaper materials having a lower degree of workability. The metal can becast by any method known to foundrymen. It can be rolled to any desiredthickness down to foil thinner than paper. Aluminum sheet can bestamped, drawn, spun, or roll formed. The metal also may be hammeredor forged. Aluminum wire, drawn from rolled rod, may be stranded intocable of any desired size and type. There is almost no limit to the different profiles (shapes) in which the metal can be extruded.Alloy Categories. It is convenient to divide aluminum alloys into twomajor categories: wrought compositions and cast compositions. A furtherdifferentiation for each category is based on the primary mechanism ofproperty development. Many alloys respond to thermal treatment based onphase solubilities. These treatments include solution heat treatment,quenching, and precipitation, or age, hardening. For either casting orwrought alloys, such alloys are described as heat treatable. A large numberof other wrought compositions rely instead on work hardening throughmechanical reduction, usually in combination with various annealing procedures for property development. These alloys are referred to as workhardening. Some casting alloys are essentially not heat treatable and are

Aluminum and Aluminum Alloys / 353used only in as-cast or in thermally modified conditions unrelated to solution or precipitation effects.Cast and wrought alloy nomenclatures have been developed. TheAluminum Association system is most widely recognized in the UnitedStates. Their alloy identification system employs different nomenclaturesfor wrought and cast alloys, but divides alloys into families for simplification. For wrought alloys a four-digit system is used to produce a list ofwrought composition families as follows: 1xxx: Controlled unalloyed (pure) composition, used primarily in theelectrical and chemical industries2xxx: Alloys in which copper is the principal alloying element,although other elements, notably magnesium, may be specified. 2xxxseries alloys are widely used in aircraft where their high strength(yield strengths as high as 455 MPa, or 66 ksi) is valued.3xxx: Alloys in which manganese is the principal alloying element,used as general-purpose alloys for architectural applications and various products4xxx: Alloys in which silicon is the principal alloying element, used inwelding rods and brazing sheet5xxx: Alloys in which magnesium is the principal alloying element,used in boat hulls, gangplanks, and other products exposed to marineenvironments6xxx: Alloys in which magnesium and silicon are the principal alloying elements, commonly used for architectural extrusions and automotive components7xxx: Alloys in which zinc is the principal alloying element (althoughother elements, such as copper, magnesium, chromium, and zirconium,may be specified), used in aircraft structural components and otherhigh-strength applications. The 7xxx series are the strongest aluminumalloys, with yield strengths 500 MPa ( 73 ksi) possible.8xxx: Alloys characterizing miscellaneous compositions. The 8xxx seriesalloys may contain appreciable amounts of tin, lithium, and/or iron.9xxx: Reserved for future useWrought alloys that constitute heat-treatable (precipitation-hardenable)aluminum alloys include the 2xxx, 6xxx, 7xxx, and some of the 8xxxalloys. The various combinations of alloying additions and strengtheningmechanisms used for wrought aluminum alloys are shown in Table 1. Thestrength ranges achievable with various classes of wrought and cast alloysare given in Tables 2 and 3.Casting compositions are described by a three-digit system followed by adecimal value. The decimal .0 in all cases pertains to casting alloy limits.Decimals .1, and .2 concern ingot compositions, which after melting and processing should result in chemistries conforming to casting specificationrequirements. Alloy families for casting compositions include the following:

354 / Light Metals and Alloys 1xx.x: Controlled unalloyed (pure) compositions, especially for rotormanufacture2xx.x: Alloys in which copper is the principal alloying element. Otheralloying elements may be specified.3xx.x: Alloys in which silicon is the principal alloying element. Theother alloying elements such as copper and magnesium are specified.The 3xx.x series comprises nearly 90% of all shaped castings produced.4xx.x: Alloys in which silicon is the principal alloying element.5xx.x: Alloys in which magnesium is the principal alloying element.6xx.x: Unused7xx.x: Alloys in which zinc is the principal alloying element. Otheralloying elements such as copper and magnesium may be specified.8xx.x: Alloys in which tin is the principal alloying element.9xx.x: UnusedHeat-treatable casting alloys include the 2xx, 3xx, and 7xx series.Tables 4 and 5 list nominal compositions for representative wrought andcast aluminum alloys. It should be noted that the alloy compositions listed in these tables make up a rather small percentage of the total amountof compositions developed. More than 500 alloy designations/compositions have been registered by the Aluminum Association Inc. for aluminum alloys. Composition limits for these alloys can be found in theMetals Handbook Desk Edition, 2nd ed., (see the article “ChemicalCompositions and International Designations on pages 426–436) and inRegistration Records on wrought alloys, castings, and ingots published bythe Aluminum Association.Table 1 Classification of wrought aluminum alloysaccording to their strengthening mechanismAlloy systemAluminum seriesWork-hardenable alloysPure 8xxxPrecipitation-hardenable xx

Aluminum and Aluminum Alloys / 355Applications. Aluminum alloys are economical in many applications.They are used in the automotive industry, aerospace industry, in construction of machines, appliances, and structures, as cooking utensils, as covers for housings for electronic equipment, as pressure vessels forcryogenic applications, and in innumerable other areas. Tables 6 and 7 listtypical applications for some of the more commonly used wrought andcast alloys, respectively.Table 2 Strength ranges of various wrought aluminum x5xxx5xxx6xxx7xxx7xxx8xxxType ofalloycompositionAlAl-Cu-Mg(1–2.5% Cu)Al-Cu-Mg-Si(3–6% Cu)Al-Mn-MgAl-SiAl-Mg(1–2.5% Mg)Al-Mg-Mn(3–6% ningmethodTensilestrength rangeMPaksiCold workHeat treat70–175170–31010–2525–45Heat treat380–52055–75Cold workCold work(some heattreat)Cold 40Cold work280–38040–55Heat treatHeat treatHeat treatHeat –7575–9040–80Table 3 Strength ranges of various cast aluminum alloysTensile strength rangeAlloy system (AA 31033–4340–45138–22120–32Heat treatable sand cast alloys (various tempers)Al-Cu (201–206)Al-Cu-Ni-Mg (242)Al-Cu-Si (295)Al-Si-Cu (319)Al-Si-Cu-Mg (355, 5% Si, 1.25% Cu, 0.5% Mg)Al-Si-Mg (356, 357)Al-Si-Cu-Mg (390, 17% Si, 4.5% Cu, 0.6% Mg)Al-Zn (712, 713)Non-heat treatable die cast alloysAl-Si (413, 443, F temper)Al-Mg (513, 515, 518, F temper)Non-heat treatable permanent mold cast alloysAl-Sn (850, 851, 852, T5 temper)

356 / Light Metals and AlloysTable 4 Product forms and nominal compositions of common wrought aluminum alloysComposition, ct(a)DTS, P, ET, DTS, P, F, E, ES, ET, C, DT, FGS, P, FFS, P, E, ES, ET, CE, ES, ET, C, DTS, P, E, ES, ET, C, DT, FGS, P, E, ES, ET, C, DTSS, PPFGS, P, E, ES, ET, C, FGCFGS, P, F, E, ES, ET, C, DT, FGS, P, ET, DTSFGCS, P, CS, P, C, DTS, P, F, C, DTF, CS, P, E, ES, ET, FGS, P, E, ES, ET, DTS, P, E, ES, ET, C, DTSSS, PCS, P, E, ES, ETS, P, E, ES, ET, DT, FGSS, PSE, ES, ETSSS, P, E, ES, ET, C, DT, FGE, ES, ET, DTE, ES, ET, DT, FGE, ES, ETE, ES, ETFGCE, ES, ETE, ES, ET, C, DTE, ESE, ESE, ESP, E, ES, FGP, E, ES, FGS, FS, P, E, ES, ET, C, DT, FGS, P, FGS, P, E, ES, CS, P, FGAl99.50 min99.60 min99.00 min99.45 min99.99 min99.50 0.090.088.190.3SiCuMnMgCrZnOthers 0.8 0.18 12.25.2 0.80.81.00.60.41.41.40.50.90.70.80.61.00.4 1.5 0.12 5.54.44.42.63.34.44.06.36.32.30.12 0.9 0.350.350.28 1.00.28 0.28 1.52.3 1.61.62.0 0.80.60.250.40.6 0.30.3 1.21.20.55 0.120.70.4 0.35 0.120.80.80.3 0.50.5 0.80.7 0.1 0.6 0.45 0.51.50.451.51.51.5 1.6 1.00.501.0 50.60.81.00.71.10.80.60.60.80.51.00.60.71.42.52.3 2.52.52.72.3 0.250.120.150.150.25 0.250.120.120.12 0.25 0.2 0.25 0.10.09 0.130.15 0.230.230.260.22 4.57.66.21.05.65.66.85.7 0.4 Bi; 0.4 Pb 2.0 Ni0.06 Ti; 0.10 V; 0.18 Zr0.18 Zn; 0.15 Ti; 0.10 V1.1 Fe; 1.0 Ni; 0.07 Ti 0.9 Ni 0.13 Ti 0.1 Zr0.6 Bi; 0.6 Pb 0.04 Ti; 0.14 Zr 0.12 Zr (a) S, sheet; P, plate; F, foil; E, extruded rod, bar and wire; ES, extruded shapes; ET, extruded tubes; C, cold finished rod, bar and wire; DT, drawntube; FG, forgings

Aluminum and Aluminum Alloys / 357Wrought Alloy ClassesAs described in the “Introduction and Overview” to this article, aluminum alloys are commonly grouped into an alloy designation series. Thegeneral characteristics of the wrought alloy groups are described below.Strength ranges, nominal compositions, and applications for wrought aluminum alloys are listed in Tables 2, 4, and 6, respectively.1xxx Series. Aluminum of 99.00% or higher purity has many applications, especially in the electrical and chemical fields. These grades of aluminum are characterized by excellent corrosion resistance, high thermalTable 5 Designations and nominal compositions of common aluminum alloys used for castingComposition, 535.0A535.0B535.0712.0713.0771.0850.0Product(a)SS or PS or PSS or PSPS or PS or PPPS or PS or PS or PS or PS or PS or PS or PDDDDDDDDS or PDDSSS or PDSDSSSSS or PS or PSS or .20(b) 3.53.52.53.83.84.54.5 0.6(b)0.30(b)0.15(b)0.6(b) 0.7 1.0Mg0.350.250.25 1.5 1.00.500.500.500.320.350.500.60.60.500.50 0.60.6 4.08.010.06.87.07.00.60.350.9 (a) S, sand casting; P, permanent mold casting; D, die casting. (b) MaximumMn0.350.350.35 0.50(b)0.10(b)0.35(b)0.10(b) 0.180.18 SiOthers 0.10(b)0.05(b)3.0 .510.511.211.217.017.012.012.05.25.25.25.2 0.7 Ag, 0.25 Ti0.22 Ti, 0.15 Fe(b)0.22 Ti, 0.10 Fe(b) 2.0 Ni 2.5 Ni 0.6 Fe(b), 0.35Zn(b)0.20 Fe(b), 0.10Zn(b)0.6 Fe(b), 0.35 Zn(b)0.20 Fe(b), 0.10 Zn(b) 0.15 Ti, 0.005 Be 2.0 Fe(b)1.3 Fe(b)2.0 Fe(b)1.3 Fe(b) 3.0 Zn(b)1.0 Zn(b)1.3 Zn(b)0.5 Zn(b)2.0 Fe(b)1.3 Fe(b) 2.0 Fe(b) 0.18 Ti 0.18 Ti5.8 Zn, 0.5 Cr, 0.20 Ti7.5 Zn, 0.7 Cu7.0 Zn, 0.13 Cr, 0.15 Ti6.2 Sn, 1.0 Ni

358 / Light Metals and AlloysTable 6Alloy110013502011201420172024221930033004Selected applications for wrought aluminum alloysDescription and selected applicationsCommercially pure aluminum highlyresistant to chemical attack andweathering. Low cost, ductile fordeep drawing, and easy to weld.Used for high-purity applicationssuch as chemical processingequipment. Also for nameplates,fan blades, flue lining, sheetmetal work, spun holloware,and fin stockElectrical conductorsScrew machine products. Applianceparts and trim, ordnance, automotive, electronic, fasteners,hardware, machine partsTruck frames, aircraft structures,automotive, cylinders and pistons, machine parts, structuralsScrew machine products, fittings,fasteners, machine partsFor high-strength structural applications. Excellent machinability inthe T-tempers. Fair workabilityand fair corrosion resistance.Alclad 2024 combines the highstrength of 2024 with the corrosion resistance of the commercially pure cladding. Used fortruck wheels, many structuralaircraft applications, gears formachinery, screw machineproducts, automotive parts,cylinders and pistons, fasteners,machine parts, ordnance, recreation equipment, screws andrivetsStructural uses at high temperature (to315 C, or 600 F). Highstrength weldmentsMost popular general-purpose alloy.Stronger than 1100 with samegood formability and weldabilty.For general use including sheetmetal work, stampings, fueltanks, chemical equipment, containers, cabinets, freezer liners,cooking utensils, pressure vessels, builder’s hardware, storagetanks, agricultural applications,appliance parts and trim, architectural applications, electronics,fin stock, fan equipment, nameplates, recreation vehicles, trucksand trailers. Used in drawingand spinning.Sheet metal work, storage tanks, agricultural applications, buildingproducts, containers, electronics,furniture, kitchen equipment,recreation vehicles, trucks n and selected applicationsResidential siding, mobile homes,rain-carrying goods, sheet metalwork, appliance parts and trim,automotive parts, building products, electronics, fin stock,furniture, hospital and medicalequipment, kitchen equipment,recreation vehicles, trucks andtrailersSpecified for applications requiringanodizing; anodized coating iscleaner and lighter in color than3003. Uses include appliances,utensils, architectural, applications requiring good electricalconductivity, automotive parts,containers, general sheet metal,hardware, hospital and medicalequipment, kitchen equipment,name plates, and marine applicationsStronger than 3003 yet readilyformable in the intermediatetempers. Good weldability andresistance to corrosion. Usesinclude pressure vessels, fanblades, tanks, electronic panels,electronic chassis, mediumstrength sheet metal parts,hydraulic tube, appliances, agricultural applications, architectural uses, automotive parts,building products, chemicalequipment, containers, cookingutensils, fasteners, hardware,highway signs, hospital andmedical equipment, kitchenequipment, marine applications,railroad cars, recreation vehicles,trucks and trailersCable sheathing, rivets for magnesium, screen wire, zippers, automotive applications, fence wire,fastenersFor all types of welded assemblies,marine components, and tanksrequiring high weld efficiencyand maximum joint strength.Used in pressure vessels up to65 C (150 F) and in manycryogenic applications, bridges,freight cars, marine components,TV towers, drilling rigs, transportation equipment, missile components, and dump truck bodies.Good corrosion resistanceUsed in generally the same types ofapplications as 5083, particularlywhere resistance to either stresscorrosion or atmospheric corrosion is importantAlloyDescription and selected applications5454For all types of welded assemblies,tanks, pressure vessels. ASMEcode approved to 205 C(400 F). Also used in truckingfor hot asphalt road tankers anddump bodies; also, for hydrogenperoxide and chemical storagevessels5456For all types of welded assemblies,storage tanks, pressure vessels,and marine components. Usedwhere best weld efficiency andjoint strength are required.Restricted to temperatures below65 C (150 F)For anodized auto and appliance trimand name platesGood formability, weldability, corrosion resistance, and strength inthe T-tempers. Good generalpurpose alloy used for a broadrange of structural applicationsand welded assemblies includingtruck components, railroad cars,pipelines, marine applications,furniture, agricultural applications, aircrafts, architecturalapplications, automotive parts,building products, chemicalequipment, dump bodies, electrical and electronic applications,fasteners, fence wire, fan blades,general sheet metal, highwaysigns, hospital and medicalequipment, kitchen equipment,machine parts, ordnance, recreation equipment, recreationvehicles, and storage tanksUsed in pipe railing, furniture, architectural extrusions, applianceparts and trim, automotive parts,building products, electrical andelectronic parts, highway signs,hospital and medical equipment,kitchen equipment, marine applications, machine parts, pipe, railroad cars, recreation equipment,recreation vehicles, trucks andtrailersHigh-strength alloy in aircraft andother structures. Also used inordnance and recreation equipmentFor aircraft and other applicationsrequiring highest strengths.Alclad 7075 combines thestrength advantages of 7075 withthe corrosion-resisting propertiesof commercially pure aluminumclad surface. Also used inmachine parts and ordnance56576061606370507075

Aluminum and Aluminum Alloys / 359and electrical conductivities, low mechanical properties, and excellentworkability. Moderate increases in strength may be obtained by strainhardening. Iron and silicon are the major impurities.2xxx Series. Copper is the principal alloying element in 2xxx seriesalloys, often with magnesium as a secondary addition. These alloysrequire solution heat treatment to obtain optimum properties; in the solution heat-treated condition, mechanical properties are similar to, andsometimes exceed, those of low-carbon steel. In some instances, precipitation heat treatment (aging) is employed to further increase mechanicalproperties. This treatment increases yield strength, with attendant loss inelongation; its effect on tensile strength is not as great.The alloys in the 2xxx series do not have as good corrosion resistance asmost other aluminum alloys, and under certain conditions they may besubject to intergranular corrosion. Therefore, these alloys in the form ofsheet usually are clad with a high-purity aluminum, a magnesium-siliconalloy of the 6xxx series, or an alloy containing 1% Zn. The coating, usually from 212 to 5% of the total thickness on each side, provides galvanicprotection of the core material and thus greatly increases resistance to corrosion.Alloys in the 2xxx series are particularly well suited for parts and structures requiring high strength-to-weight ratios and are commonly used toTable 7 Selected applications for aluminum casting alloysAlloyRepresentative applications100.0201.0Electrical rotors larger than 152 mm (6 in.) in diameterStructural members; cylinder heads and pistons; gear, pump,and aerospace housingsGeneral-purpose castings; valve bodies, manifolds, and otherpressure-tight partsBushings; meter parts; bearings; bearing caps; automotivepistons; cylinder headsSole plates for electric hand ironsHeavy-duty pistons; air-cooled cylinder heads; aircraftgenerator housingsDiesel and aircraft pistons; air-cooled cylinder heads; aircraftgenerator housingsGear housings; aircraft fittings; compressor connecting rods;railway car seat framesGeneral-purpose permanent mold castings; ornamental grillesand reflectorsEngine crankcases; gasoline and oil tanks; oil pans; typewriter frames; engine partsAutomotive and heavy-duty pistons; pulleys, sheavesGas meter and regulator parts; gear blocks; pistons; generalautomotive castingsPremium-strength castings for the aerospace industrySand: air compressor pistons; printing press bedplates; waterjackets; crankcases. Permanent: impellers; aircraftfittings; timing gears; jet engine compressor casesSand: flywheel castings; automotive transmission cases;oil pans; pump bodies. Permanent: machine tool parts;aircraft wheels; airframe castings; bridge railingsStructural parts requiring high strength; machine parts; truckchassis partsCorrosion-resistant and pressure-tight applicationsHigh-strength castings for the aerospace tative applicationsOutboard motor parts; instrument cases; cover plates; marineand aircraft castingsCover plates; instrument cases; irrigation system parts;outboard motor parts; hingesHousings for lawn mowers and radio transmitters; air brakecastings; gear casesApplications requiring strength at elevated temperaturePistons and other severe service applications; automatictransmissionsInternal combustion engine pistons, blocks, manifolds, andcylinder headsArchitectural, ornamental, marine, and food and dairy equipment applicationsOutboard motor pistons; dental equipment; typewriterframes; street lamp housingsCookware; pipe fittings; marine fittings; tire molds;carburetor bodiesFittings for chemical and sewage use; dairy and foodhandling equipment; tire moldsPermanent mold casting of architectural fittings andornamental hardwareArchitectural and ornamental castings; conveyor parts;aircraft and marine castingsAircraft fittings; railway passenger care frames; truck andbus frame sectionsInstrument parts and other applications where dimensionalstability is importantGeneral-purpose castings that require subsequent brazingAutomotive parts; pumps; trailer parts; mining equipmentBushings and journal bearings for railroadsRolling mill bearings and similar applications

360 / Light Metals and Alloysmake truck and aircraft wheels, truck suspension parts, aircraft fuselageand wing skins, structural parts, and those parts requiring good strength attemperatures up to 150 C (300 F). Figure 1 shows the relationshipsbetween some of the more commonly used alloys in the 2xxx series.3xxx Series. Manganese is the major alloying element of 3xxx seriesalloys. These alloys generally are non-heat-treatable but have about 20%more strength than 1xxx series alloys. Because only a limited percentageof manganese (up to about 1.5%) can be effectively added to aluminum,manganese is used as a major element in only a few alloys. However, oneof these, the popular 3003 alloy, is widely used as a general-purpose alloyfor moderate-strength applications requiring good workability.4xxx Series. The major alloying element in 4xxx series alloys is silicon,which can be added in sufficient quantities (up to 12%) to cause substantial lowering of the melting range without producing brittleness. For thisreason, aluminum-silicon alloys are used in welding wire and as brazing21172011Extrusions, bar, tubing;screw machine stock;good strength/machinability2017DuraluminRivet wire,softerRivetsFasteners20482024Lower strength,very high toughness202521242036Commercial versionGood formability, moderate strength, spot weldable2014Highest strengthPoor SCC resistanceGood properties (thick sections)Good elevated-temperature propertiesHigh-strengthplate/sheet upto 1 in.; goodSCC resistance2319Forging versionof 2024Plate productBetter toughness (lower impurities)Good SCC resistance2219Weld wire for2219 (betterstrength than4043, possiblebetter ductility)Good weldabilityGood elevated-temperaturestrength (up to 316 C, or 600 F)High fracture toughness2018Add Ni for improvedhigh-tempertature strength24192218251926182020Good weldabilityHigher toughnessGood weldabilityHigher strength ( 7039)Greater SCC resistance than 5083Used as armor plateAdd Li forhigh modulus, low density2090Fig. 1 Relationships among commonly used alloys in the 2xxx series (Al-Cu)

Aluminum and Aluminum Alloys / 361alloys for joining aluminum, where a lower melting range than that of thebase metal is required. Most alloys in this series are non-heat treatable, butwhen used in welding heat-treatable alloys, they pick up some of thealloying constituents of the latter and so respond to heat treatment to alimited extent. The alloys containing appreciable amounts of siliconbecome dark gray to charcoal when anodic oxide finishes are applied andhence are in demand for architectural applications. Alloy 4032 has a lowcoefficient of thermal expansion and high wear resistance; thus it is wellsuited to production of forged engine pistons.5xxx Series. The major alloying element in 5xxx series alloys is magnesium. When it is used as a major alloying element or with manganese,the result is a moderate-to-high-strength workhardenable alloy.Magnesium is considerably more effective than manganese as a hardener,about 0.8% Mg being equal to 1.25% Mn, and it can be added in considerably higher quantities. Alloys in this series possess good welding characteristics and good resistance to corrosion in marine atmospheres.However, certain limitations should be placed on the amount of cold workand the safe operating temperatures permissible for the higher-magnesiumalloys (over 3.5% for operating temperatures above 65 C, or 150 F)to avoid susceptibility to stress-corrosion cracking. Figure 2 shows therelationships between some of the more commonly used alloys in the 5xxxseries.BeautyMg,%Mg,%50050.82.5Weldable / strength 40/18)5.0(42/21)4.43.550502.552522.5 AnodizeAuto trimSuper clean54571.0 AnodizeAuto 565456(45/23)5.155545454(36/17)2.7Eyeglass framesMg,%Increase strength, Mg contentWeld wiresNonweldable / strength (TS/YS) Mg,%Auto panels4.551825056(42/22)5.1ContainerendsFig. 2Relationships among commonly used alloys in the 5xxx series (Al-Mg). Tensilestrength (TS) and yield strength (YS) are in ksi units.

362 / Light Metals and Alloys6xxx Series. Alloys in the 6xxx series contain silicon and magnesiumapproximately in the proportions required for formation of magnesiumsilicide (Mg2Si), thus making them heat treatable. Although not as strongas most 2xxx and 7xxx alloys, 6xxx series alloys have good formability,weldability, machinability, and corrosion resistance, with mediumstrength. Alloys

†1xx.x: Controlled unalloyed (pure) compositions, especially for rotor manufacture †2xx.x: Alloys in which copper is the principal alloying element. Other alloying elements may be specified. †3xx.x: Alloys in which silicon is the principal alloying element. The other alloying elements such as copper and magnesium are specifi