Transcription

Ipsen deliversAerospace Aluminum Brazing andCompliance: Meeting AMS 2750E andNadcap CertificationsBy Jim Grann and Craig Moller

Aerospace Aluminum Brazing and ComplianceJim Grann and Craig MollerIpsen Incorporated, Cherry Valley, Illinois USAAbstractThere are many heat treating processes for which Nadcapaccreditation may be sought. Normally speaking, most heattreating companies will seek acceptances that relatespecifically to their actual processes for Aerospace; forinstance, in the aluminum vacuum brazing arena, it iscommon to see customers seeking Nadcap approval on:Removing the fear from the phrase, Aerospace AluminumBrazing and Compliance, can be significantly simplifiedwith increased knowledge, understanding and properimplementation of the requirements and adherence torequired guidelines and checklists. In the past, the majority of aluminum brazing processeshave managed to escape the critical eye of AMS 2750E andNadcap certifications. In general, we must first pecifications (AMS) 2750E and Nadcap certificationfrom a topical view. While the two normally form asynergistic bond, they first must be separated in order tounderstand the fundamental differences between the two.For aerospace aluminum brazing, this understanding iscritical, because most Nadcap inspectors require adherenceto AMS 2750E before granting consideration of yourspecific aerospace-related processes.AC7102/1 (If seeking brazing approval)AC7102/2 (If seeking aluminum approval)With possible additional adherence to: AWS C3.7M/C3.2005 [5] AMS 2769A PRI Introduction to Pyrometry AMS 2759 AWS C3.7M/C3.7:2005 An American National Standard*Aerospace primes may have their own specifications.Understanding AMS 2750E & NadcapIntroductionWith a clearer definition of AMS 2750E and Nadcapcertification, it is now important to gain a betterunderstanding of each. Nadcap is a certification processlinked closely with AMS 2750E, so it is imperative toexplore these requirements in more depth.Clarification of Definition of AMS 2750E and NadcapAMS 2750E is a pyrometry (temperature driven)specification that employs procedures, timelines,calibration data, record archiving, SAT (System AccuracyTesting), TUS (Temperature Survey Surveys) andthermocouple guidelines and applications. According toNadcap’s website they are defined as,When attempting to comply to AMS 2750E one mustconsider their process, the configuration of their equipmentand the classification of their equipment. Normallyspeaking, these are the guidelines set forth within AMS2750E to insure the validation, calibration and verificationof the ability of the heat treatment equipment todemonstrate process repeatability.“The leading worldwide cooperative program of majorcompanies designed to manage a cost-effective consensusapproach to special processes & products and providecontinual improvement within the aerospace & automotiveindustries.” [1]Nadcap is considered a systematic approach of checkpointsthat confirm proven control and repeatability of a givenprocess for which approval is being sought. When anorganization claims they are Nadcap accredited, it generallymeans that they have been complying with AMS 2750E[2], AWS C3.7M/C3.2005 [5] and in some cases AMS2769B [3], but there can be other internal customerspecifications dependent on processes and other factors*.ProcessThe first thing to consider when attempting compliancewith AMS 2750E is your process. It extremely importantto understand the parts that you will be processing andwhat specifications you need to meet for that particularprocess.1

Configuration of Equipmentbeing the tightest tolerance rating. [2]Once the process and specifications are understood, theselection of the actual vacuum heat treatment system isconsidered. It’s important to have a thoroughunderstanding of your process in order to make the correctselection of furnace. The furnace you choose must be ableto achieve the necessary requirements for the parts you areprocessing to ensure compliance is achievable.When selecting a furnace for aerospace aluminum brazingconsider the following: Parts’ weight, materials and geometry Geographical location of end user’s facility Control of retained water vapor from stamping tobrazing Furnace vacuum levels during braze Furnace pumping systems and time required toevacuate Temperature uniformity regulation and zones ofcontrol Temperature zone offset abilities Optional part (in furnace) cooling systems Slow pumping bypass event to negate core shifting Cold-wall temperature regulation (water vapor) Double-ended opening door systems (ease of cleaning) Brazing furnace tuned for core and/or flat plate ologies)While reviewing furnace options and abilities, many thingsmust be taken into consideration, for example total desiredcycle times, resting metallurgy of processed parts,uniformity of heat treatment, cooling, sublimation of alloycontrol, ease of operation and total component complianceto AMS 2750E.Furnace ClassificationAnother factor that affects compliance is the class of yourfurnace. Figure 1 shows an internal view of a aluminumvacuum brazing furnace. While many claim to be AMS2750E compliant, there are actually several differentversions that constitute compliance in regards to vacuumheat treatment systems. Therefore, it is again imperativethat you know the process for which you need compliancein order to make sure the furnace classification meets thespecifications.Aerospace Prime SpecificationsIn addition to AMS 2750E and Nadcap, most Aerospacemanufacturers have their own specifications that you mustmeet in order to run their parts. In many cases, theAerospace prime specifications are stricter than thatrequired for AMS 2750E and Nadcap certification. Bestpractice would be to make sure you are certified to thestrictest specifications related to your customer’srequirements and processes. [3]You must know what class you are attempting to subscribeto as predicated by your metallurgy specifications. AMS2750E requires two categories for furnaces - c lass a n dinstrumentation type. Temperature uniformity rangedetermines furnace class, and the number, location, andfunction of the sensors within the furnace determinefurnace instrumentation type.AMS 2750E Vacuum SpecificationsThere s e e m s t o b e a b i t o f c o n f u s i o n i n t h e areaof AMS 2750E as it relates to vacuum processes, so it isworth delving into this topic in order to reach a better,more thorough understanding. While AMS 2750E remainsa pyrometry specification, there are many field inspectorswho have annexed in the requirement for vacuum gaugecalibration.Section 3.5.12 of AMS 2750E says that, “Furnace VacuumLevel during TUS shall be run at the lowest vacuum levelused in production, but need not be less than 1 micron Hg.”[2]Figure 1 Vacuum Aluminum Brazing Furnace (IpsenR&D)Translation: a ccording to several inspectors, if yourprocesses u t i l i z e a r g o n or nitrogen gas in theform of partial pressure above one micron, the vacuumgauge must be part of the certification and calibration ofAMS 2750E outlines furnace class by numbers onethrough six, with one being the highest class rating.Instrument class is qualified by letters A through E, with A2

your vacuum furnace systems.The Nadcap team has published a paper to help heattreaters to better understand the reason for their failures andoffer guidance to achieve successful certification. Keyfactors that are often overlooked by those seekingcertification include the pre-certification checklist andsuccessful completion of the self-audit, both of which mustbe done prior to seeking resting Nadcap accreditation.The thoughts behind this relate to the production parts: ifthey are processed at or below one micron, vacuum gaugecalibration is not an issue with AMS 2750E. If theproduction parts are normally processed in a partialpressure environment the vacuum gauge system by defaultbecomes a part of the process; thus, the requirement forcalibration being drawn into AMS 2750E. AMS 2759 andAWS C3.7M/C3.2005 often make reference to vacuumlevels.An excerpt from the Nadcap guidance paper:Ancillary to the above, some inspectors mandate thatsystem accuracy tests (SAT) and temperature uniformitysurveys (TUS) be run in partial pressure as well. This bestemulates the furnace calibrations to the actual productionprocess when validating the furnace for compliance.“During the period that the Nadcap Heat Treat Task Grouphas been reviewing audits, we have found Pyrometry to bethe least understood and the causes of the most problemsand confusion. A recent study indicated aside from jobaudit non-conformance reports (NCR), eight of the top tenNCR causes are related to pyrometry. However, pyrometryis also the core and basis of all heat treatment practice.Due to recent changes in AMS 2750E and Nadcaprequirements, it is possible to encounter auditors whosubscribe to this theory and those who do not. It has been agrey area in certain regions of the world, but beingprepared for it is better than being surprised.We have prepared this guide to improve the understandingof pyrometry and the performance of pyrometric functions.It provides guidance and interpretations of AMS2750E, aswell as fundamental pyrometry principles and tells youwhat a Nadcap auditor will expect to see during an audit.SCOPE: This guide is not intended to replace AMS 2750Eor waive any of its requirements or those imposed bycustomers. The following are Nadcap interpretations of thespecification and these interpretations must be used only asguidance to the specification. Customer requirements mayexceed those discussed here. It is the responsibility of thesupplier to understand and comply with all customerrequirements.” [1]Figure 2 Vacuum GaugeNadcap CertificationFigure 3 TUS Fixture (Ipsen R&D)Several heat treaters have failed Nadcap audits simplybecause they lack understanding of the basic requirements.Nadcap accreditation is based on many factors. Whengenerally summarized it comes down to the end user beingable to prove that they maintain their equipment, followbasic guidelines of AMS 2750E, have proper workinstructions in place, history (records) being maintained inaccordance with guidelines, process repeatability, trainedoperators and so fourth prior to accreditation.3

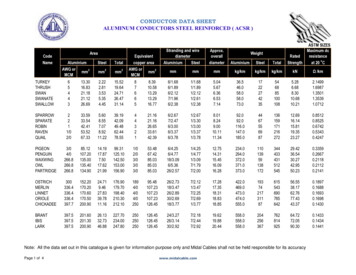

Figure 5 Types of ThermocouplesThe next thing to consider is the number of TC penetrationsyou need in order to perform SAT testing for the desiredcompliance. AMS 2750E requires three penetrations:control TC, over temp TC and SAT TC. The commonlyused control and over temp TCs are the R, S, and B family,because these TCs have minimal drift in thermalelectromagnetic frequencies (EMF) when exposed to hightemperatures and oxidizing and reducing atmospheres.Figure 4 TUS Fixture in Furnace (Ipsen R&D)System Accuracy Tests (SAT) & TemperatureUniformity Surveys (TUS)SAT TCs must be of a different family from the furnacecontrol TC. Normally type K and type N are utilized. SATsshall be performed on the temperature control andrecording systems in each control zone of each piece ofthermal processing equipment that is used for productionheat treatments. The SATs shall also be performed onadditional systems that qualify instrumentation as types A,B or C. [2]As mentioned earlier, the self-audit and checklists need tobe performed before the Nadcap auditor arrives on-site.Part of this self-audit is the testing of your equipment todocument that it does comply with the requiredspecifications for your particular processes. SAT and TUSvalidate the furnace performance criteria of the systemproving accurate, repeatable results that fall within theguidelines. TUS fixtures can be seen in Fig. 3, 4, 6 and 7.A TUS is done utilizing a fixture that enables the preciselyplaced TCs to validate the uniformity throughout theheating zones within the hot zone environment. Whenselecting survey TCs it is important to ensure that themaximum correction factor of the TCs being utilized is lessthan the specification you are attempting to achieve withinthe vacuum furnace.SAT is a simple test performed in order to determine thatthe thermocouples and instruments are giving an accuratedepiction of temperature. These tests provide informationas to changes over time, by comparing temperature controland recording systems in each control zone with a separatetest instrument and thermocouple combination.Considerations when testing include age of the furnace andhot zone, as well as the age and classification of theinstrumentation. Types of thermocouples (TC), seen inFigure 5, utilized for SAT and TUS are also important toconsider when testing for compliance.Types of commonly used load TCs: Type K - Positive leg of chromel (90% nickel, 10%chromium) and a negative leg of alumel (95% nickel,5% aluminum and silicon). Type N - Positive leg of nicrosil (84.5% nickel, 14%chromium, 1.5% silicon) and a negative leg of nisil(95.4% nickel, 4.5% silicon, 0.1% magnesium).Figure 6 Vacuum Aluminum Brazing Furnace (IpsenR&D)4

Aluminum Brazing is a dirty processA vacuum aluminum brazing furnace needs magnesium tobe able to braze, but conversely an excessive buildup ofmagnesium oxide (residue left over from the brazingprocess) prevents the furnace from being able to braze.There is a synergistic bond and balancing act between thetwo thresholds.Cleaning is mainly done via mechanical scraping and acombination of air and vacuum burn-out cycles. Figure 8shows the front and back doors of Ipsen’s aluminun brazingfurnace open for cleaning. Figures 9 through 11 showvarious levels of magnesium buildup.Figure 7 Vacuum Aluminum Brazing Furnace (IpsenR&D)Customers that are new to the aluminum brazing arena areoften taken aback by the condition of the hot zone andfurnace after a few short months of operation. Only withtime and experience will one be able to fully realize what isconsidered normal, and ho

AMS 2759 AWS C3.7M/C3.7 . AMS 2750E outlines furnace class by numbers one through six, with one being the highest class rating. Instrument class is qualified by letters A through E, with A being the tightest tolerance rating. [2] When selecting a furnace for aerospace aluminum brazing consider the following: Parts’ weight, materials and geometry Geographical location of end .