Transcription

SP FIRESTOPSYSTEMSThe purpose-made solution for cavity fire stopping

FIREPRO SP FIRESTOP SYSTEMSFIREPRO SP FIRESTOPSYSTEMSThe SP FireStop Slab has been specifically designedto form cavity fire stops within buildings.SP FireStop Slab is a one-piece system enablingeasy cutting and installation. The solution providesa unique lateral compression to facilitate a tight fitbetween substrates.ROCKWOOL Ltd2

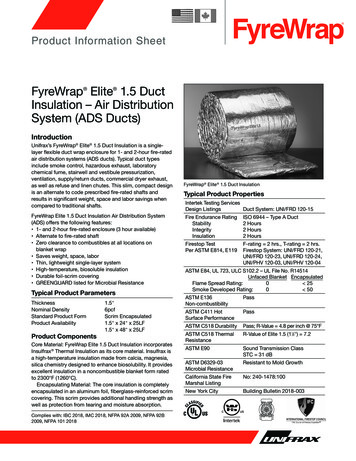

FIREPRO SP FIRESTOP SYSTEMSAdvantagesDescriptionROCKWOOL SP Firestop Systemcomprises of both the SP Firestop Slaband SP Firestop fixing brackets. TheSP Firestop Slab is a medium densitystone wool slab which incorporates afoil facing to both sides. The foil facingincludes cutting lines to support accurateinstallation. Easy to install, dry fit system Can accommodate limited movement Tested to provide up to 2 hours of fire resistance Resists the passage of smoke – aluminium foil facedon both sides Suitable for cavity widths up to *1000mm*Please contact ROCKWOOL Technical Solutions for fire resistance ratings invoids over 600mm wide.ApplicationsSP Firestop System may be installedhorizontally or vertically and is suitablefor cavity widths between 50mm and600mm. SP Firestop can also be usedhorizontally in cavity widths up to1000mm for further information pleasecontact ROCKWOOL Technical Solutions.SP Firestop System is suitable for: Masonry constructions Curtain Walling Systems Large cavity voids Rainscreen Facades (vertical use only)SP Firestop System is not suitable for useas a horizontal fire barrier in ventilatedfaçade systems. For these applicationsconsider using the ROCKWOOL SPFirestop OSCB.ROCKWOOL Ltd3

FIREPRO SP FIRESTOP SYSTEMSPerformanceStandards and approvalsSP Firestop System has been tested and assessed to BS 476: Part 20. It has also beentested to BS EN 1366-4: 2006 and classified to BS EN 13501-2.Achieves Euroclass A1 in accordance with BS EN 13501-1.SP Firestop System is third party approved with LPCB – certificate no. 022b.This product has been authorised for use in LUL surface and sub-surface premiseswhen installed in accordance with this datasheet. Please refer to the LUL ApprovedProduct Register at www.LU-apr.co.uk for specific details. LUL Ref: 2244.Fire performanceThe SP Firestop System can achieve a fire resistance rating of up to 2 hours in voids ofup to 600mm.ProductWallFloorCavity (mm)Test standardSP60 (Standard)EI60EI60400BS 476 Part 20SP120 (Standard)EI120EI120400BS 476 Part 20SP60 (Standard)EI60300BS EN 1366-4SP120 (Standard)EI120300BS EN 1366-4EI120600BS EN 1366-4EI601000BS EN 1366-4Fire performance with /- 3% MovementSP Plus (With XL Bracket)EI120SP Plus (With XL Bracket)Movement testingSP Firestop Slab has been tested with movement applied in accordance withthe provisions set out in Annex B of BS EN 1366-4: 2006. SP60 and SP120 canaccommodate /- 3% movement in cavities up to 300mmMasonry support bracket penetrationThe SP Firestop System has been tested in conjunction with the masonry supportbrackets where the masonry support system penetrated the SP 60 Firestop Slab.ProductBracketPenetrationFire ResistanceCavity (mm)Test StandardSP60 Firestop Slab50%EI60400BS EN 1366-4SP60 Firestop Slab100%EI60400BS EN 1366-4For further information on the use of masonry support brackets with the SP FirestopSystem please contact ROCKWOOL Technical Solutions.ROCKWOOL Ltd4

FIREPRO SP FIRESTOP SYSTEMSAcoustic performanceROCKWOOL products have excellent acoustic properties and can significantly reducethe levels of airborne sound transmission through wall and floor cavities. For furtherinformation please contact ROCKWOOL Technical Support.Product mmThickness75 & 90mmFire ResistanceUp to 2 hoursHandlingROCKWOOL SP Firestop Slabs are light and easy to handle. They are supplied incompression wrapped polyethylene, which will provide short term protection. For longterm storage they must be protected by a waterproof covering.InstallationROCKWOOL SP Firestop Slabs are designed for cutting on site with a sharp knife orsaw and a straight edge. The cavity to be fire stopped should be measured and theROCKWOOL SP Firestop Slab cut to suit this dimension, using one piece only per gapwidth - see Figures 4 and 5.For easy compression fitting and to accommodate the fixing pattern, cutting shouldbe along the 1000mm length as indicated in figure 1.The SP Fixing Brackets are then re-profiled by hand and cut as necessary to allow atleast 75% penetration of the fire stop material – see Figures 2 and 3.They should be placed as shown in the diagrams, or fixed by other suitablemechanical means.WRe-profile the bracket byhand to form a Z shapeBreak off tab at serrationprior to installation1000mmFigure 2SP Firestop Fixing Bracket650mmSP Firestop Slab - direction of cut toproduce 1000mm long Firestop strips tosuit cavity width WSecure bracket withmetal fixings suitable formasonryFigure 1Cutting method for SP Firestop Slabmin. 75% penetrationFigure 3Sectional view of Firestop Slab and BracketROCKWOOL Ltd5

FIREPRO SP FIRESTOP SYSTEMSFixing within cladding & curtain walling systems1.Cut the ROCKWOOL SP Firestop Slab to suit the *cavity size, allowing foradditional compression of up to 10mm.2.The ROCKWOOL SP60 or SP120 Firestop Slab is impaled onto the SP FixingBrackets at the rate of 2 per 1000mm length, fixed at 500mm 10mm centres asshown in Figure 4. The SP Fixing Brackets should be placed 250mm 10mm infrom each end of the ROCKWOOL SP Firestop Slab.3.The product should then be fitted securely into the void and tightly butted to theadjacent ROCKWOOL SP Firestop Slab.4.Once the ROCKWOOL SP Firestop Slab has been accurately fitted, the SP FixingBrackets must then be fitted to the edge of the concrete floor slab with metalfixings suitable for masonry.Fixing into masonry wall cavities:5.Cut the ROCKWOOL SP Firestop Slab to suit the *cavity size ensuring a tight fit.6.After suitably re-profiling the SP Fixing Brackets they can be built into the bedjoints of the internal leaf at 500mm 10mm centres. Alternatively the SP FixingBrackets may be re-profiled by hand into an ‘L’ shape and mechanically fixed tothe face of the inner leaf.7.The ROCKWOOL SP Firestop Slab is then impaled onto the SP Fixing Bracketafter the next lift of inner leaf masonry.8.Work on both leaves can then be continued and must include either a verticaldamp proof course (vertical installation) or a cavity tray (horizontal installation)installed over the SP Firestop Slab as shown in Figure 5.*For cavity widths of 250mm or more, joints between adjacent lengths of SP Firestop Slab should be sealed onthe top surface with aluminium foil tape.Plan viewVertical sectionCurtain wallY500mmConcrete floor slabDimension Y is 75mm (SP 60)or 90mm (SP 120)Figure 4ROCKWOOL SP Firestop Slab between floor and curtain wallROCKWOOL Ltd6

FIREPRO SP FIRESTOP SYSTEMSVertical installationHorizontal installationCavity trayROCKWOOL SPFixing BracketsROCKWOOL SPFixing BracketsVertical dpcFigure 5ROCKWOOL SP Firestop Slab between masonry leavesAncilliariesSP Firestop Fixing BracketsBracket TypeCavity Size (Up to mm)Pieces/PackSP/S10050SP/L40050SP/XL60050ROCKWOOL SP Fixing Brackets are supplied in three standard sizes; SP/S (small),SP/L (large) and *SP/XL for cavity widths up to 600mm. The brackets are supplied incardboard boxes of 50 pieces, flat packed and designed to be easily re-profiled byhand on site.* SP/XL brackets are designed for use with SP Firestop Plus Slab for 2 hours fire resistance in cavities up to 600mm.Brackets are supplied in cardboard boxes, flat packed, and are designed to be easilyre-profiled by hand on site. The SP Fixing Brackets should be cut on site as necessaryto allow at least 75% penetration of the Firestop.*In order to comply with the fire test certification, only ROCKWOOL SP Fixing Brackets must be used to install theproduct.ROCKWOOL Ltd7

FIREPRO SP FIRESTOP SYSTEMSSpecification clausesThe SP Firestop System is associated with the following NBS Clauses:F30 Accessories/sundry items for brick/block stone walling 180 Cavity ClosersP10 Sundry insulation/proofing work 432 cavity BarriersP12 Fire stopping systems 360 Mineral Wool Rigid BattsDisclaimersThis product should only be utilised for applications as outlined in the relevantROCKWOOL product datasheet and in accordance with the relevant ROCKWOOLFire Resistance Testing. Additionally the product must be installed in accordance withthe current ROCKWOOL guidelines. For further information please visitwww.rockwool.co.uk or contact our Technical Solutions Team on 01656 868490.Supporting informationFor further information relating to any aspect of the FIREPRO range, please refer tothe applicable ROCKWOOL standard details at www.rockwool.co.uk or contact theROCKWOOL technical solution team on 01656 868490 ortechnical.solutions@rockwool.co.ukROCKWOOL Ltd8

FIREPRO SP FIRESTOP SYSTEMSSustainabilityEnvironmentAs an environmentally consciouscompany, ROCKWOOL promotesthe sustainable production and useof insulation and is committed to acontinuous process of environmentalimprovement.Made from a renewable andplentiful naturally occuring resource,ROCKWOOL insulation saves fuel costsand energy in use and relies on trappedair for its thermal properties.All ROCKWOOL products provideoutstanding thermal protection as wellas four added benefits:Fire resistanceAcoustic comfortSustainable materialsDurabilityROCKWOOL insulation does notcontain (and has never contained) gasesthat have ozone depletion potential(ODP) or global warming potential(GWP).ROCKWOOL stone wool insulationis approximately 97% recyclable. Forwaste ROCKWOOL material that maybe generated during installation or atend of life, we are happy to discuss theindividual requirements of contractorsand users considering returning thesematerials to our factory for recycling.Health & SafetyThe safety of ROCKWOOL stone woolis confirmed by current UK and Republicof Ireland health & safety regulationsand EU directive 97/69/EC:ROCKWOOLfibres are not classified as a possiblehuman carcinogen.A Material Safety Data Sheet isavailable and can be downloadedfrom www.rockwool.co.uk to assist inthe preparation of risk assessments, asrequired by the Control of SubstancesHazardous to Health Regulations(COSHH).Interested?For further information, contact the Technical Solutions Team on 01656 868490or email technical.solutions@rockwool.co.ukVisit www.rockwool.co.uk to view our complete range of products and services.Copyright ROCKWOOL February 2018.ROCKWOOL Ltd9

FIREPRO SP FIRESTOP SYSTEMSNotesROCKWOOL Ltd10

FIREPRO SP FIRESTOP SYSTEMSNotesROCKWOOL Ltd11

February 2018ROCKWOOL LimitedPencoedBridgendCF35 6NYTel: 01656 862 621info@rockwool.co.ukrockwool.co.uk

RRO RO Y ROCKWOOL Ltd 2 FIREPRO SP FIRESTOP SYSTEMS The SP FireStop Slab has been specifically designed to form cavity fire stops within buildings. SP FireStop Slab is a