Transcription

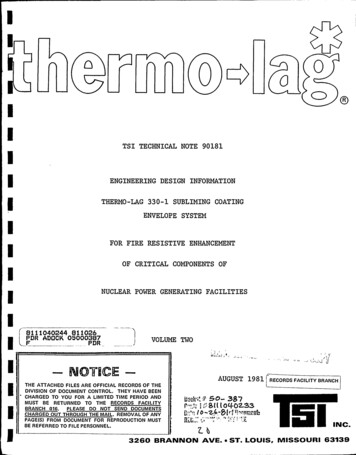

TSI TECHNICAL90181NOTEENGINEERING DESIGN INFORMATIONTHERMO-LAG330-1 SUBLIMING COATINGENVELOPE SYSTEMFOR FIRE RESISTIVE ENHANCEMENTOFCRITICALCOMPONENTS OFNUCLEAR POWER GENERATINGFACILITIESSiif040244 8ii026PDR ADQCKF05000387PDRVOLUME TWOLLu'''«AUGUST 1981THE ATTACHED FILES ARE OFFICIAL RECORDS OF THEDIVISION OF DOCUMENT CONTROL. THEY HAVE BEENCHARGED TO YOU FOR A LIMITED TIME PERIOD ANDMUST BE RETURNED TO THE RECORDS FACILITYBRANCH 016.PLEASE DO NOT SEND DOCUMENTSCHARGED OUT THROUGH THE MAIL. REMOVAL OF ANYPAGE(S) FROM DOCUMENT FOR REPRODUCTION MUSTBE REFERRED TO FILE PERSONNEL.-l uIIal.',JRECORDS FACILITYBRANCH5- 387Scar".-. C-;.',; I;II-auStt too-oZ.&S(O-Sf -8l fR IImCrrh««gg-',6,," «««««H64w,B 4I'« «l«/IIggIIIINC.3260 BRANNON AVE. ST. LOUIS, MISSOURI 63138

IIIIII

TABLE OF AL METHOD OF OPERATIONTSI TECHNICALNOTE 71880PART 1 — -THERMO-LAG 330 SUBLIMING COATINGLISTING OF SELECTED APPROVALS FROMINDEPENDENT TESTING AND UNDERWRITINGAGENCIESPART 2—REFERENCE LIST OF SELECTED USERSOF THERMO-LAG SUBLIMING COMPOUNDSPHOTOGRAPHS OF THERMO-LAG330-1 SUBLIMINGCOATING INSTALLATIONSDATA SHEETS FOR:THERMO-LAG 330-1 SUBLIMING COATINGTHERMO-LAG 350 TWO PART SPILL RESISTANCE TOPCOATTHERMO-LAG STRESS SKIN TYPE 330-69THERMO-LAG 330-70 CONFORMABLE CERAMIC BLANKETTHERMO-LAG FIBERGLASS ARMORING

lI

TABLE OF CONTENTS(CONTINUED)VOLUMEITITLESECTIONENGINEERING REPORT ON ONE HOUR ASTM E119 FIRESIMULATION FACILITY FIRE TEST FOLLOWED BY A SHORTTERM WATER HOSE STREAM IMPACT TEST ON A NUCLEARFACILITY CLASS 1E CABLE TRAY, CONDUITS AND AIRDROP ASSEMBLYFIRE ENDURANCE TESTSON CABLE TRAYS, CONDUITSAND CABLE DROP ASSEMBLIES PROTECTED WITHTHERMO-LAG 330-1 SUBLIMING COATING ENVELOPE SYSTEMENGINEERING REPORT ON ONE HOUR ASTM E119 FIRESIMULATION FACILITY FIRE TEST FOLLOWED BY A SHORTTERM WATER HOSE STREAM IMPACT TEST ON A NUCLEARFACILITY CLASS 1E CABLE CONDUIT ASSEMBLYUNDERWRITERS LABORATORIES REPORT NOS. R6076SURFACE BURNING CHARACTERISTICS OF GENERAL PURPOSECOATINGS10330-1 SUBLIMINGA.THERMO-LAGB.THERMO-LAG 350 TWO PART SPILL RESISTANT TOPCOATTSI TECHNICALCOATINGNOTE 10280EVALUATION OF THE WEATHERING CHARACTERISTICS OFTHERMO-LAG 330-1 SUBLIMING COMPOUND AS APPLIED TOMETAL SUBSTRATES

IIIII

TABLE OF CONTENTS(CONTINUED)VOLUMEIITITLESECTIONTHREE HOUR TESTS ON THERMO-LAG 330UNDERWRITERS LABORATORIES DESIGN'NO. X611MONSANTO SPECIAL REPORT 8008FACTORY MUTUAL REPORT NUMBER 23187FACTORY MUTUAL REPORT NUMBER'23187.11213UNDERWRITERS LABORATORIES FILE NO. 6802-7REPORT ON THE PERFORMANCE OF A STEEL LOADBEARING WALL ASSEMBLY PROTECTED WITH A'MASTICCOATING DURING'FIRE AND HOSE STREAM TESTSUNDERWRITERS LABORATORIES FILE NO. R6802HOUR FIRE TESTS PER ASTM E119FIVETHREE HOUR FIRE ENDURANCE TESTS ON TSI'SCONFORMABLE THERMO-LAG 330 STRESS SKINFIRE WALL ASSEMBLY15FACTORY MUTUAL REPORT NO. 23160.1FIRE ENDURANCE TESTTWO HOURS16INTERIM MEMORADUM REPORT NO. 459COMPARISON OF VARIOUS THER'YSTEMS FOR THEPROTECTION OF RAIL TANK CARS TESTED AT THEFRA/BRL TORCHING FACILITY

TABLE OF CONTENTS(CONTINUED)VOLUMEIITITLESECTIONTSI TECHNICALNOTE 77629THERMO-LAG'30 SUBLIMING COATING SYSTEMSELECTED DATA ON WATER IMPINGEMENT,TESTS,FULL SCALE TORCH TESTS AND FIRE ENGULFMENTTESTS18PRELIMINARY ACCIDENT REPORTTANK CAR DERAILMENTJOAQUIN; TEXAS19TSI TECHNICAL NOTE 80181THERMO-LAG 330-1 SUBLIMING COATINGENVELOPE SYSTEM APPLICATION PROCEDURES20OUTLINE OF TSI'S QUALITY ASSURANCE ANDQUALITY CONTROL SYSTEM

UXDERM'RITERS LABORATORIES l.iC.st) rflk)nTE ntttl K rrf tsal%%,Q)t t),'t! 'pt'.)!t,c)tt, )tt E-(0)'-p)'ct lla l I4%%"I v)'r,'"))):t)»t 'c.'.''.".'") Ptt'. I!C 80teR6S02Yorttbrook, ILJanuary 9, 1979TSI, Inc.3260 Brannon Ave.St; Louis, liO 63139Atten tion: R. Fe 1 dmanSubject: MASTIC COATINGS(CDWZ)Gentlemen:We are enclosing one copy of the Report revision coveringthe above subject. The revision consists of the folloving:Reviseddated 1-S-79.illustration6for reportissued 6-5-78,VeryG. D.truly yours,PalikijFire Protection Dept.GP-.r gencl.GuideBXUV.Ftro )tcalatanco Ratings.Novctnbcr 3, 1978t)tS11-A card.)X6llDesign No.Rotint) 3 Hr.—(Continued onXstl-8 card.)rwritcrs Laboratories Inc.This card is issued by UnI

IagH

FITPLOT OF BEST'EQUATION FOR 3 HR. RATING I :aa.'el la all a l»j''jl:I j:llj' ll I o» 4 gli I el ajI; ':.'.'.'.a aa II . joe.a. 4I f a«»»»*» l'L ' «oo4 I lla« 'f' 44 ! 4 0 4 o» I 4 Vaa aaaa af.J I 0.493- Y —I/2In.0.000471X''L':: lII: j LL f '' ll « a a I:::!I0.25 » I «4»a4 4 )I o » I I 0.11.« 4 4I'la ao aaO» 4 f I 4 IlifoLj» II I Ijaj 'Ll IjIIIaf j'eiP" 'I l''',," I fI ljlWIIojaaS »0 l»««4 4 »I«aol10 «a»oj«4I I50 . ,.!Iill l»VWqI"I'I a II;I4'a«4a»»f«j a lf IIalWaa a al la aW»»4« a j.r. I«a»100200I TIME, MINUTESILL.6R6802-6A

an independent, nu.'-fur-prufi t organi "at''un testi ny J'or puolic ASTIC COATING APPLIED TO AM14X228 STEEL COLUMNYSI, Inc.CopyrightCSt. Louis, MissouriUnderwriters Laborator ies Inc.1978Underwriters Laboratories Inc. authorizes the above namedto reproduce this Report providedis reproduced incompanyits entirety.it

FilePageR6802-6AG1Issued:6-5-78GENERALsubject of this Repor t is the fire resistancewith Type 330Classification of a W14X228 steel column protectedthickness'ffilmamastic subliming coating applied to dry15/32 in. as described in the section entitled "Protection of TestAssembly," and as shown in ILL. 1.The object of this investigation was to establish a fireresistance Classification for the column described herein by meansof a fire endurance test conducted in accordance with the Standardfor Fire Tests of Building Construction Materials, UL263 (ASTMTheE119,NFPANo. 251) .In addition to the fire endurance test, the submittorthat we conduct an engineer ing evaluation of the testsr equestedde"cubi.bed in this Repor t and their column tests described inRepor ts R6802-3 and R6802-4, to determine the minimum dry filmthic'kness of the Type 330 mastic coating necessary to afford arating when applied to a W14X228 steel3 hr fire resistancecolumn.IThefir e testwassupplemented'y other testsandFexaminations to furnish information regarding the composition and,.physical proper ties of the mater ials used and to determine thepracticability of handling and applying the coating.GDP/RHB: plh

IIIII

ON OF HATERIALS:materials used in the test assembly are described below.Column — The column used in the test assembly was a W14X228steel section measuring 8 ft, 3 in. long between the top andThebottom concrete caps.Primer — The pr imer was a corrosionpr imer manufactur ed by TSI, Inc.-inhibiting modified alkydglass fiber gauze wasThe gauzereinforcement.mastic coating to provideGlass Fiber GauzeThewide and weighed 1.70 oz per sq yd.embeddedwas 12.in thein.Mastic Sublimin Coatin — The mastic subliming coatingmaterial was manufactured by TSI, Inc. (and designated Thermo LagType 330, The coating material was supplied in 55 gal steeldrums. The mastic coating is*presently Classified by Under wr itersLaboratories Inc. under Follow-Up Service. The composition andother properties of the mastic coating are considered proprietaryand are on file at the Laborator ies.PROTECTION OF TEST ASSEMBLY:protected by workmen in the employ ofthe submittor under the obser vation of members of theLabor atorThe column surfaces were wiped with a solvent to removeThe primer was sprayed onto the columnsurface contaminates.using an air gun.The mastic coating, which wa's supplied in steel drums, was.spray-applied to the column surfaces using. equipment designed forThesteel columnies'taff.such purposes.was

FileR6802-6APageIssued:26-5-78The -mastic coating was applied to the column in several coatsat thicknesses of approximately 1/32 to 1/16 in. Each coat wasallowed to become tacky befor e the following coat was applied.thickness of. After the coating. had been .-prayed to an approximateintothecoating overessedwasthefiber13/32 in.,glassgauzeprthe entire column with adjacent sections of the gauze overlappedto 3 in. The gauze was lightly rolled with a paint roller .Approximately 3/32 in. of additional coat'ing was then applied to1the column.coating was applied to a wet film thickness ofapproximately 1/2 in. as determined by several measur ements takenafter spraying had been completed.The wet and dry densities of the mastic subliming coatingwere determined by applying the mater ial at a repr esentativethickness to a 2 by 2 ft steel plate. The wet density wasobtained by weighing the plate immediately after spraying and thedry density was determined using the air dried constant weight oft'e steel plate and coating. The average wet and dry densities ofthe mastic coating were 85.8 and 61.2 pcf,Therrespectively.'hilethe mastic coating mater ial was curing, severalin width from hairline to 1/8 in. formed at theintersection of webs and flanges of the column. These cracks wererepaired nine days after the spraying had been completed.The final dry film thickness of 15/32 in. was determined onthe basis of 108 measurements taken on the column 40 days afterthe spraying had been completed and the material had dried at r oomtemperature to a constant weight condition. Individual thicknessreadings varied fr om ll/32 to 19/32 in.crack'aryingThe appearanceendurancetest isGDP/8MB: plhof theshown oncolumn assembly before theILL. 2.fire

FileIssued:Page T1-1R6802-6ATESTRECORD6-5-78NO.FIRE ENDURANCE TEST:This test was conducted in accordance'iththe Standard ofUnderwriters Laboratories Inc. for Fire Tests of BuildingConstruction and Mater ials, UL263 (NFPA No. 251, ASTM E119).DESCRIPTION OF SAMPLE.Prior to placing the column assembly in the furance, severalcracks were observed in the mastic coating at each web and flangeintersection. These varied in width from hairline to 1/16 in. andwereto 2 in. long.1METHODThe column was placed in the furnace and exposed to flames ofcontrolled extent and severity in accordance with the StandardTime-Temperature Curve. Eight thermocouples, distributed aroundthe column in two levels as shown on ILL. 3, measured thetemperatures in the furance chamber.The temper atur es of the steel column were measur ed by 14ther mocouples located as shown on ILL. 4. Thr oughout the test,obser vations wr e made to note the character of the fire, thecondition of the exposed sur face of the column, .and all other datapertinent to the fire resistance performance of the column.Character and Distribution of the Fire - The furnace fire wasluminous and well distributed during the test, and thetemperatures recorded in the furance chamber followed the StandardTime-Temperature Curve as defined in the Standard for Fire Testsof Building Construction and Materials, UL263, and as shown onILL. 3.

II

FileR6802-6AAsummar yPageof thecolumnengineering evaluation isHaterIRe test results included in thisialIn.R6802-3R6802-4R6802-6AOccur r ence OfLimiting Temperature,Min 5/32-'Limiting aver age cross-sectional 771271721/415/321000 F used.6-5-78shown below:Thickness,ortissued:T1-5temperature ofTo deter mine the thickness of the mastic coating r equir ed forthe 3 hr rating, a computer analysis of the above materialthicknesses and time to reach the limiting temperatures wasobtainyd. Based upon the resulting equation, Y 0.00047 xwas determined that a minimum thickness of 1/2 in. would afforda 3 hr rating.The test data and the plot of the equation ar.eshown on ELL. 6.it1A safety factory of 8 percent (14 min) was used to determinethe above thickness since the equation is an extrapolation of testdata.GDP/RMB

g conclusions represent the judgement ofiter s Laborator ies Inc'. based upon. the results of theexamination and tests conducted in the Report, as they relate toestablished principles and previously recorded data.TheUnderwrFIRE RESISTANCE PROPERTIES:Itis judged that a 1/2 in. thickness of mastic coating,applied as described in this Repor t will afford a 3 hr rating whenapplied to a stc uctural steel column whose size is equal to otgreater than a W14X228 with- a minimum flange thickness of1-11/16 in., a minimum web thickness of 1-1/16 .in., and a minimumcross sectional area of 67.06 sq in.The assembly, in summa ized form as shown-:. on the individualdesign illustration included in this Report, will be illustratedin the Fire Resistance Directory as Column Design No. X611.This Classification is based on the temperature limitationsof 1000 F average and 1200 F maximum. allowable as'escribed underthe ",Conditions of Acceptance" for structural steel columns of theStandard of Underwriters Laboratories Inc. for Fire Tests ofBuilding Construction and Haterials, Standard UL263 (ASTH E119,NFPA No.251).mastic coating and glass fiber gauze of the type used forcan be readily applied to steel columns byMaterials andexper ienced workmen using proper equipment.spraying procedures .in accordance with those described in thisReport are significant factors in the fire resistance- of thisconstr uction.The,this investigationCONFORMITY:This construction was tested in accordance with the StandardTests of. Building Construction and Materials, UL263 (ASTHE119, NFPA No. 251).for Fire

III

FileR6802-6APage1'ssued:C26-5-78FOLLOW-UP PROGRAM:mastic coating as descr ibed her ein is cur r ently coveredunder the Classification and Follow-Up Service of Unde writersLabor atories Inc. Under the Ser vice, the manufacture er isauthor ized to use the Laboratories'lassification Marking on suchproducts which comply with the Follow-Up Service Procedure andany other applicable requirements of Underwriters LaboratoriesInc. Only those products which properly bear theMarking are considered as Classified byTheLaboratories'lassificationUnderwriters Laboratories Inc.The Classification Markingillustrated,below:used on the masticUNDERWRITERS LABORATORIESINC.RCLASSIFIEDMASTIC COATINGSFIRE RESISTANCE CLASSIFICATIONDESIGN NO. X611SEE UL FIRE RESISTANCE DIRECTORXcoating is

k4M14X228 STEEL COLUMNtGLASS 'IBER GAUZETYPE 330 ISTIC COATS'AGAPPLXED TO A DRY FXLMTHXCKNZSS OF 19/32 XN.XLL. 1R 8C2--6A

IIIIII

RILL.6802-6A . ee I 2

jjItIII

IH W W W W W W W W W W W W RR

ILL.5QtI p I 11 i il1 0 1I 0 o l 01 1 M 0 a 'o o'o 0

PLOT OF BEST FIT EQUATION FOR 3HR RATING f i1.0'S e0 4 f\ 05C.Y 0.000471 x t' t0.493 T/2 in.CQ 04- II I0 I 0"f JIII I II 120--30 " 1 )ff .;-150180.210.I„ Time, MinutesI I y I 0 I Ie

IIIIII

('(i:."iE i:::.!lvXollRES ESTANGE RAT lNQSA CARDDESXGN NO. X611RATING-3 HR.' ,R6802-6A

GuideIBXUVFire ResistanceRatingsJune 5, 1978(X611-B Car d)(Continued From X611-A Card)I'asticin-lr 2.Coatin s» - Coating mixed thoroughly and spray appliedsever al coats for a dry film thickness of 1/2 in. tocolumn surfaces which must be free of dirt, loose scale andpr imed with a modified alkydoil. Column sur faces to be (Item2),pressed into coatingfiberimer'.gauzeGlassprcoatand lightly rolled infinalofprior to applicationCoatingmay shrink causing cracksplace with a paint roller.filled with additionalbeshallacksdur ing cur ing. These crmastic coating.TSl Inc. - Type 330. investigated for exterior and inter ioruse. For'xterior use, Type 350 top coat to be applied overmastic coating at a r ate of approximately 150 sq ft per gal.G1- "s Fiber Gauze - Nominally 12 in. wide, 1. 70 oz per sq yd.E:mbedded in mastic coating around entire col,'umn.Steel Column - Hinimum size of column a MlNX228, with outsidedimen-ions of 16 by 15-7/8 in., a- flange thickness of1-11/16 in., a web th'ckness of 1-1/16 in., and a crosssectional area of 67.06 sq in.Bearing theULClassificationHarking.,

I

FileR6802-6AReportG.PageIssued:C36-5-78Reviewed by:by:D. PALIKIJEngineering Assistant p' .oFire Protection DepartmentR. M. BERHINIGr v.cc (Engineering Group LeaderFir e Pr otection Depar tmentSUBMITTED BY:G. T. CASTINOManaging EngineerFir eGDP/RMB:plhProtection

MONSAiITO MASTIC FL'3.YA ETUNNEL TEST REPORTThe Insulative Performanceof Experimental Formulationsof Subliming FireRe s is tant Coating 33 C -1A re ort re ared for: TSI Inc.3620 Brannon AvenueSt, Louis, Missouri 63139Special Report 8008-Date of Test:March 16, )973Monsanto Industrial Chemicals CompanySpecial Chemical SystemsResearch and Development DepartmentSt. Louis, Missouri 63)66Prepared byeD G. SchneiderThe information contained herein is true and accurate to the3est of our knowledge and belief, but is transmitted withoutguarantee since the conditions of use are beyond our control.Monsanto Industrial Chemicals Comoany disclaims any liabilityincurred in connection with the use of this information.Furthermore, nothing contained herein shall be construed asa recomzr.cndation to use any product or practice any processin conflict with any existing patents covering any material oritsuse

TABLE OF CONTE aSPaINTRODUCTI'ONSUM MARYDETAILS .e a a e ,e e - I-I Ão.eII-I -IIIXSubliming Fire Resistant Coating 330-1,Formulation No. 02131L on Large Beaxn,Nominal 350 mil CoatingTablebleIVI Figure1 Figure2 , QObservation Notes.Sample and FurnaceTempe rature ProfilesSample IllustrationsMONSANTO MASTIC TES'XING FURNACE . IV-

I INTRODUCTIONThis report describes the insulative performance of experimentalformulations of subliming fire resistant coating 330-1 @(hen testedin a small furnace according to the time/temperature conditionsdescribed in ASTM EL19-67 This. small Monsanto furnace test is intended to be used as ascreening device for the development of insulative coatings. It isnot intended to displace the large furnace test or evaluation ofprop'osed products by recognized testing laboratories.

II

SUMMARYThe coating was applied to a sandblasted carbon steel (ASTRA-52)column. The column was fabricated from two I»beams elded togetherto form a hollow rectangular core. The coating was applied and driedby TSI personnel before being submitted for testing.The test column was subjected to the time/temperature conditionsspecified in ASTM E119-67 using the Monsanto furnace. This furnace„is a modified version of the larger ASTM E119-&7 test furnace.Substrate (steel column) temperature is monitored by six continuously'ecording the rmocouples within the column core. These thermocouplesare spaced at even intervals along the column length from S" to 38"from the bottom of the specimen.A performance rating of 172 minutes was obtained for the test specimenon February 24, 1973 (see Table I for the Test Observation Notes).Performance ratings are, in fact, the length of time between furnaceignition and the atta nment of,a 1100'F (593'C) substate temperature. Atthe time of failure, only one of the six substrate thermocouples had reachedthis temperature. The furnace and sample temperatures recorded duringthis test are illustrated in Figure 1. Figure 2 illustrates the condit:on ofthe specimen before and after testing Fabricated from 10-inch beams, modified and weldect torectangular core of 10" x 5-1/4" x 40"fora@ a

ITA BLE IOBSERVATION NOTES: Subliming Fire Resistant Caating 330-1,Formulation OZ131I on Large Beam,Nominal 350 mil CoatingMinu'. esObservationsUpper half of cyluma beginning to darken with intumescence.Ci. 1/8" of intumescence.P'someblisters.Some surface Gaming (quasi-halo effect).Intumescencemine14.1/4"-1/2" thick and plastic, teznperature rise ca.Intumescence 1/2"-3/4" thick and.elastic/plastic,continues, temperature rise ca. O'C/xnia.surface6C/flaminSurface beginning to whiten,Surface skin has become plastic/tough(rubbery) Temperature zise ca. 4 C/min., intumesce

engineering design information thermo-lag 330-1 subliming coating envelope system for fire resistive enhancement of critical components of nuclear power generating facilities siif040244 8ii026 pdr adqck 05000387 f pdr volume two ll u'' '«-au-l u i i al.',j the attached files are official re