Transcription

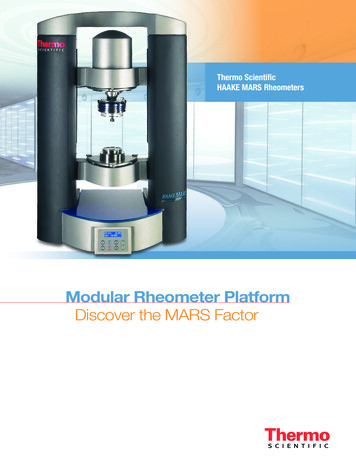

Thermo ScientificHAAKE MARS RheometersModular Rheometer PlatformDiscover the MARS Factor

MARS FACTOR 01FUTURE-ORIENTATIONWhat we offer mostlikely exceeds your presentrequirements, but will supportyour future applications withoutexception.As a world leader in serving science,we bring highperformance rheometersto scientists in advanced quality controland applied research.In developing our Modular AdvancedRheometer System (MARS), we focusedthe Thermo Scientific HAAKE MARS Rheometer Platform on the followingfactors: 2Future-orientationAccuracyEase of useModularityApplication-based solutionsBring the flexibility of the HAAKEMARS platform to your lab andsee how quickly you can respondto changing testing requirementsof today’s new materials. Theenhanced modularity expandsyour options to analyze the mostdemanding challenges faced bythe pharmaceutical, petrochemical,mining, cosmetics, food, coatingsand paints, and polymer industries.Expandable for the FutureHAAKE MARS – rheometer platformin different models for individual demands –today and tomorrow: Wide range of accessories Temperature modules Application-focused measuring cells Measuring geometaries Adaptable to evolving testing requirements with new accessories Hardware and software upgrades for existing HAAKE MARS usersto easily incorporate future technological innovations Compatible with the Thermo Scientific HAAKE Viscotester iQrheometer for transfering test methods from research and developmentto quality control.3

MARS FACTOR 02ACCURACYHAAKE MARS Measuring Head withOptimized, Unique ComponentsFourth generation unique diffusion air bearing withextremely low moment of inertia to measure at verylow torquesMounting rods (optional) for thetemperature-controlled test chamberand additional modules for combinedmeasurement methodsDrag-cup motor withan extremely low inertiaMeasuring head with mount for uppertemperature module lifts to accomodatesampleTwo radialbearingsOne axial bearingFixer lower mount for temperaturemodules and other application-orientatedmodules (Thermo Scientific HAAKE RheoScope , Rheonaut)Optical encoder for highangular resolutionErgonomic 7 button control panel forstatus/error display, lift control androtor releaseQuick fit coupling for rotor on motor axisAdditional access from below for individualtesting requirementsIntegrated control electronics for exchangeabletemperature modules including control valvesfor optimal temperature controlAir bearingNormal force sensorThe HAAKE MARS drag cup motorfeatures the lowest inertia of 10-5 kgm2and due to that has fast responsecharacteristics. The integrated memorychip contains all relevant calibration dataand therefore allows a quick exchangeof the measuring head without timeconsuming calibration.The highly precise and unique fourthgeneration air bearing in the HAAKEMARS is the result of more than30 years of experience anddevelopment.The unique normal force sensor isH-shaped Frame for Optimal Force DistributionOptical encoderA one-piece, aluminum-cast H-shaped frame offers unmatched stabilityand force distribution for reproducible results.The HAAKE MARS optical encoder ismounted to the bottom of the measuringhead to minimize the influence of theinevitable compliance of the motor shaft.The optical encoder has a very highresolution of 12 nanorad, enabling forinstance the determination of the zeroshear viscosity at ultra low shear rates 10-6 s-1 or probing delicate samples inoscillation at very small deformations.The active forces from the sample and the reactive forces in the framework in the same plane in the HAAKE MARS “H-shaped” frame. Thiseffectively prevents the measuring gap from widening as a result of highnormal forces compared to a standard “C-shaped” frame.4MotorThe HAAKE MARS air bearing systemis based on the interaction of threeindividual air bearings: One axial air bearing, supporting themotor shaft in the vertical direction,and is responsible for excellent axialstiffness. Two separate, widely spaced radialair bearings support the motor shaftin the radial direction.based on temperature-compensatedstrain-gauge technology and offers highresolution normal force measurementswithin a range of 0.01 N to 50 N inboth the positive and negative direction.Sensitive tensile strain measurementsbecome possible.Furthermore, it’s feasible to performquick normal force measurements,as well as a timely and accuratecompensation of positive and negativenormal forces that may result fromshrinkage or expansion of the sample.5

MARS FACTOR 03EASE OF USEUser-focused Design Minimizes Errorsand Simplifies OperationUniversal temperature module formaximum measuring flexibilityPneumatic rotor release for a convenient handlingSwitching between coaxial cylinder geometries, plates and conesoccurs in seconds by using a measuring plate insert.Remove the rotor with the click of a button or simple release of the rotorafter curing or crosslinking reactions as part of an automated job routine.TCP/IP Ethernet interface for fast data acquisitionUsing the TCP/IP Ethernet data communication interface allows data points to beacquired and displayed every two milliseconds in real time, critical when measuringsamples with fast changing properties, e.g., UV-curing materials.Integrated web server for password-protectedremote control and maintenanceThe rheometer has its own IP address, so the integrated web servercan be accessed via the internet or company intranet for remoteoperation or to monitor measurements as they happen.‘‘Connect Assist‘‘ technology fora fast accessory exchangeTemperature modules and measuring geometries with quickcouplings are automatically recognized by the HAAKE MARSto reduce mistakes and assure perfect alignment.Optimized measuring geometries foraccurate sample loadingLower measuring plates with the same diameteras the upper plate or cone geometry assureswcorrect sample filling.67

MARS FACTOR 03EASE OF USECustomizable HAAKE RheoWin SoftwareComponentsFunctionality Thermo Scientific HAAKE RheoWin JobManager for fullyautomated process control of measuring Jobs and analysis routinesand report printout or export RheoWin DataManager for interactive evaluation of measured dataas well as sophisticated tools for creating reports and generatingtemplates for graphs, tables and screen views RheoWin UserManager for comprehensive user management regardinguser access control and assignment of specific access rights Monitor mode for preliminary testing, for displaying selectedparameters and for saving manually acquired data Convenient creation and customization of measuring routines usingpredefined measuring and evaluation elements via “drag and drop”techniques Fully automated measurement, analysis and documentation within onemeasuring procedure Real multitasking – simultaneous measurements using severalrheometers and data evaluation Freely configurable data export (ASCII, MS-Excel , XML) Save graphs in a wide variety of formats (pdf, jpg, etc.) Numerous algorithms for data analysis (e.g. interpolation, regressionand automated quality control) Availability of saving the raw data and numerical values for dataevaluation Loop programming with break criteria Integrated image capture with USB and Firewire camera Save numerical raw data of oscillation (OSC) and rotational (ROT)measurements for further evaluationCustomization User-defined configuration of paths and subdirectories for data filing Push-button selection of one out of 12 languages Automatic and modular generation of a file name and automated savingin a predefined subdirectory Data transfer to ERP and laboratory systems (e.g. SAP , LIMS, etc.) Snapshot for quick characterization of an unknown sample RheoWizard expert help to set up a measuring routine Customizable report templates to permit the use of customlogos and textPredefined methods (Jobs) with explanation anduser guidanceAll predefined measuring Jobs include comprehensive testexplanations and further application related information(e.g. application reports)RheoWin range calculator Displays the maximum and the optimal measuring range for allavailable measuring geometries Measuring range plot can be overlaid with actual measurementplot to assess data quality Shows the occurrence of Taylor vortices for coaxial cylindermeasuring geometriesRheoWin raw data viewerThe RheoWin raw data v-iewer provides the following information: Sine wave raw data for stress and strain Lissajous plots for further data analysis Contributions of third and fifth higher harmonics to stressand strain sine wave Influence of instrument inertia and rotor compliance on testresults Raw data for rotational step experiments89

MARS FACTOR 04MODULARITYMeasure from water-like samples up to solidsusing individual measuring geometriesConfidently Control SampleTemperature from -150 ºC to 600 ºC ’’Connect Assist’’ technology for quick exchange of measuring geometriesand automatic rotor identification Plug-and-play temperature modules with quick coupling and automaticrecognition Integrated solvent trap ring used in combination with a sample cover toavoid drying out Universal modules switch between coaxial cylinders and parallel platesor cone and plate geometries in seconds Different types of coaxial cylinders of variousmaterials, in multiple sizes and with different surfaces Double-gap cylinder geometry for measuringlow-viscosity fluidsUniversal Peltier temperature module High-heat transfer materials guarantee fast temperature equilibriumand rapid temperature changes Rotors with ceramic shafts reduce heat conduction when using sample hood Automatic temperature calibration tool ensures correct sample temperature Parallel plates in different diameters and withdifferent surfaces Cone and plate geometries in multiple diametersand with different cone angles Lower plates matching the upper geometry indiameter and surface appearance. For precisesample filling and ideal measuring conditions Vane rotors for relative measurements on highlyfilled or inhomogeneous samples with large particlesas well as for measurements in original containers Disposable geometries for hardening materials Cylinders and parallel plates with serrated orsandblasted surface to avoid wall-slip effects Solid clamps for Dynamic Mechanical ThermalAnalysis (DMTA) SER (Sentmanat Extensional Rheometer ) tool forextensional properties Universal adapters for individual rotors, e.g.,for ISO 2555 spindles Customized measuring geometries available onrequestTemperature module for parallel plates withsample hoodPeltier temperature module – quickly change temperaturewithin the mid temperature range, from -60 C for parallel plateas well as cone and plate measuring geometries or from -40 Cfor coaxial cylinders up to 200 C.Liquid temperature module – control temperature with highprecision; this offers the most reasonably priced temperaturecontrol method when using an existing circulator.Electric temperature module – measure within a broadtemperature range; for parallel plates as well as cone and platemeasuring geometries for temperatures up to 400 C; for coaxialcylinders or application-based measuring cells such as highpressure cells for temperatures up to 300 C.Controlled Test Chamber (CTC) – Unique combination ofconvection and radiation heat transfer for very fast temperaturechanges and homogeneous temperature distribution from 30 Cto 600 C; can be extended to -150 C with the premium, lowtemperature option.Universal active and passive upper temperature modules– Combine individually with the lower temperature module.Set-up is done in seconds with a mounting mechanism which ispart of the measuring head, along with trim position for optimalsample filling, nitrogen connection for inert gas atmosphere andintegrated solvent trap.10Temperature module for parallel plates withInsulated sample hoodElectrical temperature module for parallelplates with active upper heater11

MARS FACTOR 05APPLICATION-BASED SOLUTIONSWe are glad to consult youon further applications andcan offer a broad accessoryportfolio for these, too.Upside-down version of theHAAKE MARSOpen platform forspecific expansions12Thanks to its spacious and modular design,the HAAKE MARS rheometer can be easilyand quickly adapted to new requirements.A variety of specialized and applicationoriented measuring cells are available, e.g.for food, construction materials or UV-curingmaterials.Custom measurement setups can be realizedon request: The measuring head can beinstalled in the bottom holder if desired foroptimal positioning in a beam path to enablethe use of two measuring heads.13

MARS FACTOR 05APPLICATION-BASED SOLUTIONSCosmetics and PharmaceuticalsFoodCreams, ointments, sprays, foams, gels –no matter what the product or application– rheological tests are essential for thedevelopment and optimization of cosmeticand pharmaceutical formulations.While simple viscosity measurementsMany important properties of food (e.g.,flowability, pourabilty, and stability) aredirectly linked to measureable rheologicalparameters like viscosity, yield stress orviscoelasticity. Understanding rheologicalbehavior helps food scientists tode velop new formulations according toconsumer preferences and manufacturingrequirements.are often sufficient for evaluating rawmaterials, extensive rheological testing isnecessary in order to predict and adjustproduct shelf life as well as processingand application behavior. The HAAKEMARS offers an extensive range ofaccessories for testing cosmetic andpharmaceutical materials.Selection of accessories for pharmaceuticalproducts and cosmetics: High-performance Peltier temperature control units forprecise temperature control Universal holder for measurements in original productcontainers e.g., cream jars or cosmetic pots Thermo Scientific RheoScope microscope module forinvestigating structural changes of multi-phase systems andfoams Du Noüy ring and Bi-Cone measur

The rheometer has its own IP address, so the integrated web server can be accessed via the internet or company intranet for remote operation or to monitor measurements as they happen. Optimized measuring geometries for accurate sample loading Lower measuring plates with the same diameter as the upper plate or cone geometry assures wcorrect sample filling. ‘‘Connect Assist‘‘ technology .