Transcription

Firestone Building ProductsFounded in 1982Leader in lowlow-sloped commercial products EPDM, Asphalt & TPO membranesPolyisocyanurate & other insulationsFastenersAccessories2 billion Square feet roofing annual sales50 billion Sq.q Ft. under warrantyy currentlyy1 in 4 LowLow-sloped roofs has Firestone productson it.Acquired Copper Sales, UNAUNA-CLAD, spring2005

Metal Roof BasicsRoof typesBase metal typesPPanellCCoatingsti

Metal Roof SystemsThrough FastenedArchitectural Panel SystemsFlat-Lock clip systemsFlat Standing Seam - water shedding Structural Panel Systems Double-lock, Trapezoid, InsulatedDoublestructural

Through Fastened Roof System

May need to practice beforeattemptingi one off these!!!h!!!

Never underestimate theusefulness of Metal Roofing!!!

Through Fastened Roof SystemSimple InstallationsCorrugated PanelF t iinstallationFastt ll tiExposed FastenersOmega seriesyoffered byFirestone

Architectural Roof SystemsHydrokinetic (water shedding)Steep Roof Slope (minimum 3”/12”)RRequiresiSSubstrateb t t ((non(non-loadl dbbearing)i )Concealed Panel Clips ProvideAttachmentMinimum ExposedpFastenersAdditional Waterproofing Required

Architectural Panel SystemsFlat--Lock Systems:Flaty Independent Panel ClipsStanding Seam Systems: Independent Panel CapsCan Be RadiusedIntegralg Seam Systems:y Simple InstallationNo Seamer RequiredMechanical Seam: Single & Double Fold SeamsRequires Mechanical SeamerCan Be Radiused

Base Metal for Roof PanelsCopperRHEINZINKAl iAluminumStainless SteelSteelAcrylume

Base Metal for Roof PanelsCopperOld world charm and durabilityLow maintenanceWater shedding/nonshedding/non-structural applicationsIdeal for coastal environmentAluminumWater shedding/nonshedding/nong-structural applicationsppAnodic or Kynar coatings required for aesthetics &durabilitySSuperiori ffor coastall environmenti

Base Metal for Roof PanelsStainless SteelVery durableOptional coating for aesthetics (Terne(Terne,, Lead coat)Limited roofing manufacturers, cost prohibitive foruse as a roofing material.SteelMostos commoncoo materiala e a used foro aarchitecturalc ec u a aanddstructural systemsOffered in variety of coatingsPanel durability is dependent on substrate used

Copper – The “Original”Original Metal

CopperThe oldest metal of the metals that is still usedtoday.Very easy to work with (with proper tools).tools)The best life cycle value.Easily recycled.recycledA commodity that is traded on the exchangeeveryday.everydayCan be 33--4 times as expensive as coatedsteel/alum.steel/alum

AluminumLightg weightg and nonnonferrous are thestrengths.GGreatlifelif cyclel costsFlatness is the best ofall the coatablesubstrates.GlobalGoba presencep ese ce &availabilityGreat for Salt regions

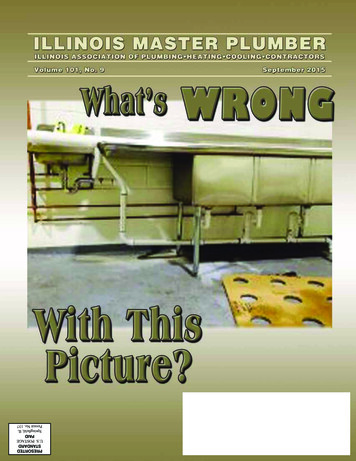

Stainless Steel N t usedd a llott iin roofing.fiNotUsed in column covers, wall panels, customprojects decorativeprojects,decorative, food service areasareas.The two most common are Type 304 andType 316.316 The latter has a higher nickelcontent and thus is the most resistant torusting.There are four predominant (mechanical)finishes.#8 Mirror finish#6 In line brushed finish#4 Standard brush finish2B standard mill finish

Stainless SteelThis is a good example ofdesigning a trulyfinished appearance.The stainless columncovers are #8 mirrorfinish.

SteelThe most popularmaterial used forroofing. It is cost efficient.EEasytot workk with.ithA strong performer.Galvanized steel andGalvalume are theleaders.

Substrate CoatingsMetallic Coatingsg GalvanizedZinc protective coating over base steel( GG-40, GG-60, GG-90 ) GalvalumeAluminum/zinc protective coating over basesteel ( AZAZ--50,50 AZAZ--55 ) AcrylumeClClearacrylicli coatingti ffor unpaintedi t d substrateb t tNote: Both are trademark names

Galvanized SteelSteel strip is hothot-dipped in a continuousline. The thickness of the zinc coating G90 - .90 ounces per square foot 48” x 120” sheet 2.25 lbs of coatingg wt.G60 - .60 ounces per square foot 48” x 120” sheet 1.5 lbs. of coating wt.G40 - .4040 ounces per square ffoot 48” x 120” sheet 1 lbs. of coating wt.

GalvalumeGalvalume sheet steel isan 55% aluminumaluminum--43.4%zinc alloy coated sheetsteel product that isideally suited for mosttypes of roofingapplications.Pictured is an applicationof Acrylume which isacrylic coated Galvalume.

GalvalumeSteel strip that is hothot-dipped in acontinuous line. The thickness of the zinc coating AZ55 - .55 ounces per square foot 48” x 120” sheet 1.375 lbs. of coating wt.AZ50 - .50 ounces per square foot 48” x 120” sheet 1.25 lbs. of coating wt.

Who’sWho s Best?Galvalume versus Galvanized Application many times drives the decisionE g You can not use Galvalume around animalE.g.confinement.Both are the wrong selection for true performancei a saltinlt watert environment.it TheTh correctt substrateb t tfor a salt water environment is aluminum. In realityy both ggalvanized and ggalvalume arelong lasting products and a good selection foran exterior of a project in most conditions.(Salt water being the exclusion for bothboth.))

AcrylumeFor unpainted applications, bare Acrylumeis recommended.It has a clear “Acrylic”yresin coatingg appliedppto both sides of the steel sheet.Can be rollroll-formed without lubricants.The clear coating prevents blackening fromfinger prints and oil spots.The clear coating will dissipate and allowthe Acrylume to age to a soft gray uniformappearance.

RheinzinkWe have developed a relationship withRheinzink,, the market and industry leader.Rheinzink A German mill that is known for producing thebest zinc product world wide.A European leader that selected UNAUNA-CLADt bringtob i ththeiri productd t tto marketk t iin ththe UUnitedit dStates and some parts of Canada.Firestone is Rheinzink’sRhein ink’s largest distribdistributor.torU.S. Warehouse opened about a year ago inthe Boston areaarea.

Rheinzink

Two Primary Alloys3000 Series – Used for painted coatingsAre alloyed with manganesemanganese,, and can be workworkhardened5000 Series – Used for anodized finishes.A alloyedArelld withith magnesiummagnesium,i , derived i mostt offtheir strength from work hardening. Howeveris susceptible to corrosion above 60 60 C,C140 F.140

Why Do We Paint?Provide protectionAdd aesthetic appealPromote corporatebrand and increaserecognitiongDecrease energycosts

From Coil to Building

End UsesWall panelsRoofing panelsComponent ngs

Fluoropolymers (Teflon)A fluoropolymer is a fluorocarbon basedpolymerlwithith multiplelti l strongtcarboncarbon–b –fluorinefl ibonds. It is characterized by a high resistance tosolvents acidssolvents,acids, and basesbases.Excellent resistance to chalk and fadeExcellent chemical resistanceExcellent postpost-formabilityEExcellentll t glosslretentiont tiExcellent humidity resistanceWid range off colorsWidelavailableil bl

ConclusionPaint is comprised of pigmentspigments, resinsresins,solvents, and additives.The quality of the paint ingredients andchemical technology are key to productperformance.performanceThe best choice of paint coating dependsupon a varietyi t off factorsf tincludingi l di endduse, color and gloss desired, budget,productd t lifelifelif -cycle,l andd environment.it

The Valspar CorporationFounded in 1806Celebrating 200 yearsHeadquartered inMinneapolis, MNWorlds largestnon--automotivenoncoatings company 6th in world3rd in USACorporate Headquarters

UNDERLAYMENTSSelf--adhered membraneSelfASTM D 1970 for nail sealability.M bMaybe lleftft exposedd ffor 60 ddays or more.Minimum high temperature resistance of230º F.Contact FSBP Roof Solutions forApproved Alternates (manufacturers)

UnderlaymentsFelt/Rosin Paper (non(non--warranted systems)Non-Asphaltic Membranes (MANon(MA-mechanicallyattached)Self Adhering Membranes (SA(SA-Peel & Stick)Ventilation Mats (Required for Rheinzink)

CLAD-GARD underlaymentsCLADFirestone is proud to present two newunderlayments: CLAD--GARD SA – a modified SBS self adheringCLADunderlayment with a nonnon-skid woven top film CLAD--GARD MA – an inorganic coated wovenCLADunderlayment that is mechanicallymechanically--attached with capnails

CLAD-GARD SACLADunderlaymentFeatures: Woven nonnon-slip top surfaceNon--reinforced modified SBSNonHigh--temp resistantHighUV resistantSilicon--coated splitSiliconsplit--release filmLight--colored reflective surfaceLight

CLAD-GARD MACLADunderlaymentFeatures: Woven top surface is texturedand has a rubberized coatingHigh--temp resistance to 230High230 FUV resistantLight--colored reflectiveLightsurfaceLight weight48” wide x 250’ roll size(10 sq. gross coverage)Warranted for slopes 5/12 ( )

CLAD-GARD RCLADUnderlaymentFeatures: Styrene-ButadieneStyreneButadiene--Styrene (SBS) rubbermodifiedSelfS lf-adhesiveSelfdh i membrane.bReinforced with a nonnon-woven fiberglassmat.matTextured, slipslip-resistant traction film on thetopp surface and a siliconesilicone-treated.Split--back opaque release film on theSplitbottom surface.

RED SHIELDWARRANTED SYSTEMSUC-3 Double LockUCUC--4 Nail Strip,UCp, 40 ft max,, UnidirectionalUC--6 Tall UCUCUC-3UC--14 Snap Lock w/clipUC

UC-1UCSnap--On Standing SeamSnap

UC-2UCSnap--on Batten SeamSnapUL-580 Class 90

UC-3UCDouble Lock Standing SeamUL-580 Class 90M t DadeMetroD d CountyCt ApprovedAd

Double-Lock Architectural SeriesRed Shield Warranty5, 10, 15, 20UC-3

No-Clip Architectural SeriesUC-4Red Shield & 25 Year Red Shield Medallion5, 10, 15, 20, 25

UC--6 Structural Double LockUCStanding SeamUL-580 Class 90ASTM 1592Metro Dade County Approved

Double-Lock Structural SeriesUC-6Red Shield Warranty5,10,15,20

UC--7UCSnap--On Standing SeamSnap

Radius Standing Seam Roof

UC-14Factory-formed panelFactorywith an interlockingseam that snapstogether overconcealed clips Accommodates verylong runs and virtuallyunlimitedli it d ththermallexpansion

UC--14UC

Wth TihtWtiWeatherTightnessWarrantiesNot all warranties are structured the same Read the fine print, exclusions and interpret themeaningExamples Guaranteed not to leak “unless roof system isinstalled improperlyimproperly”Warranty “Excludes Flashings and Trims”Warranty covers panels onlyMany “Weather Tight warranties are propro-rated overtime Some Warranties only cover the cost of materialreplacement, with no labor

Firestone Metal WarrantiesWarranty OfferingsMetal Finish WarrantiesMetal SystemyWarranties ((Red Shield)) Panels/UnderlaymentClips/ScrewsFirestone Brand - It is covered!!

Contractor-FabricatedContractorSSnapSnap-OnO RoofR f EdEdge(Firestone Detail RE-10 or Similar)Note: Not suitable for extended wind warranties,projects requiring FM approval, or projects requiringANSI ES-1compliance.Material RequirementsUNA-CLAD MATERIALS:Snap-On Cover &Splice PlatesOTHER MATERIALS:Water DamFastenersSealantsMin. 24 Ga. G-90 Galv. Steel w/ Kynar Finishor Min. .040 Aluminum (Painted or Anodized)Min. 24 Ga. G-90 Galv. Steel1 1/4" Hot Dipped Galv. Roofing NailsFirestone AP SealantInstallation Requirements1.2.3.4.5.Back-edge of Snap-on cover shall be formed upward to avoid cutting membrane (as illustrated inFirestone drawing)Water dam shall be continuous and fastened 4" O.C. max. with roofing nails.Min. 88" wide splice plates shall be installed at all connections and intersections.A continuous bead of Firestone AP Sealant shall be installed at all connections and intersections.(Note: Sealants at metal connections are an owner maintenance item in accordance with FirestoneRed Shield Maintenance Guidelines.)Follow all Firestone drawing notes and an application specifications.

Contractor-FabricatedContractorCoping(Firestone Detail T-12 or Similar)Note: Not suitable for extended wind warranties,projects requiring FM approval, or projects requiringANSI ES-1compliance.Material RequirementsUNA-CLAD MATERIALS:Coping Cap &Splice PlatesOTHER MATERIALS:CleatsFastenersSealantsMin. 24 Ga. G-90 Galv. Steel w/ Kynar FinishMin. .040 Aluminum (Painted or Anodized)Min. 22 Ga. G-90 Galv. Steel1 1/4" Hot Dipped Galv. Roofing NailsFirestone AP SealantInstallation Requirements1.2.3.4.In lieu of the factory-fabricated spring clip supplied with Firestone Coping, minimum 22 ga. shopfabricated cleats may be used. Cleats shall be continuous on both sides of the parapet and fastened4" O.C. max. with roofing nails.Min. 88" wide splice plates shall be installed at all connections and intersections.A continuous bead of Firestone AP Sealant shall be installed at all connections and intersections.(Note: Sealants at metal connections are an owner maintenance item in accordance with FirestoneRed Shield Maintenance Guidelines.)Follow all Firestone drawing notes and an application specifications.

Metal Accessory WarrantiesOther OptionsFacades & Equipment Screens can also be included when designedgand quotedqbyy Firestone MetalProducts @ FSBP

Metal System WarrantiesType & AvailabilityWarranty Type: Red Shield 5, 10, 15, or 20 year standard termMay be combined with other systems (EPDM / TPO /Asphalt),Plus new 25 year Red Shield Medallion term for UCUC-4onlyWarranty Availability: Licensed Contractors Must be authorized for metal by local sales rep andapproved by Regional Sales ManagerMay need to provide a job history of past projects

Metal System WarrantiesTh i d Systemyand Componentsp UC-3, UCUCUC--4, UCUC--6 or UCUC--14 panel systems onlyFasteners, clips & sealants supplied by factoryFactory or Contractor fabricated trim with some field optionsInstalled over Firestone’s or Approved Underlayment*Follow standard Firestone Red Shield details or detailswith prior approval from FirestoneQuoted by FSBP – Estimating Services Lump-sum quote similar to Tapered IsoLumpRequires approved shop drawings & verified field measurements

Metaleta SysteSystem Warrantiesa a t esContractor Procedures1.22.3.44.5.6.Receive quote from Firestone Building Products SalesReps.S b i purchaseSubmithorderd to FiFirestone BBuildingildi PProductsdSubmit PrePre-Installation Notice (P.I.N.)Submit shop drawings to Firestone Building Products forreviewComplete InstallationSubmit RFI

Other ItemsOil CanningUnderlaymentsD k /S b t tDecks/SubstratesGreen Design (Tree Hugger’s delight)Shipping/Jobsite stagingHands On!!!

Oil Canning“OilOil canning is an aesthetic issue, not a structuralproblem or a defect. It is unrealistic to expectany architectural roof or similar widewide-metalelement to be totally free of some degree of oilcanning. While oil canning cannot be totallyeliminated,li i t d adherencedhtto iindustryd t acceptedt d anddrecognized methods of design, metalspecification handlingspecification,handling, fabricationfabrication, andinstallation can minimize its occurrence.”- 6th editionedition, SMACNA Technical Manual

Oil CanningCauses of oil canningg Coil manufacturingExcess material in themiddle of the coil stripExcess material in theedges of the coil stripCamber - coil side edge isnot straightgFabrication Slitting of coil for properpanel widthLess control with onon-sitegroll forming

Oil CanningCauses of oil canning installationSubstrates and underlaymentsyOut of plane sub – structureStretched seam engagementOver - driven fastenersHandling

Methods of Control Oil CanningStringent specifications for maintainingproper plane of subsub-structureTension leveling material before forming(not possible with onon-site roll forming)Design panel with stiffening ribs orStriationsChoosing narrow panel widthsHeavier gauge materialInstall Foam Backer Rod @ center of Pan

Tension Leveling (factory)

STIFFENING RIBS

Foam Backer RodBacker Rod

Backer--Rod Works!!!!Backer

How to applyapply, What Diameter?After removal from the cratecrate, simply tape acontinuous pc. full length of the panel.If difficult staging (roof heightheight, distancedistance,weather) Backer can be applied prior topanel placement.placementStart with ½” dia. Adjust if needed to largerdidiameter.tThis is not a Firestone product, it will notbe included in your order

Green DesignRecyclability Copper zinc,Copper,zinc aluminum & steel are all 100%recyclableRecycled percentages vary on type of metal andmarket conditionsSSolarReflectivityf Deflection of solar energy from the material’s surfaceTh greaterThet theth amountt off solarl energy reflected,fl t d thethless energy the building will need to cool down

Stagingg g the JobBundles should be lifted with equipment thatsupports most of the panel length. (spreaders)Bundles should be rigidlyg yppackagedg withcrosswise and lengthwise blocking, on levelsurface.Protected from contact with other items such asstructural components.PANEL/CRATES NEED TO BE TARPED ORCOVERED AFTER EACH DAY!!!!!

When using a forklift, carefulhandling and unloading practicesshould also be used toAvoid excessive bundleflexing or abrasion of thepanelsForklift forks must be aminimum of five feetapart.Do not transport openbundles.bundlesDrive slowly whencrossing rough terrain toprevent panel buckling.

Field Cuttingfactory-supplied cutcut-toto-Minimized by using factorylength Panels.If required use Straight blade shears, profile shears, nibblersor hand snipssnips.Clean-cut edge without damaging theCleanpainti t or metalt l coating.tiThe shear blades should be kept sharp tominimize burrsDO NOT cut with an abrasive wheel,hacksaw, or other cutting tools!!!!

Firestone Buildingg Productswww.firestonebp.comfi tbwww.unaclad.com

A European leader that selected UNAA European leader that selected UNA--CLAD CLAD t bi thi d tt kti th Uitdto bring their product to market in the United States and some parts of Canada. Firestone isFirestone is Rhein ink’sRheinzink’s largest distri