Transcription

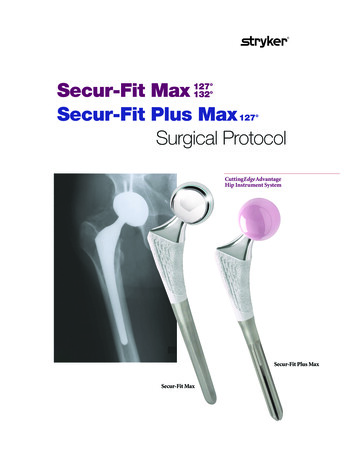

DECEMBER 2016VOLUME 11 NO 1The Leader in Replacement Parts for Healthcare Equipment Since 1972RPI Now Offers Parts to FitSterrad NX & 100S SterilizersPlanned Maintenance continues tobe a driving factor in keeping equipment on line and productive.grew, so did our enthusiasm and nowwe are pleased to offer three newPlanned Maintenance Kits.RPI ContinuesSupport for theMidmark 411 (75L)Power Exam TablesWhen Midmark In 2014 we were asked to investigatethe possibility of developing thePlanned Maintenance Kits for Sterradsterilizers, models NX and 100S. Asthe requests for the parts and PM KitsFor some great Service Tipson the Sterrad NX & 100S,you will find them on page 3.We now offer the PM-2 Kit (RPI Part#SDK003) to fit the NX. This annualmaintenance Kit addresses the basicwear items such as shelf supports,electrode spacers, lamp assembly, andfilters – along with several other service parts. (The only item not included in the RPI major PM Kit at thistime is the catalytic converter, however, we are in the process of developingContinued on the back pageMore New Parts to FitDental Vacuum Unitsrecently discontinued support for the 411 (75L)Power Exam Tables, RPI was contacted by many upset service technicianslooking for ways to help the hundredsof clinics and doctor’s offices thatcurrently own and love their 411's.So, we carefully reviewed the tablesand developed an action plan based onthe parts our customers needed most.Continued on the back pageFilter Kit to fit Bison SeriesRPI Part #VPK117By Mark Micucci, RPI Product DevelopmentAdding to RPI’s ever increasing lineof parts for Dental Vacuum Systems,RPI is proud to announce yet anotherset of new parts to help you serviceyour customers' dry and wet ring vacuum systems.For the DentalEZ line of Dry VacuumSystems, RPI now offers the FilterKits to fit the Badger, Bulldog andBison Series units.For the Bulldog 550 & QT Series, RPIoffers RPI Part #VPK113, the FilterKit that includes the Oil FilterElement, the 3 micron Filter Elementand the medium size 5 micron FilterElement.Filter Kit to fit Bulldog 550 & QT SeriesRPI Part #VPK113For the Badger Units, RPI offers aFilter Kit that includes both the largeand small 5 micron Filter Elements.Just ask for RPI Part #VPK110.Filter Kit to fit Badger UnitsRPI Part #VPK110And for the Bison Series, ask for theRPI Part #VPK117 Filter Kit, whichincludes the Oil Filter Element, themedium size 5 micron Filter Elementand the larger 5 micron FilterElement.As with all RPI Filter Kits, all partsare also sold separately.For the separator tanks, RPI offers theSeparator Lid Gaskets for both sizesof Midmark PowerMax andPowerMax G separator tanks, alongwith the CAS (Cyclone ActionSeparator) Cover Gasket to fit the AirTechniques units.Also, for the Air Techniques CAS systems, the Drain Assembly is availableas a complete Kit, along with theDrain Valve by itself. The Gasket to fitthe DentalEZ 4000/8000 DryMaxFlange is also now available.Continued on the back page

THE RPI FAMILYHello my name is Jocelyn.I grew up here in the San FernandoValley where I graduated from SanFernando High School. I'm theyoungest of four children.I am a mother to a beautiful baby girlnamed Elizabeth. We spend our timeplaying dress up and having tea parties with her stuffed animals.Ira LapidesCEO & PresidentReplacement Parts Industries, Inc.In our Spring, 2016 newsletter, I wrote about our plan to transition to new enterprise software, converting from our 30 plus year old software to a new, modern, and more capableplatform. On July 5th of this year, we went live on our new software, which includes all of ouraccounting, sales order, customer, inventory, supplier, and all of our other modules. It was anenormous task, but everyone here was up to the challenge, and the transition went fairly well.As to be expected, there were a few hitches, and we are continuing to work to get the software where we need it to be to allow us to continue to provide you with excellent service andparts. The inventory side of things ended up with a couple of unexpected snags, and ourbackorders spiked for a little while, but we are in much better shape now and will continueto work to make improvements in that area to minimize backorders as much as possible. Wewill be adding additional software modules over time and streamlining processes as we arealways looking for ways to improve, and as always, your feedback and suggestions arealways welcome.I must thank all of our customers for your patience during this transition, as I know we fellshort a few times from our normal level of service. I sincerely apologize if this caused you anyproblems. We tried to anticipate all potential issues, but with a software conversion it is sometimes impossible to catch everything in advance. We will do everything possible to maintainthe level of service and parts availability that you are accustomed over these many years, andhopefully, make some nice improvements that will benefit you down the road.My daughter amazes me everyday.I've watched her grow from wearingdirty diapers to now wanting to doeverything on her own (withoutMommy's or Daddy's help). She is myworld.In my spare time I enjoy hiking withmy friends, because it takes me out ofmy comfort zone.I also enjoy the spectacular areas thatthis part of California offers. Myfavorite spot is Malibu with the beautiful hills and blue ocean views.I also love visiting my family. Andsince they are close by, I get to spendtime with all my loved ones includingmy niece and nephews.On a different note, many of you might also be aware of the docket that the FDA opened forcomment this past April regarding definitions and clarification of terms such as refurbisher,remarketer, remanufacturer, and service, and asking for feedback on the potential for regulation of refurbishers and servicers of medical equipment (remarketers and remanufacturersare already regulated by the FDA).We spend most of our family nightsplaying board games and watchingmovies while enjoying fresh bakedcookies. I think that the best way toend the weekend is with the familia.This drew quite a response from the medical equipment, service, and healthcare industries,and parties from all corners submitted feedback to the FDA. The comments were quite varied,and it would be worth your time to visit the FDA website to read some of the feedback theyreceived and keep up to date on this important matter. The FDA also held an informationalconference the end of October with interested parties to discuss these issues, so we will seewhat comes of this.I have been working at RPI in theShipping and Warehouse Departmentsince 2014. It is a pleasure to workwith Brian, my Supervisor, and therest of the crew.The FDA took a look at this issue back in the late 1990’s and came away with the decisionnot to regulate these additional areas. Excellent data was provided by the ECRI Institute backthen, and now again in 2016 evidencing a lack of issues with OEM or aftermarket service. Itwill be interesting to see what the FDA decides to do this time around, but if they decide tomove toward regulation, the ramifications will be quite significant and I believe quite damaging to our industry as a whole. However possible, get informed on this issue and get involved.It will have significant impact on your job and your business.We wish you happy holidays, and the very best to you in the coming New Year!2Jocelyn VilledaShipping & WarehouseReplacement Parts Industries, Inc “The Alternate Source” December 2016

Sterrad NX & 100SService Tips and Helpful HintsBy Phil Goldstein and Chris Jacobs, RPI Product DevelopmentBelow you will find useful tips tohelp make life a little easier whenservicing the Sterrad NX scopereprocessor. There is valuable information from simple time savers toservice tips that can keep you safewhen removing parts from the unitduring servicing. While removing the top cover, if themachine has been on for a while, becareful of the door closing mechanism.It is very hot along with several valvesthat are part of the vaporizer/condenserassembly. When installing a new conical screenfilter or oil mist filter, make sure tonote the direction of the two largeclamps (side by side) that allow accessto both filters. It is easiest to removeand place these two clamps backtogether at the same time, using theclamp associated with the conical filteras a point of reference. Also note thedirection of the shaft leading to the oilmist filter. There is one side of thisshaft that is short and one that is justslightly longer. The shaft must beplaced with the shorter side attachingto the clamp. If cassettes that were placed in themachine ejected immediately, thosecassettes are no longer usable even ifthey were never punctured. This is dueto the barcode reader. There is a wayto clear the memory for the barcodereader so you may use those cassettesagain. Here's what to do: The keyboardmust be connected to the machine. Atthe login screen, press CRTL ALT M, you will see a commandprompt “sh-2.06b#” in the upper leftcorner. Type in cd /idew (include thespace after cd) and press ENTER.Then type in ls –a (the first letter is alower case L and include the spaceafter ls) and press ENTER. You willsee all the files in the /idew directory andwill see a specific file called “.laser.dat”.You will need to type rm .laser.dat(include the space after rm) and pressENTER. This will remove the laser fileand you can check to see it’s removed bytyping the ls –a and press ENTER. Nowthat you have removed the file, pressCRTL ALT M and reboot the system.Now login as service and insert a cassette.After inserting the cassette there will bean error message saying “invalid cassettedatabase, please call ASP” then the unitwill eject the cassette. Press AdditionalUtilities, Service Functions, and thenCassette. Press the RESET button on thelower right of the screen. This is the finalstep in clearing your barcode reader’smemory. This process removes thesystem’s memory for cassettes whichallows unused cassettes that were ejectedduring testing of the machine to bereused. It is not to allow the use ofexpired cassettes. If you are unable to usethe unused cassettes repeat the steps listed above and try again. Many of the door sensor problems canbe caused by the smallest of particlesgetting on the door locking mechanism’ssensor. Use a small Q-tip or microfibercloth on the sensor to remove any particles, and the errors should not appear. When replacing the catalytic converter,oil mist filter, the conical screen filter orany part of the vacuum pump assemblythat involves removing the three largeclamp assemblies, take note as to whichdirection the straight lever on the clamp isfacing. Facing the straight lever towardsthe back of the NX allows the least interference between the clamps and yourhands. If you remove both tubes (conicalscreen filter to vacuum pump control andoil mist filter to pump) at the same time,start with the outside clamp on the conical screen filter assembly then remove theclamp on the oil mist filter. Reassembly isReplacement Parts Industries, Inc “The Alternate Source” December 2016just the opposite. This actually allowsyou to attach the last clamp over thepump assembly from an unobstructedposition through the opening in thesterilizer housing. When removing an old sterile airHEPA filter and installing a new one,use both hands. Steady the vent valveassembly with one hand while removing and installing the filter capsule withthe other hand. Prior to disassembling any portion ofthe hydrogen peroxide monitor anddetector assembly, make sure the surrounding area is clean and free of anyair born dirt or dust. A can of compressed air works well. Clean lint freegloves are advised when handling theoptical windows. Be careful when replacing the delivery valve. Always wear rubber glovesand inspect the area just below thedelivery valve for leaks. The 59%hydrogen peroxide solution is toxic andit will burn your skin. You will noticean immediate oxidation reaction andyour skin will turn white. When replacing the vacuum pump oilin the compressor, you will notice thatRPI supplies a yorker cap with thebottle to make refilling a little easier.These are just a few tips from us here atRPI, and if you would like more information about this unit, please give ourtech support team a call at (800) 2219723 option 5 or extension 135. Also ifthere is anything you would like toshare with us about these units, you canalways email us at techsupport@rpiparts.com. For a complete list of all ofthe RPI parts to fit the Sterrad NX and100S, please see the center pages ofthis newsletter or visit the RPI websiteat www.rpiparts.com.3

The following new parts are now in stock,DENTAL EQUIPMENTMore Parts to fit Dental Vacuum UnitsDRAIN ASSEMBLYRPI Part #VPA121OEM Part #54660OIL FILTER ELEMENTRPI Part #VPE116OEM Part #310705FLOAT ASSEMBLY (NEW)RPI Part #VPA125OEM Part #002-1448-00 2 FloatsFILTER ELEMENTRPI Part #VPE118OEM Part #003549SPGASKET (SEPARATOR LID)RPI Part #VPG106OEM Part #053-1616-00FLOAT ASSEMBLY (OLD)RPI Part #VPA126OEM Part #015-2067-00 3 FloatsVPE118VPE114VPE116VPK117VPA125FILTER ELEMENTRPI Part #VPE111OEM Part #004691SPGASKET (SEPARATOR LID)RPI Part #VPG107OEM Part #053-2159-00FILTER KITRPI Part #VPK117OEM Part #003750FLANGE GASKETRPI Part #VPG108OEM Part #65950000FLOAT SWITCH (FAIL-SAFE)RPI Part #VPS129OEM Part #62950600VPG108FILTER ELEMENTRPI Part #VPE112OEM Part #004876SPCAS COVER GASKETRPI Part #VPG109OEM Part #54619FLOAT SWITCH (DIFFERENTIAL)RPI Part #VPS130OEM Part #62950500FILTER ELEMENTRPI Part #VPE114OEM Part #003550SPFILTER KITRPI Part #VPK110OEM Part #005301SPVACUUM RELIEF VALVERPI Part #VPV124OEM Part #029-3811-00FILTER ELEMENTRPI Part #VPE115OEM Part #003548SPFILTER KITRPI Part #VPK113OEM Part #003740VACUUM RELIEF VALVE (PLATFORM)RPI Part #VPV141OEM Part #77002144VPE115TABLE TOP STERILIZERSParts to fit Midmark Ritter UltraClave M9 & M11 SterilizersDOOR MOTOR ASSEMBLYRPI Part #MIA180OEM Part #002-0790-00Models: M9-020 thru -022& M11-020 thru -022MAIN HARNESSMIA180RPI Part #MIH238OEM Part #015-1554-00 (Main Harness)/015-1640-00 (Hi Limit Jumper)Models: M9-020 thru -022 (Serial # prefixesRN, RP, RR & V), M9D-020 thru -022 (Serial #prefixes RW, RX & V), M11-020 thru -022(Serial # prefixes RS, RT, RV & V) & M11D-020thru -022 (Serial # prefixes RY, RZ & V)4PRINTER CARTRIDGERPI Part #MIC226OEM Part #053-0505-00Models: M9-001 thru -019, M9-020 thru -022,M11-001 thru -019 & M11-020 thru -022LABEL (PRESSURE RELIEF VALVE WARNING)RPI Part #MIL260OEM Part #061-0309-00/061-0309-01Models: M9-001 thru -019 & M11-001 thru -019STEAM BLOCK KITRPI Part #MIK236OEM Part #002-1244-01Models: M9-020 thru -022 &M9D-020 thru -022LABEL (DOOR WARNING)RPI Part #MIL261OEM Part #061-0381-00/061-0532-00Models: M9-001 thru -019 & M11-001 thru -019STEAM BLOCK KITRPI Part #MIK237OEM Part #002-1244-02Models: M11-020 thru -022 &M11D-020 thru -022SNAP CLIPRPI Part #RPC957OEM Part #042-0182-00Models: M9-020 thru -022, M9D-020 thru -022,M11-020 thru -022 & M11D-020 thru -022Replacement Parts Industries, Inc “The Alternate Source” December 2016

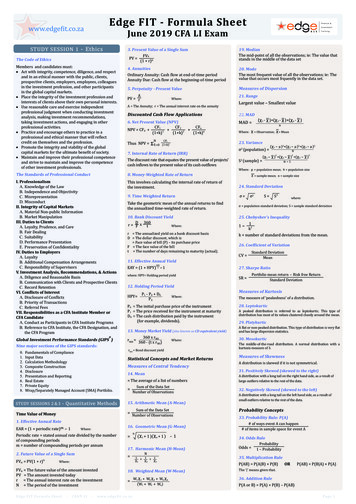

ready to ship the day your order is received!SCOPE PROCESSING SYSTEMSNew Line of Parts to fit Sterrad NX & 100S Sterilization SystemsPM-2 KITRPI Part #SDK003OEM Part #100798-02Model: NXIncludes:- (1) UV Lamp Assembly (RPI Part #SDA006),- (5) Thermistor Assembly (RPI Part #SDA007),- (1) Air Filter (Base) (RPI Part #SDF001),- (1) Oil Mist Filter (Red) (RPI Part #SDF002),- (1) Conical Screen Filter (RPI Part #SDF017),- (1 pc) Air Filter (RPI Part #SDF025),- (1 pkg of 2) Handle (Shelf Extension) (RPI Part#SDH011),- (1) Feedthru Screw Washer Kit (RPI PartSDK012),- (1) Optical Window Kit (RPI Part #SDK014),- (1 pkg of 2) Upper Shelf Support (RPI Part#SDS008),- (1 pkg of 2) Lower Shelf Support (RPI Part#SDS009),- (1 pkg of 6) Spacer (Electrode) (RPI Part#SDS013),- (1 pkg of 2) Sleeve Gasket (RPI Part #SDS015),- (1) Door Seal (RPI Part #SDS018),- (1) Delivery Valve (RPI Part #SDV010),- (1) Sterile Air (HEPA) Filter (RPI Part #SSF011),- (2) Vacuum Pump Oil (RPI Part #RPL926),- (1 pc) Absorbent Pad (RPI Part #RPP958),- (18" lg.) Tubing (Clear 3/8" ID PVC) (RPI Part#RPT646),- (1) Bottle (1 liter/32 fl. oz.) (RPI Part #RPB939),- (1) Thermal Grease (ThermalCote ) (RPI Part#RPG938)PM-1 KITRPI Part #SDK020OEM Part #05-06899-1-100Model: 100SIncludes:- (1) Oil Mist Filter (Red) (RPI Part #SDF002),- (1) Vacuum Pump Oil (RPI Part #RPL926),- (1) Bottle (1 Liter / 32 fl. oz.) (RPI Part #RPB939),- (1 pc) Absorbent Pad (RPI Part #RPP958)- (18" lg.) Drain Tubing (Clear 3/8" ID PVC) (RPIPart #RPT646)PM-2 KITRPI Part #SDK021OEM Part #05-06899-2-200Model: 100SIncludes :- (1) Sterile Air (HEPA) Filter (RPI Part #SSF011),- (1) Door Seal (RPI Part #SDS018),- (1) Oil Mist Filter (RPI Part #SDF022),- (1 pkg of 18) Spacer (Electrode) (RPI Part#SDS023),- (1 pkg of 2) Shelf Stop Kit (RPI Part #SDK024)UV LAMP ASSEMBLYRPI Part #SDA006OEM Part #40-52125-001Model: NXTHERMISTOR ASSEMBLYRPI Part #SDA007OEM Part #40-52136-001Model: NXLOWER SHELF SUPPORTRPI Part #SDS009OEM Part #33-51152-0-001Model: NXSDA006SPACER (ELECTRODE)RPI Part #SDS013OEM Part #33-51158-0-001Model: NXAIR FILTER (BASE)RPI Part #SDF001OEM Part #25-52153-001Model: NXSLEEVE GASKETRPI Part #SDS015OEM Part # (No OEM Part # Available)Model: NXOIL MIST FILTER (RED)RPI Part #SDF002OEM Part #25-08560-001Models: NX & 100SDOOR SEALRPI Part #SDS018OEM Part #22-00537-385Models: NX & 100SCONICAL SCREEN FILTERRPI Part #SDF017OEM Part #100147-01Model: NXELECTRODE SPACERRPI Part #SDS023OEM Part #33-00888-0-001Model: 100SOIL MIST FILTERRPI Part #SDF022OEM Part #25-04351-001Model: 100SDELIVERY VALVERPI Part #SDV010OEM Part #28-53786-001Model: NXAIR FILTERRPI Part #SDF025OEM Part #25-50703-001Model: NXSDF022SDS023STERILE AIR FILTERRPI Part #SSF011OEM Part #25-51198-001Model: NXHANDLE (SHELF EXTENSION)RPI Part #SDH011OEM Part #33-05440-0-002Model: NXBOTTLE (1 Liter/32 fl. oz.)RPI Part #RPB939OEM Part # (No OEM Part # Available)Models: NX & 100SFEEDTHRU SCREW WASHER KITRPI Part #SDK012OEM Part #109522-01Model: NXTHERMAL GREASE (THERMALCOTE )RPI Part #RPG938OEM Part # (No OEM Part # Available)Models: NX & 100SOPTICAL WINDOW KITRPI Part #SDK014OEM Part #32-51413-0-001/22-00537-209Model: NXVACUUM PUMP OILRPI Part #RPL926OEM Part #37-00579-003Model: NXSHELF STOP KITRPI Part #SDK024OEM Part #33-02069-0-001Model: 100SABSORBANT PADRPI Part #RPP958OEM Part # (No OEM Part # Available)Models: NX & 100SUPPER SHELF SUPPORTRPI Part #SDS008OEM Part #33-53558-0-001Model: NXReplacement Parts Industries, Inc “The Alternate Source” December 2016SDK014RPG938TUBING (CLEAR 3/8" - ID PVC)RPI Part #RPT646OEM Part # (No OEM Part # Available)Models: NX & 100S5

TECHTALKBy Mark MicucciRPI Product DevelopmentHow to Check a Start CapacitorTo See If It's Dead or NotIf your motor makes a humming noise, but will not start,you need to check the Start Capacitor. The following testwill tell you if the capacitor is completely dead or not.Sherry LapidesVice President, Customer RelationsReplacement Parts Industries, Inc.Over the course of the almost 45 years that RPI has been in business, I have met a few of our many customers on their home turf.Some of these meetings have been memorable, to say the least.One customer who comes to mind had a service company on LongIsland. Al and I arranged to meet him and his wife for drinks and dinner in New York City. This was probably in the early 1990's. We wentto the lounge at the top of the World Trade Center, had drinks,watched the sunset, admired the view and then decided to go backdown to go for dinner. And then the unthinkable happened. The elevator lurched to a stop and a disembodied voice came through thespeaker: “Don’t worry, folks. We’ll have this little problem fixed in amoment.” Picture it – we’re stuck in a crowded elevator filled withpeople who have had too much to drink, around 90 floors up, andsomeone is telling us not to worry. And my husba

time is the catalytic converter, howev-er, we are in the process of developing RPI Now Offers Parts to Fit Sterrad NX & 100S Sterilizers As with all RPI Filter Kits, all parts are also sold separately. For the separator tanks, RPI offers the Separator Lid Gaskets for both sizes of Midmark