Transcription

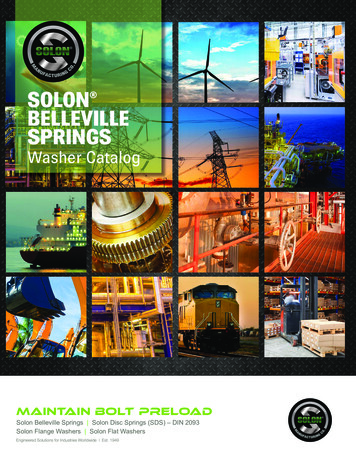

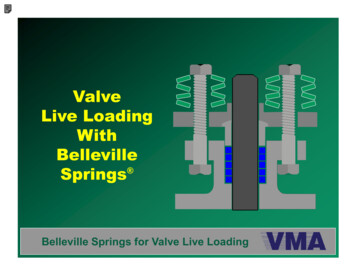

ValveLive LoadingWithBellevilleSprings Belleville Springs for Valve Live Loading

What is Valve Live Loading?The addition of BellevilleSprings to the gland followerstuds to maintain thepacking load of the valveover time.Belleville Springs for Valve Live Loading

What’s In The Name?BellevilleNamed for Julian F. Belleville who received aBritish patent in the 1860’s.(It was on a valve application)Belleville Springs, Belleville Disc Springs, Disc Springsand Conical Compression Washersare all names for the same type of spring.Belleville Springs for Valve Live Loading

Typical Belleville SpringODhIDComprised of 5 main componentsOutside DiameterInside DiameterMaterial ThicknessOverall HeightDeflection or MovementBelleville Springs for Valve Live LoadingH

Single Belleville Spring1500 lb. Flat Load(Example)15001250100075050000101520Belleville Springs for Valve Live Loading

Belleville Springwith1500lb/689kg Flat elleville Springs for Valve Live LoadingFlat1500lbs/680kg

Stacking Arrangementsof Solon Belleville SpringsSingleSeriesParallelParallel / SeriesBelleville Springs for Valve Live Loading

Deflection ille Springs for Valve Live Loading

Which Valves Are CandidatesFor Live Loading?Frequently Cycled ValvesOperated Valves (Air or Motor)Critical ApplicationsSafety or Difficult LocationHistory of Packing LeaksMonitored ValvesBelleville Springs for Valve Live Loading

Reasons For Valve Leaks?Wrong Packing for the ApplicationBent, Scored, or Pitted Valve StemsImproper Packing InstallationInfrequent UseFrequent or High CyclesLoss Of Packing LoadBelleville Springs for Valve Live Loading

34.55000WithLive Load300020.7WithoutLive Load0510In - Service Consolidation (%)Belleville Springs for Valve Live LoadingPacking Compressive Stress (MPa)Packing Compressive Stress (PSI)How Live Loading Works

Packing PressureRetightening Vs Live LoadingLeakageThresholdYears 1Loss Of Torque Leads To Leakage2No Live LoadGland NutsRe-tightened3456Live LoadSprings MaintainPacking PressureBelleville Springs for Valve Live Loading

Basic Formula For CalculatingValve Live LoadingRequiredBolt Load A x PBA Packing AreaP 1.5 x System Pressure or Manufacturers Load Factor(Whichever is greater)B Number of Gland BoltsTorque(Ft. Lbs.).2 x Bolt Load x Bolt Diameter 12Formula based on 5 ring graphite set (EPRI)Belleville Springs for Valve Live Loading

Selecting the Proper Spring MaterialOperating Environment & Temperature17-7PH – Most Widely UsedGood for most environments except Chloride & Fluorides (Unlessplated) -400 F / -240 C to 550 F / 288 C301 SS – Limited Size Range-400ºF/-240ºC to 550ºF/288ºCInconel 718 – Higher CostHigh Temperatures & Corrosives -400F / -240C to 1100F / 593 C6150 Alloy – Needs to be plated for outdoor use-40ºF/-40ºC to 350ºF/177ºCH-13 Tool Steel – High TempAmbient to 1100F / 593CBelleville Springs for Valve Live Loading

Selecting the Proper Spring MaterialSpring Load vs MaterialIt is important to note when selecting a Bellevillespring that the same size part made with a differentmaterial may have a different flat load.Belleville Springs for Valve Live Loading

Factors in Selecting a Belleville ingsSize ConstraintsOD, ID, Height of spring stackLoadUsually select a spring with a flat load20% higher than the preloadBelleville Springs for Valve Live Loading

Typical Installation ofSolon Belleville SpringsBelleville Springs for Valve Live Loading

Alternate InstallationsBelleville Springs for Valve Live Loading

Alternate InstallationsBelleville Springs for Valve Live Loading

Alternate InstallationsBelleville Springs for Valve Live Loading

SleevesNo SleevesBelleville Springs for Valve Live Loading

Why Sleeves Are UsedI.D. Of Spring Is Too Large For The Gland StudMetric Springs Used With Inch StudsSleeve Is Used To Limit TorqueSpring Thickness Is LessThan The Stud Thread RootSleeve Is Used To MeasureRelaxation In Packing(Usually Done With External Sleeve)Belleville Springs for Valve Live Loading

Other Live Loaded AreasLive Loaded BonnetBellevilleSpringBelleville Springs for Valve Live Loading

Other Live Loaded AreasLive Loaded Ball SeatBellevilleSpringBelleville Springs for Valve Live Loading

TypicalLiveLoadingSurveySheetLive Loading InformationStem Dia.*Stuffing Box Dia.*Stuffing Box Depth*Stud Dia.*No. of Studs*System Temp.*System Pressure*Packing Type*Available Stud LengthNo. of Packing RingsPacking LoadPacking TorqueIn-Service ConsolidationBushing HgtGeneral InformationCustomerUnitSystemValve Mfg.Valve SizeValve ClassValve TypeSerial No.Tag No.LocationPositionOperatedFlange Information* Req’d For Live Loading CalculationsSpring InformationSolon Part No.No of Springs / StudSpring ConfigurationNo. of StudsStud Dia.Gasket TypeGasket SizeGasket No.TorqueSolon Part No.Bonnet InformationNo. of StudsStud Dia.Gasket TypeGasket SizeGasket No.TorqueSolon Part No.Belleville Springs for Valve Live Loading

Thank you!Solon Manufacturing Co.George Davet, Chief ille Springs for Valve Live LoadingH

Belleville. NamedNamedfor Julian F. Belleville who received a British patent in the 1860’s. (It was on a valve application) Belleville Springs for Valve Live Loading. Belleville Springs, Belleville Disc Springs, Disc Springs and Conical Compression Wa