Transcription

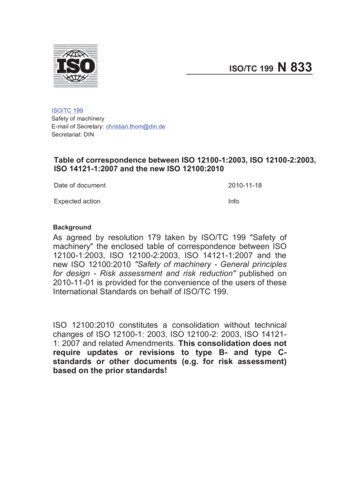

ISO/TC 199N 833ISO/TC 199Safety of machineryE-mail of Secretary: christian.thom@din.deSecretariat: DINTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003,ISO 14121-1:2007 and the new ISO 12100:2010Date of document2010-11-18Expected actionInfoBackgroundAs agreed by resolution 179 taken by ISO/TC 199 "Safety ofmachinery" the enclosed table of correspondence between ISO12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and thenew ISO 12100:2010 "Safety of machinery - General principlesfor design - Risk assessment and risk reduction" published on2010-11-01 is provided for the convenience of the users of theseInternational Standards on behalf of ISO/TC 199.ISO 12100:2010 constitutes a consolidation without technicalchanges of ISO 12100-1: 2003, ISO 12100-2: 2003, ISO 141211: 2007 and related Amendments. This consolidation does notrequire updates or revisions to type B- and type Cstandards or other documents (e.g. for risk assessment)based on the prior standards!

ĸ 1 Scope ĺĸ Foreword ĺĸIntroduction ĺISO .103.93.73.73.43.43.43.63.33.33.13.23.7ĸ 2 Normative references ĺĸ 3 Terms and definitions ĺISO 12100-2:20033.23.1ISO 12100-1:2003ISO 12100: 2010provided by ISO/TC 199 "Safety of machinery"Improvement in the wording : theprotective measures are implemented.Second sentence becomes a noteIntroduction of the NoteIntroduction of Note 2French synonymous deleted –Introduction of Note 3Wording slightly improvedWording slightly improvedUpdated according to Directive2006/42/ ECCombination of the definitions of thethree standards. Origins are in boldcharacters.UpdatedCombination of the scopes of thethree standardsISO 12100-1 the three last indentsof ISO 14121-1 updatedUpdatedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

73.163.183.163.13ISO 14121-1:20073.173.15ISO 12100-2:20033.16ISO 12100-1:2003ISO 12100: 2010ndsentence deletedprovided by ISO/TC 199 "Safety of machinery"Second sentence becomes a noteThe note disappeared.Wording slightly improvedSimplified – 2Wording slightly improvedWording slightly improvedWording slightly improvedIntroduction of”/or “ to 1 dashstWording slightly improvedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

423.373.383.395.1.3ISO 12100: 201034 Strategy for riskassessment and riskreduction3.393.364 Hazards to betaken into accountwhen designingmachinery3.383.354.1 1 9ISO 14121-1:20073.28.8ISO 12100-2:20033.26.8ISO 12100-1:2003ndtermprovided by ISO/TC 199 "Safety of machinery"SubdividedImprovedCombination of indents coming fromISO 12100-1:2003, Clause 5 andISO 14121-1:2007, 4.1Deleted,overlapping with ISO 14121-1:2007,Annex AIntroduction of a 2Wording slightly improvedFrench version, change of the order ofthe terms – Wording improvedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

Remarks5.1.3 1 sentencestFigure 2 — Risk reductionprocess from point of view ofdesignerFigure 15.4 Hazard identification5.5 Risk estimation6 Hazard identification7 Risk estimation45.3 Determination of limits ofmachinery5.3.1 General5.3.2 Use limits5.3.3 Space limits5.3.4 Time limits5.3.5 Other limits5 Determination of limits ofmachineryprovided by ISO/TC 199 "Safety of machinery"2 indent deletedndSome improvements (wording andorder of subclauses)Some improvements;new 5.2.c) 34.2 Information for riskassessment5.2 Information for riskassessmentLast indent simplified, Figure 1 and 1indent deletedstImprovement in the wording : theprotective measures are implemented.Figure slightly improvednd4.1 last indents5.1 General5 Risk assessmentFigure 1 — Schematicrepresentation of riskreduction process includingiterative three-step methodFigure 25.1.4Improvement in the wordingISO 12100: 20105.1.2ISO 14121-1:2007Wording improved (see 3.13). A 2sentence is introducedISO 12100-2:20035.1.1ISO 12100-1:2003Table of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

5.3 last indent5.1.6ISO 12100-1:2003ISO 12100-2:2003ISO 12100: 20105.5.2.3.2 Occurrence of ahazardous event5.5.2.3.3 Possibilities ofavoiding or limiting harm5.5.3 Aspects to beconsidered during riskestimation5.5.3.1 Persons exposed5.5.3.2 Type, frequency andduration of exposure5.5.3.3 Relationship betweenexposure and effects5.5.3.4 Human factors5.5.3.5 Suitability ofprotective measures7.2.3.3 Occurrence ofhazardous events7.2.3.4 Possibilities ofavoiding or limiting harm7.3 Aspects to be consideredduring risk estimation7.3.1 Persons exposed7.3.2 Type, frequency andduration of exposure7.3.3 Relationship betweenexposure and effects7.3.4 Human factors7.3.5 Suitability of protectivemeasures55.5.2.3.1 Exposure of personsto the hazard7.2.3.2 Exposure of personsto hazards5.5.2.2 Severity of harm7.2.2 Severity of harm5.5.2.3 Probability ofoccurrence of harmFigure 3 — Elements of riskFigure 27.2.3 Probability ofoccurrence of harm5.5.2 Elements of risk5.5.2.1 General5.5.1 General7.2 Elements of risk7.2.1 General7.1 GeneralISO 14121-1:2007provided by ISO/TC 199 "Safety of machinery"Second indent improvedLast indent of 7.3.4 become 5.5.3.4 g)modifiedNew note 2Wording slightly improvedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

5.4 Elimination ofhazards orreduction of risk byprotectivemeasures5.1.5ISO 12100-1:2003First indent modified6.2.2 Consideration ofgeometrical factors and4.2 Consideration ofgeometrical factors66.2.1 General4.1 General6.1 General6.2 Inherently safe designmeasures8.2.16 Risk reductionprovided by ISO/TC 199 "Safety of machinery"Wording slightly improvedWording slightly improvedThis subclause has been improved.Combination of indents coming fromISO 12100-1:2003, 5.4 andISO 14121-1:2007, 8.2.1 modifiedThe wording of the last indent hasbeen modified5.6.2 Adequate risk reduction8.2 Achievement of adequaterisk reduction5.6.3 Comparison of risks5.6.1 General8.1 General8.3 Comparison of risks5.6 Risk evaluation8 Risk evaluationThe introductive sentence has beenmodified.5.5.3.8 Information for use7.3.8 Information for useLast indent: first sentence modifiedSome editorial improvementsRemarks8.2.2 Presumptions ofadequate risk reduction5.5.3.7 Ability to maintainprotective measures5.5.3.6 Possibility of defeatingor circumventing protectivemeasuresISO 12100: 20107.3.7 Ability to maintainprotective measures7.3.6 Possibility of defeatingor circumventing protectivemeasuresISO 14121-1:20074 Inherently safedesign measuresISO 12100-2:2003Table of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.2.2.2 Physical aspects6.2.3 Taking into accountgeneral technical knowledgeof machine design6.2.4 Choice of appropriatetechnology6.2.5 Applying principle ofpositive mechanical action6.2.6 Provisions for stability6.2.7 Provisions formaintainability6.2.8 Observing ergonomicprinciples6.2.9 Electrical hazards6.2.10 Pneumatic andhydraulic hazards4.2.2 Physicalaspects4.3 Taking intoaccount the generaltechnical knowledgeregarding machinedesign4.4 Choice of anappropriatetechnology4.5 Applying theprinciple of thepositive mechanicalaction of acomponent onanother component4.6 Provisions forstability4.7 Provisions formaintainability4.8 Observingergonomicprinciples4.9 Preventingelectrical hazard4.10 Preventinghazards frompneumatic and76.2.2.1 Geometrical factors4.2.1 GeometricalfactorsISO 12100: 2010physical aspectsISO 14121-1:2007and physicalaspectsISO 12100-2:2003provided by ISO/TC 199 "Safety of machinery"Improvement of the subdivisions: e.g.4.8.7 - 6.2.8.f)Wording slightly improvedSubclause modified.Reference updatedWording slightly improvedWording slightly improvedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.2.11.2 Starting of an internalpower source/switching onan external power supply6.2.11.3 Starting/stopping of amechanism6.2.11.4 Restart after powerinterruption6.2.11.5 Interruption of powersupply6.2.11.6 Use of automaticmonitoring6.2.11.7 Safety functionsimplemented byprogrammable electroniccontrol systems6.2.11.7.1 General6.2.11.7.2 Hardware aspects6.2.11.7.3 Software aspects4.11.2 Starting of aninternal powersource/switching onan external powersupply4.11.3Starting/stopping ofa mechanism4.11.4 Restart afterpower interruption4.11.5 Interruption ofpower supply4.11.6 Use ofautomaticmonitoring4.11.7 Safetyfunctionsimplemented byprogrammableelectronic controlsystems4.11.7.1 General4.11.7.2 Hardwareaspects4.11.7.3 Softwareaspects86.2.11.1 General4.11.1 GeneralISO 12100: 20106.2.11 Applying inherentlysafe design measures tocontrol systemsISO 14121-1:20074.11 Applyinginherently safedesign measures tocontrol systemhydraulic equipmentISO 12100-2:2003provided by ISO/TC 199 "Safety of machinery"These two subclauses have beenmerged.Merging of the first two indentsEditorial improvementSubclause modifiedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.2.11.10 Selection of controland operating modes6.2.11.11 Applying measuresto achieve electromagneticcompatibility (EMC)6.2.11.12 Provision ofdiagnostic systems to aidfault-finding6.2.12 Minimizing probabilityof failure of safety functions4.11.10 Selection ofcontrol andoperating modes4.11.11 Applyingmeasures to achieveelectromagneticcompatibility (EMC)4.11.12 Provision ofdiagnostic systemsto aid fault-finding4.12 Minimizing theprobability of failureof safety functions6.2.12.3 Use of "orientedfailure mode" components6.2.12.4 Duplication (orredundancy) of components4.12.2 Use of"oriented failuremode" components4.12.3 Duplication(or redundancy) of96.2.12.2 Use of reliablecomponents4.12.1 Use of reliablecomponents6.2.12.1 General6.2.11.9 Control mode forsetting, teaching, processchangeover, fault-finding,cleaning or maintenance4.11.9 Control modefor setting, teaching,processchangeover, faultfinding, cleaning ormaintenanceISO 12100: 20106.2.11.8 Principles relating tomanual controlISO 14121-1:20074.11.8 Principlesrelating to manualcontrol4.11.7.4 ApplicationsoftwareISO 12100-2:2003thprovided by ISO/TC 199 "Safety of machinery"Hanging textA 4 dash has been introducedRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.2.14 Limiting exposure tohazards throughmechanization or automationof loading (feeding) /unloading (removal)operations6.2.15 Limiting exposure tohazards through location ofsetting and maintenancepoints outside danger zones6.3 Safeguarding andcomplementary protectivemeasures6.3.1 General6.3.2 Selection andimplementation of guards andprotective devices6.3.2.1 GeneralFigure 4 — Guidelines forchoosing safeguards againsthazards generated4.14 Limitingexposure to hazardsthroughmechanization orautomation ofloading (feeding) /unloading (removal)operations4.15 Limitingexposure to hazardsthrough location ofthe setting andmaintenance pointsoutside of dangerzones5 Safeguarding andcomplementaryprotective measures5.1 General5.2 Selection andimplementation ofguards andprotective devices5.2.1 GeneralFigure 1 —Guidelines to helpmake the choice of106.2.13 Limiting exposure tohazards through reliability ofequipment4.13 Limitingexposure to hazardsthrough reliability ofequipmentISO 12100: 2010or subsystemsISO 14121-1:2007components orsubsystemsISO 12100-2:2003provided by ISO/TC 199 "Safety of machinery"RemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.3.2.3 Where access to thehazard zone is requiredduring normal operation6.3.2.4 Where access to thehazard zone is required formachine setting, teaching,process changeover, faultfinding, cleaning ormaintenance6.3.2.5 Selection andimplementation of sensitiveprotective equipment6.3.2.5.1 Selection6.3.2.5.2 Implementation6.3.2.5.3 Additionalrequirements for sensitiveprotective equipment whenused for cycle initiation5.2.3 Where accessto the hazard zone isrequired duringnormal operation5.2.4 Where accessto the hazard zone isrequired formachine setting,teaching, processchangeover, faultfinding, cleaning ormaintenance5.2.5 Selection andimplementation ofsensitive protectiveequipment5.2.5.1 Selection5.2.5.2Implementation5.2.5.3 Additionalrequirements forsensitive protectiveequipment whenused for cycleinitiation116.3.2.2 Where access to thehazard zone is not requiredduring normal operation5.2.2 Where accessto the hazard zone isnot required duringnormal operationISO 12100: 2010by moving partsISO 14121-1:2007safeguards againsthazards generatedby moving partsISO 12100-2:2003provided by ISO/TC 199 "Safety of machinery"Improvement of the subdivisionsIntroduction of a reference toIEC/TS 62046 in a note.Improvement of the subdivisionsRemarksTable of correspondence between ISO 12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and ISO 12100:2010 (version date 2010-11-05)

ISO 12100-1:20036.3.3 Requirements for designof guards and protectivedevices6.3.3.1 General requirements6.3.3.2 Requirements forguards6.3.3.2.1 Functions of guards6.3.3.2.2 R

12100-1:2003, ISO 12100-2:2003, ISO 14121-1:2007 and the new ISO 12100:2010 "Safety of machinery - General principles for design - Risk assessment and risk reduction" published on 2010-11-01 is provided for the convenience of the users of these International Standards on behalf of ISO/TC 199. ISO 12100:2010 constitutes a consolidation without technical changes of ISO 12100-1: 2003, ISO 12100-2 .