Transcription

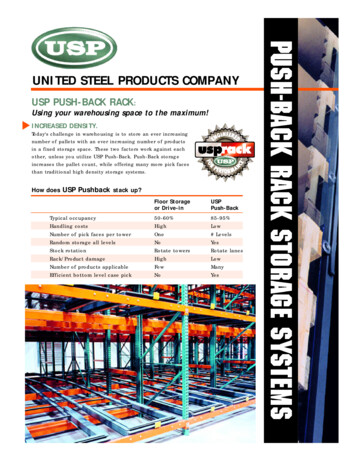

UNITED STEEL PRODUCTS COMPANYUSP PUSH-BACK RACK:Using your warehousing space to the maximum!INCREASED DENSITY.Today‘s challenge in warehousing is to store an ever increasingnumber of pallets with an ever increasing number of productsin a fixed storage space. These two factors work against eachother, unless you utilize USP Push-Back. Push-Back storageincreases the pallet count, while offering many more pick facesthan traditional high density storage systems.How does USP Pushback stack up?Typical occupancyHandling costsNumber of pick faces per towerRandom storage all levelsStock rotationRack/Product damageNumber of products applicableEfficient bottom level case pickFloor Storageor Drive-inUSPPush-Back50-60%HighOneNoRotate towersHighFewNo85-95%Low# LevelsYesRotate lanesLowManyYes

PUSH-BACK ACCESSIBILITY – All 12 lanes and pallets are accessiblefrom the aisle.all the time!USPPushback90of% Utilizationpallet positionsDrive-inHoneycombing60%Utilization ofpallet positionsWHEN SHOULD YOU USE PUSH-BACK?When the average number of pallets per product exceeds five, a pushback system is easily justified.The higher the number, the deeper the lane is feasible (usually 3 lanes per product minimum). Thesemultiple lanes allow rotation to achieve first-in/first-out. USP Push-Back systems can be configuredto attain up to 100% more pallets stored than standard pallet rack and equal or greater increases overpoorly occupied drive-in or floor storage configurations.SYSTEMFLEXIBILITYUSP Push-Back is available in2, 3, 4, 5 and 6 deep stylesand can be arranged as backto back islands or standalone bays. Number of levelshigh is restricted only byyour lift truck’s reach.No special fork trucks arerequired. Pushback systemsare fully operational infreezers, coolers and hightemperature environments.THE STORAGE RACK COMPANYPHONE: 570-476-1010 FAX: 570-476-4358e-mail: usp@usprack.comwww.usprack.com

USP PUSH-BACK – High Density and Product AccessibilityPush-back over floorstorage provides a costeffective way to achievedensity, selectivity andhigh occupancy.Push-back provideseasy replenishment forfull pallet pick lanesin this pick module.Back to back push-back inany combination,to suit buildingconstraints andinventory requirements.The ultimate in highdensity storage.Here push-backfills in a train wellto make use offormerly wasted orobsolete space.Push-back over cartonflow allows for highdensity pallet storageand case pickingwithout compromisingstorage space.USP Push-Back works with all types of forklifts: counter balance,narrow aisle and swing reach.THE STORAGE RACK COMPANYPHONE: 570-476-1010 FAX: 570-476-4358e-mail: usp@usprack.comwww.usprack.com

USP PUSH-BACKFeatures & BenefitsUSP push-back is loaded with safety features andsmart innovations. Its unique design providestrouble-free operation, and structural steelpush-back components ensure long life in tough warehouse environments.Low Profile: USP push-back has alower profile than other cart typesystems. This allows for extra liftclearance, and possibly anadditional storage level.Linked Carts: Carts are linked whenextended, elimination thepossibility of single pallethang-ups, which can lead touncontrolled pallet load movement.No push-back system is completewithout this importantsafety feature.Lift-Out Protectors: Each push-backcart is equipped with lift-outprotectors, which prevent accidentaldislodgement of carts byforklift operators.Gauge Bars: Maintain the properdistance between cart rails. Thisassures precise alignment and smoothoperation of the cart nesting system.Flanged Steel Wheels: Our wheelsare manufactured from solid steeland equipped with heavy dutybearings. Sturdy 5/8” shafts arewelded to the carts and are oversizedto withstand shock loading,capacities of up to 1,400 lbs.per wheel.Multi PurposePlate: Acts as–Height gauge: Ifthe load is highenough to clearthe safety stop,then the palletwill notprematurely move the awaiting cart. Strip-offstop: If an operator has his forks in an impropertilt position, the safety stop will catch thebottom of the pallet and “strip” it off his forks. End stop: The end stop,situated on the lowest cart, prevents pallets from shifting beyond the frontload beam. Push plate: Pushing on the plate with the last pallet beinginserted into the lane ensures proper placement on the rails as well asguaranteeing safe clearance of the cart. Full lane indicator: The operatorcan tell if a lane is full by the absence of the plate. If it is not showing,the last cart has been pushed back by the last load and the lane is full.THE STORAGE RACK COMPANYPHONE: 570-476-1010 FAX: 570-476-4358e-mail: usp@usprack.comwww.usprack.com

THREE PRINCIPLES OF SUCCESSFUL PUSH-BACK APPLICATIONS1. First-In/First-Out Stock Rotation2. High Occupancy3. Random StorageRule #1: Select products to be stored thathave at least 3 times the lane depth in averagepallets in inventory.Most storage facilities have products that range fromone pallet per item up to many pallets per item. Theaverage amount of storage per item should be usedto select optimum lane length.The table shown will yield occupancy rates of80% – 90%. The higher the number of lanes perproduct the higher the occupancy rate.PALLETS PER PRODUCTLANE DEPTH1 – 4 . . . . . . . . . . . . . . . . STANDARD RACK5 – 8 . . . . . . . . . . . . . . 2 DEEP PUSHBACK9 – 12 . . . . . . . . . . . . 2 – 3 DEEP PUSHBACK13 – 16 . . . . . . . . . . . . 3 – 4 DEEP PUSHBACK17 – 20 . . . . . . . . . . . . 4 – 5 DEEP PUSHBACKOVER 20 . . . . . . . . . . . 5 – 6 DEEP PUSHBACKRule #2: Never replenish a partially filled lanewith a new lot code of the existing product ora different product.As a result of rule number 1, there are a minimumof three to five lanes available for any one product.Therefore, when a new lot code is introduced, a newlane (as depicted in Red B) is selected so as tonot block access to an existing lot code (as depictedin Red A).These 3 principles can easily be implementedby following the simple rules below.Rule #3: When retrieving loads for shipping or foruse within the company, be sure to pick from theoldest part lane first.Picking from the oldest part lane, (as shown in Red A)will automatically rotate your stock while freeing upempty lanes for general availability. This will result inno more than one part lane, per lot code.This procedure will ensure FIFO Stock Rotation(First in – First Out).Rule #4: Use random storage to minimizehoneycombing. This will enable you to maximizeyour storage facility.Random storage in any of the lanes that becomeavailable will allow the storage requirement for anyitem to grow and shrink as necessary. Fixed locationswould require storage to be preset for every item atits peak. Exceptions could be made for bottom levelcase picking with fixed locations.THE STORAGE RACK COMPANYPHONE: 570-476-1010 FAX: 570-476-4358e-mail: usp@usprack.comwww.usprack.com

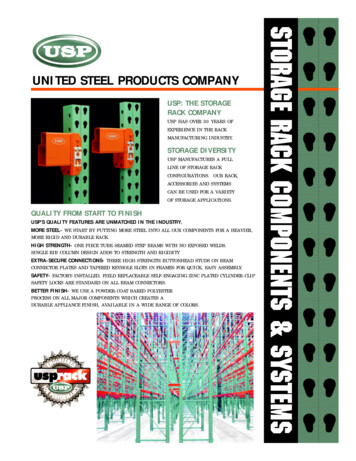

USP PUSH-BACK – Depth Options & SpecificationsStandard colors: Stone Grey, Royal Blue, Forest GreenCarts can be painted other colors for an additionalcharge*. Paint process is air-dried enamel.*Please note: colors in the drawings below are intended to shownumber of carts for each depth and do not illustrate standard colors.Specifications based on a 40” face by 48” deep GMAor CPC/CHEP type pallet, weighing up to 3,000 lbs.For special size pallets or loads, please contact yourUSP representative.2 DEEPOVERALL HEIGHT – 4 1/2”RAIL LENGTH – 98”3 DEEPOVERALL HEIGHT – 5 1/2”RAIL LENGTH – 148”4 DEEPOVERALL HEIGHT – 6”RAIL LENGTH – 198”5 DEEPOVERALL HEIGHT – 6 3/4”RAIL LENGTH – 248”6 DEEPOVERALL HEIGHT – 7 1/2”RAIL LENGTH – 298”UNITED STEEL PRODUCTS COMPANYA DIVISION OF UNITED STEEL ENTERPRISES, INC.P.O. BOX 407, EAST STROUDSBURG, PA 18301-0407570-476-1010 / FAX: 570-476-4358 e-mail: usp@usprack.com www.usprack.comthe storage rack companyMANUFACTURERS OF HIGH QUALITY STORAGE RACK PRODUCTS:PALLET SELECTIVE DRIVE-IN PUSH-BACK DOUBLE DEEP MARINE STORAGE BULK STORAGEARCHIVE STORAGE RETAIL DISPLAY CARTON FLOW PALLET FLOW RACK-SUPPORTED BUILDINGS &MEZZANINES INSTALLATION CUSTOM DESIGNS ROLL-FORMED OR STRUCTURAL STEEL

USP PUSH-BACK – High Density and Product Accessibility USP Push-Back works with all types of forklifts: counter balance, narrow aisle and swing reach. Push-back over carton flow allows for high density pallet storage and case picking without compromising storage space. Push-back provides

![Shareholders’ Agreement of [Company name] company. 1 .](/img/1/startup-founders-sha-sample.jpg)