Transcription

BLACK PIPESGALVANISED TUBES & PIPESSQUARE & RECTANGULAR PIPESERW STEEL TUBES & TUBESGROOVED TUBES, CR COILS, CRCAGP/GC, POWER & TELECOM TOWERSGood Luck Steel Tubes Ltd.Regd. Office :5/102, Sikka Complex,Community CentrePreet Vihar, Vikas Marg,Delhi - 110 092 (INDIA)Administrative Office :II F 166-167, Goodluck House,Nehru Nagar, Ambedkar Road,Ghaziabad (U.P.) (INDIA)E-mail : goodluck@goodlucksteel.comWorks:Khasra No. 2839,Gram Dhoom Manikpur,G.T. Road , Gautam Budh Nagar,Dadri, (U.P.) INDIATel.: 91-11-22465439Telefax : 91-11-22214254Tel. : 91-120-4196600, 4196700Fax : 91-120-4196666, 4196777Tel. : 0091-5735-221969, 221970Fax : 0091-5735-222863www.goodlucksteel.comGood Luck Steel Tubes Ltd.

““A Versatile Business Groupwith Strong Foundations”Infinite,The possibilitieswe aspire”Good Luck Group a manufacturer and exporter of a wide range of Cold Rolled Steel, Hot Dip Galvanized Steel(HDGI), Towers, Tubes & Pipes, forgings and flanges, was established over two decades ago. With its innovativeand progressive approach the group today is one of the leading and fastest business groups in the Steel Industry.An ISO 9001 certified organization, Good Luck group operates under three verticals; Good Luck Steel Tubes Ltd.,Good luck Engineering Co. and Good Luck Industries.Good Luck Steel Tubes Ltd.Galvanised Tubes& PipesBlack PipesGood Luck IndustriesCR CoilsCRCAGP/GCPower &Telecom TowersPower &Telecom TowersGood Luck Engineering Co.Power &Telecom TowersPower &Telecom TowersSquare &Rectangular PipesERW Steel Tubes& TubesGrooved TubesWe have an advanced manufacturing unit located at Bulandshahar District of Uttar Pradesh, (India)facilitating fabrication of steel products in bulk quantity. A thorough inspection by distinguished agenciessuch as DGS & D, RITES, BHEL and SGS ensures highest quality in our product range. As a group we havealways strived for continuous expansion and constant growth.Good Luck Steel Tubes Ltd.Established in the year 1986, Goodluck Steel Tubes Ltd is an ISO 9001:2008 certified organization, engagedin manufacturing and exporting of a wide range of galvanized sheets & coils, towers, hollow sections, CRcoils CRCA and pipes & tubes. We also specialize in providing Telecommunication Structures, ERWSteel Tubes, ERW Steel Pipes, and Galvanized Black Steel Tubes. These are acclaimed for high tensilestrength, long service life and higher efficiency.

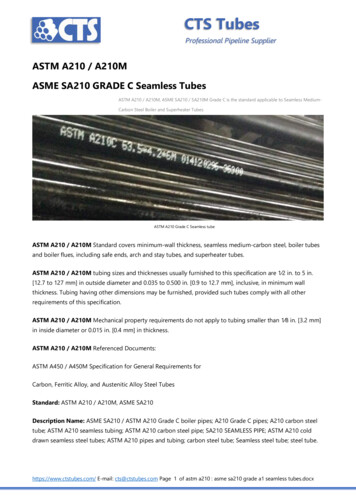

“State of the Art Pipe &Section Making Technology”“Process Flow thatworks with precision”Our plant is situated at Sikandarabad industrial area just 45km from Delhi. It has the state of the art tube mills ,galvanizing units , cold rolling mills galvanized coil unit and corrugation machines. Pipe and lattice type structures arealso fabricated and galvanized here.Manufacturing Tubes according to SpecificationsIS : 1239 (Part - 1) 2004IS : 277 / 1992JIS : G-3452DIN : 1626IS : 1161 / 1998BS : 1387 /1985ASTM : A-120EN : 10255IS : 3589 / 2001BS : 534ASTM : A-53IS : 3601 / 1984BS : 1139 / En39ISO : 65-1981IS : 9295 / 1983BS : 6323IS : 4923 : 1997IS : 4270 / 2001DIN : 2439EN : 10219IS : 2713 /1980DIN : 2440EN : 10217IS : 1978 / 1982DIN : 2441DIN : 2458Infrastructure

““A VersatileProduct RangeWall ThicknessERW TubesSpecifications of TubesEQUIVALENT STANDARDS - 51.000.90EQ-Standards IndustryBicycle TubesAutomobile TubesGeneral Engg. TubesBoiler IS 2039(parts 1-3)/1991BS 1717/1983IS 3074BS 6323/1982JIS G 3445/1983ASTMA513/1994IS 3601/1984BS 6323/1982JIS G 3445/1983DIN 2393/1994DIN 2394/1994DIN 2393/1994DIN 2393/1994IS 1914(parts 1-4)/1982BS 3059 (part-1)/1987BS 3059 (part-1)/1990JIS G 3461/1984Customer SpecificationAir Heater TubesIS 3601/1984Transformer TubesIS 8036/1976Oil PipesShock Absorber TubesIS 1978/1982/1979IS 3074/1979Furniture TubesIS 7138/1973Heat Exchanger TubesOutside DiameterCDW TubesStructural TubeIS 1161/1979Idler TubesIS 9295/1983Sectional TubesTelescopic Frontfork TubesBobbin Tubes forTextile MachineryCasing & TubingHydro Carban &IS 4923/1985Condeser Tubes8101216 19.05 22.23 25.40 28.58 31.75 33.70 34.93 38.10 40.00 42.70 44.45 45.00 48.60 50.80 57.15 60.30 63.50 69.85 76.20 81.20 88.90101.60108.00Outside DiameterStandard Product RangeProduct Range Extended on Customer’s Request110.00BS 3059 (part-1)/1987JIS G 3461/1984ASTM A214/1990BS 1387/1985JIS G 3452/1983DIN 17177/1979API 5L Gr. A/1995JIS G 3452/1983DIN 2393/1994ASTM A513/1994DIN 17177/1979Customer SpecificationJIS G 3445/1983BS 3606/1982JIS G 3461/1984BS 7613/1994JIS G 3444/1984ASTM A178/1990ASTM A214/1990ASTM A 500 Gr. A/1993JIS G 3466/1982ASTM A500 Gr. A 1993CustomerSpecificationCustomerSpecificationAPI 5CT/1995IS 6286Process 501.251.000.90Any OtherStandardsASTM A53/1993ASTM A214/1990Propeller Shaft Tube19.05 22.23 25.40 28.58 31.75 33.70 34.93 38.10 40.00 42.70 44.45 45.00 48.60 50.80 57.15 60.30 63.50 69.85 76.20 81.20 88.90 101.60 108.00 114.30Wall ThicknessIndianISASTM A53IS 1914 (PT-IV)IS 246 (PT-V)IS 11714 (PT-III)

Steel Tubes for uses inWater, Gas, Air & SteamSteel Tubes for Water,Gas and Sewage PurposesCONFORMING TO IS:1239 (PART-1) 2004/ BS:1387/85CONFORMING TO IS:3589 / 2001 (GRADE FE 330 AND FE al Weight Black TubesPlain EndmmMin(mm)15 LMHNominal Weight Galvanised TubesPlain EndScrewed gthm/tonnemmmmScrewed 1.221.45104681968927.037.020 196375321.391.571.8871963753232.539.025 4113392.02.432.9550041133939.546.032 93192612.573.133.8238931926149.051.040 62272263.273.604.4130622722656.051.050 1691594.155.106.2624116915968.060.065 1531245.836.548.0517115312484.069.080 117966.898.5310.101451179698.075.0100 4.50100806710.012.5014.801008067124.087.0125 018.4615415.9017.9615416.4018.46154151.0150 /mm/tonne Kg/m96.096.0Weight (Plain End)ThicknessmmKg / MM / sa. Outside Diameter /- 0.75%b. Thickness /- 10%c. LengthUnless otherwise specified, length are in singlerandom Length of 4 to 7 meters or doublerandom length of 7 to 14 MAlso Available:Internal Bead Free & Screwed & SocketedBlack & Galvanized PipesTolerances(a) Thickness1. Light TubeChemical Composition2. Medium andHeavy Tubes Not limited-8% Not limited-10%(b) Weight1. Single Tube(Light Series) 10%-8%2. Single Tube(Medium And Heavy Series) /- 10%(c) Length4 to 7 meters unlessotherwise specified3. For Light Series-5%, 7.5%(d) Tensile Strength320 mp (min)4. For Quantities per load of 10 tonnes 7.5%, -5%minimum (Medium and heavy Series)(e) % of elongation20% (min)Mechanical PropertiesTS (MPa)320% EL12 Upto & Including 25 mm NB20 Above 25 mm NBMechanical PropertiesSteel Grade%E(Max)% MN(Max)%P(Max)%S(Max)CE(Max)YSTTS(MPa) Min (MPa) Min% EL(Min)Fe 0400.4523541018

Steel Tubes forStructural PurposesCONFORMING TO IS: ulatedNominal WeightGalvanized TubesPlain EndNominal WeightBlack TubesPlain EndmmmmKg/mm/tonneKg/mm/tonne15 9100379467120 5 LMH33.72.63.24.01.982.412.9350541534132 LMH42.42.63.24.02.543.103.7940 LMH48.32.93.24.050 LMH60.365 LMH76.180 LMH88.990 LMH100 minal WeightBlack TubesPlain EndCalculatedNominal WeightGalvanized TubesPlain EndmmmmKg/mm/tonneKg/m110 .80726861699621521125 .156662552.032.462.98493407336135 .986056553943232642.623.183.87382314258150 3150 991624.205.156.31238194158175 .5410.0814511799200 3332225 115144878.977.2011.7711113985250 010382699.9712.4214.721008168300 H323.96.349.302050.2820350 H355.68.068.601569.5814B. TOLERENCESi) Outside diameter upto & including 48.3 mm 0.4 mm -0.8 mm Over 48.3 mm /- 1 %A. TENSILE PROPERTIESGRADEN.B.AndSeriesY.S. (MIN)Mpa(Kg/mm2)T.S. (MIN)Mpa(Kg/mm2)%ageElongation210 (21.42)240 (24.48)310 (31.62)330 (33.66)410 (41.82)450 (45.9)20178NOTE: For tube size upto and including 25 mm NB, elongation of 12% shall be permissibleC. THICKNESSFor all sizesWelded TubesD. WEIGHTSingle tube (Light Class)For medium & Heavy Class10 Tonne Light, Medium& Heavy Not Limited- 10%- 8% 10% /- 10% /- 5% /- 7.5%m/tonne

Steel Tubes for Line Pipes used inOil & Petroleum IndustriesCONFORMING TO IS:1978NB(mm)OD(mm)8088.9090100101.60114.30Test Pressure (Min)WallThickness(mm)Plain lain 18996110122A. Outside Diameter - The Outside diametertolerance shall be as follows,Pipe BodyFor Size48.3 mm and less60.3 mm and aboveTolerance 0.40 mm- 0.80 mm /- 1%B. Wall thickness - The Tolerance on the wallthickness of line pipes shall be as follows:TypeWelded PipesTolerance 20.0%-12.5%88.90 mm O.D. & Larger 18.0%-12.5%For73.0 mm and smallerTest Pressure (Min)WallThickness(mm)GradeGradeYST 210 STD YST 240 STD100 kpa100 kpaC. Weight The Tolerance shall be as follows:Grade YST - 210 & YST - 240Grade YST - 170Special Plain End Pipes - All GradesCar loads lots for min 18000 Kg:Grade YST 210 & YST 240Grade YST 170NB(mm)OD(mm)200 10.0%-3.5% 10.0%-5.0% 10.0%-5.0%-1.75%-2.5%GradeGradeYST 210 STD YST 240 STD100 kpa100 kpa

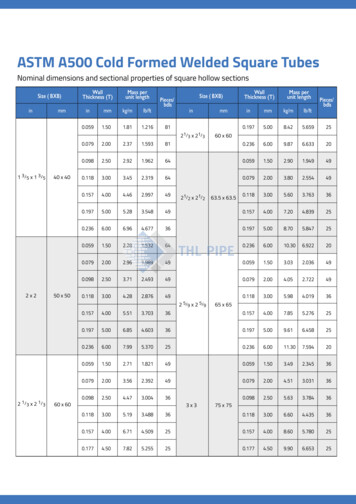

Hollow Steel Sectionsfor Structural UseCONFORMING TO IS : 4923 1997 (HOT DIP / BLACK, GALVANIZED & PER GALVANIZED)Square Hollow Sections (SHS)Rectangular Hollow Sections (RHS)DepthD(mm)WidthB(mm)ThicknessT(mm)WeightW(Kg / m)Mtr./ Tonne20 x 2.402.600.9641.051.211.28103795282677925 x 2525.0025.0025.0025.002.603.201.691.9859150430 x 492.9447640234032 x 240337238 x 033.293.6345939036333030427640 x 17.247.978.8520118616815413812611372 x 229.6614912210380 x 1.5 x 11038471100 x .5210.6411.7313.0913.8814.41105948

ASTM A178/1990 ASTM A214/1990 ASTM A 500 Gr. A/1993 ASTM A500 Gr. A 1993 Any Other Standards Customer Specification Customer Specification Telescopic Front fork Tubes API 5CT/1995 Customer Specification Customer Specification Casing & Tubing Process Industries IS 1914 (PT-IV) IS 246 (PT-V) IS 11714 (PT-III) ASTM A53 Specifications of Tubes Wall Thickness Outside Diameter