Transcription

NOT ALL BLACKS ARETHE SAMENuances, variety and variance succeed only by theuse of different blacks. We generate more than280 Specialty Carbon Black grades using fivemanufacturing processes plus after treatments.01We know black.

FOCUSED02Market launch ofCOLOUR BLACKFW 200Founding ofDegussa acquiresFirst application ofFirst applicationPlant acquisitionsAugust Wegelin AGAugust Wegelin AGGas Black processof Furnace Blackaround the globeprocess’861986 – 2002International Expansionce0s’61905 – 1958Historical Backdropsintela5819381932190519We have been helping to shape the CarbonBlack materials market since the start of the 20thcentury. Our specialization in Specialty CarbonBlack makes us a proficient partner due to ourcommitment to quality. Emerging from AugustWegelin AG, the Degussa Group and Evonik, allCarbon Black expertise has been concentratedin Orion Engineered Carbons since 2011. Thismakes Orion Engineered Carbons number onein Specialty Carbon Black production. Ourcustomers gain the benefits of this uniquedetailed knowledge.

Market launch ofFounding of OrionMarket launch ofCOLOUR BLACKEngineered CarbonsCOLOUR BLACKMarket launch of newhigh jetness pigmentFW 171(OEC)FW 255COLOUR BLACK FW 310Installation of newEvonik acquires fullConversion of severalInvest in R & DOEC entersAcquisition of QECCSpecialty Gas Blackownership of Degussaproduction lines toand focus onNew York Stock(now OECQ) for localunitsEngineered Carbons LLCSpecialty Carbon BlackinnovationExchangeChinese production19Operates as Standalone Business20Specialty Carbon Black152011 – 2019Orion Engineered 8 – 2010Repositioning Towards

Short Facts Almost 125 years of innovation 14 plants, three regional headquarters,more than 1,400 employees Four technical centers – in Germany,USA, China and South Korea Only supplier with five Carbon Blackproduction processes: Furnace Black,Gas Black, Lamp Black, Acetylene Blackand Thermal Black Commercial presence in more than90 countries Global capacity of more than 270 kt/yrfor Specialty Carbon Black

ApplicationsWe can provide solutions to any coatingsapplication using Carbon Black. Get in touch withus to discuss your application and your needs.We will find the optimum solution for you, asdifferent applications have individual performancerequirements: Automotive OEM Automotive Refinish Plastic Coatings Industrial Coatings Powder Coatings Coil Coatings Protective/Marine Coatings Architectural/Decorative Coatings

INNOVATIVECoating systems are complex. Our knowledgeis not limited to our pigments. What effects dobinders, additives, quality of dispersion, clearcoats or film thickness have on shade and colorstrength? How do pigments and a recipe scompounds impact the shade? We have preciseknowledge of the chemistry and process-relatedproperties of our products. Our primary focus is onthe quality of our products and services, as well asthe appropriate solution in each individual case.03We work with you to design the right black for you.Our large coatings laboratory and knowledgeableteam can overcome the challenges facing ourcustomers’ adaptions and applications. We worktogether to drive enhancements and innovationforward. Our well-known product COLOUR BLACKFW 200 has been setting the market standard forblack pigments for decades. But being state ofthe art is not enough for us; with COLOUR BLACKFW 255 introduced in 2014 and now our newproduct COLOUR BLACK FW 310, we are onceagain raising the bar for jetness.A wide range of technologies, developmentexpertise and profound knowledge of systemsand effects of formulation changes – that is the“magic formula” for the perfect product for yourindividual needs.

RESPONSIVE04We listen carefully and achieve the bestperformance of our pigments in your coatingssystem. We are the perfect partner to accompanyyou on the path to your perfect application.Because we truly know black inside-out. We aremore than just a pigment manufacturer.We are a solution provider.

OUR PIGMENTS05Environmentally-friendly coatings will gain evenfurther importance. Consequently, all of ourpigments are presented in a water-borne coatingsystem. The mean primary particle size and particlesize distribution of the Specialty Carbon Blackhave the greatest influence on the performanceand colorimetric properties of the coating.We present our three most recommendedpigments for high jetness in water-borne systems.All result in very high jetness, which are muchdarker compared to many black coatings currentlyin use.Key parameter for high jetness Carbon Blacks: Small mean primary particle size Small mean aggregate size Narrow primary particle andaggregate size distribution Dispersibility Balanced surface chemistry

COLOUR BLACK FW 171COLOUR BLACK FW 171 is an outstanding productfor coloring high jetness black mass tone andmetallic water-borne coating systems. Highestjetness levels combined with very strong bluishundertones, high gloss and low haze can beobtained.The grade is recommended for all kinds ofwater-borne coating systems where a high jetnessis required. COLOUR BLACK FW 171 improves theperformance of high end industrial, plastic andautomative OEM applications and shows excellentcolorimetric properties in powder coatings.Properties*Jetness MY307Undertone dM12.3Volatile Matter at 950 [%]BET [m /g]22.0600Primary particle size [nm]11pH8.0* For definition of analytical test methods see chapter 06.

COLOUR BLACK FW 255COLOUR BLACK FW 255 is an after-treatedSpecialty Carbon Black. The after-treatmentproess generates a functional surface withoxygen-containing groups. When incorporatedin a coating system, these groups inducebetter wetting and dispersing properties.An enhanced interaction with polar bindersimproves the stabilization of the SpecialtyCarbon Black significantly, resulting in very highjetness and a deep blue undertone. COLOURBLACK FW 255, with its tailored and well-balancedproperties, offers formulators a broad range ofpossibilities for high jet coatings – not only inautomotive applications but also in all kinds ofapplications where highest jetness levels arerequired.COLOUR BLACK FW 255 demonstrates superiorproperties and can be used both in solvent-borneand water-borne coating systems.Properties*Jetness MY319Undertone dM11.4Volatile Matter at 950 [%]12.0BET [m /g]6002Primary particle size [nm]11pH2.5* For definition of analytical test methods see chapter 06.

COLOUR BLACK FW 310With our new product COLOUR BLACK FW310, we are again expanding our portfolio. Wedesigned this pigment based on our experiencewith COLOUR BLACK FW 255. The after-treatmentinduces better wetting and dispersing propertiesfor water and solvent-borne coatings.This Carbon Black gives highest jetness values incombination with blue undertone for both solventand water-borne coating systems. To achieve this,it is also essential to select the right additive forthe coating system. Customers using COLOURBLACK FW 310 can fulfill the requests of carmanufacturers to achieve ultra-high jetnesscoatings with deep blue undertone, as well asoffering options for metallic and effect coatings.Properties*Jetness MYUndertone dM3258.7Volatile Matter at 950 [%]12.0BET [m /g]6002Primary particle size [nm]11pH2.5* For definition of analytical test methods see chapter 06.

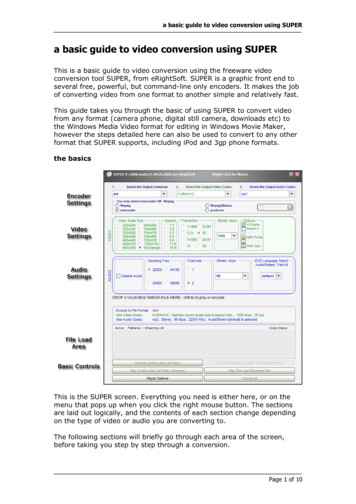

IT DEPENDS: SUMMARY &CONCLUSION06Different requirements in terms of stylingrequire different pigments to be selected foruse. Not every pigment is equally suited to eachapplication.Due to the pigment itself and then depending onthe additive, admixture or recipe, the color, flopand brilliance properties change. We supportour customers in selecting the right pigment fortheir individual requirements. In our systematictool you will find our three most recommendedpigments for water-borne coating systems.Examples of the versatile application, in additionto the mass tone in white, include metallic anda pearl pigment mixture. Here, you can alreadysee the color variance and diversity that isincorporated in the individual pigments. Thecoating examples contain an amount of 1.0 %(White Blend) or 1.5 % Carbon Black (Solid, AluBlend, Blue Pearl).Aggregate size distributionDiff. Mass DistributionCOLOURBLACKFW 310Analytical test methodsJetness MYPA PI-AT-CS B004 D.04*Undertone dMPA PI-AT-CS B004 D.04*Volatile Matter at 950 BETDIN 53552ISO 4652Primary particle sizepHTGZ3*COLOURBLACKFW 171COLOURBLACKFW 255ISO 787-9* Internal test method (further information on request).Diameter/µm

12320831543100305-4300-8295-120.040-160.020COLOUR BLACK FW 171COLOUR BLACK FW 2550.140COLOUR BLACK FW 3100.1200.100COLOURBLACKFW 255COLOURBLACKFW 310700COLOURBLACKFW 1710.0606502900.080600 COLOUR BLACK FW 310 appears deeper andbluer than the other pigments based on thecombination of highest jetness and a highbluish undertone.3250.160550 The effect of COLOUR BLACK FW 255 is morereddish. It reaches the second highest jetnessvalue.Reflection [%]16500 The effect of COLOUR BLACK FW 171 is grayerand paler. It has less color depth than theother two pigments.Undertone dM330450All of our pigments open the possibility of aresult with excellent color depth and jetness inthe top range of over MY 300. They all fulfill thehighest requirements in terms of color depthand undertone. However, when comparing thepigments, obvious differences can be seen:Jetness MY400SOLIDWavelength [nm]

WHITE BLENDALU BLENDBLUE PEARLThe White Blend has a ratio of 100 : 3 TitaniumDioxide to Carbon Black. Although the colordepth of these pigments means that they arenot the first choice for a white blend, the effectsare convincing and make it possible to drawconclusions for metallic and effect coatings:The Alu Blend has a ratio of 4 : 1.5 of aluminum flakesto Carbon Black. Not just the color but also theflop and brilliance are parameters that change viathe pigment blends and make interesting optionspossible for styling work:The styling of the effect-blacks demonstrates theunique benefits of the different pigments. Anintegrated coating process was used, taking themass tone as the basis. The styling was designedwith 0.06 % glass flakes in blue and transparent ata ratio of 1 : 1: Compared to the other grades, COLOURBLACK FW 171 is bluer and darker with thehighest color strength. In comparison, COLOUR BLACK FW 255demonstrates the lowest color strengthand is paler and more yellow than COLOURBLACK FW 310. The effect of COLOUR BLACK FW 310 isredder, darker and bluer than COLOUR BLACKFW 255. It has a higher color strength thanthe other two pigments. COLOUR BLACK FW 171 has more color depththan the other two grades. The brilliant angle isdarker, bluer and grayer. The effect of COLOUR BLACK FW 255 appearscooler and more metallic and stands out dueto a stronger flop compared to the other twopigments. The brilliant angle is brighter, grayerand bluer. From all angles, the blend of COLOUR BLACKFW 310 appears more golden and shows arather neutral flop than the other two pigments. The effect of COLOUR BLACK FW 171 is moreyellowish and paler with a lack of color depthand purity. Compared to COLOUR BLACK FW 310, theeffect of COLOUR BLACK FW 255 is somewhatredder and paler with a lower color depth. COLOUR BLACK FW 310 has the highestcolor intensity. This new product providescaptivating depth and its effect is cleanerand clearer than the other COLOUR BLACKs.

SOLIDw/bWHITE BLENDw/bALU BLENDw/bBLUE PEARLw/bCOLOUR BLACKFW 171HJT01HJT02HJT03HJT04COLOUR BLACKFW 255HJT05HJT06HJT07HJT08COLOUR BLACKFW 310HJT09HJT10HJT11HJT12

TECHNICAL INFORMATIONFor detailed information regarding technical properties of our three mostrecommended pigments, you can download the related technical informationunder the following URL:https://www.orioncarbons.com/colour black tis

The AmericasOrion Engineered Carbons LLC4501 Magnolia Cove Drive, Suite 106Kingwood, TX 77345USAEurope/ Middle East/ AfricaOrion Engineered Carbons GmbHHahnstraße 4960528 Frankfurt am MainGermanyAsia PacificOrion Engineered Carbons Trading (Shanghai) Co., Ltd.BM Intercontinental Business Centre, Room 3701-3702100 Yutong Road200070 Shanghai, ChinaPhone 1 832 445 3300AMERICAS@orioncarbons.comPhone 49 69 36 50 54 100EMEA@orioncarbons.comPhone 86 21 6107 0966APAC@orioncarbons.comGlobal Corporate HeadquartersOrion Engineered Carbons S.A., 6 Route de Trèves, L-2633 Senningerberg, Luxembourg, Phone 352 27 04 80 60All information and statements contained herein are believed to be accurate, however Orion Engineered Carbons GmbH (as well as all other Orion Engineered Carbons group companies including Orion EngineeredCarbons SA), its agents and/or affiliates give no warranty with respect thereto, including but not limited to any results to be obtained or the non-infringement of any proprietary right. Use or application of suchinformation or statements or the material or systems described herein is at user’s sole discretion and risk, and consequently user acknowledges that Orion Engineered Carbons GmbH (as well as all other OrionEngineered Carbons group companies including Orion Engineered Carbons SA), its agents and/or affiliates shall bear no responsibility or liability for same. Nothing herein shall be construed as a license of orrecommendation for use, especially with concern to the potential infringement of any proprietary right. All sales are subject to the respective Standard Terms & Conditions of Sale issued by Orion Engineered CarbonsGmbH or - as the case may be - another Orion Engineered Carbons group company, including but not limited to the Limited Warranty clauses contained therein. 2019 Orion Engineered Carbons GmbHOEC-II 0406-03/2019

Founding of Orion Engineered Carbons (OEC) Market launch of COLOUR BLACK FW 171. Short Facts Almost 125 years of innovation 14 plants, three regional headquarters, more than 1,400 employees Four technical centers - in Germany, USA, China and South Korea Only supplier with five Carbon Black production processes: Furnace Black, Gas Black, Lamp Black, Acetylene Black and Thermal Black .