Transcription

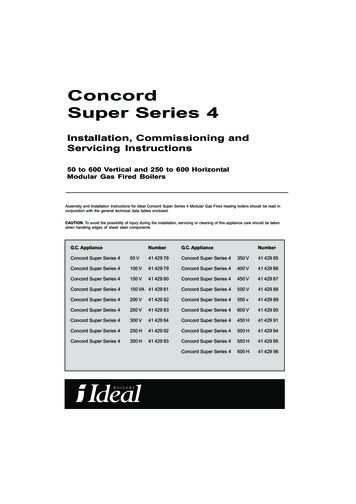

ConcordSuper Series 4Installation, Commissioning andServicing Instructions50 to 600 Vertical and 250 to 600 HorizontalModular Gas Fired BoilersAssembly and Installation Instructions for Ideal Concord Super Series 4 Modular Gas Fired heating boilers should be read inconjunction with the general technical data tables enclosed.CAUTION. To avoid the possibility of injury during the installation, servicing or cleaning of this appliance care should be takenwhen handling edges of sheet steel components.G.C. ApplianceNumberG.C. ApplianceNumberConcord Super Series 450 V41 429 78Concord Super Series 4350 V41 429 85Concord Super Series 4100 V41 429 79Concord Super Series 4400 V41 429 86Concord Super Series 4150 V41 429 80Concord Super Series 4450 V41 429 87Concord Super Series 4150 VA 41 429 81Concord Super Series 4500 V41 429 88Concord Super Series 4200 V41 429 82Concord Super Series 4550 v41 429 89Concord Super Series 4250 V41 429 83Concord Super Series 4600 V41 429 90Concord Super Series 4300 V41 429 84Concord Super Series 4450 H41 429 91Concord Super Series 4250 H41 429 92Concord Super Series 4500 H41 429 94Concord Super Series 4300 H41 429 93Concord Super Series 4550 H41 429 95Concord Super Series 4600 H41 429 96100920-9.pmd111/8/2005, 1:31 PM

GENERALCONTENTSAssembly . 19Commissioning and Testing . 22INTRODUCTIONThe Ideal Concord Super range of boilers is suitable forconnection to fully pumped, open vented or pressurisedcentral heating, indirect domestic hot water and combinedsystems - in commercial and industrial premises.Note. British Gas certification does not apply to pressurisedsystems.DUTYElectrical Data . 14The range of boiler is suitable for: combined indirect pumpeddomestic hot water and central heating systems; independentindirect pumped domestic hot water or central heatingsystems.Exploded Diagrams . 19Fully pumped systems may be open vented or sealed.The range of boiler is NOT suitable for:Combustion Data Sheet . 361. Gravity DHW systems.2. Gravity heating systems.3. Direct domestic hot water supply.General . 2FOUNDATIONInstallation Requirements . 3Technical Data . 4Boiler House Clearances . 6Flue Requirements . 7Design Requirements . 12Service & Fault Finding . 26The boiler must stand on a non-combustible floor (i.e.concrete or brick) which must be flat, level and of a suitableload bearing capacity to support the weight of the boiler (whenfilled with water) and any ancillary equipment.INSTALLATION REQUIREMENTSIMPORTANTGAS SAFETY (INSTALLATION AND USE) REGULATIONS, 1994All gas appliances must, by law, be installed by competentpersons, e.g. Gas Safe Registered Engineer in accordance withthe above regulations. Failure to install appliances correctlycould lead to prosecution.It is in your own interest, and that of safety, to ensure that thelaw is complied with.In addition, the installation must comply with the relevantBritish Standard Specifications and Codes of Practice:IGE-UP-1Cleaning . 27Purging Procedures for Non-domestic GasInstallations and Soundness Testing Proceduresfor Industrial and Commercial Gas Installations.Short List of Parts . 33IGE-UP-2Guidance for Installation of Gas PipeworkBoosters and Compressors for CustomersPremises.BS. 6644Installation of Gas Fired Hot Water Boilers ofRated Inputs between 70kW and 1.8MW (net).BS. 6880Central Heating by Low Pressure Hot Water.IGE-UP-10Installation of Gas Appliances in Industrial andCommercial Premises.IM/22Installation Guide for High Efficiency(Condensing) Boilers (industrial andCommercial Appliances).Note: The Ideal Concord Super is a partiallycondensing boiler therefore the condensatedrain should be run in accordance with IM/122.BS. 5440:2Specification for Installation of Ventilation forGas Appliances.CP 342.2Centralised Hot Water Supply.Health and Safety Document No. 635.The Electricity at Work Regulations 1989.Note: All threaded gas and water connections must be sealedusing appropriate jointing compound.Concord Super Series 4 - Installation & Servicing2100920-9.pmd211/8/2005, 1:31 PM

GENERALBOILER DESCRIPTIONMODE OF OPERATIONEach boiler consists of;The normal mode of operation of the boiler is preceded, incertain conditions, by a period in which the complete boilercasing is given a three volume air change. The air changeis an important safety feature of the Europeanrequirements, with which the boiler is designed to comply.(a) The insulated stainless steel casing with flue outlet,flue coupling point and condensate drain.(b) The heat exchanger module(s).(c) The module control pack.(d) Wiring centre with high & low voltage wiring harnesses.and in case of multi-module boilers;(e) Gas header - complete with individual module gasservice taps and mains inlet gas tap.(f) Flow and return water headers.(g) Each boiler is supplied with instructions for installationand use.The air change will occur whenever the boiler goes from asituation of no modules firing to a situation of one modulefiring. This includes morning start-up and those occasionsof low load when the last module firing goes off on itsthermostat (or external controls) and is called again.The air change will NOT occur if one or more modules arefiring and a further module is called.The 50kW boiler is supplied with a module gas service taponly.The three volume air change period operates as follows, inthe case of multi-module boilers: All the module fans areenergised and run for a period of not less than 30seconds. At the end of this period all the fans switch off.Each module is connected in parallel across the flow andreturn water headers, ensuring that water is flowingthrough all of the modules at all times.After a delay of approximately 1 second, the fan of themodule being called begins its 15 second pre-purgeperiod. Refer to Frame 30.The Ideal Concord Super range of boilers provides goodload matching & sequence control by the following method:In the case of single module boilers: only its own 15second nominal prepurge period occurs.As the load on the boiler decreases so the return watertemperature increases.Each module is fitted with an electronic thermostatcapable of being set to within 0.5oC. These thermostatssense the return water temperature.Once the flow temperature reaches 82oC (i.e. the returnreaches 71oC) the modules are set to switch off atintervals to maintain the flow at 82oC 3oC.With basic controls the modules switch off from left toright and from top to bottom. Thus the top left module isalways the first to go off and the bottom right the last.The standard wiring centre, on the side of the boiler, isthe connection point for the mains supply, the low gasinlet pressure and low water pressure switches provided for boiler protection. The centre also providesfacilities for the wiring in (via voltage free connections)of remote indicators/alarms, for ‘burner on’, ‘lock out’and ‘overheat’. (Indicating that at least one module is inthe signalled condition).Facility is also provided for the connection of the ‘BoilerManagement System’. Additional controls such as waterflow switch, programmer, energy management systemsetc. may also be used.MODULE DESCRIPTIONEach module can be sub-divided into 4 main elements:(a) The heat exchanger, which consists of finned coppertubes expanded into cast iron end plates, and cast ironflow and return elbows (refer to Frame 15).(b) The gas line, which supplies and regulates the gas flowto the burner (refer to Frame 17).When the electronic adjustable control thermostat calls forheat, the fan is switched on and purges the combustionchamber for 15 seconds. At the end of this time the ignitionsequence starts; the control box delivers a spark from theignition electrode to the burner and the gas valves areopened.Gas is delivered, via the injector, to the distribution plate atthe inlet to the fan. This pre-mixes the gas with the airwhich then passes from the fan through a multi-hole plateto the burner, where it is ignited. The flame is sensed viathe ionization electrode and the controls keep the valvesopen until the thermostat is satisfied.The module is protected against blockage of the burner,heat exchanger or flue, and against fan failure by the gas/air control. This senses the difference in pressure acrossthe multi-hole plate and controls the gas injector pressureaccording to the amount of air flowing.After combustion, the products flow past the finned coppertubes and through the gas distribution screen into theboiler casing. In doing so, heat is given up to the waterflowing through the tubes.The installation must also conform to current buildingregulations, any requirement of the local authority healthand safety executive, gas region, insurance companiesand the Health and Safety at Work Act 1974. All wiringmust conform to I.E.E. (BS. 7671) regulations for theelectrical equipment of buildings.The boiler modules are very quiet in operation and noadditional noise soundproofing is required.(c) The fan assembly, which draws gas (from the injector)and air, mixes them and supplies the mixture to theburner. (Refer to Frame 16).(d) The electrical control assembly.Concord Super Series 4 - Installation & Servicing100920-9.pmd3311/8/2005, 1:31 PM

GENERALTECHNICAL DATATable 1Boiler50 VNo. of modulesHeat outputkWBtu/h x 103Heat input100 V150 V200 V250 V300 V150 VA250 H300 76.4235.2294.0352.8176.4294.0Btu/h x 103200.6401.3601.9802.51003.11203.8601.91003.1 1203.8m 58477997311685849731168Flue gas 3716482137164at 120 C (248 F)ft. /min58116174232290348174290348Required waterl/s1.072.143.214.285.356.423.215.356.42flow rate 0450540Gas rateoo312.5 kN/m2 (50 in w.g.)Hydraulic resistanceMinimum static head**2 m (6.5 ft.)60.0 m (197 ft.) 6.0 bar 85 lb/in2)Maximum static headElectricity supply230 V 50 Hz,Power consumptionW90180270360Boiler l)in.30.856.475.361.081.181.161.058.358.3Boiler 1.576.6106.698.984.0107.099.0and .0218.0Weight 464580696348580696Gas supply pressure †54020.0 mbar (8 in. w.g.)Boiler depth (overall)Weight of casing450698 mm (27.4 in.)Weight of gas &kg.-34.053.659.489.494.353.492.296.7water headers ‡lb.-75118131197200118203213Water gal.1.02.64.65.98.39.94.98.89.9Flow and returnmm405065658080658080connection ††in.11 /2212 /212 /23Gas connectionRc3/411 1/41 1/41 1/2in. BSP3/411 1/41 1/4125175200578312 /2331 1/21 1/41 1/21 1/21 1/21 1/21 1/41 1/21 1/225025030020025030010101281012Flue pipe sizemm(nominal bore) †††in.Flue socket sizemm159213238288288339238288339in.6 1/48 3/89 3/811 3/811 3/813 3/89 3/811 3/813 3/8Injector size7.3 mm (0.28 in.)Type of gasNatural gas (G20 only)Notes.* Flue gas volumes are calculated from a calorificvalue of 38.4 MJ/m3 (1,031 Btu/ft.3) at 15oC and1.013 bar - based on a CO2 content of 9.0%.‡Total weights of all headers, fully assembled.†The minimum gas supply pressure is with all modules firing.††Flange size; refer to BS. 4504.** For further information on minimum headrequirements refer to page 10.††† For 150 VA, 250 V and 250 H models ONLY, a flue adaptor issupplied as standard.Concord Super Series 4 - Installation & Servicing4100920-9.pmd411/8/2005, 1:31 PM

GENERALTECHNICAL DATATable 2Boiler350 VNo. of modulesHeat outputHeat inputGas rate400 V450 V 500 V550 V600 V 450 H500 H550 H 600 tu/h x 470.4592.2 588.0646.8705.6 529.2588.0646.8 705.6Btu/h x 10314041605180622072407200622072006180624073m 63155717521947214323361752194721432336Flue gas 219246273301328246273301328at 120 C (248 F)3ft. /min406464522580638696522580638696Required waterl/s7.498.569.6310.7011.7712.849.6310.7011.77 12.84flow rate 10%gal./min.98.7112.8126.9 141.0155.1169.2 126.9141.0155.1 169.2oo12.5 kN/m2 (50 in w.g.)Hydraulic resistanceMinimum static head**2 m (6.5 ft.)60.0 m (197 ft.) 6.0 bar 85 lb/in2)Maximum static headElectricity supply230 V 50 Hz,Power consumptionW630720810900Boiler .484.4Boiler widthmm182218221833(overall)in.71.771.772.2Weight of casingkg.134126197190182and insulationlb.295278435418Weight ofkg.371424477530moduleslb.81893510521168Gas supply pressure .0 mbar (8 in. w.g.)Boiler depth (overall)1350 mm (53.1 in.)Weight of gas &kg.260263311313315318298300302304water headers ‡lb.573580686690694701657661665670Water Flow and returnmm100100125125125125125125125125connection ††in.4.04.05.05.05.05.05.05.05.05.0Gas connectionRc22222222222222222222Flue pipe sizemm350350400400450450400400450450(nominal bore) †††in.14141616181816161818Flue socket sizemm400400450450501501450450501501in.15 3/415 3/417 1/417 1/419 3/419 3/417 3/417 3/419 3/419 3/4in. BSPInjector size7.3 mm (0.28 in.)Type of gasNatural gas (G20 only)Concord Super Series 4 - Installation & Servicing100920-9.pmd5511/8/2005, 1:31 PM

BOILER HOUSE CLEARANCESGENERAL1RECOMMENDED BOILER-HOUSECLEARANCES 50 - 300KWAll dimensions in millimetres (inches)2RECOMMENDED BOILER-HOUSECLEARANCES 350 - 600KWAll dimensions in millimetres (inches)LOCATIONAIR SUPPLYThe floor must be flat, level, and capable of supporting theweight of the WET boiler pipework. In addition concretefloors must be sealed. The siting of the boiler must be inaccordance with the guidance given in BS. 6644 and withreference to minimum boiler-house clearances. Refer toFrames 1 & 2.Detailed recommendations for air supply are given in BS.5440:2 and BS. 6644 which MUST be consulted beforeproceeding.CONNECTION TO GAS SUPPLYThe gas installation MUST be in accordance with therequirements of the local gas region (refer also IM/16).The gas supply must be capable of maintaining aminimum pressure of 15.0 mbar (6 in.w.g.) at the inlet tothe boiler, with all modules firing. Gas consumption isgiven in Tables 1 & 2.The boilers are for use with NATURAL GAS ONLY.FLUE REQUIREMENTSOpen flue, induced draught and fan diluted systems maybe used but must comply with the following basicrequirements:1. A draught diverter MUST NOT be fitted.2. A draught stabiliser MUST be fitted to all types of fluesystems within 1 metre of the flue outlet and set tocontrol the draught in the casing between neutral and0.2 mbar (0.08 in.wg.) irrespective of flue height ornumber of modules firing. Refer to Frames 3 and 4 forfurther guidance.3. ALL flue systems must be insulated and/or lined andimpervious to acid condensate. Prefabricatedchimneys must have a ’U’ value of no greater than 1.4W/m2 oC at 540oC (0.25 Btu/h ft.2 oF at 1000oF.)4. Drainage must be provided at the base of the chimneyor liner. All boiler casings are fitted with a condensatedrain point - refer to Frame 14.5. For fan diluted or induced draught systems, air flow/pressure switches MUST be fitted to protect against fanfailure. Switches should be set to open if the air flowreduces by more than 15%.6. Flue products must not be allowed to enter the boilerhouse or adjacent buildings.Contamination of the air supply from any external sourcemust be avoided, with particular reference to dust,insulation debris and flue products. Concrete floors mustbe sealed. If any work is to be carried out in the boilerhouse which is likely to generate dust (e.g. structuralalterations or the lagging of pipework) it is recommendedthat the boiler is shut down and the modules covered witha dust sheet, otherwise the boiler will require cleaning andservicing.1. In particular, the contamination of the air supply withchlorides must be avoided as they will cause thedeterioration of the aluminium fan impellor.2. The boiler-house requires ventilation openings atBOTH high and low levels, direct from the outside.Allowances MUST be made for stabiliser dilution in allcases.3. Mechanically forced ventilation systems must includeprovision for boiler shut down in the event of fan failure.4. High speed air streams within the boiler house mustbe avoided.5. Extraction mounted ventilation fans alone are NOTpermitted.6. The minimum effective areas of the permanent airvents direct from the outside by natural ventilation areas follows:Required area (cm2) per kW of total rated input (net)Boiler roomEnclosureLow level (inlet)410High level (outlet)25Note: Where a boiler installation is to operate in summermonths (e.g. DHW) additional ventilation requirementsare stated, if operating for more than 50% of time (referto BS6644).7. Refer also to BS. 6644 and to IGE UP/10 Installation ofGas Appliances in Industrial and CommercialPremises and IM/22 for further guidance.Concord Super Series 4 - Installation & Servicing6100920-9.pmd611/8/2005, 1:31 PM

FLUE REQUIREMENTS3GENERALAPPLICATION OF DRAUGHT STABILISER - SINGLE BOILER INSTALLATIONNote: The discharge from both types of system MUSTnot allow recirculation of combustion products intothe boilerhouse or adjacent buildings.Note: Air intake and discharge should be on thesame outside wall face. Design must comply withBritish Gas requirements -refer page 5 andPublication IM/11.INDUCED DRAUGHTAll dimensions in millimetres (inches)4FAN DILUTED FLUE (FDF) SYSTEMFLUEING - GENERAL GUIDANCE BOILER INSTALLATIONNotes:The draught at the boiler casing must be controlledbetween neutral and 0.2 mbar (0.08 in. w.g.) negativeirrespective of the number of modules firing. The draughtstabiliser must be fitted within 1 metre of the boiler casing.To achieve the minimum neutral draught condition a verticalflue length of 2 metres is needed plus whatever extra heightis necessary to overcome the resistance of any bend or ductwork between the boiler casing and the vertical flue.Contact should be made with the Customer Care department ofIdeal Stelrad Group for further advice and information on this subject.All dimensions in millimetres (inches)Concord Super Series 4 - Installation & Servicing100920-9.pmd7711/8/2005, 1:31 PM

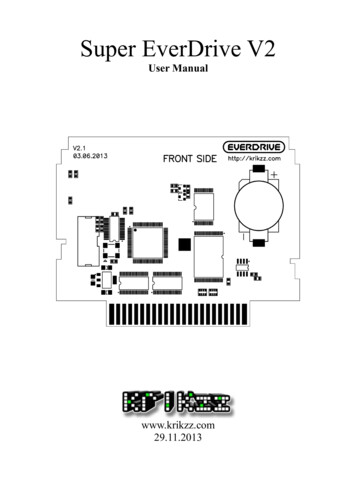

8100920-9.pmd811/8/2005, 1:32 PMAll dimensions in millimetres (inches)50kW Vertical100kW Vertical150kW Vertical150kW Vertical/Alternative5gc Gas Connectionfp Foot ProjectionGENERALDIMENSIONAL DATABOILER DIMENSIONS 50KW - 150KW MODELSConcord Super Series 4 - Installation & Servicing

100920-9.pmd9Concord Super Series 4 - Installation & Servicing11/8/2005, 1:32 PMAll dimensions in millimetres (inches)200kW Verticalrc Return Connection250kW / 300kW Vertical250kW / 300kW Horizontal6gc Gas Connectionfp Foot ProjectionDIMENSIONAL DATAGENERALBOILER DIMENSIONS 200KW - 300KW MODELS9

DIMENSIONAL DATAGENERAL450kW - 600kW HorizontalBOILER DIMENSIONS 350KW - 600KW MODELSConcord Super Series 4 - Installation & Servicing10100920-9.pmdAll dimensions in millimetres (inches)350kW - 400kW Vertical450kW - 600kW Verticalgc Gas Connection71011/8/2005, 1:32 PM

DIMENSIONAL DATA8INSTALLATIONSITE ASSEMBLY - 600kW Vertical BoilerNote.1. To aid the assembly procedure, on the flow &return manifolds and the flow & return spools,the flanges are left loose for site welding.2. The double M/F elbows (16) are to enable easeof fit and squareness.LEGEND1. Insulated boiler casing (c/w feet).2. 80 nom. bore elbow.3. Flow manifold (long).4. Flow and return headers.5. Flexible bellows unit.6. Blank flange.7. Gas header complete with gas cocks.8. Rc 1 1/2 union elbows.9. Space nipple.10. Flow and return spools.11. Rc1 1/2 elbow.12. Space nipple.13. Short space nipple.14. Main gas cock (not shown).15. Rc 2 twin elbow (with two hex bushes).16. 1 1/2 M/F elbow.17. Return manifold (short).9SITE ASSEMBLY - 600kW Horizontal BoilerNote.1. To aid the assembly procedure,on the flow & return manifoldsand the flow & return spools, theflanges are left loose for sitewelding.2. The double M/F elbows (12) areto enable ease of fit andsquareness.LEGEND1. Insulated boiler casing (c/w feet).2. 125 nom. bore elbow.3. Flow manifold (long).4. Flow and return headers.5. Flexible bellows unit.6. Blank flange.7. Gas header complete with gascocks.8. Rc 1 1/2 union elbows.9. Short space nipple.10. Main gas cock (not shown).11. Rc 2 twin elbow (with two hexbushes).12. 1 1/2 M/F elbow.13. Return manifold (short).Concord Super Series 4 - Installation & Servicing100920-9.pmd111111/8/2005, 1:32 PM

DESIGN REQUIREMENTSGENERAL7. The minimum air requirements by mechanicalventilation are as follows:Table 3 - MECHANICAL VENTILATION FLOW RATESType of boilerForced/induceddraught boilersFlow rate per kW total ratedheat input (net)Inlet airExtract air(combustion(ventilation)ventilation)2.6 m3/h1.25 m3/h 0.18m3/hA purpose designed flueing ventilation system based solelyon a high level permanent opening to an otherwise sealedboiler-house or compartment may be used, provided thatspecialist advice is taken, and that the combustion air andventilation requirements of the boiler is provided in line withBS6644. In addition to this, the boiler house temperaturemust be prevented from exceeding 32 C at mid-level.BS6644 provides details of temperature requirements.WATER CIRCULATION SYSTEMDESIGN REQUIREMENTSIdeal Concord Super gas boilers are intended for use inconjunction with FULLY PUMPED, OPEN VENTED orPRESSURISED systems - subject to the requirementsdetailed below. They are NOT suitable for use on gravitycirculation systems.Note. In some cases, pump manufacturers will require ahead as high as 12m (40ft). This must be allowed for andthe minimum head increased accordingly. Refer to Frame10 for further clarification.Safety ValveA safety valve must be sized and fitted in accordance withBS. 6644. The valve should be set at 0.7 bar (10 lb/in2)above the available static head of water over the boiler.The maximum safety valve setting is 0.7 bar (10 lb/in2)above the maximum design operating head of 6.0 bar (85Ib/in2), i.e. 6.7 bar (95 Ib/in2).Table 4 - VENT, COLD FEEDThe open vent and cold feed pipe sizes must comply withBS. 6644 and must be of the following minimum size.Boiler50 V100 V, 150 V200 V, 250 V, 300 V150 VA250 H, 300 H350 V - 600 V450 H - 600 HCold feednominal dia.19 mm25 mm32 mm25 mm32 mm38 mm38 mmOpen ventnominal dia.25 mm32 mm38 mm32 mm38 mm50 mm50 mmDrainWater Flow Rate1.07 l/s (14.1 gal/min) 10% through each module.The drain valve must comply with BS. 2879 and beoperated with a removable key.Thus a six module boiler requires 6.42 l/s (84.6 gal/min)volume flow rate. Refer to Tables 1 & 2 for other boilers.Pressure GaugeNote. Failure to maintain this flow rate will result inoperation of the module overheat cut off device.The water pressure gauge and temperature gauge mustthe fitted in accordance with BS. 6644.The boilers are suitable for operation when connected tosystems requiring lower flow rates than those quoted aboveand to systems where the volume flow varies with load,PROVIDED they are installed in accordance with Frame 10.Any other method of installation should be discussed withIdeal Stelrad Group before proceeding.Water flow switchHydraulic Resistance - refer Graph 1When operating at the correct volume flow rate given above,the hydraulic resistance of all Ideal Concord Super boilersis 12.5 kN/m2 (50 in.w.g.).A water flow switch must be fitted to protect the boiler frompump failure.Graph 1 - HYDRAULIC RESISTANCEPump Over-runA pump over-run time of 30 seconds minimum must beallowed for on plant shutdown.Maximum Static Head60m (197 ft.), i.e. maximum operating pressure 6.0 bar (85Ib/in2).Minimum Static HeadMinimum static head requirements for open ventedsystems must comply with boiler design characteristics,pump manufacturer’s requirements and the requirementsof the Health and Safety executive Publication PM5.In order to comply with the above, a minimum static head of2m (6.5 ft), i.e. 0.20 bar (3 lb/in2) will be adequate undermost operating conditions, measured either from thehighest circulating point of the system or from the boilerwhen the boiler house is roof mounted.Concord Super Series 4 - Installation & Servicing12100920-9.pmd1211/8/2005, 1:32 PM

DESIGN REQUIREMENTSGENERALGENERAL GUIDANCE ON APPLICATIONSFrame 10 is intended to provide basic information only onthe application of the Ideal Concord Super boiler. BritishGas approval has not been sought in the matter.It is impossible to cover all applications and installers arerecommended to contact Ideal Stelrad Group if advice on aspecific application is required.It is essential that the water flow rates given in Tables 1 & 2be maintained within the limits stated - therefore anycompensating devices must not be connected to IdealConcord Super boilers directly but may be used inconjunction with a mixing header. The mixing header mustbe sized at least one pipe size larger than the boiler flowand return manifold size. This will avoid hydraulicinterference between the boiler primary pump and systemzone pumps. The use of a mixing header means thatcompensating controls can be used to operate mixingvalves on a variable temperature circuit, without affectingthe water flow rate through the boiler.10 GUIDE TO MINIMUM REQUIREMENTS FOR OPEN VENT - Feed / Expansion TankHeight and boiler Primary Circuit1. Roof top or single storey applications.2. Ground floor or basement applications.LEGEND1. Cold Feed(sizes MUST complywith BS. 6644).2. Open vent. (sizes MUSTcomplywith BS. 6644).3. Safety valve.4. Water flow switch.5. Dual primary pumps.6. Mixing header- see note above.7. Feed and expansion tank.8. Mixing valve.9. Highest point inthe system.All dimensions in millimetres (inches)Concord Super Series 4 - Installation & Servicing100920-9.pmd131311/8/2005, 1:32 PM

ELECTRICAL DATAGENERALExisting systems and, where necessary, new systemsshould be thoroughly cleaned prior to the use of a stableIdeal Stelrad Group, advise contact directly with specialistson water treatment, such as:Fernox, Cookson Electronics,Forsyth Road, Sheerwater, Woking,Surrey, GU21 5RZTel. 44 (0) 1799 550811orG E Betz, Sentinel Division,Foundry Lane, Widnes, Cheshire, WA8 8UDTel. 44 (0) 151 420 9563ELECTRICAL SUPPLY230 V - 50 Hz. Consumption: 90W per module (excludingremote alarms etc.)Note. External wiring and any installer-supplied remotewarning lights MUST be in accordance with the I.E.E. (BS.7671) regulations and any local regulations which apply.The method of connection to the mains supply shouldfacilitate complete electrical isolation of the boiler.Connection should be made via a fused double poleswitch or fused spur box, serving the boiler only, andincorporating contacts with a separation of at least 3 mm inall poles. The point of connection should be readilyaccessible and adjacent to the boiler.The length of the power supply conductors between thecable anchorage and the terminals must be such that thecurrent conductors become taut before the earth conductor,if the cable slips out of the cable anchorage.The water flow switch and any other overriding safetydevices should be wired in series with the isolation mainssupply to the boiler.50 kW SINGLE MODULE BOILERS ONLY (Frame 11)50 kW boilers are supplied with a multi-pin plug forconnection to the mains, as follows:EARTH . Terminal 1LIVE . Terminal 2NEUTRAL . Terminal 4Link betweenTerminals 6 & 8 . by installer11 MULTI-PIN PLUG WIRING FORSINGLE MODULE BOILER ONLY56743182Legend:Terminal 1 - EARTH (Green/Yellow)Terminal 2 - LIVE (Brown)Terminal 4 - NEUTRAL (Blue)Terminal 6 - linked to Terminal 8 by installerConcord Super Series 4 - Installation & Servicing14100920-9.pmdinhibitor, which does not require continual topping up tocombat the effects of hardness salts and corrosion on theheat exchangers of the boiler and associated systems.con 6111Frame 10 shows how constant and variable temperaturecircuits can be used on low and high head applications.The following points should be noted:1. The recommended positions of the cold feed and openvent are shown. Sizes should comply with BS. 6644. Ifisolating valves are to be fitted in the flow and returnpipes of the boiler they must not isolate the boiler fromthe open vent, safety valve or cold feed.2. The minimum tank height shown is measured from thehighest point of the system and must be increased, ifnecessary, to comply with pump manufacturers’requirements.3. The open vent height above tank water level cannot beguaranteed adequate in all circumstances and does nottake into account any instantaneous changes in headbrought about by ancillary equipment operating.4. Water flow switch is shown in its recommended position. ItMUST NOT be located on the mixing header whereoperation of z

Concord Super Series 4 300 H 41 429 93 Concord Super Series 4 550 H 41 429 95 Concord Super Series 4 600 H 41 429 96 100920-9.pmd 1 11/8/2005, 1:31 PM. 2 Concord Super Series 4 - Installation & Servicing CONTENTS