Transcription

Technical SpecificationsRev. C - 10/2020Consolidated 13900 SeriesPilot-Operated Safety Relief ValveDesigned specifically for high capacitysteam applications, this series ofvalves contributes to the overallefficiency and profitability of plantoperations.Baker Hughes Data Classification : Public

Table of ContentsConversion Table.Table. 3Features and Benefits.Benefits. 4Applications. 5ApplicationsScope of Design.Design. 5Materials. 6-8MaterialsOptions.Options. 9Dimensions and Weights.Weights.10.10Capacities.11Capacities. 11Valve Configuration Code.Code.1212Ordering a 13900 Series POSRV.POSRV.13132 Baker Hughes 2020 Baker Hughes Company. All rights reserved.

Baker Hughes provides a full range ofConsolidated pressure valve styles, sizes, optionsand configurations for multiple industries,applications, environments, and media. Fromspring-actuated to pilot-operated, each pressurevalve is configured to offer safer process flowcontrol in harsh environments.Conversion TableAll the USCS values are converted tometric values using the following conversion factors:USCS UnitConversion FactorMetric rpsig0.06894757bargft lb1.3558181Nm F5/9 ( F-32) C 2020 Baker Hughes Company. All rights reserved.Consolidated 13900 Series POSRV Technical Specifications 3

Features and BenefitsFor system applications that require largedischarge release capacities, the Consolidated13900 Series Safety Relief Valve provides extremelyreliable working economy and a simple efficientvalve design. It also features a valve configurationthat simplifies installation and in-line valvemaintenance.Greater Total System EfficiencyThe main valve can handle extremely large relievingcapacities, in excess of 3 million pounds of steam perhour (1,360,777 kg/hr). It has a seven-to-one dischargecapacity over a “T” type orifice, and a two-to-onedischarge capacity over a “W” type orifice.Improved DesignThe total valve external configuration is considerablysmaller in size, and the valve is lighter in weight thana comparable spring-loaded valve. Because of thesefeatures, less space is required for valve installation.A simple, efficient and reliable direct acting valvedesign with few components eliminates the needfor excessive spare parts inventory and reducesmaintenance time.Easy Installation and MaintenanceValve configuration is considerably smaller in size andlighter in weight than a comparable spring-loadedvalve. This makes installation, field handling, testing,and valve maintenance easy.Valve maintenance is relatively simple andstraightforward. The simple valve design meansfewer parts. Fewer valve parts mean that less can gowrong, malfunctions can be readily diagnosed, andmaintenance costs and process downtime can bekept to a minimum.To simplify valve maintenance, all main valvecomponents can be removed through the top bonnetof the valve. The pilot valve can be field tested andrepaired without breaking inlet and outlet pipingconnections on the main valve. The pilot valveopening and closing is easily adjusted on a small testfacility.DescriptionThe 13900 Series Pilot-Operated Safety Valve is anASME Section VIII-approved valve intended for useon compressible fluids. The valve design is simple. Itconsists of a small conventional, fail-safe pilot safetyvalve and main valve.Overcompression of the main valve seat O-ring,located between the disc and bushing, is eliminatedby the metal- to-metal contact bearing surfacesbetween the disc and bushing. Removing the pressurefrom behind the O-ring via two small slots when thevalve is open and flowing eliminates O-ring sealblowout. A condensate drain hole in the disc easilydrains any accumulated moisture in the upper disccavity.The spring-loaded U-shaped PTFE guide sealprovides increased seat tightness as system pressureincreases. The PTFE material greatly reduces friction onthe main disc and allows for reliable, dependable andrepeatable disc action. The seal spring load ensuressealing at all times.PTFE guide rings eliminate friction along with metalto-metal contact between the disc and guide. Mainvalve disc action is repeatable and reliable.The pilot valve action directly controls the pressureforces on the main valve disc and eliminates the needfor a transfer valve. System pressure that actuatesthe pilot valve is transmitted through a simple, fullflow design sensing tube. The sensing tube eliminatessmall orifice control parts and their possible cloggingcharacteristics and is enclosed within the valve body,which protects it from damage and freezing.Pilot valve blowdown can be adjusted independentlyof the main valve and before the pilot valve is installedon the main valve.The pilot valve disc is a metal-seated design that iseasily serviced and provides a seat tightness to 95percent of set pressure.The main unloading valve has a large orifice of upto 200 in2 (1290 cm2), which reduces the numberof valves required for overpressure protection. Thiseliminates installation costs for additional headernozzles and exhaust lines.The O-ring seat seal design and the spring-loadedPTFE rings assure tightness, valve integrity, and easyvalve maintenance.4 Baker Hughes 2020 Baker Hughes Company. All rights reserved.

Applications The 13900 Series Pilot-Operated Safety Relief Valveis designed for steam applications where pressuresrange from 50 psig (3.45 barg) to 300 psig (20.68barg) and temperatures range from 250 F (121 C)to 550 F (288 C). The temperature limit is appliedto the valve to ensure that the PTFE seal rings willmaintain sealing integrity. The 13900 Series Pilot-Operated Safety Relief Valvecan be used on any compressible fluid withinthe pressure and temperature limits of the valve,provided the fluid media exhibits characteristicssimilar to saturated steam. For applications otherthan steam, the open lift lever cap should bereviewed for adequacy. If another cap design isrequired, it should be so stated. For all sizes except the 200 in2 (1290 cm2), thelargest possible relieving capacity is supplied forthe valve inlet size specified. For those applications where discharge pressuresat the valve outlet exceed 10 percent of the pilotvalve set pressure, or where economics dictatethat higher discharge pressures be required, thepilot valve can be exhausted separately and thedischarge pressure of the main valve can beallowed to increase above the limit of 10 percent ofthe pilot valve set pressure. Typical valve applications include boiler feed pumpturbines, flash tanks, steam lines and deaerator.CAUTION The 13900 Series Pilot-Operated Safety Relief Valveis available in four sizes, 114, 143, 176 and 200 in2 (735,923, 1135 and 1290 cm2).These valves are not to be used onpower boilers.Scope of Design13900 Flanged Series Pilot-Operated Safety Relief ValveStandard Valve ConnectionsValveType1.InletOrifice s16.00406.4300# R. F.18.00457.2150# R. F.(1)923.22018.00457.2300# R. F.22.00558.8150# R. F.(2)176.7001140.00020.00508.0300# R. F.24.00609.6150# R. F.201.0001296.77020.00508.0300# R. F.24.00609.6150# R. 13906-17613906-200The 22" (558.8 mm) 150# flange is not covered by ASME B16.5. Drilling is (20) 1.375” (34.93 mm) diameter holes on a 27.25”(692.2 mm) diameter bolt circle. Covered by MSS-SP-44.2. Two holes on outlet drilling are tapped and threaded 1.125-7UNC-2B Thread, 1.5” (38.1 mm) deep.Pressure/Temperature LimitsValveTypeAll SizesSet g F C F C503.4430020.68250121.1550287.7 2020 Baker Hughes Company. All rights reserved.Consolidated 13900 Series POSRV Technical Specifications 5

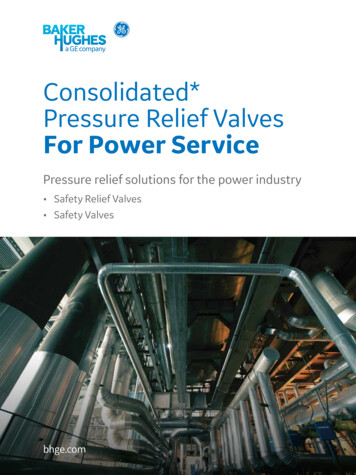

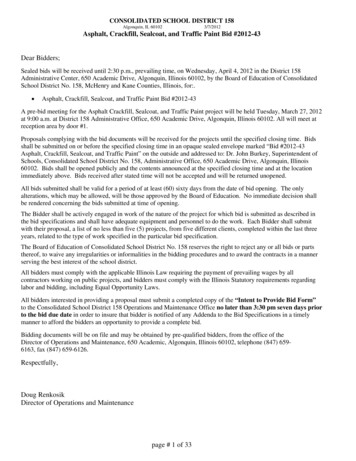

Materials13900 Type Main Valve13900 Series Main 16915131485771369511449210316 Baker Hughes 2020 Baker Hughes Company. All rights reserved.

Materials13900 Series Standard MaterialsStandard Material for 13900 Series POSRVRef.No.Nomenclature1Main Base2Seat Bushing3Seat Bushing Ret. Scr. Jam Nut4Standard Material for 13900 Series POSRVRef.No.Material (-CC)ASME SA216 WCC CS30Bottom Spring WasherASTM A451 CPF8M SSt.31Spindle AssemblyCarbon Steel(Cadmium Plated)Carbon Steel(Nickel Plated)Retainer Lock RingNomenclatureASTM A240410(1)5O-ring Retainer6Disc Drain Plug7Main Disc8Main Guide9Back-up Ring10Seat Bushing Retainer Screw11O-ring Seat SealPTFE12Discharge Tube Fitting SealPTFE13Guide Seal14Floating WasherASTM A276 410(3)15Floating Washer RetainerASTM A276 410(3)16Fl. Washer Retainer Lock Ring17Sensing Tube Assembly316 Stainless SteelASTM A743 CA6NM SSt.ASTM A743 CA15 SSt.PTFEASTM A582 416(1)Virgin PTFE Cover(2)Upper TubeASME SA-479 31617bLower TubeASTM A249 TP304 SSt.17cTube FlangeASTM A36 CS18Bonnet GasketASTM A167 304 SSt.(4)19BonnetASME SA216 WCC CS20Pilot BaseASME SA-479 316 SSt.21Pilot Base FlangeASME SA105 Carbon Steel22Base StudsASTM A193 B7 Alloy Steel23Base Stud Nuts24Eye Bolt Lock Nut25Pilot Bonnet Gasket26Eye Bolt27Adjusting Ring Pin28Adjusting Ring29Pilot Bonnet AssemblyASTM A194 2H Carbon SteelCarbon SteelSoft IronCarbon SteelASTM A582 416(1)ASTM A743 CA15 SSt.SpindleASTM A108 1213 CS31bSpindle CollarASTM A276 410(3)32Top Spring WasherASTM A108 1018/19/20 CS33Lever34Compression Screw Lock Nut35Release Nut36Release Lock Nut37Cap38Lever Pin39Cap Lock Screw40Compression Screw41Spring42Pilot Disc AssemblyMalleable IronCarbon SteelASTM A47 35018(5)Martensitic SSt.Carbon SteelASTM A582 416(3)InconelASTM A276 410(3)42aDisc42bDisc Holder42cDisc Collar42dRetainer Ring43ASTM A108 1018/19/20 CSASTM A276 410(3)ASME SA-479 316L SSt.ASTM A167 304 SSt.PH15-7 MO Stainless SteelDischarge Tube Assembly43aFitting43bDischarge TubeASME SA105 Carbon SteelASTM A106 Grade B CS44Bonnet StudsASTM A193 B7 Alloy Steel45Bonnet Stud NutsASTM A194 2H Carbon Steel46Main Bonnet PlugASTM A182 F304 SSt.47Main Base Nameplate(6)Nameplate(6)48Pilot Base49Main base Drain Plug50Main Base Nameplate Screws(6)Stainless SteelStainless SteelASTM A182 F304 SSt.Screws(6)51Pilot Base Nameplate52Sensing Tube Flange Gasket53Adjusting Ring Pin Gasket54Seal(6)55Seal Wire(6)Steel (Nickel Plated)Steel (Nickel Plated)ASTM A167 304 SSt.(4)Soft IronAluminum29aBonnetASME SA216 WCC CS56Disc Spring (Main Valve)29bGuideASTM A479 316L SSt.57Disc Spring Ring29cPinASTM A479 304 SSt.1.ASTM A108 1018/19/20 CS31aPH15-7 MO Stainless Steel17aMaterial (-CC)SteelInconel X-750ASTM A276 410(3)Cond. A Stainless Steel2. Elgiloy Spring3. Cond. T Stainless Steel4. Grafoil Filled5. Malleable Iron6. Not Shown 2020 Baker Hughes Company. All rights reserved.Consolidated 13900 Series POSRV Technical Specifications 7

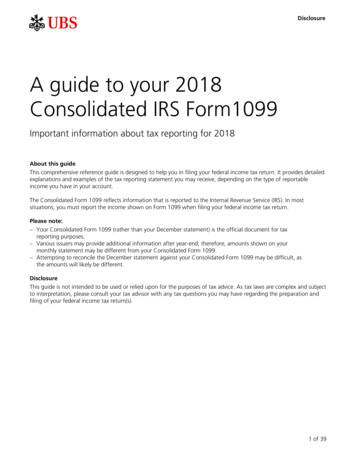

Materials13900 Type Pilot Valve13900 Series Pilot 742c2753258 Baker Hughes 2020 Baker Hughes Company. All rights reserved.

OptionsStandard OptionsConsolidated 13900 Series Pilot-Operated Safety Relief Valves are available with the followingoptions:Omit Pilot Discharge Piping:Dump Valve Design:Omit Pilot Discharge PipingDump Valve DesignPilot valve vent to area other than main valve outlet. 2020 Baker Hughes Company. All rights reserved.Rather than having a spring-loaded safety valve asits pilot valve—which opens automatically at the predetermined set pressure—the dump valve has a pilotthat is operated by an electrical signal so that the valvemay be opened at any time independently of

40 Compression Screw ASTM A582 416(3) 41 Spring Inconel 42 Pilot Disc Assembly 42a Disc ASTM A276 410(3) 42b Disc Holder ASME SA-479 316L SSt. 42c Disc Collar ASTM A167 304 SSt. 42d Retainer Ring PH15-7 MO Stainless Steel 43 Discharge Tube Assembly 43a Fitting ASME SA105 Carbon Steel 43b Discharge Tube ASTM A106 Grade B CS 44 Bonnet Studs ASTM A193 B7 Alloy Steel 45 Bonnet Stud Nuts ASTM