Transcription

—M EC H A N I C A L P OW E R T R A N S M I S S I O NRaptor coupling

R APTOR EL A STOMERIC COUPLING2—A better choice has arrivedCoupling maintenance and reliability should not monopolize yourmaintenance team. The Dodge Raptor elastomeric coupling eliminatesthese concerns.The Raptor’s easy to assemble, patented split natural rubber elementsignificantly decreases total costs of ownership and extends drivenequipment life. Built for drop-in interchangeability, the Raptor featuresan innovative design offering easier installation, reduced maintenance,and improved reliability in a wide range of new and existing applications.*Not actual sizeCall 630-969-7890

3

4R APTOR EL A STOMERIC COUPLING—Elastomeric coupling innovationLonger drivenequipment lifeFlexiblemountingoptionsPatentedWingLock elementdesign Call 630-969-7890

5Drop-ininterchangeabilityEasierinstallation

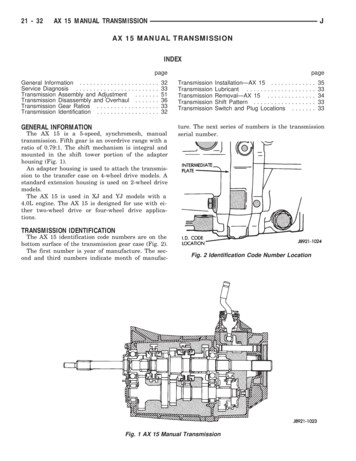

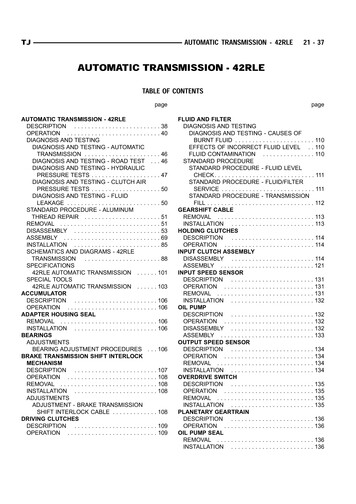

R APTOR EL A STOMERIC COUPLING6—Designed and developed at DodgePatented WingLock element designThe Dodge Raptor utilizes a patented finiteelement optimized winged elastomeric elementdesign. This WingLock technology increasessurface area in the most critical regions of theelement, resulting in higher bond strength,improved fatigue resistance, and longer life versuscompetitive designs.—01 Pressure at bondwithout WingLocktechnology—02 Pressure at bond withWingLock technology—03 Average life,Dodge Raptor versuscompetitors.Dodge Raptor patented WingLock technology—01—03—02Documented performanceComparative benchmark testingconfirms the performanceimprovements associated with Raptor’sWingLock element design. Even underworst-case misalignment and torqueconditions, testing results show thatRaptor lasts six times longer than theclosest competitor.65.554.5Lifetime43.532.5Results based on accelerated life testingat 1.5x cataloged torque, while subjectto 4 angular misalignment and 3/16"(4.8mm) parallel misalignment.21.510.50Dodge RaptorCall 630-969-7890Competitor 1Competitor 2

7Tested toughEngineers from Dodge’s Advanced Development Laboratory designed and tested the Raptor to performunder the most extreme conditions. This includes successfully passing the rigorous DIN 740 (reverse cyclicloading) coupling test standard – not once, not twice, but ten times for a single coupling.Easy to interchangeDesigned to be a drop-in interchange, the Raptor meets or exceeds torque, bore, and speed ratings forthese styles of commonly used couplings. All Raptor components can be used in existing applicationswithout any modifications. This allows current users of these styles to immediately realize the benefit oflonger driven equipment life and improved reliability by switching to the Raptor.Coupling sizeDodge Rexnord E2WE3WE4WE5WE10WE20WE30WE40WE50WE60WE70WE80---TB Wood's Dura-FlexIndustry leading 5-year warrantyWith over 100 years of coupling manufacturing experience,Dodge has a history of providing reliable coupling solutions ina wide range of industries and applications. Raptor couplingscarry an industry leading 5-year limited warranty, even whenused with competitors’ components.

R APTOR EL A STOMERIC COUPLING8—Longer driven equipment life andimproved reliabilitySuperior natural rubber elementLeveraging over 50 years of Dodge’s natural rubberexpertise, the Raptor features a natural rubberflexible element that offers a number ofperformance benefits when compared tocompetitive urethane designs. Static conductive for grounding redundancy,allowing current to safely pass through thenatural rubber element, preventing the possibilityof arcing during operation Exceptional resistance to hydrolysis, for improvedperformance in humid environments Superior thermal conductivity and ability todissipate heat and hysteresis build upLower stiffness, longer driven equipment lifeBecause the Raptor element uses a natural rubber compound, it is significantly more flexible than urethanedesigns. Natural rubber yields an element with approximately 50% lower torsional and bending stiffness,resulting in longer life for all types of connected driven equipment – including motors, pumps,compressors and gearboxes.—01 Connectedequipment L 10 life,Dodge Raptor versuscompetition Reduced bearing loads yield over 15 times increase in L10 bearing life connected equipment Less vibration transmission to connected equipment Better shock damping capabilitiesResults based on tested bendingstiffness values applied to a motor andcentrifugal pump arrangement with 4 angular misalignment.181614L10 Life121086420—01Call 630-969-7890Dodge RaptorCompetition

9Industry leading misalignment capabilitiesOver time foundations settle, vibration occurs, andsome level of misalignment may occur. Whilecompetitive urethane couplings can handle pureangular or parallel misalignment, their capabilities aregreatly diminished in applications with combinedangular and parallel misalignment. Unfortunately forthe competition, combined misalignment is reality.When an elastomeric coupling is misaligned duringoperation, cyclic stresses are created, generating heatin a phenomenon known as hysteresis. The Raptor’snatural rubber element has superior heat dissipatingcapabilities versus competitive urethane elements.Additionally, the Raptor has a lower angular stiffness,allowing it to be more forgiving in misalignedconditions. These two features combined allow theDodge Raptor to offer industry leading misalignmentcapabilities.The Raptor provides accommodation of shaftmisalignment during installation, operation, andreplacement better than competitive urethaneelements.Attention to every detailDodge highly engineered every aspect of the Raptorfor performance, including specification of highstrength Grade 8 flanged head cap screws. This robusthardware gives a 40% increase in proof strengthversus competitor’s standard head Grade 5 fasteners.Serrations under the flanged head and a thread lockingpatch help to resist loosening and minimize thepotential for stripping. This attention to detailprovides a more reliable connection betweenelastomeric element and shaft hubs.Dodge Grade 8 serrated flanged-head capscrew (shown without Nylok patch)Competitor Grade 5 hex-head cap screw

R APTOR EL A STOMERIC COUPLING10—Easier installation and reducedmaintenanceImproved features, easier installationThe Dodge Raptor has everything needed for easierinstallations and reduced maintenance costs. Split element for easy replacement withoutmoving and re-aligning connected equipment Slotted clamp ring holes offer 187% extramounting hardware clearance versuscompetitor’s circular through holes. Approximately 50% lower torsional stiffnessmakes the element significantly easier tomanipulate by hand during installation Maintenance free non-lubricated natural rubberelement for trouble-free operationRaptor’s slotted clamp rings offer more clearance at the boltholes, for an easier installation than competitive designs.Easy as 1-2-3Installation for Dodge Raptor couplings are quick and easy. The Raptor’s horizontally split element doesn’trequire locking shafts during installation, meaning a faster installation, requiring fewer tools andeliminating shaft damage. Simply fasten the shaft hubs, install the element, and tighten the hardware.—01Step 1Install hubs—02Step 2Set spacing—03Step 3Install element—01—02Note: Shaft engagement should be equal to or greater than 80% the hub length-through bore.Call 630-969-7890—03

11—Suited for any applicationA practical solution to spacer couplingsThe innovation behind the Raptor coupling alsoextends to applications requiring additional spacebetween shaft ends. One spacer element fits all standard ANSI and ISOspacer lengths Spacer elements can be replaced with standardclose-coupled elements, resulting in lowerreplacement costs and reduced inventory Eliminates the need for high-speed rings,resulting in easier installation, while alsoreducing purchase costs and inventoryrequirementsArmored elements for extra protection from harshenvironmentsRaptor elements are available with an optionalArmored Element. This allows users to benefit fromthe increased performance and longer drivenequipment life of standard Raptor elements, whileproviding an added layer of protection from ozone,petroleum oils, and some chemical environments.Raptor Armored Elements exceed ASTM 1149-07rubber deterioration standards, as determinedthrough third-party testing.Third-party ATEX certifiedWhen it comes to applications in hazardousenvironments, there’s no reason for customers toassume any risk by using a product which is selfcertified. That’s why all Raptor couplings are thirdparty ATEX certified for worry-free use inhazardous environments. All required productmarkings and documentation are included witheach coupling at no additional charge. When itcomes to hazardous environments, you can trustDodge.II 2 GD c T5 I M2 cSira 15 ATEX 6170XDODGE RAPTOR COUPLINGSMFG by Baldor Electric Company .GREENVILLE, SC / FT. SMITH, AR USA

12R APTOR EL A STOMERIC COUPLING—Shaft hubsFlexible mounting options for any application Available in a wide range of shaft attachmentmethods, including finished bore, Taper-Lock and QD bushed options. Suited for any application, hubs are reversible toaccommodate a wide range of shaft gaps Interchangeable hubs are used for both closecoupled and spacer designs for reduced inventory65OFinished bore Setscrew locking mechanism ensures a quick,easy installation Two setscrews at a 65 angle optimizes radial andtorsional holding power, resulting in a 75%holding power increase versus competitivedesigns using one setscrewHolding Poweras Function of Setscrew AngleHolding power(Percent of single setscrew assembly)25020065 150100Competition50020406080100120140Angle between setscrewsCall 630-969-7890Torsional holding powerRadial holding power160180

13Taper-Lock bushed Reduced maintenance time and costs Easy installation and removal Minimal shaft damage Clean, compact design Dodge original design, an industry standard for over50 years Conforms with MPTA-B9i-2013 Taper-Lock bushingstandard Combine with Dodge Integral Key bushings for addedvalue and convenienceQD bushed “Quick Detachable” QD bushings for easy installationand removal Reduced maintenance time and costs Minimal shaft damage Increased bore capacities Robust flanged design featuring capscrew hardware Conforms with MPTA-B6i-2010 QD bushing standard

14R APTOR EL A STOMERIC COUPLING—How to orderA complete Raptor coupling assembly consists of one element (standardor spacer) and two shaft hubs (finished bore, Taper-Lock, or QD). IfTaper-Lock or QD shaft hubs are selected, bushings must also beselected for the desired shaft size.Nomenclature:Elements:E2020HSBElementE Standard (close-coupled)ES SpacerSizeHubs:SizeHubStyleRB Rough boreSB Finished bore (stock)CB Finished bore (custom)CBMM Custom bore, mill motorTL Taper-Lock bushedQD QD bushedCall 630-969-7890

15—EngineeringSelection methodsTorque method:Hp/100 method:Step 1:Obtain required S.F. (service factor) from Table 1 onpages 16 and 17.Step 1:Obtain required S.F. (service factor) from servicefactor tables on pages 16 and 17.Step 2:Determine torque required for application.Step 2:Determine the application Hp per 100 RPM:Torque (in. - lbs.) 63025 x motor Hp x S.F.Coupling RPMHp / 100 RPM Motor Hp x 100 x S.F.Coupling RPMStep 3:From rating tables, find a rating equal to or greaterthan the torque. Note coupling size from left handcolumn.Step 3:From rating tables, find a rating equal to or greaterthan Hp design. Note to or greater than the Hp/100RPM. Note coupling size from left hand column.Step 4:Check maximum RPM capability.Step 4:Check maximum RPM capability.Step 5:Check maximum bore capacity. If maximum bore isexceeded, move to larger size with adequate bore.Be sure maximum RPM of coupling is not exceeded.Step 5:Check maximum bore capacity. If maximum bore isexceeded, move to larger size with adequate bore.Be sure maximum RPM of coupling is not exceeded.Notes:1. If system peak torque is known and is nonreversing, start at step 3. If system peak torqueis known and reversing, multiply by 2.0 andstart at step 3.2. If ambient temperature of the application isabove 180 , a high temperature adjustmentmust be made to the system service factor. Seepage 34 for high temperature adjustmentfactors.3. If spring set motor brake is used, and brake Hpis greater than prime mover, use brake Hp inplace of motor Hp.

16R APTOR EL A STOMERIC COUPLING—EngineeringService Factor Table 1Factor Factor Application (read footnotes)RaptorApplication (read footnotes)RaptorDredgesAgitatorsFactor Application (read footnotes)RaptorMachine toolsPaddle or propeller (vert. or horiz.)1.00Cable reel, screen drive, stacker1.50Auxiliary1.00Screw1.00Conveyor1.50Main drive1.50Cutter head drive, jig drive2.50Notching press, planer (reversing),plate planer, punch press1.50Traverse1.00BlowersCentrifugal1.00Pump, utility winch1.50Lobe1.50Dynamometer1.00Vane1.00Brewing & distillingMetal forming machinesElevatorsBucket, freight2.001.00Bottling machinery, brew kettle1.00ExciterCooker (continuous duty)1.00FansMash tub1.00Centrifugal1.00Scale hopper-frequent starting peaks1.50Cooling tower2.00Can filling machine1.00Heavy duty (forced draft)1.50Car dumper1.50Induced draft1.50Car puller1.50Light1.00Clarifier1.00Propeller indoor1.50Classifier1.00Food industryClay-working machinesBrick press, briquette mach., clayworking mach., pug mill1.50CompressorsCentrifugal lobe, screwLobe, rotary**Beet slicer1.50Cereal cooker1.00Dough mixer, meat grinder1.50Generators1.002.00Reciprocating**Even load1.00Hoist or railway service1.50Welder load2.00Draw bench, carriage, main drive,extruder2.00Wire drawing, flattening machine2.00Mills rotary typeBall or pebble direct or2.50On LS shaft gear reducer2.50On HS shaft gear reducer2.00Dryer and cooler1.50Rod or tube direct or2.50On LS shaft gear reducer2.50On HS shaft gear reducer2.00Tumbling barrel1.50MixersConcrete (continuous or intermittent)1.50Muller-Simpson type1.50Oil industryChiller1.002.001.501 cylinder - single acting3.50Grizzly2.001 cylinder - double acting3.00Oil well pumping (not over 150%peak torqueKiln2.002 cylinder - single acting3.00Paraffin filter pressLaundry machines2 cylinder - double acting2.503 cl. or more - single acting2.503 cl. or more - double acting2.00ConveyorsApron, assembly, belt, chain, flight, Oven1.00Reciprocating2.50Screw1.00Cranes and hoistsMain hoist-medium duty1.50Main hoist-heavy duty2.00Skip hoist, travel motion, trolley1.50Motion, slope1.50CrushersCane2.00Gyratory2.50Call 630-969-7890Tumbler washerPaper mills2.00Line shaftsAgitator1.00Barking drum2.50Driving processing machinery1.00Beater and pulper1.50Light1.00Bleacher1.00Calender2.00Lumber industryBand resaw1.50Chipper3.00Circular resaw1.50Couch cylinder dryer1.50Edger head rig, hog, log haul2.00Felt stretcher1.00Planer1.50Fourdrinier1.50Rolls non-reversing1.50Jordan2.00Rolls reversing2.00Press2.00Sawdust conveyor1.00Pulp grinder2.00Slab conveyor1.50Stock chest1.50Sorting table1.50Stock pumpReciprocating2.00

17Factor Application (read footnotes)Factor RaptorApplication (read footnotes)Paper mills (continued)RaptorPumps (continued)Factor Application (read footnotes)RaptorSteel industrySuction roll2.002 cylinder - single acting2.00Winder1.502 cylinder - double acting1.50Coiler up or down1.50Paraffin filter press1.503 cylinder or more1.50Strip, temper2.00Printing press1.50Rubber industry1.50Propeller marine1.50Banbury mixer1.50Coiler up or down1.50Calender2.00Edger drive1.50Cracker mixing mill plasticator2.50Feed roll blooming3.00Refiner, sheeter2.00Roughing mill delivery3.002.00Non-reversing, sheet strip3.00PullersBarge hall2.50PulverizersHammermill - light duty1.50Tire-building machineHammermill - heavy duty2.001.00Hog2.00Tire and tube press opener basedon peak torqueRoller1.50Tuber and strainer1.50Warming mill2.00Washer2.50PumpsFor stock pumps see paper millsCentrifugal1.00Descaling gear type1.50Oil well pumping (not over 150%peak torque)Rotary - other than gearScreensAir washing1.00Coal and sand rotary1.502.00Vibrating2.501.50Water1.00Sewage disposal equipment1.00Reciprocating1 cylinder - single acting2.50Shovel2.001 cylinder - double acting2.00Shredder1.50Cold millsHot millsRod mill2.50Soaking pit cover drive lift3.00Soaking pit cover drive travel3.00Rollout table (non-reversing)2.00Rollout table (reversing)3.50Steering gear1.00StokerTextile millsBatcher1.00“Calender, card machine, D can”1.50Dyeing machine1.00Loom1.50Mangel, napper, soaper1.00Spinner, tenter frame1.50Windlass1.50Woodworking machines1.00System service factor calculationTo determine the system service factor, the driver service factor adder (Table 1A) must be added to the driven service factor(Table 1). Example: Determine the system service factor for a Raptor coupling used to couple a barking drum and a six-cylinderdiesel engine.Driven S.F. Driver S.F. Adder System S.F.2.5 0.5 3.0 The service factors listed are intended only as a general guide. Where substantial shock occurs or starting and stopping is frequent as on some “inching”drives and on some reversing drives or where the power source is an internal combustion engine with less than four cylinders - consult Dodge. Wheretorsional vibrations occur as in, for example, internal combustion engine or reciprocating compressor or pump applications, check the coupling stiff ness for the possible development of damaging large- amplitude vibrations. A complete system torsional analysis may be necessary.** Add 0.5 to factor if without flywheel Consult Dodge for selection assistance—Table 1A - driver service factor addersType of couplingRaptorElectric motorstd. torqueHigh torquemotorsTurbines0.000.000.00Reciprocating engine number of cylinders12 or more8 to 116 to 74 to 5Less than 40.000.500.500.50

R APTOR EL A STOMERIC COUPLING18—Ratings & dimensionsClose-coupled - finished boreCBCBBDE ACouplingsizeBBDE ACBDE AFFFOutboardInboardHybridMin.boreMax.bore nboardHybridF(4)DEOutboardInboardHybridWeight .0119.0217.0218.02593.4(1)(2)(3)(4)Consult page 29 for larger bore capacities with shallow keys.Weight of complete coupling in poundsAll dimensions in inchesHubs are reversible and will accommodate different shaft spacing requirements—Close-coupled inch element assembliesStandard(natural andard(natural ze017001017180017002017004017003(1) Element assemblies include imperial hardware.(2) Raptor elements are also available with metric hardware. This requires use of shaft hubs tapped for metric hardware. Reference International Couplings Catalog (9AKK107387) orcontact Dodge for more information.Call 630-969-7890

19—Ratings & dimensionsSpacer - finished boreBC (BSE)BBEDAC (BSE)EAC (BSE)BDEAFFFull spacer - 80BDFCoupling sizeBHalf spacer - hybridHalf spacer - outboardMin. boreMax. bore( 1)Hp/100Max rated torque (in.-lbs.)Max. RPMABDEWeight (2) (1) Consult page 29 for larger bore capacities with shallow keys.(2) Weight of complete coupling at maximum bore with four spacer extensions(3) All dimensions in inches—Finished bore spacer length optionsCouplingsizeStandard (natural rubber)element part numberArmored element part numberC (BSE)(4)(5)Full spacerHalf spacerF(4)(5)Full spacerHalf spacerFull spacerHalf spacerFull spacerHalf .9815.8813.7821.0218.8225.62(1)(2)(3)(4)(5)Element assemblies include imperial hardware.Table shows actual spacer lengths.All calculations based off of outboard hubs.Hubs are reversible and will accommodate different shaft spacing requirementsConsult factory for minimum shaft spacing

R APTOR EL A STOMERIC COUPLING20—Hub part numbersFinished bore - inch boresBore(in.)Coupling "015687015732015783015897015026015085015150 Stock bores Listed shaft hubs are tapped for imperial hardware, and intended for use with Imperial element assemblies. Shaft hubs and element assemblies are also available for use withmetric hardware. Reference International Catalog (9AKK107387) or contact Dodge for more information. Unless otherwise specified, finished bores for sizes E2-E60 are Class 1 clearance fit and sizes E70-E140 are interference fit per AGMA 9002. See pages 29-33 for additionaldetails.Call 630-969-7890

21Bore(in.)Coupling 0151978-3/4"0151988-15/16"0151999"015200 Listed shaft hubs are tapped for imperial hardware, and intended for use with Imperial element assemblies. Shaft hubs and element assemblies are also available for use withmetric hardware. Reference International Catalog (9AKK107387) or contact Dodge for more information. Unless otherwise specified, finished bores for sizes E2-E60 are Class 1 clearance fit and sizes E70-E140 are interference fit per AGMA 9002. See pages 29-33 for additionaldetails.

R APTOR EL A STOMERIC COUPLING22—Hub part numbersFinished bore - metric boresBore(mm)Coupling 7016533150016462016484016508016534 Listed shaft hubs are tapped for imperial hardware, and intended for use with Imperial element assemblies. Shaft hubs and element assemblies are also available for use withmetric hardware. Reference International Catalog (9AKK107387) or contact Dodge for more information. Unless otherwise specified, finished bores for E2-E60 are transitional fit and sizes E70-E80 are interference fit per ISO R775. See page

All Raptor components can be used in existing applications without any modifications. This allows current users of these styles to immediately realize the benefit of longer driven equipment life and improved reliability by switching to the Raptor. Coupling size. Dodge Raptor E2 E3 E4 E5 E10 E20 E30 E40 E50 E60 E70 E80 E100 E120 E140