Transcription

Reciprocating CompressorRod PackingLessons Learned from theNatural Gas STAR ProgramChevron Corporation,New Mexico Oil and Gas Association,Texas Oil and Gas AssociationTechnology Transfer WorkshopMidland, TexasJuly 23, 2008epa.gov/gasstar

Industry Emissions: Production, Gathering,and BoostingStorage TankOtherWell Venting VentingSources6 Bcfand Flaring8 Bcf8BcfMeters andPipeline Leaks8 BcfPneumaticDevices48 BcfCompressor Fugitives,Venting, and EngineExhaust13 BcfDehydratorsand Pumps13 BcfOffshoreOperations29 BcfSource: EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks 1990 – 2006. April, 2008. Available on the web rt.htmlNote: Natural Gas STAR reductions from gathering and boosting operations are reflected in the production sector.1

2006 Processing Sector Methane EmissionsDehydratorsPlantand Pumps OtherFugitivesSources 1 Bcf2 Bcf1 BcfBlowdowns2 BcfReciprocatingCompressors16 BcfCentrifugalCompressors5 BcfGas EngineExhaust7 BcfEPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks 1990 – 2006. April, 2008. Available on the web rt.htmlNote: Natural Gas STAR reductions from gathering and boosting operations are reflected in the production sector.2

Compressor Methane EmissionsWhat is the problem?Methane emissions from the 51,500 compressors in thenatural gas industry account for 89 Bcf/year or about 24% ofall methane emissions from the natural gas orStationProductionProcessingTransmission & Storage38,500 Compressors 5,000 Compressors 8,000 CompressorsDistribution0 Compressors3

Methane Savings from Compressors: AgendaReciprocating CompressorsMethane LossesMethane SavingsIndustry ExperienceDiscussion4

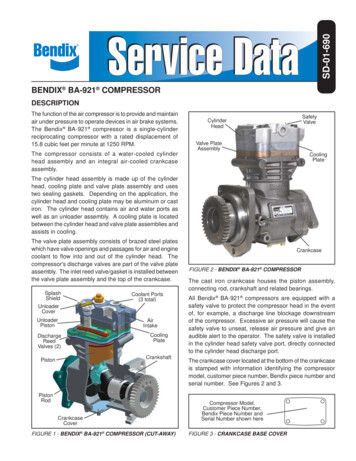

Methane Losses from ReciprocatingCompressorsReciprocating compressor rod packing leaks somegas by designNewly installed packing may leak 60 cubic feet per hour(cf/hour)Worn packing has been reported to leak up to 900 cf/hour(Side View, Cut in Half)Distance PieceCylinderSuctionPiston RodPistonOILDischargeRod Packing Case5

Reciprocating Compressor Rod PackingA series of flexible rings fit around the shaft toprevent leakageLeakage may still occur through nose gasket,between packing cups, around the rings, andbetween rings and shaftTwo Rings(In Three Segments)LubricationHigh PressureGasLeakagePiston RodFlangeGas InsideCylinderCylinder WallPacking CupSprings(Side View, Cut in Half)6

Impediments to Proper SealingWays packing case can leakNose gasket (no crush)Packing to rod (surface finish)Packing to cup (lapped surface)Packing to packing (dirt/lube)Cup to cup (out of tolerance)What makes packing leak?Dirt or foreign matter (trash)Worn rod (.0015”/per inch dia.)Insufficient/too much lubricationPacking cup out of tolerance( 0.002”)Improper break-in on startupLiquids (dilutes oil)Incorrect packing installed(backward or wrong type/style)7

Methane Losses from Rod PackingEmission from Running CompressorEmission from Idle/Pressurized Compressor99145Leakage from Idle Compressor Packing Cup79Leakage from Idle Compressor Distance Piece hour-packingLeakage from Rod Packing on Running CompressorsPacking TypeLeak Rate lon24Leakage from Rod Packing on Idle/Pressurized CompressorsPacking TypeLeak Rate flon22PRCI/ GRI/ EPA. Cost Effective Leak Mitigation at Natural Gas TransmissionCompressor Stations8

Steps to Determine Economic ReplacementMeasure rod packing leakageWhen new packing installed – after worn-inPeriodically afterwardsDetermine cost of packing replacementCalculate economic leak reductionReplace packing when leak reduction expected willpay back cost9

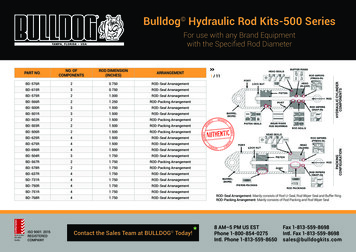

Cost of Rod Packing ReplacementAssess costs of replacementsA set of rings:(with cups and case)Rods: 135 to 1,080 1,350 to 2,500 2,430 to 13,500Special coatings such asceramic, tungsten carbide,or chromium can increaserod costsSource: CECO10

Calculate Economic Leak ReductionDetermine economic replacement thresholdPartners can determine economic threshold for allreplacementsThis is a capital recovery economic calculationEconomic Replacement Threshold (cf/hour) Where:CR DF CR DF 1,000(H GP )Cost of replacement ( )Discount factor at interest i H Hours of compressor operation per yearGP Gas price ( /thousand cubic feet)DF i (1 i )n(1 i )n 111

Economic Replacement ThresholdExample: Payback calculations for new rings and rodreplacementCR 1,620 for rings 9,450 for rodCR 11,070HR 8,000 hours per yearGP 7/McfOne year payback 1.1 1,000ER 11,070 8,000 7 DF @ i 10% and n 1 year0.1(1 0.1)0.1(1.1) 0.11DF 1.111.1 10.1(1 0.1) 11 217 scf per hourDF @ i 10% and n 2 yearsDF 0.1(1 0.1)2(1 0.1)2 1 0.1(1.21) 0.121 0.5761.21 10.2112

Is Rod Packing Replacement Profitable?Replace packing when leak reduction expected willpay back cost“leak reduction expected” is the difference between currentleak rate and leak rate with new ringsRings OnlyRings: 1,620Rod: 0Gas: 7/McfOperating:8,000 hours/yearLeak 121822Rod and RingsRings: 1,620Rod: 9,450Gas: 7/McfOperating:8,000 hours/yearLeak ReductionExpected(cf/hour)376197137108Based on 10% interest rateMcf thousand cubic feetPayback(months)713182213

Industry Experience – Northern Natural GasMonitored emission at two locationsUnit A leakage as high as 301 liters/min (640 cf/hour)Unit B leakage as high as 105 liters/min (220 cf/hour)Installed Low Emission Packing (LEP)Testing is still in progressAfter 3 months, leak rate shows zero leakage increase14

Industry Experience – OccidentalOccidental upgradedcompressor rod packing atits Elk Hills facility insouthern CaliforniaAchieved reductions of 400Mcf/day/compressorSavings 145 MMcf/yrPayback in under 3 years15

Northern Natural Gas - Leakage RatesLeak Rate (liters/min)350640 cf/hour300250200Unit AUnit B1501005060 cf/hour01997 1998 1999 2000 2001 2002 2003 2004 2005 LEP16

Northern Natural Gas Packing LeakageEconomic Replacement PointApproximate packing replacement cost is 3,000 percompressor rod (parts/labor)Assuming gas at 7/Mcf:1 cubic foot/minute 28.3 liters/minute50 liters/minute/28.316 1.8 scf/minute1.8 x 60 minutes/hour 108 scf/hr108 x 24/1000 2.6 Mcf/day2.6 x 365 days 950 Mcf/year950 x 7/Mcf 6,650 per year leakageThis replacement pays back in 6 months17

Low Emission PackingLow emission packing (LEP) overcomes lowpressure to prevent leakageThe side load eliminates clearance and maintainspositive seal on cup faceLEP is a static seal, not a dynamic seal. No pressureis required to activate the packingThis design works in existing packing case withlimited to no modifications required18

LEP Packing Configuration19

Orientation in Cup20

Reasons to Use LEPUpgrade is inexpensiveSignificant reduction of greenhouse gas are majorbenefitRefining, petrochemical and air separation plantshave used this design for many years to minimizefugitive emissionsWith gas at 7/Mcf, packing case leakage should beidentified and fixed.21

DiscussionIndustry experience applying these technologies andpracticesLimitations on application of these technologies andpracticesActual costs and benefits22

Replace packing when leak reduction expected will pay back cost "leak reduction expected" is the difference between current leak rate and leak rate with new rings. Based on 10% interest rate. Mcf thousand cubic feet. Rod and Rings. Rings: 1,620. Rod: 9,450. Gas: 7/Mcf .