Transcription

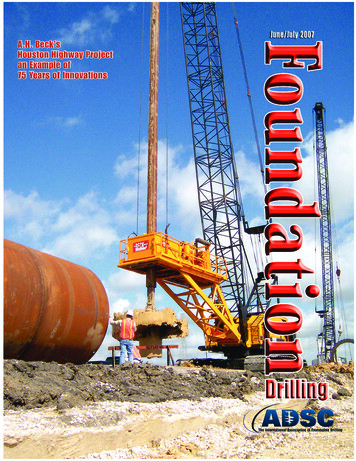

COVER FEATUREThe IH-45DirectConnector:Innovations75 Yearsin theMakingby Keith Anderson,Operations Manager,A. H. BeckFoundation Co., Inc.H. Douglas Steadman,P.E., W. E.Simpson Company, RetiredAt first glance, the IH-45 DirectConnector project in Houston, Texas,doesn’t seem that unusual compared toother engineering projects of the NewMillenium. A.H. Beck Foundation Co.was selected for the job, set up its equip-Foundation pier drillingwas first originated in theearly 1920s by Willard E.Simpson, an engineer, andEd Duderstadt, a water welldriller who drilled using amule-drawn turntable.inated in theearly 1920s byWillard E. Simpson, an engineer, and EdDuderstadt, aAugust Beck Sr. (center) on early steam shovel.water well driller whodrilled using a mule-drawn turntable.Their technology – state-of-the-art for itsday – enabled foundations for the firsttime to go below the zone of seasonalmoisture change. By the end of thedecade, foundation pier drilling hadbecome the primary foundation system,particularly in the expansive clay areasof the country. However, as you canimagine, a mule-driven drill could onlydig small holes, was very slow and limited in scope.It would take another innovator,August Henry Beck, Sr., to bring foundation pier drilling to the next level ofcapability. Sometime during the 1920s,with money he had earned working as asteam shovel operator at the city quarry,ment, constructed a slurry displaceddrilled shaft along the centerline of thehighway, and – voila! – the traffic usingNASA Rd. 1 will soon have an interchange allowing easy access to I-45, amajor 8-lane highway connectingHouston to Galveston.But it wasn’t always this way, or thiseasy. It’s interesting to look back to thebeginnings of the industry and see howtimes have changed.What Size HoleCan a Mule Drill?Foundation pier drilling was first origPage 2August Beck, Sr. on left and AugustBeck, Jr., “Buddy” on right.August Sr. purchased two steam shovelsand went into the general excavationbusiness, forming A.H. Beck &Company. During this time, to obtainhigher capacities, the company dug piersas large rectangular excavations usingthe shovels and a pier hole excavatorthat Beck developed. In 1932, whileworking on a project with Duderstadtand his mule-driven drill, the 36-yearold saw an opportunity to modernizeand, as time would tell, create the legacyof A. H. Beck Foundation Company.Recognizing the inefficiencies of rectangular footings, August Sr. modified oneIt would take another innovator, August Henry Beck,Sr., to bring foundation pierdrilling to the next level ofcapability.of his steam shovels to be able to drillround excavations. First, he removed themain shovel arms. He then fabricated aboom and attached this to the shovelbody to support the turntable, throughwhich he ran a long, slender kelly bar.Steam from the shovel boiler was pipedup to the turntable to power a steamengine that turned the kelly bar. Thiskelly bar and the added horsepower gavethe modified steam shovel the ability togo deeper faster than the other methodsof pier drilling or excavating available atthe time. Beck’s creativity increased his(continued on page 9)FOUNDATION DRILLING June/July 2007

IH-45 Contd.tools and equip- veloped improvements and innovationsment required such as a powered Pier Hole Excavatorhad to be capable for larger rectangular excavations andofexcavating bell excavating buckets or under reamersfast, holding up to gain more capacity out of the drilledto the torque of pier excavations. He had at least threethe Beck-built patents registered in his name: Pier Hole500-horsepower Excavator (granted in April 1952),drill attachment, Under Reaming Device (grantedturning a 40,000 September 1967), and an aircraft patent.pound 24” teleBuddy was constantly improving thescopic kelly bar, company’s drilling equipment andhoisting quickly, improvising to make it fit special purand excavating a poses. For example, he faced the chalEarly Beck steam powered drilling rig.p l u m bshaft. Toreduce theexcavation capabilities considerably,allowing for bigger and better excava- operating weight, the Beck-builtauger was fabricated with onlytions.Flash forward to 2006, where the IH- with one full turn of flights; but45 Direct Connector project was in its since it was so short, it would beearly stages. While the majority of the difficult to keep the excavationstructures were to be constructed with a plumb in the silty sands and clayspile cluster/footing foundation, two found on the Texas Gulf Coast. Tobents required single large diameter ensure a plumb excavation, a 48”drilled shafts due to the limited width of pilot hole was drilled plumb underslurry to the design tip elevationBuddy Beck and inspector Jack Orr inside 32’and a 48” pilot stub projecteddiameter bell.A. H. Beck Foundation below the 12’ diameter auger to folCompany was selected to low the pilot hole. The auger also had an lenge of the excavation for the basementflow channel that allowed it to of San Antonio’s AT&T Equipmentinstall the 12’ diameter x internalbe extracted through the slurry at a fast Building which was surrounded on three130’ deep drilled shafts.rate without washing the excavated sides by heavily traveled streets. Thematerial off of the auger.streets were loaded with utilities and thefourth side of the excavation was adjaEarly Experiments Ledcent to an existing building. This wouldbe a common urban scenario in today’sthe construction zone and to eliminate to Today’s Technologymarket, but not so common at the time.the differential settlement of theembankment. Through a competitive bidIn 1920, August Beck’s son, August H. He adapted a drilling rig to drill 45process, A. H. Beck Foundation “Buddy” Beck, Jr., was born. A go-getter degree belled shafts for the tiebacks forCompany was selected to install the 12’ from the start (at the age of 12, he drove(continued on page 10)diameter x 130’ deep drilled shafts. Thehis own Model T toschool every day,and by age 16, he’dearned his pilot’slicense), Buddy tookover the businesssometime after returning home fromWWII in the mid1940s, when hisfather’s health started to decline. Buddy,August “Gus” Beck III (center) with earlyaided by the compaModified drill rig to install 45 degree shafts withhydraulic drill rig.ny’s mechanics, debells.FOUNDATION DRILLING June/July 2007Page 3

IH-45 Contd.shoring a 36-foot deep (52-foot in onecorner) excavation.Always seeking ways to dig bigger anddeeper, Buddy Beck took on manydemanding projects that other companies wouldn’t touch. In the late 1950s,he worked closely with W.E. SimpsonEngineering (the company formed bythe engineer who pioneered foundationpier drilling in the early 1920s) to construct the largest belled pier ever excaPage 4vated up to thattime. This pierhad to support aone million gallon water tank.The bell on thisshaft was 32-feetin diameter andwas mostly excavated using pneumatic hand tools.Upon his retirement,Buddy’sson, August H.“Gus” Beck, III,August Beck Sr. (center w/tie) and August “Buddy” Beck Jr. ontook over thehis left with early mechanical drill rig and crew.company in 1978.Gus had grown up in the drilling busi- mounted drill attachment would later beness, but started working for the compa- used on the IH-45 Direct Connector.ny full time after he graduated from the The project was The Super ConductingUniversity of Texas in 1972 with a B.S. in Super Col-lider, an under-ground tunnelsystem to beCivil Engiforneering. Gus In the early 1990s, Gus developed a usedand his dad 1000-horsepower drill rig along with a s m a s h i n gsaw the need 500-horsepower crane mounted drill atoms. Due tothe depth offor higher toattachment for a Department of Energy the tunnel,rque drillingequipment to project. The 500-horsepower crane access shaftsdrill larger mounted drill attachment would later up to 30-feetd i a m e t e r be used on the IH-45 Direct Connector. in diameterover 265piers in rock,The project was The Super Conducting andfeet deep hadso they worked together in Super Collider, an underground tunnel to be installedatvariousdeveloping a system to be used for smashing atoms.locations.hydraulically powered, crane-mounted drill attach- Gus developed the two rotary tablesment to replace the mechanical, chain(continued on page 11)driven units that were being used at thattime. Under Gus’s leadership, the company was awarded many highly challenging projects, often because Beck wasthe only company that could perform therequested operation or because its solutions were the most cost-effective. Duringthese years, the company saw anincrease in both the type of equipmentand the geographical deployment of thatequipment throughout the SoutheasternUnited States, Caribbean, South Americaand Russia.In the early 1990s, Gus developed a1000-horsepower drill rig along with a500-horsepower crane mounted drillCharles Harrell operating the 150attachment for a Department of Energyton crane and 500 hp drill unit onproject. The 500-horsepower craneNASA Rd 1.FOUNDATION DRILLING June/July 2007

IH-45 Contd.with the capacity to handlethese large excavations.During this era, Gus alsoidentified a need for,designed and built severalhigh capacity, low-clearancedrilling rigs. These rigs utilized self-contained, telescoping kelly bars for productive installation of drilledshafts with tight spacedrilling conditions. Continuing in his father’s footsteps, Gus also had eightpatents issued to him, all related to the deep foundationindustry. (His most notablepatent was for the co-invention August Beck IV (left) with IH-45 Direct Connector crew inof the Post Stressed Pier, grant- front of 11-foot diameter 75,000 lb reinforcing cage.ed in April of 2002.)Returning once again toDoran Steel set thetemplates to support the2006, we see how this “typigiant rebar cagecal” road project that wetake for granted today isactually the culmination of decades of lons) of bentonite mineral slurry had to the slump retention requirements. Thecreative ideas and equipment modifica- be mixed and then a 12-foot diameter x mix was designed using trial and errortions. In very tight quarters, adjacent to 20-foot long permanent casing had to be test batches to see how much slumpspeeding freeway traffic – something that set. The huge, slurry-displaced drill shaft retention the concrete had and the effecton the concrete’s compressive strength.would have been nearly impossible in would then have to be excavated.Of course, the concrete placement The ultimate mix came out with sixthe “old days” – 3,000 Bbl (126,000 galhours of slump retention: five hoursThe ultimate mix came out allocated for the actual pour and an extrawith six hours of slump hour added in case of possible delays.retention: five hours allocated for the actual pour andan extra hour added in caseof possible delays.Installation of the 12 foot diameterX 20 feet long permanent steel casing.FOUNDATION DRILLING June/July 2007would have to meet the Texas Department of Transportation’s (TxDOT) specifications of maintaining a 4” minimumslump for the duration of the concretepour (thus ensuring that the entire column of concrete would remain fluid or“plastic”). The industry-standard specifications would not normally present aproblem for typical drilled shaft projects,which average about 50 cubic yards ofconcrete per shaft. But for this job, 625cubic yards of concrete had to be poured.Beck worked with Dorsett BrothersConcrete Supply and the TxDOT todesign a concrete mix that would meet(continued on page 12)Tight working conditions added tothe challenge.Page 5

IH-45 Contd.ago. Beck’s early modifications to thesteam shovel allowed him to develop asteam drill rig that went deeper andOnly time can tell, but onething is clear: if Beck andthe rest of today’s foundation engineers are willing toexperiment like their forefathers, the future of theindustry looks brighter thanever!Fresh concrete at the end of the 625 cubic yard pour.made bigger holes than anything else inits time. With each generation of Beckheirs trying new things, the company(continued on page 13)Prior to the concrete placement,Doran Steel helped design and manufacture the templates and bracing requiredto fabricate the reinforcing steel cages.The structural steel templates had tosupport and brace the 120-foot long,75,000 lb. reinforcing steel cage, constructed with 40 #18 bars. To lift, placeand suspend the reinforcing steel, Beckused a 500-ton and 150-ton crane, aswell as a 100-ton crane to tail the cage.After installation of the reinforcingcage, Beck proceeded with placing thecustom 7 sack concrete mix in less than5 hours. In all, 625 cubic yards werebatched, delivered and placed with theuse of two articulated boom pumpspumping into two 12” tremie pipes –supplying enough concrete to theexcavation fast enough to meet theTxDOT slump requirements. Withaccessibility restrictions and thetraffic on the adjacent highway aprimary concern, concrete placement began early in the morning, at1:00 a.m. Dorsett provided enoughtrucks and drivers to supply 150cubic yards of concrete per hour,which was also critical for meetingthe requirements.Backto the FutureProjects like the IH-45 DirectConnector are good for remindingus how equipment and technical processeshavechangedthroughout time.What seems likea mundane project to our 21stCentury mindset would neverhave been possible if innovatorslike A.H. Beck,Sr. hadn’t beenwilling to tryReady Mix trucks as far as you can see to place 150 cubic new things longyards of concrete per hour.Page 6Two 54 meter concrete boom pumpspumping into two 150’ long tremie pipes.FOUNDATION DRILLING June/July 2007

IH-45 Contd.Installation of the 75,000 lb reinforcing steel cage with a 500 toncrane.continually modified its equipment andadapted processes based on the needs ofvarious project owners. As owners’needs grew for larger buildings andstructures, requiring larger and deeperfoundations to support constantly higher loads, the equipment used to excavatethe corresponding foundations grew asWhat seems like a mundaneproject to our 21st Centurymindset would never havebeen possible if innovatorslike A.H. Beck, Sr. hadn’tbeen willing to try newthings long ago.well. Over the decades, these innovations have contributed, little by little, toinnovations like the 500-horsepower rigand giant auger that was used on NASARd. 1.As Beck Foundation Co. celebrates 75years of history, August Beck, IV, hasjoined the firm with a B.S. in CivilFOUNDATION DRILLING June/July 2007Engineering fromTexasA&MUniversity.Hewill become thenext generation ofBeck family members who haveplaced their markupon the foundationdrillingindustry througha dedication toinnovative solutions, a tirelesscommitment toproviding superior services andperformance, andthe efforts of versatile and talentedemployees. It isimportant to takea look at whereour industry istoday verses itsbeginnings. Froma mule drawnturntable to a 625Beck built 500 hp drill attachment mounted on a 150 toncubic yard drilledAmerican crane.shaft excavation,our industry hastheir forefathers, the future of the indusmade great progress since its inception. try looks brighter than ever!If Beck and the rest of today’s foundation engineers are willing to experiment likePROJECT TEAMOwnerTexas Department of TransportationMaureen Wakeland– Area EngineerGeneral ContractorW.W. Webber LLC ContractorsIvan Svec – Project ManagerMike Cosas – Project SuperintendentSpecialty ContractorA. H. Beck Foundation Co., Inc.David Cox – Branch ManagerAugust Beck, IV – Project ManagerDean Harrell – SuperintendentConcrete SupplierDorsett Brothers Concrete SupplyGene Potter – Vice PresidentRebar SubcontractorDoran Steel, Inc.David Doran – Vice PresidentPage 7

From building thefirst mechanized steampowered drilling rig to ourhigh torque hydraulicdrilling rigs of today.BECK is the nameyou can trust to providesolutions for all of yourdeep foundation needs.With BECK’s people,equipment, design-buildcapabilities, andexperience on yourproject, you have thecomfort of knowingall your foundationproblems have solutions.Contact Us At:Corporate Office5123 Blanco RoadSan Antonio, TX 78216210-342-5261210-342-4965 FaxBranch Office13650 HycohenHouston, TX 77047713-413-3800713-413-3811 FaxBranch Office907 South I-45Ferris, TX 75125972-846-2097972-846-2107 FaxBranch OfficeLuchetti Industrial ParkSuite #2#245 Road #5, KM.26.2Bayamon, Puerto Rico00959787-622-4815787-622-4814 FaxAlabama Electric CooperativeLowman Power PlantS l o p e S t a b i l i z a t i o n P ro j e c tw w w. a h b e c k . c o m

1000-horsepower drill rig along with a 500-horsepower crane mounted drill attachment for a Department of Energy project. The 500-horsepower crane mounted drill attachment would later be used on the IH-45 Direct Connector. The project was The Super Conducting Super Col-lider, an under-ground tunnel system to be used for smashing atoms. Due to .