Transcription

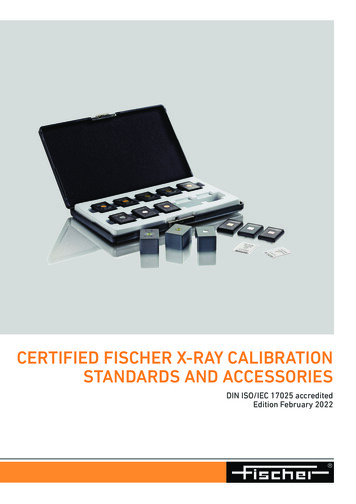

CERTIFIED FISCHER X-RAY CALIBRATIONSTANDARDS AND ACCESSORIESDIN ISO/IEC 17025 accreditedEdition February 2022

X-RAY Calibration StandardsQuality assurance with energy-dispersive X-rayfluorescence analysis (EDXRF analysis)Quality assurance and optimum processing procedures play an ever greater role in production.From this stems the necessity to perform reliablemeasurements, which also comply with thedemanding requirements of an ISO certified quality management system.Energy-dispersive X-ray fluorescence analysis(EDXRF analysis) is a particularly universal, fastand non-destructive measuring method. By usingsuitable reference materials, it enables coatingthicknesses and material composition for a largenumber of applications to be determined with ahigh level of precision and in a traceable way. Thewide range of industrial applications and the shortcycle of product innovation place special challenges on measuring technology and on the availability of calibration standards that are suitablefor EDXRF analysis.The Fischer Calibration LaboratorySince July 2003 Fischer has been the first institution in Germany to be approved as a DKD/DAkkScalibration laboratory for the "Mass per unit area"measured variable and accredited in accordancewith DIN EN ISO/IEC 17025. This accreditationentitles it to issue DAkkS calibration certificatesfor "Mass per unit area" calibration standards,which are used for calibrating X-ray fluorescenceinstruments for measuring coating thicknesses.The DAkkS certified calibration standards that areproduced by Fischer meet the highest possiblequality standard of national metrological institutessuch as NIST, BAM etc.More than 300 Calibration StandardsThe standard portfolio comprises more than 300calibration standards for EDXRF analysis and covers a large number of applications for differentindustries, such as for example plug contacts,jewelry, PCBs, semi-conductors, RoHS/WEEE andhigh reliability.Why DAkkS Accreditation?The Fischer Calibration Laboratorycomplies with DIN EN ISO/IEC 17025Calibration standards from Fischer with DAkkSaccreditation give you the following benefits: The expertise of the Calibration Laboratory ischecked and confirmed at regular intervals byan independent state authority. Traceability of the measured results: there is aseamless measuring chain up to internationallyrecognized base units, e.g. the SI-unit "meter".Only traceability proves, that the printed valueis correct with a defined measurement uncertainty. The value is independent of time, personchecking, test laboratory and measuringmethod, and it therefore creates the basis forprocess and quality control.With DAkkS certified calibration standards fromFischer, you benefit not only from unique expertise in producing certified reference materials, butyou also receive at the same time the warranty fortheir quality. Thanks to the internationally recognized DAkkS calibration certificate, you also gainsecurity and strengthen customer trust in yourproducts.Note on TerminologyCalibration standards are also often called reference standards or comparison standards. In theinterests of uniform terminology, "calibrationstandard" is used throughout in this document.Customer-specific Calibration StandardsThanks to the technical expertise and many yearsof experience of the Fischer Calibration Laboratory, we can also offer our customers the uniqueservice of being able to have their own productscertified as EDXRF calibration standards in accordance with the DAkkS accredited procedure - aninvaluable benefit for you and your customers.2X-RAY Calibration Standards

Traceability of Calibration StandardsThe traceability of Fischer calibration standards iseffected on the basis of the following procedures: In accordance with a procedurethat is accredited by the GermanAccreditation Service, DeutscherAkkreditierungsservice(DKD/DAkkS), see the accreditationcertificate at www.helmutfischer.de/akkreditierung. This procedure canbe applied for many pure-element coatings.The Fischer Calibration Laboratory ensurestraceability to internationally recognized material measures. You can find the accreditationcertificate on the Fischer ons-and-accreditions Through comparison measurements with calibration standards, which have either beenquantified by the accredited procedure and/or by other procedures. Reference to the calibration standards used and to their nominal valuesand measurement uncertainty is documentedin the traceability reports, see www.helmutfischer.de/traceability. Specific reference ismade to these in the test certificate for the calibration standard. This enables you to track, towhich physical material measures your Fischerstandards are traceable. You can find the traceability reports on the Fischer libration-standardsContentThe DAkkS Calibration Certificate . . . . . . . . . . . . . .4Customer-specific Calibration Standards . . . . . . . 6Notes on the Catalogue . . . . . . . . . . . . . . . . . . . . . . . 7CAL-X-S-1: Solid Standards Single Coatings . . . . 8CAL-X-S-2: Solid Standards Double Coatings . . .10CAL-X-S-3: Solid Standards Triple Coatings . . . .12CAL-X-S-A: Solid Standards Alloy Coatings. . . . .13CAL-X-solid: Solid Standards Pure elements . . .14CAL-X-S-analysis: Solid Standards Alloys . . . . . .15CAL-X-F-1: Foil Standards Single Coatings . . . . .17CAL-X-F-2: Foil Standards Double Coatings . . . .19CAL-X-F-3: Foil Standards Triple Coatings . . . . .20CAL-X-F-A: Foil Standards Alloy Coatings . . . . . .21CAL-X-set-1: Standard Sets Single Coatings. . . .22CAL-X-set-2: Standard Sets Double Coatings . . .24CAL-X-set-3: Standard Sets Triple Coatings . . . .25CAL-X-set-A: Standard Sets Alloy Coatings. . . . .26CAL-X-set-analysis: Standard Sets Alloys . . . . . .27CAL-X-app: Application Kits . . . . . . . . . . . . . . . . . .29Kits for Monitoring the Measurement Devices . .31X-RAY Accessories . . . . . . . . . . . . . . . . . . . . . . . . . .323

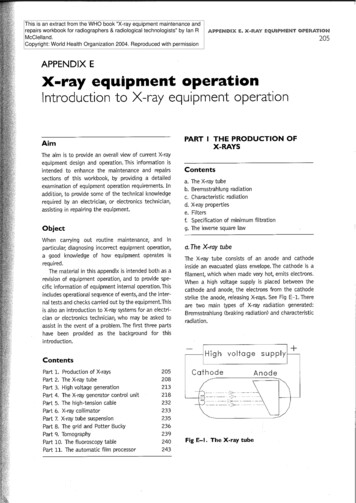

The DAkkS Calibration CertificateThe Front Page of the DAkkS Calibration CertificateKalibrierschein / Calibration CertificateErstellt durch das Kalibrierlaboratorium derissued by the calibration laboratoryHELMUT FISCHER GMBHInstitut für Elektronik und MesstechnikIndustriestraße 21D-71069 Sindelfingen9999KalibrierzeichenCalibration massenormal Au/NiMass per unit area standard Au/NiHELMUT FISCHER GMBHInstitut für Elektronik und MesstechnikIndustriestraße 21D-71069 SindelfingenTypTypeFabrikat/Serien-Nr.Serial numberAuftraggeberCustomer601-70812345Fa. MusterGmbH & Co.KGMusterstraße 2199999 MusterstadtAuftragsnummerOrder No.123456Anzahl der Seiten des Kalibrierscheines2Number of pages of the certificateDatum der KalibrierungD-K15076-01-00JJJJ-MMDieser Kalibrierschein dokumentiert die Rückführung auf nationale Normale zur Darstellungder Einheiten in Übereinstimmung mit demInternationalen Einheitensystem (SI).Die DAkkS ist Unterzeichner der multilateralenÜbereinkommen der European co-operation forAccreditation (EA) und der International Laboratory Accreditation Cooperation (ILAC) zur gegenseitigen Anerkennung der Kalibrierscheine.Für die Einhaltung einer angemessenen Frist zurWiederholung der Kalibrierung ist der Benutzerverantwortlich.This calibration certificate documents thetraceability to national standards, which realizethe units of measurement according to theInternational System of Units (SI).The DAkkS is signatory to the multilateralagreements of the European co-operation forAccreditation (EA) and of the InternationalLaboratory Accreditation Cooperation (ILAC) forthe mutual recognition of calibration certificates.The user is obliged to have the object recalibrated at appropriate intervals.The unique identifier of the calibration object.05.07.2021Date of calibrationDieser Kalibrierschein darf nur vollständig und unverändert weiterverbreitet werden. Auszüge oder Änderungen bedürfen der Genehmigung desausstellenden Kalibrierlaboratoriums. Kalibrierscheine ohne Unterschrift haben keine Gültigkeit.This calibration certificate may not be reproduced other than in full except with the permission of the issuing laboratory. Calibration certificateswithout signature are not valid.4The insignia designates theDAkkS calibration certificate asan official document. Strictrequirements apply to calibration laboratories, and theserequirements are regularlychecked by the accreditationbody of the German CalibrationService, Deutscher Kalibrierdienst (DKD).The calibration sign shows theaccreditation number of our laboratory, the number of the calibration certificate and the yearand month it was issued. Thesign is also on the wallet of yourcalibration standards.The type of calibration object,here gold coating on nickel basematerial, in the case of alloys aconsecutive sequence of elements, e.g.: NiZn/Fe: Nickel-zincalloy coating on ironDatumDateLeiter des KalibrierlaboratoriumsHead of the calibration laboratoryBearbeiterPerson in charge08.07.2021Dr. David BalleA. DinkelackerThe date and signatures confirmthe validity of the measured values.X-RAY Calibration Standards

The Back Page of the DAkkS Calibration CertificateDescription of the calibrationobjectThe traceability of the calibration standards is effected via acomparison measurement bymeans of X-ray fluorescenceanalysis against gravimetricallymeasured reference standards.Identification of the calibrationstandard (as it is also printed onthe standard), material and themass per unit area that is determined. The mass per unit area isthe size, which an X-ray fluorescence instrument determines.The coating thickness is derivedfrom the mass per unit area viathe material density.In the case of coatings: Derivedsizes, such as the thickness inmicrometers and micro inches.The nominal value is the nominal value of the calibrationobject, for example a targetcoating thickness or cataloguevalue. This value must not beused for calibration.9999Seite 2PageD-K15076-01-00JJJJ-MMKalibriergegenstand / Object of calibration:Das Flächenmassenormal besteht aus einer Goldschicht auf einem ebenen Nickelblech; gefasst in einem Kunststoffträger.The mass per unit area standard consists of a gold coating on a flat nickel sheet; fixed in a plastic frame.Kalibrierverfahren / Calibration method:Die Messungen erfolgten mit einem Röntgenfluoreszenz Messgerät unter Verwendung von Normalen und einem standardfreien Röntgenfluoreszenzverfahren. Die Normale sind über ein gravimetrisches Verfahren auf nationale Normale rückgeführt und entsprechen inAufbau und Zusammensetzung dem Kalibriergegenstand.The measurements were made with an X-ray fluorescence measuring instrument using master standards and a standard free XRF method. The master standards are traceableto national standards, by using mass and area measurements. The standards comply with the measurement sample, as far as the composition and consistence are concerned.Messbedingungen / Measurement conditions:Die Röntgenfluoreszenzmessungen wurden in einer zentralen Fläche von 2x2 mm durchgeführt (wenn die Messfläche nicht andersgekennzeichnet ist). Die aufgeführten Werte repräsentieren die Mittelwerte über diese Fläche.The x-ray fluorescence measurements were performed at a central area of 2x2 mm (unless specified otherwise). The reported values represent mean values for this area.Umgebungsbedingungen / Environmental conditions:Die Kalibrierung (Röntgenmessung) wurde bei einer Temperatur von (23 r 5)qC durchgeführt.The calibration (x-ray measurement) was performed at a temperature of (23 r 5)qC.Messergebnisse / Measurement almass per unit areaABCDEAu/NiU (k 2)[mg/cm²][mg/cm²]0.740.03Die abgeleiteten Werte der folgenden Tabelle sind aus der Flächenmasse mit der angegebenen Dichte berechnet worden.The values for the coating thickness of the following table have been converted from the mass per unit area using the specified nominal ‘‘]19.320.370.380.0215.00.8AuU (k 2)DickeU (k 2)thicknessMessunsicherheit / Measurement uncertainty:Angegeben ist die erweiterte Messunsicherheit, die sich aus der Standardmessunsicherheit durch Multiplikation mit dem Erweiterungsfaktor k 2 ergibt. Sie wurde gemäß EA-4/02 M ermittelt. Der Wert der Messgröße liegt mit einer Wahrscheinlichkeit von 95% im zugeordneten Werteintervall.Stated is the expanded measurement uncertainty, which is a result of the multiplication of the standard measurement uncertainty with the expansion factor k 2. It wasdetermined according to EA-4/02 M. With a probability of 95%, the value of the measured quantity is within the assigned value interval.Hinweis/Note:Die Deutsche Akkreditierungsstelle ist Unterzeichner der multilateralen Übereinkommen der European co-operation for Accreditation (EA) und der International Laboratory AccreditationCooperation (ILAC) zur gegenseitigen Anerkennung der Kalibrierscheine. Die weiteren Unterzeichner innerhalb und außerhalb Europas sind den Internetseiten von EA (www.europeanaccreditation.org) und ILAC (www.ilac.org) zu entnehmen.The Deutsche Akkreditierungsstelle [German Accreditation Body] is a signer of the multilateral agreement of the European co-operation for Accreditation (EA) and the InternationalLaboratory Accreditation Cooperation (ILAC) for mutual recognition of calibration certificates. Further signers within and outside of European are summarized on the web pages of EA(www.european-accreditation.org) and ILAC (www.ilac.org).Thickness (actual value) andnominal valueThe nominal value gives therange, in which the coatingthickness or alloy compositionshould lie. It is also given on thefollowing pages in the catalogue.The exact value (actual value) forthe thickness or composition of the material isdetermined during the qualification of the material. The actual value deviates from the nominalvalue, because it is not technically possible to produce the exact value, e.g. applying a zinc coatingwith exactly 37.5 µm. Example:KAL-N d Zn/Fe 25 µm, solid material standard forsingle coating, zinc coating on iron base material,nominal value for the zinc coating thickness 25 µm, but printed on the standard and documented in the certificate is the actualvalue 24.8 µm.Always use the actual value for entering the calibration data in the X-RAY software.The measurement uncertainty U is determinedfor each calibration standard individually.5

Customer-specific Calibration StandardsFischer offers you the unique service of being able to certify your own product as a calibration standard. Inmany cases it is even possible to issue an internationally recognized DAkkS calibration certificate. You canshow this to your customers and populate it to an existing quality management system in accordance withISO 9000/1. You also gain security with this in your production process, if a calibration standard corresponds to your products. The production of traceable calibration standards is very time-consuming and alsodependent on the quality of the source material. Please therefore observe the following sequence whenordering.This is how you order a customer-specific calibration standard from FischerYou contact your Fischer representative andclarify the requirements together.Then you send your material to Fischer.When you send your material to Fischer,please address the shipment directly tothe application laboratory (addressaddition application laboratory). Thisensures that your material reaches theright contact person.Fischer then processes your enquiry:The Fischer Calibration Laboratory testsyour material for suitability.This service is free-of-charge for you.Fischer produces an estimated costand sends you a quotation.You order and, if appropriate, provideyour material in a suitable form.Fischer produces and dispatchesthe calibration standards.Colour keyAction taken by youAction taken by Fischer6X-RAY Calibration Standards

Notes on the CatalogueColumn DAkkS – Order with Manufacturer's Certificate or DAkkS Calibration CertificateAll calibration standards are supplied with a manufacturer's certificate. If there is a D in the DAkkS columnin the table from page 8, then you can order a DAkkS calibration certificate as an option for this standard.Then add a D to the order number.Example:Order with manufacturer's certificate: 603-055Order with DAkkS calibration certificate: 603-055D.If there is no D in the DAkkS column, then the standard is available with manufacturer's certificate only.Differences between standards with a manufacturer's certificate and DAkkS certified standardsPropertyProduced by a DAkkS certified calibration laboratoryStandard withmanufacturer'scertificate DAkkS certifiedstandard Produced in accordance with DAkkS certified procedure Proof of traceability to internationally recognized baseunits Internationally recognized calibration certificate Worldwide comparability of the measured results Acceptance by ISO 9000/9001 certification bodiesworldwide Nominal value and actual valueIn this document the values for coating thickness and alloy composition are always given as nominal values,see page 5.Description of Coating StructureThe standards are identified in such a way, that the outer coating is always on the left and the base materialalways on the right, see the following figure.Cr coatingNi coatingCoating structureCu base materialBase material7

Solid StandardsCoatingsX-RAY Calibration Standards CatalogueCAL-X-S-1: Solid Standards Single CoatingsCoating structureBase materialThickness of thecoatingID of the calibration standardDesignationOrd. no.DAkkSDesignationOrd. no.DAkkSCAL-X-S-1 Ag/Ni 2 µm603-055DCAL-X-S-1 Cr/Cu 6 µm603-940DCAL-X-S-1 Au/Cu 0.4 µm602-651DCAL-X-S-1 Cr/Cu 12 µm603-941DCAL-X-S-1 Au/Cu 0.85 µm690-158DCAL-X-S-1 Cr/Cu 16 µm605-506DCAL-X-S-1 Au/Cu 1.3 µm602-684DCAL-X-S-1 Cr/Fe 0.3 µm603-157DCAL-X-S-1 Au/Ni 0.2 µm603-008DCAL-X-S-1 Cr/Fe 0.5 µm605-680DCAL-X-S-1 Au/Ni 0.5 µm603-279DCAL-X-S-1 Cr/Fe 1 µm605-500DCAL-X-S-1 Au/Ni 0.35 µm603-007DCAL-X-S-1 Cr/Fe 2.5 µm605-501DCAL-X-S-1 Au/Ni 0.85 µm602-992DCAL-X-S-1 Cr/Fe 5 µm604-583DCAL-X-S-1 Au/Ni 1 µm603-278DCAL-X-S-1 Cr/Fe 10 µm604-584DCAL-X-S-1 Au/Ni 1.5 µm603-277DCAL-X-S-1 Cr/Fe 15 µm605-502DCAL-X-S-1 Au/Ni 2.5 µm603-057DCAL-X-S-1 Cr/Fe 20 µm605-503DCAL-X-S-1 Cr/Cu 0.5 µm690-169DCAL-X-S-1 Cr/FeNi42 0.6 µm 604-566DCAL-X-S-1 Cr/Cu 2 µm603-939DCAL-X-S-1 Cr/Ni 0.5 µmD605-494Continued on the next page8X-RAY Calibration Standards

Solid StandardsCoatingsCAL-X-S-1: Solid Standards Single Coatings – ContinuationDesignationOrd. no.DAkkSDesignationOrd. no.DAkkSCAL-X-S-1 Cr/Ni 1.0 µm605-495DCAL-X-S-1 Ni/Cu 20 µm604-090DCAL-X-S-1 Cr/Ni 2.5 µm605-496DCAL-X-S-1 Ni/CuZn30 1.0 µm 604-643DCAL-X-S-1 Cr/Ni 5 µm605-497DCAL-X-S-1 Ni/CuZn30 3.0 µm 604-644DCAL-X-S-1 Cr/Ni 10 µm605-498DCAL-X-S-1 Ni/Fe 2 µm603-564DCAL-X-S-1 Cr/Ni 15 µm605-499DCAL-X-S-1 Ni/Fe 5 µm605-484DCAL-X-S-1 Cr/Ni 20 µm602-441DCAL-X-S-1 Ni/Fe 10 µm605-485DCAL-X-S-1 Cu/Fe 20 µm604-092DCAL-X-S-1 Ni/Fe 20 µm605-486DCAL-X-S-1 Cu/PCB 5 µm690-575CAL-X-S-1 Pd/Ni 0.7 µm602-993DCAL-X-S-1 Cu/PCB 9 µm690-577CAL-X-S-1 Pd/Ni 1.25 µm603-145DCAL-X-S-1 Cu/PCB 35 µm690-579CAL-X-S-1 Rh/Ni 0.1 µm603-056DCAL-X-S-1 Ni/Al 5 µm690-521DCAL-X-S-1 Rh/Ni 2.0 µm602-114DCAL-X-S-1 Ni/Al 10 µm690-523DCAL-X-S-1 Sn/Ni 2.5 µm604-132DCAL-X-S-1 Ni/Al 20 µm690-525DCAL-X-S-1 Sn/Ni 4.0 µm604-154DCAL-X-S-1 Ni/Cu 1.0 µm604-155DCAL-X-S-1 Sn/Ni 6 µm604-502DCAL-X-S-1 Ni/Cu 2.5 µm604-156DCAL-X-S-1 Zn/Fe 5 µm603-205DCAL-X-S-1 Ni/Cu 5 µm605-476DCAL-X-S-1 Zn/Fe 10 µm603-638DCAL-X-S-1 Ni/Cu 10 µm605-477DCAL-X-S-1 Zn/Fe 38 µm603-284DCAL-X-S-1 Ni/Cu 16 µm602-991D9

Solid StandardsCoatingsX-RAY Calibration Standards CatalogueCAL-X-S-2: Solid Standards Double CoatingsCoating structureBase materialThickness of thecoatings*10ID of the calibration standardDesignationOrd. no.DAkkSDesignationOrd. no.DAkkSCAL-X-S-2 Ag/Ni/Alloy421.0/1.0 µm604-635DCAL-X-S-2 Au/Ni/Alloy420.25/3.0 µm604-630DCAL-X-S-2 Ag/Ni/Alloy421.0/3.0 µm604-636DCAL-X-S-2 Au/Ni/Alloy421.0/1.0 µm604-631DCAL-X-S-2 Ag/Ni/Alloy425.0/1.0 µm604-637DCAL-X-S-2 Au/Ni/Alloy421.0/3.0 µm604-632DCAL-X-S-2 Ag/Ni/Alloy425.0/3.0 µm604-638DCAL-X-S-2 Au/Ni/Alloy422.5/1.0 µm604-633DCAL-X-S-2 Ag/Ni/Cu1.0/1.0 µm604-619DCAL-X-S-2 Au/Ni/Alloy422.5/3.0 µm604-634DCAL-X-S-2 Ag/Ni/Cu1.0/3.0 µm604-620DCAL-X-S-2 Au/Ni/Base*0.03/3 µm604-466CAL-X-S-2 Ag/Ni/Cu1.0/15 µm604-116DCAL-X-S-2 Au/Ni/Base*0.12/3 µm604-457CAL-X-S-2 Ag/Ni/Cu5.0/1.0 µm604-621DCAL-X-S-2 Au/Ni/Base*0.12/7 µm604-458CAL-X-S-2 Ag/Ni/Cu5.0/3.0 µm604-622DCAL-X-S-2 Au/Ni/Base*0.21/0.1 µm604-455CAL-X-S-2 Ag/Ni/CuZn301.0/1.0 µm604-651DCAL-X-S-2 Au/Ni/Base*0.5/0.3 µm604-456CAL-X-S-2 Ag/Ni/CuZn301.0/3.0 µm604-652DCAL-X-S-2 Au/Ni/Cu0.1µm/10 µm604-158DCAL-X-S-2 Ag/Ni/CuZn305.0/1.0 µm604-653DCAL-X-S-2 Au/Ni/Cu0.1µm/3.0 µm604-157DCAL-X-S-2 Ag/Ni/CuZn305.0/3.0 µm604-654DCAL-X-S-2 Au/Ni/Cu0.25/1.0 µm604-613DCAL-X-S-2 Au/Ni/Alloy420.25/1.0 µm604-629DCAL-X-S-2 Au/Ni/Cu0.25/3.0 µm604-614DThe substrate material Base/PCB consists of copper-laminated PCB material.The Cu coating is approx. 35 µm thick and not certified.X-RAY Calibration Standards

Solid StandardsCoatingsCAL-X-S-2: Solid Standards Double Coatings – ContinuationDesignationOrd. no.DAkkSDesignationOrd. no.CAL-X-S-2 Au/Ni/Cu0.3/7.5 µm602-994DCAL-X-S-2 Ni/Cu/Zn15/25µm605-614CAL-X-S-2 Au/Ni/Cu0.8/2.5 µm601-895DCAL-X-S-2 Pd/Ni/Cu1.0/1.0 µm603-193CAL-X-S-2 Au/Ni/Cu1.0/1.0 µm604-615DCAL-X-S-2 Pd/NiP10/Cu/PCB* 0.05/4.5 μm690-508CAL-X-S-2 Au/Ni/Cu1.0/3.0 µm604-616DCAL-X-S-2 Pd/NiP10/Cu/PCB* 0.1/4.5 μm690-510CAL-X-S-2 Au/Ni/Cu1.5/10 µm602-087DCAL-X-S-2 Pd/NiP10/Cu/PCB* 0.25/4.5 μm690-512CAL-X-S-2 Au/Ni/Cu2.5/1.0 µm604-617DCAL-X-S-2 Sn/Ni/Alloy42**1.0/1.0 µm604-639DCAL-X-S-2 Au/Ni/Cu2.5/3.0 µm604-618DCAL-X-S-2 Sn/Ni/Alloy42**1.0/3.0 µm604-640DCAL-X-S-2 Au/Ni/Cu2.5/5.0 µm602-086DCAL-X-S-2 Sn/Ni/Alloy42**5.0/1.0 µm604-641DCAL-X-S-2 Au/Ni/CuZn300.25/1.0 µm604-645DCAL-X-S-2 Sn/Ni/Alloy42**5.0/3.0 µm604-642DCAL-X-S-2 Au/Ni/CuZn300.25/3.0 µm604-646DCAL-X-S-2 Sn/Ni/Cu1.0/1.0 µm604-623DCAL-X-S-2 Au/Ni/CuZn301.0/1.0 µm604-647DCAL-X-S-2 Sn/Ni/Cu1.0/3.0 µm604-624DCAL-X-S-2 Au/Ni/CuZn301.0/3.0 µm604-648DCAL-X-S-2 Sn/Ni/Cu4.5/5µm601-898DCAL-X-S-2 Au/Ni/CuZn302.5/1.0 µm604-649DCAL-X-S-2 Sn/Ni/Cu5.0/1.0 µm604-625DCAL-X-S-2 Au/Ni/CuZn302.5/3µm604-650DCAL-X-S-2 Sn/Ni/Cu5.0/3.0 µm604-626DCAL-X-S-2 Au/NiP10/Cu/PCB* 0.1/4.5 μm690-506CAL-X-S-2 Sn/Ni/CuZn301/1 µm604-655DCAL-X-S-2 Cr/Ni/Cu0.5/10 µm603-156DCAL-X-S-2 Sn/Ni/CuZn301/3 µm604-656DCAL-X-S-2 Cr/Ni/Fe0.8/7 µm603-155DCAL-X-S-2 Sn/Ni/CuZn305.0/1.0 µm604-657DCAL-X-S-2 Ni/Cu/PCB*3/15 µm604-207CAL-X-S-2 Sn/Ni/CuZn305/3 µm604-658DCAL-X-S-2 Ni/Cu/Zn8/15 µm605-613DDAkkSD*Base/PCB consists of copper-laminated PCBmaterial. The Cu coating is approx. 35 µmthick and not certified.** Composition Alloy42: 58% Fe, 42% Ni11

Solid StandardsCoatingsX-RAY Calibration Standards CatalogueCAL-X-S-3: Solid Standards Triple CoatingsCoating structureBase materialThickness of thecoatingsDesignation12ID of the calibration standardOrd. no.DAkkSDesignationOrd. no.CAL-X-S-3 Au/Pd/NiP10/Cu/ 690-516PCB 0.05/0.03/4.5 µmCAL-X-S-3 Au/Pd/NiP10/Cu/ 690-514PCB 0.02/0.03/4.5 µmCAL-X-S-3 Au/Pd/NiP10/Cu/ 690-517PCB 0.05/0.1/4.5 µmCAL-X-S-3 Au/Pd/NiP10/Cu/ 690-519PCB 0.1/0.2/4.5 µmDAkkSX-RAY Calibration Standards

Solid StandardsCoatingsCAL-X-S-A: Solid Standards Alloy CoatingsCompositionof the alloy coatingBase materialThickness of thecoatingID of the calibration standardOrd. no.DAkkSOrd. no.DAkkSCAL-X-S-A NiP10/Cu 5 µm605-480CAL-X-S-A Ni15Zn/Fe 1µm603-928DCAL-X-S-A NiP10/Cu 15 µm605-481CAL-X-S-A Ni6Zn/Fe 6 µm606-069DCAL-X-S-A NiP12/Cu 1 µm605-479CAL-X-S-A Sn60Pb40/Ni2.5 µm602-069CAL-X-S-A NiP10/CuZn 5 µm 605-482CAL-X-S-A NiP10/CuZn15 µm605-483CAL-X-S-A Sn60Pb40/Ni10 µm602-070CAL-X-S-A NiP2.5/Fe 3 µm605-487CAL-X-S-A Sn60Pb40/Ni40 µm602-071CAL-X-S-A NiP2.5/Fe 5 µm605-488602-072CAL-X-S-A NiP5/Fe 17 µm605-489CAL-X-S-A Sn90Pb10/Ni2.0 µmCAL-X-S-A NiP10/Fe 3 µm605-490602-073CAL-X-S-A NiP10/Fe 15 µm605-491CAL-X-S-A Sn90Pb10/Ni10.5 µmCAL-X-S-A NiP10/Fe 20 µm605-492CAL-X-S-A NiP10/Fe 30 µm605-493CAL-X-S-A Pd70Ni/Cu 15 µm 603-198CAL-X-S-A Pd70Ni/Cu 3.5 µm 603-197CAL-X-S-A Ni13Zn/Fe 4.5 µm 603-071DCAL-X-S-A Ni13Zn/Fe 6 µm605-513DCAL-X-S-A Ni13Zn/Fe 17 µm 605-514DCAL-X-S-A Ni13Zn/Fe 27 µm 603-072DCAL-X-S-A NiP10/Cu 4µm602-697CAL-X-S-A NiP10/Cu 10µm602-696CAL-X-S-A NiP8.5/Fe 25µm603-785CAL-X-S-A NiP8.5/Fe 8.5µm603-78413

X-RAY Calibration Standards CatalogueSolid StandardsBulkCAL-X-solid: Solid Standards Pure ElementsPure Element*14Designation*Ord. no.CAL-X-solid AgWZ*Designation*Ord. no.601-842CAL-X-solid Pd601-856CAL-X-solid Al601-854CAL-X-solid Pt601-862CAL-X-solid Bi603-257CAL-X-solid Rh601-851CAL-X-solid Cd601-847CAL-X-solid Ru604-034CAL-X-solid Co601-858CAL-X-solid Re605-671CAL-X-solid Cr601-850CAL-X-solid Sn601-843CAL-X-solid Cu601-846CAL-X-solid Ti601-859CAL-X-solid Fe601-848CAL-X-solid V601-860CAL-X-solid Ir603-618CAL-X-solid W601-853CAL-X-solid Mn602-074CAL-X-solid Zn601-840CAL-X-solid Mo601-861CAL-X-solid Zr602-719CAL-X-solid Ni601-845CAL-X-solid Ta605-593CAL-X-solid Pb601-844CAL-X-solid Au601-841WZ*FNo Fischer manufacturer's certificates and no DAkkS calibration certificates are available for thesestandards. Exception: If there is an entry F in the WZ column, then you can order a Fischer manufacturer's certificate for this standard as an option.Example:Order without certificate: 601-841,Order with Fischer manufacturer's certificate: 601-841FX-RAY Calibration Standards

Solid StandardsBulkCAL-X-S-analysis: Solid Standards Alloys (Bulk)Compositionof the alloyElementpercentagesDesignationOrd. no.DAkkSDesignationOrd. no.CAL-X-S-analysis Au10Ag35- 605-129Cu55 2 kt*CAL-X-S-analysis Au64Ag10- 605-126Cu26 15 kt*CAL-X-S-analysis Au10Ag80- 605-121Cu10 2 kt*CAL-X-S-analysisAu70Ag30 17 kt*605-128CAL-X-S-analysis Au30Ag10- 605-124Cu60 7 kt*CAL-X-S-analysisAu70Pt10Ag12Cu8 17 kt*604-694CAL-X-S-analysis Au30Ag60- 605-122Cu10 7 kt*CAL-X-S-analysis Au75Ag5Cu8Cd12 18 kt*603-745CAL-X-S-analysis Au33Ag12- 603-683Cu39Zn16 8 kt*CAL-X-S-analysis Au75Ag5Cu10Zn10 18 kt*603-680CAL-X-S-analysisAu33Ag67 8 kt*CAL-X-S-analysis Au75Ag5Cu20 18 kt*603-679604-970CAL-X-S-analysis Au34Ag33- 605-123Cu33 8 kt*CAL-X-S-analysis Au75Ag10- 603-747Cu15 18 kt*CAL-X-S-analysisAu37.5Ag20Cu42.5 9 kt*CAL-X-S-analysis Au75Ag15- 603-746Cu10 18 kt*605-020CAL-X-S-analysis Au50Ag25- 605-125Cu25 12 kt*CAL-X-S-analysis Au75Cu8Pd10Ni7 18 kt*603-744CAL-X-S-analysis Au59Ag5Cu37 14 kt*603-682CAL-X-S-analysisAu82Ag9Cu9 20 kt*605-127CAL-X-S-analysisAu59Ag27Pd14 14 kt*603-748CAL-X-S-analysisAu90Ag5Cu5 22 kt*603-752CAL-X-S-analysisAu90Ag10 22 kt*603-750CAL-X-S-analysis Au59Ag30- 603-681Cu12 14 kt*DAkkSContinued on the next page*The standard measurement uncertainty is determined for each calibration standard individually.15

X-RAY Calibration Standards CatalogueSolid StandardsBulkCAL-X-S-analysis: Solid Standards Alloys (Bulk) – ContinuationDesignationOrd. no.CAL-X-S-analysisAu95Ag3Cu2 23 kt*603-751CAL-X-S-analysis Ag75Cd20- 605-562Cu3Zn2*CAL-X-S-analysisAu95Ag5 23 kt*603-749CAL-X-S-analysis Ag80Cd2Cu10Zn8*605-563CAL-X-S-analysisSterling Silver 935*603-790CAL-X-S-analysisAu75Ag25 S-analysis Alloy42601-865CAL-X-S-analysis S-analysis CuZn37601-855CAL-X-S-analysisAg92.5Cu 7.5*(Sterling Silver 925)605-552CAL-X-S-analysis CuZn30690-354CAL-X-S-analysis CAL-X-S-analysis AL-X-S-analysis Ag50Cd47- 556CAL-X-S-analysis Ag35Cd36- 605-557Cu25Zn4*CAL-X-S-analysis Ag59Cd37- 605-558Cu4Zn0.5*CAL-X-S-analysis Ag60Cd26- 605-559Cu9Zn5*CAL-X-S-analysis Ag65Cd25- 605-560Cu8Zn2*DAkkSDesignationOrd. no.DAkkSCAL-X-S-analysis Pt950Cu50 604-036CAL-X-S-analysis Pt960Ru40 604-037CAL-X-S-analysis RoHS PELow603-896CAL-X-S-analysis RoHS PEHigh603-895CAL-X-S-analysis RoHSPVC-BLANK603-988CAL-X-S-analysis RoHSPVC-Low603-987CAL-X-S-analysis 268CAL-X-S-analysis Sn97Pb3604-330CAL-X-S-analysis Ag69Cd21- 605-561Cu6Zn4** The standard measurement uncertainty is determined for each calibration standard individually.** Kovar is a registered trade mark of CRS Holdings, Inc.16X-RAY Calibration Standards

CAL-X-F-1: Foil Standards Single CoatingsThickness of the foilElementDesignationOrd. no.DAkkSDesignationOrd. no.DAkkSCAL-X-F-1 Ag 0.1 µm602-581DCAL-X-F-1 Cd 5 µm602-244DCAL-X-F-1 Ag 0.25 µm602-580DCAL-X-F-1 Cd 10 µm602-245DCAL-X-F-1 Ag 0.5 µm602-949DCAL-X-F-1 Cd 20 µm605-177DCAL-X-F-1 Ag 1 µm601-817DCAL-X-F-1 Co 3 µm602-989DCAL-X-F-1 Ag 2 µm603-431DCAL-X-F-1 Co 5 µm602-990DCAL-X-F-1 Ag 5 µm601-818DCAL-X-F-1 Cr 1 µm603-239DCAL-X-F-1 Ag 9 µm603-556DCAL-X-F-1 Cu 0,02 µm605-507DCAL-X-F-1 Ag 15 µm601-819DCAL-X-F-1 Cu 0.05 µm605-508DCAL-X-F-1 Ag 20 µm603-557DCAL-X-F-1 Cu 0.1 µm605-509DCAL-X-F-1 Ag 35 µm601-820DCAL-X-F-1 Cu 0.2 µm605-510DCAL-X-F-1 Al 6 µm603-335CAL-X-F-1 Cu 0.5 µm605-511DCAL-X-F-1 Al 10 µm603-554CAL-X-F-1 Cu 1 µm605-512DCAL-X-F-1 Al 20 µm603-336CAL-X-F-1 Cu 2 µm601-832DCAL-X-F-1 Al 100 µm601-990CAL-X-F-1 Cu 3 µm601-833DCAL-X-F-1 Au 2 nm605-991CAL-X-F-1 Cu 5 µm605-592DCAL-X-F-1 Au 5 nm605-996CAL-X-F-1 Cu 6 µm601-834DCAL-X-F-1 Au 20 nm605-998CAL-X-F-1 Cu 10 µm601-835DCAL-X-F-1 Au 0.05 µm602-594DCAL-X-F-1 Cu 20 µm601-836DCAL-X-F-1 Au 0.1 µm602-773DCAL-X-F-1 Cu 25 µm601-837DCAL-X-F-1 Au 0.25 µm601-810DCAL-X-F-1 Cu 30 µm603-555CAL-X-F-1 Au 0.5 µm601-811DCAL-X-F-1 Fe 15 µm603-883DCAL-X-F-1 Au 1 µm601-812DCAL-X-F-1 Ir 11 nm605-452DCAL-X-F-1 Au 3 µm601-813DCAL-X-F-1 Ir 22 nm605-453DCAL-X-F-1 Au 6 µm601-814DCAL-X-F-1 Mo 4 µm603-063Foil StandardsID of the calibration standard17

X-RAY Calibration Standards CatalogueFoil StandardsCAL-X-F-1: Foil Standards Single Coatings

jewelry, PCBs, semi-conductors, RoHS/WEEE and high reliability. Customer-specific Calibration Standards Thanks to the technical expertise and many years of experience of the Fischer Calibration Labora-tory, we can also offer our customers the unique service of being able to have their own products certified as EDXRF calibration standards in accor-

![[AWS Black Belt Online Seminar] AWS X-Ray](/img/17/20200526-blackbelt-x-ray.jpg)