Transcription

March 2017The Magazine for ENERGY EFFICIENCY and WATER CONSERVATION in Industrial Cooling SystemsINDUSTRIAL COOLING SYSTEMS12 Ball Corporation Engineers aReduction in Cooling Tower Load16 Designing a Dedicated ModernWine Cooling SystemPICKSCOOLING TOWERS & CHILLERSERTECH19 Cooling Towers Offer Data CentersTOkW2HOGLINHILLER&COO2017 AHR Show Report5C24WWater and Energy SavingsCO2

CONFERENCE - SEMINARS - TRADE SHOWMarch 22-23, 2017Pennsylvania Convention Center, Philadelphia, PAEnergy, Power & Facility ManagementStrategies & Technologies ExpoPresented ByImprove your energy management program, and get up tospeed on the current generation of innovative technologies.www.globalconevent.comOther Energy Events for 2017ATTENDANCE 770.447.5083 x226SEMINARS 770.925.9633EXHIBITS com

COLUMNSM A R C H2 0 1 7 V O L U M E3 ,N O .1 INDUSTRIAL COOLING SYSTEMS12THE COOLING SYSTEM ASSESSMENTBall Corporation Engineers a Reductionin Cooling Tower LoadBy Chiller & Cooling Best Practices Magazine16Designing a Dedicated Modern Wine Cooling SystemBy Kevin Trowhill, Century Refrigeration12COOLING TOWERS & CHILLERS19Cooling Towers Offer Data Centers Waterand Energy SavingsBy Douglas Bougher and Kent Martens, P.E.,SPX Cooling Technologies24SHOW REPORTChillers and Cooling Towers at 2017 AHR EXPOBy Rod Smith, Chiller & Cooling Best Practices Magazine19COLUMNS4From the Editor5Resources for Energy EngineersChiller & Cooling Tower Technology Picks29Industrial Cooling System Industry News33Advertiser Index24coolingbestpractices.com3

COLUMNS0 3 / 1 7FROM THE EDITORWe began the year by visiting AHR Expo 2017 in Las Vegas. The AHR Expo setseveral records, including attendance of more than 68,000 registered visitorsand exhibitor personnel, as well as 500,159 square feet sold. The Show wasby far the largest and best attended Expo in the Western states, with some1,968 exhibiting companies. Exhibitors said they’d never seen so much trafficat AHR. Business optimism over 2017 prospects was palpable. There were some booths so full ofpeople they were hard to get into. I spent two full days visiting the booths of cooling tower andcentral chiller plant manufacturers. I hope you enjoy the Show Report.Keven Trowhill, from Century Refrigeration, has sent us an article about how only customdesigned chillers can optimize wine production. “Cooling systems must meet three maincriteria in order to be effective in wine production and storage applications: the coolingsystems must be able to achieve the ideal temperatures for wine production processes;they must deliver consistent, reliable operation; and they must be well-designed for safe,convenient use.”Data Centers have become major energy and water consumers. Douglas Bougher and KentMartens, from SPX Cooling Technologies, write about how some have incorrectly questionedthe use of cooling towers vs. dry systems. They state, “In evaluating the best cooling strategyfor a data center, it is critical to view water usage holistically, including water use where thepower is made. When viewed in this light, mechanical evaporative cooling systems are oftenfar more efficient than alternative dry systems.”Thank you for investing your time and efforts into Chiller & Cooling Best Practices.ROD SMITHEditortel: 412-980-9901rod@airbestpractices.com2017 MEDIA PARTNERS4coolingbestpractices.comIndustrial Energy ManagersA “Best Practice” we look for is how can plants reduce the load on their cooling towers?Thanks to our Editorial Board Member Doug Barndt, from Ball Corporation, we were ableto speak with a member of his “Energy Team” at their Saratoga Springs (NY) aluminumcan manufacturing plant. Engineering Manager Bob Nelson described how they used a heatexchanger to create a 10 F reduction in the temperature of water returning to the coolingtower. This helped an “almost maxed-out” closed-loop cooling system circulating waterthrough air compressors, compressed air dryers, vacuum pumps, decorator inkers and variousother heat exchangers.EDITORIAL ADVISORY BOARDBlackhawkEquipmentBrandon AitkenEngineering ManagerDoug BarndtManager, Demand Side BallEnergy-SustainabilityCorporationRichard FeustelSenior Energy AdvisorLeidosWilliam JeraldEnergy ManagerCalPortlandJennifer MeierGlobal EH&S/Plant EngineeringManagerVarroc LightingSystemsThomas MortSenior AuditorThomas MortConsultingBrad ReedCorporate Energy TeamToyotaLeaderBrad RundaGlobal Director, EnergyKochIndustriesUli SchildtEnergy EngineerDarigoldThomas SullivanEnergy PerformanceManagerMichelin NorthAmericaBryan WhitfieldPaint & Powder BoothSpecialistFiat ChryslerAutomotive

COLUMNS0 3 / 1 7 RESOURCES FOR ENERGY ENGINEERSCHILLER & COOLING TOWER TECHNOLOGY PICKSTrane Announces Series R RTWDWater-Cooled Chiller for Commercialand Industrial BuildingsTrane , a leading global provider of indoorcomfort solutions and services and a brandof Ingersoll Rand, is announcing thatits Series R RTWD water-cooled chillerfor commercial and industrial buildingsis now available for customers in NorthAmerica and the Middle East who are readyto transition to systems with lower globalwarming potential (GWP).The Series R RTWD chiller, available in80-250 tons, delivers energy efficiencycoupled with ease of installation, applicationflexibility and high reliability. These chillerscan operate with a choice of R-134A orOpteon XP10 (R-513A), a next-generation,low-GWP refrigerant from Chemours. Withan infinite unloading compressor design, wideoperating temperature range, heat-recoveryoptions up to 140 degrees Fahrenheit,advanced controls and high efficiencies, thesechillers can be the perfect choice for tighttemperature control in almost any application.“Trane continues to innovate its chillerportfolio by offering customers themost energy and operationally efficientsystem choices for their buildings,” saidManlio Valdes, Vice President of productmanagement and marketing at Trane. “TheSeries R RTWD is reliable, safe and efficientwhile offering customers the added benefitof sustainability now and in the future.”The Series R RTWD chiller joins theIngersoll Rand EcoWise portfolio ofproducts, which are designed to lowerenvironmental impact with next-generation,low-GWP refrigerants and high efficiencyoperation. Other Trane chillers includedin the EcoWise portfolio are CenTraVac centrifugal chillers, Trane Sintesis aircooled chillers and Trane Series E CenTraVac for Europe and the Middle East.EcoWise products:pp Are available with next-generation, lower-GWPrefrigerantspp Reduce greenhouse gasSeries R RTWD water-cooled chiller for commercialand industrial buildings.pp Maintain safety andenergy efficiency throughinnovative designpp Meet or exceed emissionsregulationsThe Ingersoll Rand Climate CommitmentIngersoll Rand, a world leader in creatingcomfortable, sustainable and efficientenvironments, made a Climate Commitmentto reduce GHG emissions from its productsand operations by 2030. The Ingersoll RandClimate Commitment pledges to:(GHG) emissionscoolingbestpractices.com5

COLUMNS0 3 / 1 7RESOURCES FOR ENERGY ENGINEERSCHILLER & COOLING TOWER TECHNOLOGY PICKSpp Cut the refrigerant GHGfootprint of its productsby 50 percent by 2020and incorporate lowerGWP alternatives across itsportfolio by 2030;pp Invest 500 million inproduct-related research anddevelopment by 2020 to fundthe long-term reduction ofGHG emissions; andpp Reduce company operations-related GHG emissions by 35percent by 2020.To date, the Climate Commitment hassupported the avoidance of approximately2 million metric tons of CO2e globally,which is the equivalent of avoiding annualCO2 emissions from energy used in morethan 270,000 homes or more than 2.1billion pounds of coal burned. By 2030,the company expects to reduce its carbonfootprint by 50 million metric tons.conditioning systems, building and contractingservices, parts support and advanced control.For more information,visit www.ingersollrand.comor www.trane.com.To learn more about the ClimateCommitment, visit www.Trane.com/EcoWise.New Marley NC Everest CoolingTower Provides Up To 50% MoreCooling CapacitySPX Cooling Technologies, Inc., a full-line,full-service industry leader in the design andmanufacture of evaporative and air-cooledheat exchangers, announces the new MarleyNC Everest Cooling Tower, a crossflowevaporative cooling system that provides upto 50% more cooling capacity than any othersingle-cell, factory-assembled cooling tower.In addition to unmatched cooling capacity,the NC Everest uses up to 35% less fanpower to achieve higher energy savings.About Ingersoll Rand and TraneIngersoll Rand advances the quality of life bycreating comfortable, sustainable and efficientenvironments. Our people and our familyof brands — including Club Car , IngersollRand , Thermo King and Trane — worktogether to enhance the quality and comfortof air in homes and buildings; transport andprotect food and perishables; and increaseindustrial productivity and efficiency. We area 13 billion global business committed toa world of sustainable progress and enduringresults. Trane solutions optimize indoorenvironments with a broad portfolio ofenergy efficient heating, ventilating and air6coolingbestpractices.comIts unique design minimizes piping andelectrical connections to reduce installationcosts. Seven-foot doors provide access to thetower’s interior service decks and mechanicalcomponents, making routine inspections andmaintenance safer and easier.Featuring the new, patent-pending MarKey Drift Eliminators, the NC Everest CoolingTower achieves the lowest measureable driftrate, down to 0.0005 percent of circulatingwater flow, so less water escapes the tower.NC Everest Cooling Tower sound levels havebeen independently verified per CTI ATC-128test code by third-party CTI-licensed testagents and certified acoustical engineers.SPX Cooling Technologies’ Marley brandis the only package tower subjected to thisrigorous independent sound testing.For more information about the Marley NCEverest Cooling Tower, visit http://spxcooling.com/nceverest.About SPX Cooling Technologies, Inc.:SPX Cooling Technologies, Inc. is a leadingglobal manufacturer of cooling towers,evaporative fluid coolers, evaporativecondensers and air cooled heat exchangersproviding full-service cooling solutionsand support to customers in the powergeneration, petrochemical, industrial,refrigeration, and heating, ventilation andair conditioning (HVAC) markets for morethan 100 years.The new Marley NC Everest Cooling TowerProvides Up To 50% More Cooling Capacity and35% Less Fan Power Per CellFor more information, pleasevisit www.spxcooling.com.SPX Cooling Technologies and itsproduct brands are part of SPXCorporation.

COLUMNS0 3 / 1 7 CHILLER & COOLING TOWER TECHNOLOGY PICKSRAE Coils ManufacturingReplacement Evaporative CondensingTube BundlesRAE Coils, a division of RAE Corporation,an industry leader in the design andproduction of engineered heating, cooling,and refrigeration systems, announces thatit is manufacturing replacement and OEMevaporative condensing tube bundles. Thetube bundles are a critical component of thehighly efficient condensing units originallymanufactured by Mammoth’s Ultraline andPenthouse brands. When compared with aircooled technology, this innovative productcan result in a reduction of up to 35% inannual operating costs.manufacture of custom-engineered andoff-the-shelf cooling and refrigerationsystems. RAE’s expertise allows the companyto design top-quality systems to meet thespecific needs of their customers. RAEdesigns and manufactures products infour divisions: Century Refrigeration,RAE Coils, Refrigeration Systems andTechnical Systems.For more information,visit www.RAECorp.com.RAE Coils announces it is manufacturingreplacement and OEM evaporative condensing tubebundles.Evaporative condensing units cool moreefficiently than air-cooled units because thesurface of the refrigerant tubes is sprayedwith water, thereby allowing the tubebundles to reject more heat than in an aircooled system with the same surface areaand airflow. The increased efficiency of theevaporative-cooled unit results in decreasedenergy usage and operational costs.The tubes in RAE Coils’ evaporative coolingtube bundles are constructed from copperto provide optimal heat transfer. Evaporativecondensing units with RAE Coils’ evaporativecondensing tube bundles are ideal for use incommercial applications, such as hospitals,universities, industrial buildings, and more.About RAE CorporationRAE Corporation, family-owned andheadquartered in Pryor, Oklahoma, isan industry leader in the design andcoolingbestpractices.com7

COLUMNS0 3 / 1 7RESOURCES FOR ENERGY ENGINEERSCHILLER & COOLING TOWER TECHNOLOGY PICKS2017 AHR Expo InnovationAwards CeremonyA highlight of the 2017 Air-Conditioning,Heating, Refrigerating Exposition (AHRExpo), held January 30 to February 1 inLas Vegas, is the 2017 AHR Expo InnovationAwards ceremony.The 2017 AHR Expo Innovation Awards honorthe most inventive and original products,systems and technologies showcased at thisyear’s Show in the categories of: buildingautomation; cooling; green building; heating;indoor air quality; plumbing; refrigeration;software; tools & instruments; and ventilation.All 2017 AHR Expo Innovation Award winnershave been selected by a panel of third-partyASHRAE member judges who evaluated eachentry based on innovative design, creativity,application, value and market impact.“The innovative and creative productdevelopment demonstrated by this year’sAward winners has served to confirm theHVACR Industry’s ongoing vitality and forwardthinking. It is exciting to see all the emergingtechnologies that are bringing about betterand better solutions to the challengeswe face,” said Clay Stevens, Presidentof International Exposition Company.“We congratulate those who have beenrecognized as 2017’s pioneers from acrossall areas of the industry, by proving thereis always more to be achieved, and fartherto be propelled, when it comes to HVACR8coolingbestpractices.cominnovation,” Stevens continued. “This is thespirit that makes each year’s competition sofresh and exciting, and is what we are proudto see, year after year, as a cornerstone ofinspiration for the HVACR industry’s ongoingcreativity and advancement.”The complete list of 2017 AHR ExpoInnovation Award winners includes:Indoor Air QualityCompany: Nortec Humidity (www.humidity.com; 2017 AHRExpo booth No. C4706)Innovation: Nortec GS Series - CS Model(Nortec GS CS) HumidifierPlumbingBuilding AutomationCompany: Taco, Inc. (www.tacocomfort.com; 2017 AHR Expo boothNo. N7926)Company: Danfoss (www.danfoss.us; 2017AHR Expo booth No. C4506)Innovation: SmartPlug Smart Hot WaterRecirculation ControlInnovation: Danfoss Enterprise ServicesRefrigerationCoolingCompany: Daikin Applied (www.daikinapplied.com; 2017AHR Expo booth No. C2509)Innovation: Pathfinder Air-cooled ScrewChillers with Variable VolumeRatio (VVR) TechnologyGreen BuildingCompany: Carrier (carrier.com/commercial; 2017 AHRExpo booth No. C1510)Innovation: Dual Stage Relief Economizer(DSRE)Company: Danfoss (www.danfoss.us; 2017AHR Expo booth No. C4506)Innovation: Danfoss CTM (ElectricalControlled TranscriticalMulti Ejector)SoftwareCompany: Nidec Motor Corporation/ U.S. MOTORS (www.usmotors.com; 2017 AHRExpo booth No. C3924)Innovation: Rescue SelectProgramming AppTools & InstrumentsHeatingCompany: Noritz America (www.noritz.com; 2017 AHR Expo boothNo. C5917)Innovation: Noritz CB Combi BoilerCompany: PEXOLOGY, Inc. (www.pexgun.com; 2017 AHRExpo booth No. C6618)Innovation: PEXGUN

COLUMNS0 3 / 1 7 CHILLER & COOLING TOWER TECHNOLOGY PICKSVentilationCompany: Titus (www.titus-hvac.com;2017 AHR Expo booth No.C3137)Innovation: Helios Digital DiffuserAbout AHR ExpoThe International Air-Conditioning, Heating,Refrigerating Exposition (AHR Expo), whichbegan more than 85 years ago as a heatingand ventilation show, has now grown intoone of the world’s largest HVACR events. TheExposition is held annually in key marketsand major cities across the U.S., hostingclose to 2,000 exhibitors and bringing incrowds of 60,000 industry professionals.The Show provides a unique forum for theHVACR community to come together andshare new products, technologies, andideas. The event is co-sponsored by ASHRAEand AHRI, and is held concurrently withASHRAE’s Winter Conference.About International ExpositionCompany, Inc. (IEC)International Exposition Company (IEC)is a Westport, Conn.-based trade showmanagement company. For more than 100years, the company has built its reputationon a track record of honesty, respect andfairness for exhibiting companies andshow attendees. IEC owns and managesthree major trade show events; the annualAHR Expo (International Air-Conditioning,Heating, Refrigerating Exposition), thebiennial AHR Expo-Mexico, and the biennialChem Show. Across the three events,attendance totals in excess of 70,000.For more information onthe 2017 AHR Expo, visitahrexpo.comDenso’s Corrosion Preventionon Cooling TowersRecently Hines, a large real estate developer,acquired the rights to the Wedge Tower indowntown Houston, TX. After inspection, itwas concluded that the cooling tower wouldhave to be rebuilt and the piping replaceddue to corrosion. Due to past successesexperienced with Denso on numerouscooling towers over the years, the decisionwas made to use the Denso PetrolatumTape System to provide long-term corrosionprotection on all of the piping, valves,flanges, etc.After a short on-site training session with aDenso representative, the contractor, MFRFluid & Air, was able to install the DensoPetrolatum Tape system quickly and easily.The scope of work consisted of minimalsurface preparation (SSPC SP-2/SSPC SP-3),followed by the application of a thin layerof Denso Paste S105, Densyl Tape witha 55% overlap, and a protective layer ofHDPE Outerwrap with SmartBand Strapping.For irregular areas such as flanges andvalves, the Denso Profiling Mastic was alsoapplied to provide a smooth profile to tapeover and then top coated with the DensoWeathershield 15 in place of the HDPEOuterwrap. Another successful applicationNeed ToReducePlant WaterConsumption?We can help.For more informationcontact us at:www.hydrothrift.comOverview of the complete Denso corrosion protectionsystem for cooling towers for pipes, valves and fittings.330-837-5141coolingbestpractices.com9

COLUMNS0 3 / 1 7RESOURCES FOR ENERGY ENGINEERSCHILLER & COOLING TOWER TECHNOLOGY PICKSEmbraco Launches ToolboxApplication for ContractorsEmbraco, a world leader in innovation andone of the largest manufacturers of hermeticcompressors for refrigeration, recentlylaunched the Embraco Toolbox, a digitalapplication that combines several uniquefeatures to provide support for contractors.Embraco has always been attentive to newdevelopments in the digital world, and notonly offers innovative solutions through itsproducts, but also provides leading servicesfor industry professionals to support themwith their day-to-day responsibilities.The Cooling Tower at Wedge Tower.gave the developer and contractor confidencethat the life of their cooling tower piping willbe extended while preventing corrosion formany years to come.About Denso North AmericaDenso North America Inc. is a subsidiaryof Winn & Coales International, a leadingmanufacturer of anti-corrosion coatingsthat include Protal liquid epoxies, Densopetrolatum tapes, mastics, primers, bitumentapes, butyl tapes, hot applied tapes, and afull line of marine pile protection systems.Winn & Coales was originally established as10coolingbestpractices.coma business in London, England, in 1883, andthe first petrolatum tape manufactured inthe UK was Denso tape, manufactured underlicense by Winn & Coales (Denso) Limited.Denso tape was developed over 80 yearsago for the "Long Life Protection" of buriedsteel pipelines against corrosion. The DensoSeaShield Marine Systems include fiberglassforms, epoxy grouts, underwater epoxies,injectable epoxies, petrolatum tape wrapsystems and much more.For more information, visit atwww.densona.com or call 1-888821-2300.The Embraco Toolbox App is the company'slatest offering to make the contractor’swork easier. "The application reaffirms ourtechnological leadership and allows us tofurther strengthen our relationship withcontractors and partners," shared Guilhermede Almeida, Marketing Manager, Embraco.Available in all countries and in morethan 10 languages, the Embraco ToolboxApp has seven features to help facilitatethe contractors’ day-to-day business. Thefeatures include: a search tool for thenearest distributor, the Embraco productcatalog, a cross-reference product guide, unitconverter, refrigerant ruler, a tool to identifycauses of the main cooling system problems,as well as all Refrigeration Club content.

COLUMNS0 3 / 1 7 CHILLER & COOLING TOWER TECHNOLOGY PICKSThe application’s launch will ensure accessto practical and efficient information and itcan be accessed, at first, via smartphoneswith iOS and Android operating systems,available for download in the App Storeand Play Store. A version for tablets will beavailable later this year.New website for the Refrigeration ClubThe Refrigeration Club (www.refrigerationclub.com), the segment’smain information website, has a new lookand many new features. One of them isthe interactive forum, a space dedicated tocontractors for exchanging information andsharing experiences.The tool makes it possible to searchfor a solution that best fits the intendedapplication’s parameters. The user justneeds to enter the necessary characteristics,such as size or cooling capacity and thedesired operating condition. It’s alsopossible to filter by refrigerant, voltage,efficiency and other criteria. After selectingthe search, the user can even simulate thecompressor’s behavior in the operatingcondition that he wants, which can beany standard norm as well as a customcondition. The software can also bedownloaded so that it can be used withoutan Internet connection.About EmbracoEmbraco is a multinational manufacturer in thesector of hermetic compressors for refrigerationfocused on innovation. The compressor is themain component responsible for producingcold in the refrigeration system. With globaloperations and an annual production capacityof 40 million units, Embraco offers solutionsthat are differentiated for their innovation andlow energy consumption. Its more than 11,000employees work in factories and offices locatedin Brazil (headquarters in Joinville, SantaCatarina, Brazil), China, Italy, Slovakia, Mexico,United States and Russia.For more information,visit www.embraco.com.“With the redesign, users can downloadexclusive materials, consult the trainingand lecture schedules and also print a Clubmembership card,” added Almeida.The new features complement existingsections that provide exclusive informationon topics including technical explanationsand tutorials on marketing, sales andsustainability.With over 50,000 visits per month,Refrigeration Club has become a resourcefor industry news and best practices. “Withthe latest updates, we plan to further expandthe number of users and continue to buildtrust in the Embraco brand and quality of ourproducts and services,” concluded Almeida.Product Selection SoftwareThe Product Selection Software replaces theelectronic catalog and assists customers inselecting the most appropriate solutions fordifferent refrigeration systems, providingmore independence for contractors, retailersand manufacturers.coolingbestpractices.com11

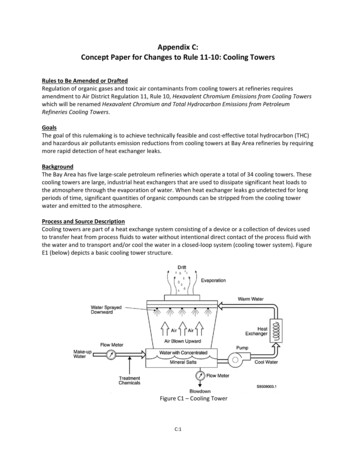

INDUSTRIAL COOLING SYSTEMS0 3 / 1 7Ball Corporation Engineers aREDUCTION IN COOLINGTOWER LOADBy Chiller & Cooling Best Practices Magazinec If you enjoy the occasional beverage froman aluminum can, there’s a decent chancethe can was made by Ball Corporation, acontainer manufacturing giant with facilitiesacross the world. The company’s facility inBall Corporation is an active participant in theEnvironmental Protection Agency’s ENERGY STARprogram.12coolingbestpractices.comSaratoga Springs, New York, services beveragecompanies throughout the northeastern UnitedStates. The plant operates four production linesproducing millions of aluminum cans per day.Ball’s Saratoga Springs plant has a longtrack record of improving energy efficiency.It is also an active participant in theEnvironmental Protection Agency’s ENERGYSTAR program. A recent project involvedthe engineering team implementing a heatrecovery project. This involved using a heatexchanger to simultaneously reduce the loadon the cooling tower and hot water heaters.Ball’s heat recovery project serves as a greatexample of clever energy engineering andtaking advantage of synergies between thesupport equipment within a manufacturingplant (i.e. air compressors, vacuum pumps,cooling towers, etc.). The team at Chiller &Cooling Best Practices Magazine spoke withBob Nelson, Engineering Manager at BallCorporation’s Saratoga Springs facility, to findout more about the heat recovery project andto learn how it impacted the plant’s overallenergy spend.

FREE SUBSCRIPTIONDIGITAL EDITION FREE WORLDWIDE PRINT EDITION FREE TO U.S. SUBSCRIBERSEVERY ISSUE CONTAINS BEST PRACTICES FORCooling Towers Central Plant ChillersCooling System ComponentsSubscribe Now!Subscribe at coolingbestpractices.com

INDUSTRIAL COOLING SYSTEMS0 3 / 1 7BALL CORPORATION ENGINEERS A REDUCTION IN COOLING TOWER LOADClosed-Loop Cooling System Nears CapacityThe Saratoga Springs plant has a closed-loop cooling system circulatingwater through air compressors, air dryers, a vacuum pump, decoratorinkers, and various other heat exchangers. The cooling system removesheat created during various manufacturing processes. Hot water istransferred to a cooling tower, placing significant demand on the tower.During periods of high humidity — with ambient temperatures in theupper 80s — the temperature of the cooling water returning from thetower reaches 90 F. During those design-day conditions, the system canexperience heat pump drop-outs, air compressor inefficiencies, andcompressed air dryers faulting due to high temperatures.“We have an Evapco closed-loop cooling tower, and we were right atthe capacity of that cooling tower in the summer time, around August,when it’s humid and it’s hot,” Nelson told us. “Our heat pump systemin the offices would sometimes kick out, and once in a blue moon we’dget to the point where one of our pieces of support equipment — likean air compressor — would want to kick out on high temp.”Obviously, Nelson wanted to ensure the comfort of the employeesworking in the offices. However, if an air compressor went down,production stopped, making it even more important to either replacethe cooling tower, or reduce its load.The machinery on the cooling loop includes a vacuum pump andvarious other heat exchangers for process equipment, such as “inkers.”Compressed air equipment puts a large demand on the cooling loop.Approximately 50 percent of the load on the cooling loop comes fromthe two compressed air systems at Ball’s Saratoga Springs plant. Themajor machinery in those systems includes two air compressors andtwo refrigerated air dryers, each of which is water-cooled.Heat Recovery Project Reduces Load on Cooling TowerWith so much depending on the cooling loop, the cooling tower’scapacity needed improvement. However, the capital expenditure forincreased cooling tower capacity would have been expensive. Instead ofreplacing the tower, the engineering team at Ball Corporation carefullyevaluated other options. Conveniently, another Ball plant was divestingitself of a heat exchanger, which Nelson creatively put to use at theSaratoga Springs plant.“I didn’t want to spend a lot of money to expand the cooling towercapacity,” Nelson explained. “One of our sister plants was putting insome cooling towers, and they had an Alfa Laval heat exchanger theywere not going to use anymore.” Incoming makeup water from thecity system is typically 55 degrees Fahrenheit. The team set up pipes totransport this water to the new heat exchanger and installed temperatureand pressure gauges. Using this heat exchanger has resulted in a 10 Freduction in the temperature of water returning to the cooling tower.Reducing the cooling tower load has had a number of other benefits.The cooling tower’s two 25-hp fans can now run at lower speeds,and the makeup water needed for the evaporation process hasbeen reduced.“The fans are running at a lower speed, and the makeup watervolume is down, More importantly, in the summer time whenthere’s the max load on the cooling tower, we’re not at the maxcapacity on the tower, so our office heat pumps aren’t kicking out.”— Bob Nelson, Engineering Manager at Ball Corporation’s Saratoga Springs facility14coolingbestpractices.com

INDUSTRIAL COOLING SYSTEMS0 3 / 1 7 anibWetrepxE6102ehtgnitnesePrylduoPrWhen to Installa VSD amoDetnalgPnwioBlelttBo“The fans are running at a lower speed, and the makeup water volumeis down,” Nelson told us. “More importantly, in the summer time whenthere’s the max load on the cooling tower, we’re not at the max capacityon the tower, so our office heat pumps aren’t kicking out.”The heat recovery project has also yielded other benefits. The heatgenerated inside the heat exchanger is used to pre-heat the incomingwater to certain production applications requiring heated water. Thishas reduced the natural gas consumption of the boilers.Cleverly Engineered Energy-Saving InstallationsThe engineers at Ball Corporation achieved energy savings with a heatexchanger, lowering demand on a hot water heaters and the coolingtower simultaneously. The cleverly engineered system has also improvedthe efficiency of the compressed air system, as it is now receiving coolerchilled water.“When I go through the math, it all kind of checks,” Nel

Drift Eliminators, the NC Everest Cooling Tower achieves the lowest measureable drift rate, down to 0.0005 percent of circulating water flow, so less water escapes the tower. NC Everest Cooling Tower sound levels have been independently verified per CTI ATC-128 test code by third-party CTI-licensed test agents and certified acoustical engineers.