Transcription

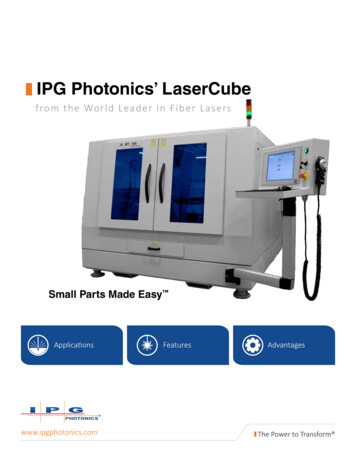

IPG Photonics’ LaserCubefrom the World L e ade r i n Fi b e r L a s e rsSmall Parts Made Easy Applicationswww.ipgphotonics.comFeaturesAdvantages

OverviewI P G Ph o to n i c s’ L a ser C ubeLeader in InnovationIPG Photonics is the world leader in high power fiberlasers and amplifiers. Founded in 1990, IPG pioneered thedevelopment and commercialization of optical fiber-based lasersfor use in a wide range of venues such as materials processing,medical, scientific and other advanced applications. Fiber lasershave revolutionized the industry by delivering superiorperformance, reliability and usability at a lower cost of ownershipcompared with conventional lasers, allowing end users to increaseproductivity and decrease operating costs. IPG is headquarteredin Oxford, MA with additional facilities throughout the world.IPG Photonics World Headquarters, Oxford MA, USASystem OverviewIPG’s LaserCube flat bed cutter isoptimized for cutting small parts. Using high-forcelinear motors built on a granite stage, it has thestability and acceleration needed for high-speedprecision machining. Utilizing IPG’s fiber lasers andcutting head technology, the LaserCube isinherently reliable with low operating andpart-processing costs.The LaserCube is the ideal cutting tool formetals, including mild steel, stainless steel, aluminum, copper, brass and exotic alloys. Being right-sized forsmaller parts, prototypes and smaller production runs, the LaserCube provides the most cost-effective capacityaddition and lowest cost of ownership of any professional laser cutter.Page 2

Wide Range of Metals & ThicknessesI P G Ph o to n i c s’ L a ser C ubeSystem VersatilityThe LaserCube is truly a general-purposelaser cutting system: high-velocity stages andhigh CW power lasers provide the fast cutting ofcarbon steel parts and reflective metals such ascopper, brass and aluminum.System Control is the key to flexibility. Storedprocess parameters allow precise setting andautomatic adjustment of laser power based on changes in cutting head velocity for complex contoured parts. The system hascomputerized control of two process gasses, with automatic monitoring of cutting head conditions.With many alloys or higher-value metals only available in smaller-size sheets, the 48 inch (1225 mm) cutting bed of the LaserCubeis optimally sized for economic material processing. Available in many different power configurations, you can buy exactly thepower you need.LaserCube Service & SupportAs the world leader in fiber lasers, IPG Photonics is your idealpartner to provide service and support for your precision laser cutting system.IPG has over 100 field service engineers, specializing in servicing industriallasers and laser systems used in 24x7 manufacturing. North Americanapplications and field service offices are located in Oxford, MA, Santa Clara,CA and Novi, MI. IPG’s Field Service Team is comprised of experienced andhighly-skilled engineers, supported by a global infrastructure including partswarehousing, applications scientists and the design and manufacturing teamsthat build the products.IPG understands the rigors of today’s manufacturing line and can provide customer support 24/7 depending on your needs. In additionto warranty coverage, IPG offers support packages ranging from on-demand and hourly paid service to scheduled preventivemaintenance and guaranteed response times. Whatever your service preference, IPG has an option that will meet your needs.Page 3

Benefits of Fiber LasersI P G Ph o to n i c s’ L a ser C ubeBenefits of Fiber LasersNo Need for Laser GassesAdjustment & Maintenance EliminatedSmaller Spot Size for Finer CuttingBetter Cutting Efficiency 37% Wall-plug EfficiencyFiber lasers are entirely solid state, with no mechanical cavity resonators ormirrors and no adjustable or replaceable parts within the laser. Light isoutputted along a flexible optical fiber pipe that is plugged directly into thelaser cutting head, eliminating the need for optics and adjustments in thebeam delivery path.With an emission wavelength of 1 micron, fiber lasers’ efficiency in cuttingmetals is better than CO2 alternatives, allowing for faster cutting of parts or the option of using a lower power laser. Typical estimatesshow an IPG fiber laser cutting 1 mm thick steel approximately 3.5 times faster than an equivalently powered CO2 system.IPG’s fiber lasers offer the highest wall-plug efficiency of any commercial laser. Not only is less electricity consumed in the cutting ofparts, but the cooling to remove unwanted heat is also proportionally reduced, decreasing the size of the electrical service needed tosupport the cutting tool installation. Achieving over 37% wall-plug power efficiency, combined with improved material couplingcharacteristics, IPG lasers typically use 70% less electrical energy than traditional CO2 alternatives in metal cutting applications.IPG’s Diode Burn-in FacilityEach laser diode is tested for a minimum of 1,000 hours with an elevatedtemperature and current before being certified for inclusion in the laser.Complete lasers are further tested for an additional 100 hours to ensure maximum reliability in the field.Page 4

Fiber Laser SelectionCho i c e o f F i ber L a ser Powe rThe LaserCube is offered with lasersranging in power from 500 W to4000 W. By offering such a broad range of options,IPG enables users to buy exactly the cuttingsolution they need.For thinner materials, the YLR-500 provides goodcutting performance in a small package that isintegrated within the workcell, reducing overallsystem footprint. The laser is air-cooled,eliminating the need for a chiller and furtherreducing electrical supply demands.Higher power YLS-series lasers are mounted externally to the workstation. They are water-cooled and housed in a NEMA 12,air-conditioned and sealed cabinet, providing additional protection for harsh environments.IPG YLS lasers are modular, with output of several fiber laser modules combined into a single output fiber. In the unlikely event of amodule failure, the remaining modules will immediately compensate for the loss by maintaining the output power and allowing partcutting to continue without interruption.Each laser is equipped with a 50 micronoutput fiber and can be used over a dynamicoperating range from 10% to full power withno change in beam divergence or beamprofile throughout the entire range. Thisallows a single laser to be utilized for bothhigh and low power applications, ideal forprocessing different thicknesses of metal.Page 5

OverviewI P G Ph o to n i c s’ L a ser C ubeFLC-30 Cutting HeadSystem Enclosure CDRH Class 1 Laser System Safety Interlocked Front Door with Laser-safe Viewing Windows Lightweight for High-speed Part Processing Maintenance-free Fiber Feed to Head Integrated Height Sensor Computer Control of Two Process Gas Supplies Manual or Automatic Door Options Access Panels on Sides of Workcell for Easy AccessMotion System Granite-based Stage for Stability High Force Direct Drive Linear Motors Position Encoder Resolution 1.0 µm Stages Sealed and Air-purged toMinimize Contamination 48 x 48 inch (1225 x 1225 mm) Cutting Area Motorized Z-axis Travel 75 mmUser Interface Intuitive HMI for Machine Control Multiple Screens for ProgrammingAll Process Parameters G/M-code Programming (Optional) CAD/CAM Software (Optional)Page 6

Why IPG’s LaserCube?Fast Cutting for Small PartsHigh-force Linear Drives andLow-mass HeadIPG’s Fiber ReliabilityNo Laser MaintenanceNo Mirrors to Clean or AlignLow Operating CostsLow Facilities CostsSome Models Don’t Require ChillersSize MattersRequires only 62 square feet ofFloor SpaceAffordableThe Right-sized Machinefor Your PartsExpanded CapabilitiesCut Brass and Copperwith Great ResultsSingle Point Service & SupportLaser and WorkstationDesigned, Built and Supported by IPGWorkcell Compact Footprint Minimizes Floor Space Rear Pass-through Door Option Light Tower Status Indicator (Optional)Position your Businessfor Growth with IPGPage 7

Laser Enable/Disable key. System programming is in GͲcode and MͲcode, with functions for setting laser power proportional to cutting speed and full lookͲahead contouring capability. Cutting HeadsI P G Ph o to n i c s’ FL C - 30 C utting Hea dLaserCube is compatible with customers’ existing CAD/CAM software packages with the adoption of toolͲspecific post process parameters. IPG also offers a variety of CAD/CAM software options; contact IPG for details. Lightweight2.95 kg as shownCutting Head Standard Features IPG has designed the FLC-30 specifically forTypical CAD/CAM Input File Formats metal cutting applications. Takingadvantage of the IPGfiber delivery, it has an extremelytoAI low weightGerber Pro/Engineer minimize moving mass when cutting small parts at highAutodesk IGES SolidEdge speed. Rated for laser power up to 10 kW and having anDWG Inventor SolidWorks integrated height sensor, the FLC-30 head is compatibleDXF across the LaserCube productrange.EPS Most CAD/CAM packages have compatibility with typical 2ͲD and 3ͲD DualLocking Connectoravailable withHLC-8 or LCA bayonetCAD formats, PDF and BMP files. NC Code STEP PDF etc . Within the cutting head, a user-replacable cover slide issituated between the cutting nozzle and the focusingCAM packages typically provide repair of data to remove any gaps and overlaps and output cutting files in standard GͲM Code. LaserCube additionally provides programmability of laser power, pressure control of cutting assist gas and an editable materials and laser parameter database. InterchangeableIPG Collimator with integrated aperature/ coolinglens and provides protection for the lens against anyCutting of multiple parts can be programmed by indexing a debris. An integrated sensormonitors the condition ofunitͲpart program within the LaserCube software for simple Ethernet connectionrectangular parts or more commonly using optional nesting the cover slide and providesa notification when asoftware available from CAD/CAM software vendors or IPG. contamination threshold is exceeded. Cover slideThe fine cutting beam and precision of the LaserCube stage replacement is a simple procedurethat requires nosystem allows small beam radii to be specified, enabling maximum usage and minimum wastage of source material. tools or alignment and is completedin a few seconds.for electronics With options for coaxial viewing, process monitoring and enhanced vision with image recognition forautomated operation, the FLC-30 is designed by IPG toprovide the best possible deliveryof the fiber laser light to the cutting surface.Nesting picture courtesy of CAMͲService GmbH1 X, Y, Z adjustmentof focus lensX, Y, Z manual ormotorized piercingversion for ZEasy to replacecover slideNozzle holder assemblyMonitoring of cover slidewith height sensor tomaintain constant distancepresence & contaminationWide range of cutting nozzlesPage 8

System ControlI P G Ph o to n i c s’ L a ser C ubeSystem Software & Control InterfaceOperator Control of the LaserCube is through a15 inch touchscreen monitor interface to aWindows-based CNC controller. The monitor, togetherwith a full-size keyboard and mouse is mounted to a swingarm at the front of the machine. System programming isin industry standard G-code and M-code, reducingtraining demands and allowing for accelerated learning.Windows-based HMIThe LaserCube is compatible with customers’ existingCAD/CAM software packages with the adoption oftool-specific post process parameters. CAM packagestypically provide repair of data to remove any gaps and overlaps and output cutting files in standard G-M Code. The LaserCubeprovides additional programmability that includes laser power, feed rate and control of cutting assist gas; all parameters being storedin an editable materials and laser parameter database. Please contact IPG for details of CAD/CAM software options.Application Support and System TrainingIPG maintains 12 Applications Labs throughoutNorth America, Europe and Asia. These centers are staffed byPhD Scientists and engineers with expertise in laser-materialinteractions. In addition to performing internal research, theseresources are available to the IPG user community throughcustom process development contracts. The overriding missionof these groups is to help IPG's customers.IPG Photonics Midwest OperationsNovi, MIIPG provides training to LaserCube customers at company headquarters following factory acceptance and again at thecustomer’s facility after installation. IPG factory training allows access to product engineers and applications specialists andgives a thorough overall grounding in the system and how it is used in your target application. Customer site training recapsfactory training for additional team members and can also cover preventive and first-line maintenance. IPG understands thatnew applications for the system continue to arise, and new employees continue to require training. We are happy to quotefollow-on training tailored specifically to meet your organizations ongoing and changing needs.Page 9

System SpecificationsI P G Ph o to n i c s’ L a ser C ubeSystem SpecificationsChoice of ModelSYS-4x4-YLR-500LaserCube Workcell with Integrated 500 W LaserSYS-4x4-YLR-1000LaserCube Workcell with Integrated 1000 W LaserSYS-4x4-YLS-1000LaserCube Workcell with Externally Mounted 1000 W LaserSYS-4x4-YLS-2000LaserCube Workcell with Externally Mounted 2000 W LaserSYS-4x4-YLS-4000LaserCube Workcell with Externally Mounted 4000 W LaserBeam DeliveryIPG Photonics’ FLC-D30 Cutting Head with Automatic Capacitive Height SensingReplaceable Cover Window, Integrated Coaxial Cutting Assist GasIncludes 1 Collimator & 1 Focus Lens per Customer SelectionWork EnvelopeX: 48.25 in. (1225 mm); Y: 48.25 in. (1225 mm); Z: 2.9 in. (75 mm)Motion PlatformLinear Stage H-gantry1.0 μm Resolution Linear EncodersMax Acceleration: 1G (10 m/s²)Maximum Speed39.0 in. (1000 mm)/ sec.Accuracy: PositioningRepeatabilityCutting SurfaceControls/ InterfaceProcess GasExhaustExternal Dimensions, WxDxH, mmin.Weight, lbs.kgPower (excluding laser & chiller)System Options:Automated DoorsHoneycomb InsertTelescoping Drawer with Metal Saw Tooth Cutting Points; Honeycomb Inserts (optional)Removable Debris Collection Bin; 200 lbs (91 kg) Load CapacityIndustrial Motion Controller, Full Look-ahead Contouring CapabilityLaser Power Proportional to Velocity, Windows-based CNC InterfaceG/M-code Programming, Editable Materials & Laser Parameter DatabaseElectronically Controlled Pressure Regulator for Gas up to 250 psi (1,725 kPA)Regulator for CuttingInputs for Two Cutting Gasses. On/Off & Pressure ControlsExhaust Plenum for Cutting Box & Debris DrawerRequires Customer to Provide House Exhaust2200 x 2600 x180086.6 x 102.3 x 70.877203500208-230 VAC, 47-63 Hz, 3 PH, 7000 W, 30 A BreakerPower Operated Front Doors for Easy Part Loading & UnloadingHoneycomb Insert Cutting Table Slats are Reversible to Quickly ConvertCutting Table to Accept Honeycomb InsertsJog PendantPendant & Control Software for 3-axis Manual Stage PositioningLight TowerSystem Status Indicator with Three Light Colors; Each with Solid, Flashing or Off ConditionsCollimating LensFocus LensCutting NozzlePage 10 25 μm ( 0.001 in.) 2 μm ( 0.0001 in.)Selectable from 50 mm to 100 mmSelectable (at time of order) from 120-250 mmSelectable from 1.0 mm to 2.5 mm Tip

Facility RequirementsWorkcell, WxD87 x 103 in. (2200 x 2600 mm)Additional 36” (900 mm) Service Access Required on All SidesYLS Laser, WxD34 x 32 in. (856 x 806 mm)Locate within 15’ (5m) of Workcell33 x 41 in. (840 x 1030 mm)Locate within 10’ (3 m) of LaserChiller, WxDElectrical PowerWorkstation with YLR-500 Laser460 V20 AWorkstation Only for YLS Lasers460 V20 AYLS-1000 including Chiller*460 V20 AYLS-2000 including Chiller*460 V40 AYLS-4000 including Chiller*460 V65 AChilled WaterExhaustProcess GasCutting head cooling. Approximately 0.25 CFM (0.75 l/min.) of DI waterbetween 700-750F (210-250C) for Laser Powers up to 4,000 W3200 CFMTypically Nitrogen or OxygenPressure Range 10-250 psi (69-1,725 kPa)*Externally mounted fiber lasers are powered independently from the cutting workstation and require a separatepower feedLegal notices: All product information is believed to be accurate and is subject to change without notice. Information contained herein shall legally bind IPGonly if it is specifically incorporated into the terms and conditions of a sales agreement. Some specific combinations of options may not be available. The userassumes all risks and liability whatsoever in connection with use of a product or its application. IPG, IPG Photonics, The Power to Transform and IPG Photonics’logo are trademarks of IPG Photonics Corporation. 2011-15 IPG Photonics Corporation. All rights reserved.Page 11

Sales & ServiceDevelopment, Sales & ServiceManufacturing, Development, Sales & ServiceIPG Photonics CorporationWorld HeadquartersOxford, MA USA 1 508 373 1100sales.us@ipgphotonics.comIPG Laser GmbHEuropean HeadquartersBurbach, DE 49 2736 44200sales.europe@ipgphotonics.comIRE- Polus Co.IPG RussiaFryazino, Moscow RU 7 (495) 702 95 89mail@ntoire-polus.ruChina 86 10 6787 3377 ext. 1020sales@ipgbeijing.comFrance 33 (0) 388 674 974sales.france@ipgphotonics.comIndia 91 80 2852 4861sales@ipgphotonics.inItaly 39 0331 170 6900sales.italy@ipgphotonics.comJapan 81 45 716 9831info@ipgphotonics.co.jpPoland 48 32 721 22 20sales.poland@ipgphotonics.comSingapore 65 62722663sales.singapore@ipgphotonics.comSouth Korea 82 42 930 2000ipgk@ipgphotonics.comSpain & Portugal 34 937 999 971sales.spain@ipgphotonics.comTurkey 90 (216) 306 0317sales.turkey@ipgphotonics.comUnited Kingdom 11 203 178 21 11sales.uk@ipgphotonics.comw w w .i pg p ho to nic s.c o mrev. 09.16

alternatives, allowing for faster cutting of parts or the option of using a lower power laser. Typical estimates show an IPG fiber laser cutting 1 mm thick steel approximately 3.5 times faster than an equivalently powered CO 2 system. IPG's fiber lasers offer the highest wall-plug efficiency of any commercial laser.