Transcription

We deliver values.drum andcontainer pumps

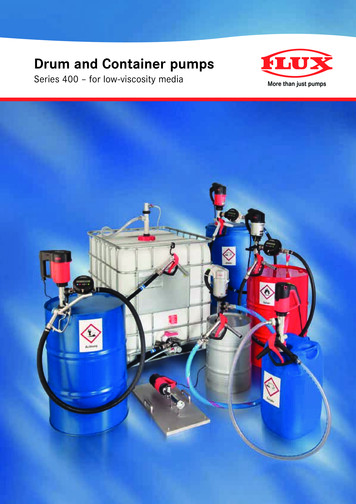

FLUX pumps: Perfection in pumpingDo you want to transfer differing liquids quickly and economically?Do you want to measure out varying quantities?Do you want to ensure total safety for the operator or theenvironment when pumping hazardous products?Do you want a pump which can cope even with peak loadings?Drum and Container pumps are used in almost every sector ofthe processing and manufacturing industries.Initially designed for decanting and transfer operations ofdiffering liquids from drums and containers, current productiontime scales are now requiring these pumps to be used onapplications with extended run times and frequent stoppingand starting.Whenever liquids are pumped out of a drum or container, FLUXcan supply a unit of unsurpassed quality: all FLUX pumps areavailable in different materials. You can choose between a pumpwith a mechanical seal or a sealless version. One of the uniquefeatures of both, the polypropylene and the PVDF mechanical sealversion, is the steel cored inner tube providing, through increasedlateral stability, a longer service life. Both, mixed centrifugal andaxial impellers are available to suit differing head and flow applications. And if you want to combine the pumping and mixingoperation FLUX also have the pump you need.Another feature is the FLUX quick assembly system.This allows for simple and speedy pump strip down.Of course, FLUX pumps require a powerful and reliable drivemotor. A wide range of electric or compressed air motors providesa matched power unit throughout the pump range – even inhazardous locations or when pumping highly flammable liquids.To complete the comprehensive FLUX program, a wide rangeof top class accessories is available – from protection againstFor further information to our pre-configuredemission of noxious vapours through to the volumetric measurementdrum-pump kits see our brochure FLUX pump kitsof liquids.2

Table of contentsWhich material goes best with which liquidDesign concepts of FLUX drum45–9and container pumpsFLUX drum pumps (pump tube sets)10 – 13in stainless steel (S), aluminium alloy (AL)and Hastelloy C (HC) in detail,together with performance chartsFLUX drum pumps (pump tube sets)14 – 17in polypropylene (PP) andpolyvinylendene fluoride (PVDF) in detail,together with performance chartsFLUX container pump (pump tube set)18in polypropylene (PP) in detail,together with performance chartFLUX drum and container pumps19for horizontal useFLUX quick action couplingFLUX motor data in detail20 – 27Summary of FLUX motor –28 – 29pump combinationOutline of FLUX drum and30 – 31container pumps with accessoriesDimensions of FLUX drum pumps32 – 34and drive motors3

FLUX drum and container pumps –which material goes best with which liquidstainless steel 1.4571/316 Ti (S) up to 100 C*Zone 0Suitable for highly flammable liquids (up to tempera-Area in which a hazardous and explosivetures of class T4) as well as for all neutral and non-atmosphere of gases, vapours or fogsflammable, thin liquids like solvents, organic acids,exists permanently or for a long period ofdilute anorganic acids and alkalis.time. In general such conditions existcertified for use in Zone 0*.inside of drums or containers only.Examples of suitable liquids: acetone, alcohol, ammo-The following pump models are tested andnia, petrol, flammable solvents, nitrocellulose varnishes,certified according to ATEX-Directive 94/9/perchlorethylene, trichlorethylene, toluene, potassicEC, category 1/2, for transferring highlyalkali, soda alkali, phosphoric acid (up to 60 %), sul-flammable liquids out of portable drumsphuric acid (up to 7,5 % and more than 96 %), fruitor containers in hazardous areas:juices, milk, salad oil andall liquids listed for aluminium alloy.F 424 S – EC Type examination certificatehastelloy C (HC) up to 120 CF 425 S – EC Type examination certificatePTB 11 ATEX 5009 XSpecially designed for pumping alternativelyPTB 11 ATEX 5009 Xhighly flammable and chemically aggressiveF 426 S – EC Type examination certificateliquids.certified for use in Zone 0*.Examples of suitable liquids: hydrofluoric acid,PTB 11 ATEX 5009 XF 430 S – EC Type examination certificatePTB 11 ATEX 5009aqua regia, oleum, hydrochloric acid (up to 30 %),F 430 HC – E C Type examination certificatesulphuric acid, various mixed acids and all liquidsPTB 00 ATEX 4110 Xlisted for aluminium alloy and stainless steel.In selecting a pump model, please alwaysaluminium alloy AlMg5 (AL) up to 100 Ccheck material of pump and material ofSuitable for neutral, hardly flammable liquids.seals for compatibility.Examples of suitable liquids: drilling emulsion, dieseloil, fuel oil, hydraulic oil, non-flammable solvents,Due to the enormous variety and complexityliquid soap, liquid wax, water.of industrial chemicals, together with therange and variation of FLUX products, wepolypropylene (PP) up to 50 Ccan only list some of all the suitableSuitable for both, chemically aggressive and neutralliquids. But we would be glad to send youliquids, together with hardly flammable liquids sucha detailed Resistance Chart.as acids and alkalis.Examples of suitable liquids: formic acid, ammonia,boric acid, chromic acid (up to 10 %), liquid fertilizers,acetic acid, photo developers, hydrofluoric acid (up to70 %), fruit acids, potassic alkali, copper chloride, lacticacid, soda alkali, phosphoric acid, hydrochloric acid,A FLUX drum pump is always asulphuric acid (up to 80 %), distilled water. Two-Component-Team consisting ofa drive motor and a pump (tube set).polyvinylendene fluoride (PVDF) up to 100 CBoth component parts are universallySuitable for both, chemically aggressive and neutralinterchangeable. For further detailsliquids, together with hardly flammable liquids such asplease see page 10 onwards.acids and alkalis.Examples of suitable liquids: hydrobromic acid, chromic acid, chloric acid, hydrofluoric acid, sodium hypochlorite, nitric acid (up to 75 %), sulphuric acid and allliquids listed for polypropylene (except soda alkali).4

The sealless FLUX F 424The liquids to be pumped areabrasive, but they do not leaveFlexible couplingany deposits. Dry running of thebetween motorpump must not cause any pro-and pumpblems. You are looking for alightweight, general purposepump in stainless steel, poly-O-ring to sealpropylene or polyvinylendenebetween inner andfluoride.outer tube (not in the1liquid section)The inner tube supports thepump shaft, which is lubricatedby the liquid. The level of theliquid in the inner tube alwaysRadial shaft seals tocorresponds to that in the drumprevent liquid and/oror container.vapours entering thecoupling areaSpecial advantages:– Safe dry running of the pump– No wearing of seals– The liquid being pumped isNon-metallic helixnot contaminated by the shaftshaped shaft supportlubricantbearing– Inner tube and helix shapedsupport bearings completelyself-drainingHere a FLUX pump in seallessversion is your pump.Pressure relief portsBottom bearingType F 424assembly which centersthe shaft within theinner tubeImpeller in ETFE1Explosion-proof versions available5

The FLUX F 430 with mechanical sealThe pump must be used withmany varying liquids, conseFlexible couplingquently the smallest residual leftbetween motor andwithin the pump is unacceptable.pumpYou want to pump adhesive substances like paints or liquidswhich tend to crystallize orharden.The inner tube houses the shaft.1It is sealed at the bottom by amechanical seal through whichthe shaft passes. Consequently2the shaft does not come intocontact with the liquid exceptSteel cored inner tubefor the small section between3in PP and PVDF pro-the impeller and seal.vides the ultimate instability. This coreSpecial advantages:prevents elongation– The shaft support bearingsof the plastics at highare isolated from the liquidtemperatures. This– Steel cored inner tube in PPresults in an extendedand PVDF pumps. This pre-service life of thevents elongation of the plastics,mechanical sealeven at high temperatures– E xtended service life throughwell proven seal designHere a FLUX pump withmechanical seal is the bestchoice.Packaging of themechanical seal androtary shaft sealType F 430adjacent to eachother ensures themaximum integrityof the sealed innertubeImpeller in ETFE16Products complying with EC 1935/2004and EU 10/2011 available233A-certified products availableExplosion-proof versions available

The FLUX F 425 for emptying drums up to 99,98 %You are not prepared to acceptany residual liquid in the drumFlexible couplingin order to avoid problems andbetween pump andcosts of disposal or to avoidmotorlosing high value liquids.Before the motor is switched off,the flowback stop valve at thepump inlet must be closed byoperating the lever. This preventsthe liquid flowing back into theempty drum.Operating leversto close/openthe flowback stop valveSpecial advantages:1– Especially easy operating ofthe pump– Optimum use of the liquids– Remains of less than 0,05 lHere the FLUX F 425 foremptying drums up to 99,98 %is your pump.Packaging of themechanical seal androtary shaft seal adjacentType F 425to each other ensures themaximum integrity of thesealed inner tubeImpeller in ETFEFlowback stop valveFlowback stop valveopenclosed1Explosion-proof versions available7

The FLUX mixing pump F 426You want to mix and pumpFlexible couplingliquids within a closed drum orbetween pump andan open container.motorBy turning the adjusting lever, thepump can either mix or pump.Liquids can also be mixed evenwhen being transferred toanother container.Special advantages:– No changes in the outerAdjusting lever to setdiameter of the pump tube inthe pump to mixing orstainless steel as the pumpdischargeworks without any additional1components– Light and handy design– P ump/drum connection glandsare also in vapour-proofversion availableHere the FLUX mixing pump isthe right pump for you.Mixing openingsPackaging of the mechanicalType F 426seal and rotary shaft sealadjacent to each other ensuresthe maximum integrity of thesealed inner tubeImpeller in ETFEmixing18Explosion proof versions availablepumping

The FLUX F 427 can be taken apart completelyYou want a safe pumping offood, cosmetic or pharmaceuticalproducts. The operating conditions require an easy and quick1Clamp connectioncleaning or sterilization of thepump at regular intervals toavoid any contamination of the2product, e.g. when pumpingvarying liquids or differentcolours as well as quick-dryingEasy to strip downor film forming liquids.– Easy to clean!Outer tubePlug-in bearingSpecial advantages:–A ll wetted parts are made ofstainless steel, PTFE or ETFE– The pump can be quicklyInner tubestripped down for cleaningor sterilizationShaft–N egligible wear by friction onseals and bearingsFLUX facilitates aseptic pumpingof delicate products. The sanitaryHere a FLUX sanitary pumppump can be stripped down-is your pump.within a few seconds because ofits ingenious design.The F 427 does not have anyinaccessible voids. This allowsyou to completely clean theType F 427pump at any time.Relief openingBearing housingImpeller1Products complying with EC 1935/2004and EU 10/2011 available23A-certified products available9

FLUX drum pumps in stainless steelFLUX drum pumps in stainless steel 316 Ti –except sanitary pump F 427 S – are approvedaccording to ATEX-Directive 94/9/EC for usein Zone 0, temperature class T4, for transferringhighly flammable liquids out of portable drums orcontainers.With the help of the performance charts youcan compare the delivery rates achieved byFBM 4000 ExF 460 ExF 460 Ex ELF 460-1 ExF 416 ExF 416-2 Exeach pump model powered by the various FLUXmotors. Detailed motor data are shown onpages 21 to 29.When using the pump with a discharge hose(of approx. 6,5 ft) and a quick action tap, thedelivery rate will be approx. 18 GPM.Depending on the motor type a 55 GAL drumcan be emptied within 3 – 4 minutes.The delivery rates shown in the performanceof the pump.Special version for horizontal use on request.This pump version will achievea higher delivery rate!F 458F 458 ELF 458-1F 414F 457F 457 ELThis pump version will achievea higher delivery head!FEM 4070Max. viscosity per pump and motor,please see pages 28 and 29.motor F 416 Ex, F 416-1 Exor F 416-2 Exmotor FEM 4070H [mWS]motor FBM 4000 ExFP 424 Ex S-43/38 with zone separationcharts are obtained at the outlet connection0010201030204030H [ft]2470206016504012308204010Detailed motor data see pages 21 to 2910004080120160

drum pump (tube set) in stainless steel, thread on outlet G 1¼ male, motors on page 21type/curveFP 424 Ex S-43/38(1FP 424 Ex S-43/37 Z(1FP 424 Ex S-50/45 Z(1versionseal typesealless within the liquid sectionmaterialshaft in stainless steel 316 Ti, impeller in ETFE, o-ring in FKMmax. temperature212 F1 1 2 immersion length 27 424 22 007 / 4,85 Ibs424 22 107 / 4,85 Ibs424 22 207 / 6,61 Ibsimmersion length 39 424 22 010 / 6,39 Ibs424 22 110 / 6,39 Ibs424 22 210 / 8,81 Ibsimmersion length 47 424 22 012 / 7,27 Ibs424 22 112 / 7,27 Ibs424 22 212 / 10,6 Ibstype/curveFP 425 Ex S-41/34(1,2F 426 S-41/38F 427 S3-43/38version99,98 % drum emptyingmixing pumpsanitary pumpouter-Ø11 1611 16part no. / weightseal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMsealless within the liquid sectionmaterialshaft in stainless steel 316 Ti, seal in FKM, impeller in ETFEshaft in stainless steel 316 Ti,impeller in ETFE, o-ring in FKMmax. temperature212 F119 32 119 32 111 16 immersion length 27 425 22 008 / 6,61 Ibs–427 20 307 / 6,61 Ibsimmersion length 39 425 22 011 / 8,37 Ibs426 20 010 / 8,37 Ibs427 20 310 / 6,39 Ibsimmersion length 47 425 22 013 / 9,70 Ibs426 20 012 / 9,70 Ibs427 20 312 / 7,27 Ibstype/curveF 430 S-41/38(1F 430 S-41/37 Z(1F 430 S-50/45 Zouter-Øpart no. / weightversionseal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMmaterialshaft in stainless steel 316 Ti, seal in FKM, impeller in ETFEmax. temperature212 F119 32 119 32 2 immersion length 27 430 20 107 / 5,29 Ibs430 20 407 / 5,29 Ibs430 20 207 / 7,49 Ibsimmersion length 39 430 20 110 / 6,61 Ibs430 20 410 / 6,61 Ibs430 20 210 / 9,92 Ibsimmersion length 47 430 20 112 / 7,93 Ibs430 20 412 / 7,93 Ibs430 20 212 / 11,46 Ibsouter-Øpart no. / weightaccessoriesmotor F 457 or F 457 EL1DN 19 part no. 959 04 061hose connection complete with nut G 1¼ femalePump models in immersion lengths of 8 – 118 (in steps of 4 ) on requestwith zone separation2DN 25 part no. 959 04 041Model for higher delivery head on request.motor F 458, F 458 EL, F 460 Exor F 460 Ex ELmotor F 458-1 or F 460-1 ExValues 10% with water (68 F) and a voltage of 230 Volt. Curves with a voltage of 120 Volt / 60 Hz are similar.11

FLUX drum pumps in aluminium alloy and hastelloy CFLUX drum pumps in aluminium alloy AlMg5are suitable for transferringneutral, hardly flammable liquids.FLUX drum pumps in hastelloy C are approved according to ATEX-Directive 94/9/ECfor use in Zone 0, temperature class T4, fortransferring highly flammable liquids out ofportable drums or containers. In addition,FBM 4000 ExF 460 ExF 460 Ex ELF 460-1 ExF 416 ExF 416-2 Exhastelloy C is chemically resistant to most ofacids and alkalis, allowing the most universal use of this pump type.With the help of the performance chartsyou can compare the delivery ratesachieved by each pump model poweredby the various FLUX motors. Detailedmotor data are shown on pages 21 to 29.When using the pump with a dischargehose (of approx. 6,5 ft) and a quick actiontap, the delivery rate will be approx.a 55 GAL drum can be emptied within3 – 4 minutes.The delivery rates shown in the performancecharts are obtained at the outlet connectionF 458F 458 ELF 458-1F 430 AL-41/3818 GPM. Depending on the motor typeF 414F 430 HC-40/38of the pump.motor F 416 Ex, F 416-1 Exor F 416-2 ExFEM 4070motor FEM 4070H [mWS]motor FBM 4000 ExF 457F 457 EL0010201030204030H [ft]2470206016504012308204012Detailed motor data see pages 21 to 2910004080120160

Drum Pump (tube set) in Aluminium Alloy, thread on outlet G 1¼ A (BSP 1¼ male), motors on page 21Type/CurveF 430 AL-41/38F 430 AL-41/37 ZF 430 AL-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in NBRMaterialshaft in Stainless Steel 316 Ti, seal in NBR, impeller in ETFEMax. temperature212 F (for short periods)Outer-Ø119 32 119 32 2 430 10 107 / 2,64 lbs430 10 407 / 2,64 lbs430 10 307 / 3,30 lbsPart No. / WeightImmersion length 27 Immersion length 39 430 10 110 / 3,30 lbs430 10 410 / 3,30 lbs430 10 310 / 3,96 lbsImmersion length 47 430 10 112 / 3,74 lbs430 10 412 / 3,74 lbs430 10 312 / 4,63lbsPump models in immersion lengths of 8 – 78 (in steps of 4 ) on request.Drum pump (tube set) in Hastelloy C, thread on outlet G 1¼ A, (BSP 1¼ male), without motorType/CurveF 430 HC-40/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FFKMMaterialshaft in Hastelloy C, seal in FFKM, impeller in ETFEMax. temperature248 FOuter-Ø19 16 Part No. / WeightImmersion length 27 430 30 107 / 5,07 lbsImmersion length 39 430 30 110 / 6,61 lbsImmersion length 47 430 30 112 / 7,71 lbsOther immersion lengths on request.This pump version will achievea higher delivery rate!motor F 457 or F 457 ELThis pump version will achievea higher delivery head!motor F 458, F 458 EL, F 460 Exor F 460 Ex ELMax. viscosity per pump and motor,please see pages 28 and 29.motor F 458-1 or F 460-1 ExValues 10% with water (68 F) and a voltage of 230 Volt. Curves with a voltage of 120 Volt / 60 Hz are similar.13

FLUX drum pumps in polypropyleneFLUX drum pumps in polypropylene areused for chemically and aggressive liquidssuch as acids and alkalis, together with mostthin and neutral liquids.With the help of the performance chartsFEM 4070you can compare the delivery ratesF 457F 457 ELachieved by each pump model poweredby the various FLUX motors.Detailed motor data are shown on pages21 to 29.When using the pump with a dischargeF 458F 458 ELF 458-1hose (of approx. 6,5 ft) and a quick actiontap, the delivery rate will be approx.18 GMP.F 414Depending on the motor type a 55 GALdrum can be emptied within 3 – 4 minutes.The delivery rates shown in the performancecharts are obtained at the outlet connectionof the pump.Special version for horizontal use onF 430 PP-40/33request.F 460 ExF 460 Ex ELF 460-1 ExFBM 4000 ExF 416 ExThis pump version will achievea higher delivery rate!motor FBM 4000 Ex14Detailed motor data see pages 21 to 29.This pump version will achievea higher delivery head!motor F 416 Ex, F 416-1 Exor F 416-2 ExF 416-2 ExMax. viscosity per pump and motor,please see pages 28 and 29.motor FEM 4070

Drum Pump (tube set) in Polypropylene, thread on outlet G 1¼ A (BSP 1¼ male), motors on page 21Type/CurveF 424 PP-41/36F 424 PP-41/35 ZF 424 PP-50/38F 424 PP-50/43 ZVersionSeal typesealless within the liquid sectionMaterialshaft in Hastelloy C, impeller in ETFE, o-ring in FKMMax. temperature122 F1 1 2 2 Immersion length 27 424 40 007 / 1,76 lbs424 40 107 / 1,76 lbs424 40 207 / 1,98 lbs424 40 307 / 1,98 lbsImmersion length 39 424 40 010 / 2,20 lbs424 40 110 / 2,20 lbs424 40 210 / 2,86 lbs424 40 310 / 2,86 lbsImmersion length 47 424 40 012 / 2,64 lbs424 40 112 / 2,64 lbs424 40 212 / 3,53 lbs424 40 312 / 3,53 lbsOuter-Ø19 3219 32Part No. / WeightType/CurveF 425 PP-50/34F 426 PP-50/33Version99,98 % drum emptyingmixing pumpSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impeller in ETFEMax. temperature122 FOuter-Ø2 2 Immersion length 27 425 40 048 / 3,53 lbs–Immersion length 39 425 40 051 / 4,41 lbs426 40 001 / 3,97 lbsImmersion length 47 425 40 053 / 5,07 lbs426 40 002 / 4,63 lbsPart No. / WeightType/CurveF 430 PP-40/33F 430 PP-40/33 ZF 430 PP-50/43 ZF 430 PP-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impeller in ETFEMax. temperature122 F1 1 2 2 Immersion length 27 430 40 107 / 2,42 lbs430 40 407 / 2,42 lbs430 40 207 / 2,42 lbs430 40 307 / 2,42 lbsImmersion length 39 430 40 110 / 3,08 lbs430 40 410 / 3,08 lbs430 40 210 / 3,30 lbs430 40 310 / 3,30 lbsImmersion length 47 430 40 112 / 3,53 lbs430 40 412 / 3,53 lbs430 40 212 / 3,75 lbs430 40 312 / 3,75 lbsOuter-Ø9 169 16Part No. / WeightAccessoriesHose connection complete with nut G 1¼DN 19 Part No. 959 04 053DN 25 Part No. 959 04 052Pump models in immersion lengths of 8 – 118 mm (in steps of 4 ) on request.motor F 457 or F 457 ELmotor F 458, F 458 EL, F 460 Exor F 460 Ex ELmotor F 458-1 or F 460-1 ExValues 10% with water (68 F) and a voltage of 230 Volt. Curves with a voltage of 120 Volt / 60 Hz are similar.15

FLUX drum pumps in polyvinylidene fluorideFLUX drum pumps in polyvinylidene fluorideare used for both chemically aggressive andhardly flammable liquids such as acids andalkalis, together withmost thin and neutral liquids.FEM 4070With the help of the performance chartsF 457F 457 ELyou can compare the delivery ratesachieved by each pump model poweredby the various FLUX motors.Detailed motor data are shown on pages21 to 29.F 458F 458 ELF 458-1When using the pump with a dischargehose (of approx. 6,5 ft) and a quick actiontap, the delivery rate will be approx.F 41418 GPM.Depending on the motor type a55 GAL drum can be emptied within3 – 4 minutes.The delivery rates shown in the performancecharts are obtained at the outlet connectionF 424 PVDF-41/36of the pump.F 460 ExF 460 Ex ELF 460-1 ExFBM 4000 ExF 416 ExThis pump version will achievea higher delivery rate!motor FBM 4000 Ex16Detailed motor data see pages 21 to 29.This pump version will achievea higher delivery head!motor F 416 Ex, F 416-1 Exor F 416-2 ExF 416-2 ExMax. viscosity per pump and motor,please see pages 28 and 29.motor FEM 4070

Drum Pump (tube set) in Polyvinylidene fluoride, thread on outlet, G 1¼ A (BSP 1¼ male), motors on page 21Type/CurveF 424 PVDF-41/36F 424 PVDF-41/35 ZF 424 PVDF-50/38VersionSeal typeseallessMaterialshaft in Hastelloy C, impeller in ETFE, o-ring in FKMMax. temperature176 F119 32 119 32 2 Immersion length 27 424 60 007 / 2,42 lbs424 60 107 / 2,42 lbs424 60 207 / 3,08 lbsImmersion length 39 424 60 010 / 3,08 lbs424 60 110 / 3,08 lbs424 60 210 / 4,18 lbsImmersion length 47 424 60 012 / 3,53 lbs424 60 112 / 3,53 lbs424 60 212 / 4,85 lbsOuter-ØPart No. / WeightType/CurveF 430 PVDF-40/33F 430 PVDF-40/33 ZF 430 PVDF-50/43 ZF 430 PVDF-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impeller in ETFEMax. temperature176 F19 16 19 16 2 2 Immersion length 27 430 60 107 / 3,08 lbs430 60 407 / 3,08 lbs430 60 207 / 3,08 lbs430 60 307 / 3,75 lbsImmersion length 39 430 60 110 / 3,75 lbs430 60 410 / 3,75 lbs430 60 210 / 3,75 lbs430 60 310 / 4,63 lbsImmersion length 47 430 60 112 / 4,41 lbs430 60 412 / 4,41 lbs430 60 212 / 4,41 lbs430 60 312 / 5,51 lbsOuter-ØPart No. / WeightAccessories Hose connection with nut G 1¼DN 19 Part No. 959 04 101DN 25 Part No. 959 04 102Pump models in immersion lengths of 8 – 118 (in steps of 4 ) on request.motor F 457 or F 457 ELmotor F 458, F 458 EL, F 460 Exor F 460 Ex ELmotor F 458-1 or F 460-1 ExValues 10% with water (68 F) and a voltage of 230 Volt. Curves with a voltage of 120 Volt / 60 Hz are similar.17

FLUX container pump in polypropylene in detailThe powerful, extremely lightweight and easy-to-handle solution fortransferring corrosive acids and alkalis and almost every thin andhardly flammable liquid out of larger containers: FLUX containerpump type F 430 PP-100/50 in polypropylene. Especially designedfor emptying 250 GAL-Containers, this pump provides the highF 457safety and ease of handling you do appreciate on FLUX drumpumps.The use of this pump allows to dispense with floor drains, to minimize leakage risks and to eliminate residual liquid within suctionpipes and subsequent handling cost. A compression gland or avapour-proof gland always secures the pump in a vertical positionwithin the dome of the container.F 458-1Depending on the motor type, this pump will achieve a maximumdelivery rate of 28 GPM and a maximum delivery head of 105 ftliquid column in transferring liquids up to a maximum viscosity of150 mPas (cP).F 430 PP-100/50FLUX container pumpF 430 PP-100/50in combination with1 Commutator motorType F 457/F 458-12 Three-phase gearmotorType F 414F 414detailed motor datasee pages 21 to 29Values 10% with water (68 F) and a voltage of 230 Volt. Curves with a voltage of 120 Volt /60 Hz are similar.Container pump (tube set) in Polypropylene, thread on outlet G 1¼ A (BSP 1¼” male), motors on page 21TypeF 430 PP-100/50Versionwith impellerSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impeller in PolypropyleneMax. temperature122 FOuter-Ø4 on the pump bodyPart No./WeightImmersion length 39”430 40 510 / 5 lbsImmersion length 47”430 40 512 / 5 lbsImmersion length 60”430 40 515 / 6 lbsAccessories Hose connection with nut G 1¼18DN 25 Part No. 959 04 052DN 32 Part No. 959 04 054

centrifugal pumps for horizontaland vertical usecentrifugal pumps for horizontal and vertical usetypeF 430 S-41/38 TRF 430 PP-40/33 TRseal typemechanical seal in ceramic oxide, PTFE/carbon,o-rings in FKMmechanical seal in ceramic oxide, PTFE/carbon,o-rings in FKMmaterialstainless steel 1.4571, seal in FKM,impeller in ETFEpolypropylene, shaft in hastelloy C, seal in FKM,impeller in ETFEdimensionssee dimensional drawingmax. temperature212 F122 Fouter-Ø119 32 19 16 part no. / weight430 20 002 / 3 Ibs430 40 002 / 1,3 Ibshose connections complete for inletmaterialstainless steelwith brass nut G 2 femalepolypropylene with nut G 2 femaleDN 32959 04 059959 04 010DN 38959 04 060959 04 011You will find the suitable motors and performance charts for the pump F 430 S-41/38 TR on page 10 and 11,for the pump F 430 PP-40/38 TR on page 14 and 15.DimensionsF 430 S-41/38 TRF 430 PP-40/33 TRF 430 S TRFLUX quick action coupling SSK 400FLUX Quick Action Coupling Type SSK 400 suits all FLUX drum and container pumps Type F 424, F 425, F 426, F 427and F 430 and allows a quick assembly/disassembly of pump and motor within a few seconds only. This allows the useof several pump tube sets with one drive motor only. The quick action coupling SSK 400 consists of a clamping elementwhich is mounted onto the pump tube set and a threaded ring which is screwed onto the drive motor.typequick action couplingSSK 400 completepart no.consisting of threaded ring (motor side)and clamping element (pump side)001 10 802threaded ringto be screwed onto the drive motor001 10 800clamping elementto be mounted onto the pump tube set001 10 804or as individual parts:19

20

FLUX brushless motor FBM 4000 Exin detailThe brushless motor type FBM 4000 Ex is featuringa compact design, a robust double shell housing inaluminium and a very low noise level. The explosionproof motor is tested and certified according to thelatest ATEX-Directive 94/9/EC.EC-Type-Examination Certificate PTB 10 ATEX 1054 X.The combined on/off switch and easy to use speedcontroller allow precise dispensing operations.Electronic monitoring of speed, voltage andtemperature.An integral no-volt release monitors the power andprevents unintentional re-start of the pump. Thisfeature ensures additional safety for the user.Due to negligible wear, the brushless motor designguarantees lowest cost of ownership, even withcontinuous use.Brushless motor, explosion-proof to II 2G Ex d e IIC T6 / T5 Gb,protection class I. Jet-proof according to IP 55. With power supply cable, 16 long,with safety plug (not tpart no. versionwith no-volt releasesafety circuitFBM 4000 Ex600 W230 V50-60 Hz13,66 Ibs400 01 000Accessoriespart no.System CEAGSystem StahlCEE Explosion-proofplugexplosion-proof to II 2 G Ex de (ia) II C T6 / T5, 3-pole, 220-240 Volt,jet-proof to IP 55937 01 030937 01 018CEE Explosion-proofsocketexplosion-proof to II 2 G Ex de (ia) II C T6 / T5, 3-pole, 220-240 Volt,jet-proof to IP 55937 50 041937 50 022Earth (ground) wirewith crocodile clip13 ft long6 ft long, reinforced version931 90 023931 90 015sarrying handleallowing easy immersion and removal of the pump001 10 55721

FLUX commutator motor F 460 Exin detailExplosion-proof commutator motor type F 460 Ex featuringa compact design, a robust double shell housing in aluminiumand a very low noise level. Tested and certified accordingto ATEX-Directive 94/9/EC.Type F 460 Ex EL, 230 volt, with infinitely variable speedcontrol included in the switch knob for an easy control ofthe delivery rate.EC-Type-Examination Certificate PTB 10 ATEX 1053 X.An improved ventilation system provides optimal coolingand ensures an extended service life.Additional safety by an integral no-volt release to preventfrom any unintentional re-starting after a voltage discontinuity.The commutator motor Type F 460-1 Ex is identical withType F 460 Ex, but has a considerably higher capacity ofF 460 Ex (pict)F 460 Ex ELF 460-1 Ex700 watt. This model is recommended for applicationsrequiring a higher delivery rate or when transferringmedium viscosity products or liquids with a higher density.120 V, 60 Hz version UL-listed, File No. E67399, class I,group C D.Commutator motor, explosion-proof to II 2 G Ex d e IIC T6 / T5 Gb, protection class I in 230, 240 or 110 volt,protection class III in 42, 24 or 12 volt. Jet-proof according to IP 55, version with novolt release, with power supplycable, 16 long, with safety plug (not explosion-proof). – 42, 24 and 12 volt version without plug.TypeCapacityVoltageFrequencyWeightwithout variablespeed controlF 460 Ex UL460 W120 V60 Hz11,24 lbs–460 00 031F 460 Ex460 W230 V50 – 60 Hz11,24 lbs–460 00 026F 460 Ex410 W24 VDC11,24 lbs–460 00 003F 460 Ex230 W12 VDC11,24 lbs–460 00 004F 460 Ex EL230 W230 V50 Hz11,24 lbs460 00 028–F 460-1 Ex UL700 W120 V60 Hz13,

FLUX drum pumps in stainless steel FLUX drum pumps in stainless steel 316 Ti - except sanitary pump F 427 S - are approved according to ATEX-Directive 94/9/EC for use in Zone 0, temperature class T4, for transferring highly flammable liquids out of portable drums or containers. With the help of the performance charts you