Transcription

BARREL ANDCONTAINER PUMPSNEW now supplied with FLUX-ClipINNOVATORSIN FLOW TECHNOLOGY

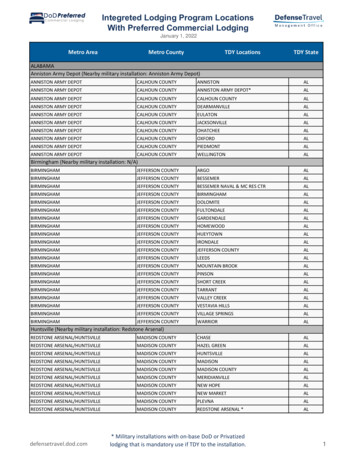

FLUX PUMPS: PERFECTION IN PUMPINGDo you want to transfer differing liquids quicklyand economically?Do you want to measure out varying quantities?Do you want to ensure total safety for the operator or theenvironment when pumping hazardous products?Do you want a pump which can cope even withpeak loadings?FLUX barrel and container pumps offer the high-tech designyou require.Whenever liquids are pumped out of a barrel or container,FLUX can supply a unit of unsurpassed quality: all FLUX pumpsare available in different materials. You can choose betweena pump with a mechanical seal or a sealless version. One ofthe unique features of both, the polypropylene and the PVDFmechanical seal version, is the steel cored inner tube providing,through increased lateral stability, a longer service life.Both, mixed centrifugal and axial impellors are availableto suit differing head and flow applications. And if you wantto combine the pumping and mixing operation FLUX also havethe pump you need.Another feature is the FLUX quick assembly system. This allowsfor simple and speedy pump strip down.Of course, FLUX pumps require a powerful and reliable drivemotor. A wide range of electric or compressed air motors2provides a matched power unit throughout the pump range –A FLUX barrel pump is always aeven in hazardous locations or when pumping high flammability"Two-Component-Team" consisting ofliquids. To complete the comprehensive FLUX program, a widea drive motor and a pump (tube set).range of top class accessories is available – from protectionBoth component parts are universallyagainst emission of noxious vapours through to the volumetricinterchangeable. For further detailsmeasurement of liquids.please see page 10 onwards.

TABLE OF CONTENTSWhich material goes best with which liquidDesign concepts of FLUX barrel45–9and container pumpsFLUX barrel pumps (pump tube sets)10 – 13in stainless steel (S), aluminium alloy (AL)and Hastelloy C (HC) in detail,together with performance chartsSmall clip, big effect!For suspending the hand tap or discharge hose,FLUX barrel pumps are now suppliedwith the new FLUX-Clip.Assembly is easy: just fit FLUX-Clip on to the outletnozzle of the pump and mount discharge hose.The FLUX-Clip allows for secure suspension of thehand tap in various positions.FLUX barrel pumps (pump tube sets)14 – 17in polypropylene (PP) andpolyvinylidenfluoride (PVDF) in detail,together with performance chartsFLUX container pump (pump tube set)18 – 19in polypropylene (PP) in detail,together with performance chartThe FLUX-Clip ensures the hand tap and dischargehose are safely stored and always ready for use.FLUX quick action coupling to suitExamples of different positions of suspension:FLUX motor data in detail21 – 31Summary of FLUX motor –32 – 3320all FLUX barrel and container pumpspump combinationOutline of FLUX barrel and34 – 35container pumps with accessoriesDimensions of36 – 37FLUX barrel pumps and drive motorsThe great range of FLUX pumps38 – 393

FLUX BARREL AND CONTAINER PUMPS –WHICH MATERIAL GOES BEST WITH WHICH LIQUIDStainless steel 1.4571/316 Ti (S) up to 120 C*Zone 0Suitable for high flammability liquids (up to temperatures of classArea in which a hazardous and explosive atmosphereof gases, vapours or fogs exists permanently orfor a long period of time. In general such conditionsexist inside of barrels or containers only.The following pump models are tested and certifiedaccording to Directive 94/9/EC-ATEX 100a,category 1/2, for transferring high flammabilityliquids out of portablebarrels or containers in hazardous areas Zone 0:F 424 S – EC Type examination certificatePTB 00 ATEX 4108 XF 425 S – EC Type examination certificatePTB 99 ATEX 4001 XF 426 S – EC Type examination certificatePTB 00 ATEX 4109 XF 430 S – EC Type examination certificatePTB 00 ATEX 4110 XF 430 HC – EC Type examination certificatePTB 00 ATEX 4110 XT4) as well as for all neutral and non-flammable, thin liquids likesolvents, organic acids, dilute anorganic acids and alkalis.Certified for use in Zone 0*.Examples of suitable liquids: acetone, alcohol, ammonia, petrol,flammable solvents, nitrocellulose varnishes, perchlorethylene,trichlorethylene, toluene, potassic alkali, soda alkali,phosphoric acid (up to 60 %), sulphuric acid (up to 7,5 % andmore than 96 %), fruit juices, milk, salad oil and all liquids listedfor aluminium alloy.Hastelloy C (HC) up to 120 CSpecially designed for pumping alternatively high flammabilityand chemically aggressive liquids.Certified for use in Zone 0*.Examples of suitable liquids: hydrofluoric acid, aqua regia, oleum,hydrochloric acid (up to 30 %), sulphuric acid, various mixedacids and all liquids listed for aluminium alloy and stainless steel.Aluminium alloy AlMg5 (AL) up to 100 CSuitable for neutral, low flammability liquids.Examples of suitable liquids: drilling emulsion, diesel oil,fuel oil, hydraulic oil, non-flammable solvents, liquid soap,liquid wax, water.Polypropylene (PP) up to 50 CSuitable for both, chemically aggressive and neutral liquids,together with low flammability liquids such as acids and alkalis.Examples of suitable liquids: formic acid, ammonia, boric acid,chromic acid (up to 10 %), liquid fertilizers, acetic acid, photodevelopers, hydrofluoric acid (up to 70 %), fruit acids, potassicalkali, copper chloride, lactic acid, soda alkali, phosphoric acid,hydrochloric acid, sulphuric acid (up to 80 %), distilled water.Polyvinylidenfluorid (PVDF) up to 100 CSuitable for both, chemically aggressive and neutral liquids,together with low flammability liquids such as acids and alkalis.Examples of suitable liquids: hydrobromic acid, chromic acid,chloric acid, hydrofluoric acid, sodium hypochlorite, nitric acid(up to 75 %), sulphuric acid and all liquids listed for polypropylene (except soda alkali).4Bold and italic printing of liquids indicates thatthe standard o-ring fitted FKM is not sufficientlyresistant to this liquid.(Please consider when selecting the pump design.)P.S.: Due to the enormous variety and complexityof industrial chemicals, together with the range andvariation of FLUX products, we can only list some ofall the suitable liquids. But we would be glad to sendyou a detailed Resistance Chart.

IN GOOD CONTACT WITH THE LIQUIDS:THE SEALLESS FLUX PUMP F424The liquids to be pumped areFlexible couplingabrasive, but they do not leavebetween motorany deposits. Dry running of theand pumppump must not cause any problems.You are looking for a generalpurpose pump without a mechanicalO-ring to seal betweenseal in the liquid section. The O-ringinner and outer tubematerial FKM is not resistant to the(not in the liquid section)liquids to be pumped.The inner tube supports the pumpshaft, which is lubricated by theRadial shaft seals toliquid. The level of the liquid in theprevent liquid and/orinner tube always corresponds tovapours entering thethat in the barrel or container.coupling areaSpecial advantages:– Safe dry running of the pumpNon-metallic helix– No wearing of sealsshaped shaft support– The liquid being pumped is notbearingcontaminated by the shaft lubricant– Inner tube and helix shaped supportbearings completely self-drainingHere a FLUX pump in seallessversion is your pump.Pressure relief portsBottom bearing assemblyType F 424 – perfectionin barrel emptyingwhich centers the shaftwithin the inner tubeImpellor in ETFENOTE All FLUX barrel pumpsare stripped for cleaningwith a minimum of effort.5

A SHAFT IN A SHELL:THE FLUX PUMP F430 WITH MECHANICAL SEALThe pump must be used withmany varying liquids, consequently the smallest residual leftwithin the pump is unacceptable.Flexible couplingYou want to pump adhesive sub-between motor and pumpstances like paints, or liquidswhich tend to crystallize orharden.The inner tube houses the shaft.It is sealed at the bottom by amechanical seal through whichthe shaft passes. Consequentlythe shaft does not come intocontact with the liquid exceptfor the small section betweenthe impellor and seal.Steel cored inner tube inPP and PVDF provides theSpecial advantages:ultimate in stability. This– The shaft support bearingscore prevents elongationof the plastics at highare isolated from the liquid– Steel cored inner tube in PPtemperatures. This resultsand PVDF pumps. This preventsin an extended service lifeelongation of the plastics,of the mechanical sealeven at high temperatures– Extended service life throughwell proven seal designHere a FLUX pump withmechanical seal is thebest choice.Packaging of themechanical seal and rotaryshaft seal adjacent to eachother ensures the maximumintegrity of the sealed inner tubeImpellor in ETFENOTE For all other applications bothdesigns – F 424 and F 430 –are equally suitable.6Type F 430 – perfectionin barrel emptying

MOST ECONOMICAL DELIVERY: THE FLUX PUMP F425FOR EMPTYING BARRELS UP TO 99,98%You are not prepared to acceptany residual liquid in the barrelin order to avoid problems andcosts of disposal or to avoidFlexible couplinglosing high value liquids.between pump and motorBefore the motor is switched off,the flowback stop valve at thepump inlet must be closed byoperating the lever. This preventsthe liquid flowing back into theempty barrel.Special advantages:– Especially easy operating ofOperating leversthe pumpto close/openthe flowback stop valve– Optimum use of the liquids– Remains of less than 0,05 lHere the FLUX F 425 foremptying barrels up to 99,98 %is your pump.Type F 425Packaging of themechanical seal and rotaryshaft seal adjacent to eachother ensures the maximumintegrity of the sealed inner tubeImpellor in ETFEFlowback stop valveFlowback stop valveopenclosedNOTE All FLUX barrel pumpsare stripped for cleaningwith a minimum of effort.7

AN EXCELLENT MIXTURE:THE FLUX MIXING PUMP F426You want to mix and pumpliquids within a closed barrel oran open container.Flexible couplingBy turning the adjusting lever, thebetween pump and motorpump can either mix or pump.Liquids can also be mixed evenwhen being transferred to another container.Special advantages:– No changes in the outerdiameter of the pump tubein stainless steel as the pumpworks without any additionalAdjusting lever to setcomponents.the pump to mixing or– Light and handy design.discharge– Pump/barrel connection glands,also in vapour-proof version,are availableHere the FLUX mixingpump is the right pumpfor you.Mixing openingsType F 426Packaging of themechanical seal and rotaryshaft seal adjacent to eachother ensures the maximumintegrity of the sealed inner tubeImpellor in ETFEmixingNOTE All FLUX barrel pumpsare stripped for cleaningwith a minimum of effort.8pumping

PURE CULTURE IN PUMPING:THE FLUX SANITARY PUMP F427You want a safe pumping ofFor use with all FLUX models:food, cosmetic or pharmaceuticalQuick Action Coupling SSK 400products. The operating condi-allows a quick assembly/disas-tions require an easy and quicksembly of motor and pumpcleaning or sterilization of the(not included with the pump –pump at regular intervals tosee page 20)avoid any contamination of theproduct, e.g. when pumpingShaft seal to preventvarying liquids or differentliquids and/or vapourscolours as well as quick-dryingentering the couplingor film forming liquids.areaThe efficient FLUX sanitary pumpEasy to strip downhas been especially designed for– Easy to clean!aseptic applications.Special advantages:– All wetted parts are made instainless steel, PTFE or ETFE– The pump can be quicklystripped down for cleaningor sterilizationClosed bearing inPTFE assures safe– Negligible wear by friction onseals and bearingsguiding of the pumpHere a FLUX sanitary pump isFLUX facilitates aseptic pumpingyour pump.of delicate products. The sanitarypump can be stripped downwithin a few seconds because ofits ingenious design.Type F 427The F 427 does not have anyinaccessible voids.This allows you to completelyclean the pump at any time.Pressure relief portsBottom bearing assemblywhich centers the shaftwithin the inner tubeImpellor in ETFE or instainless steelNOTE All FLUX barrel pumpsare stripped for cleaningwith a minimum of effort.9

FLUX BARREL PUMPS IN STAINLESS STEELFLUX barrel pumps in stainless steel 316 Ti –except sanitary pump F 427 S – are approvedaccording to Directive 94/9/EC-ATEX 100afor use in Zone 0, temperature class T4,for transferring high flammability liquids out ofportable barrels or containers.With the help of the performance charts youF 460 ExF 460 Ex ELF 460-1 ExFBM 4000 Excan compare the delivery rates achieved byeach pump model powered by the variousFLUX motors. Detailed motor data are shownon pages 21 to 31.When using the pump with a discharge hose(of approx. 2 m) and a hand tap, the deliveryF 416 ExF 416-2 ExF 458F 458 ELF 458-1F 414F 457F 457 ELF 417F 417 ELrate will be approx. 70 l/min. Depending onthe motor type a 200 l barrel can be emptiedwithin 3–4 minutes.The delivery rates shown in the performancecharts are obtained at the outlet connection ofthe pump.F 424 S -43/38Special version for horizontal use on request.This pump version will achieveThis pump version will achieveMax. viscosity per pump and motor,a higher delivery rate!a higher delivery head!please see pages 32 and 33.Motor FBM 4000 Ex10Detailed motor data see pages 21 to 31Motor F 416 Ex, F 416-1 Exor F 416-2 ExMotor F 417 or F 417 EL

BARREL PUMP (TUBE SET) IN STAINLESS, THREAD ON OUTLET G 1 1/4 A (BSP 1 1/4” MALE), WITHOUT MOTORType/CurveF 424 S-43/38F 424 S-43/37 ZF 424 S-50/45 ZVersionSeal typesealless within the liquid sectionMaterialshaft in stainless steel 316 Ti, impellor in ETFE, o-ring in FKMmax. temperature120 Couter Ø41 mm (foot piece 43 mm)41 mm (foot piece 43 mm)50 mmPart No./WeightImmersion length700 mm424 20 007/2,2 kg424 20 107/2,2 kg424 20 207/3,0 kgImmersion length 1000 mm424 20 010/2,9 kg424 20 110/2,9 kg424 20 210/4,0 kgImmersion length 1200 mm424 20 012/3,3 kg424 20 112/3,3 kg424 20 212/4,8 kg Typ /KennlinieF 425 S-41/34Version99,98 % barrel emptyingF 426 S-41/38F 427 S3-43/38Mixing pumpSanitary pumpSeal typemechanical seal in ceramic oxide, PTFE/carbon,o-rings in FKMMaterialshaft in stainless steel 316 Ti, seal in FKM,impellor in ETFEmax. temperaturesealless withinthe liquid selectionshaft in stainless steel 316 Ti,impellor in ETFE, o-ring in FKM120 Couter Ø120 C41 mm41 mm41 mm (foot piece 43 mm)700 mm425 20 008/3,0 kg–427 20 307/2,2 kgImmersion length 1000 mm425 20 011/3,8 kg426 20 010/3,8 kg427 20 310/2,9 kgImmersion length 1200 mm425 20 013/4,4 kg426 20 012/4,4 kg427 20 312/3,3 kgTyp /KennlinieF 430 S-41/38Part No./WeightImmersion lengthF 430 S-41/37 ZF 430 S-50/45 ZF 430 S-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in stainless steel 316 Ti, seal in FKM, impellor in ETFEmax. temperature120 Couter Ø41 mm41 mm50 mm50 mmPart No./WeightImmersion length700 mm430 20 107/2,4 kg430 20 407/2,4 kg430 20 207/3,4 kg430 20 307/3,4 kgImmersion length 1000 mm430 20 110/3,0 kg430 20 410/3,0 kg430 20 210/4,5 kg430 20 310/4,5 kgImmersion length 1200 mm430 20 112/3,6 kg430 20 412/3,6 kg430 20 212/5,2 kg430 20 312/5,2 kgAccessoriesHose connection complete with nut G 11/4DN 19 Part No. 959 04 061Pump models in immersion length of 200 – 3000 mm (in steps of 100 mm) on request.Motor F 457 or F 457 ELMotor F 458, F 458 EL, F460 Exor F 460 Ex ELDN 25 Part No. 959 04 041* Model for higher delivery head on request.Motor F 458-1 or F 460-1 ExValues 10 % with water (20 C) and a voltage of 230 Volt.11

FLUX BARREL PUMPS IN ALUMINIUM ALLOY OR HASTELLOY CFLUX barrel pumps in aluminium alloyAlMg5 are suitable for transferringneutral, low flammability liquids.FLUX barrel pumps in Hastelloy C areF 460 ExF 460 Ex ELF 460-1 ExFBM 4000 Exapproved according to Directive94/9/EC-ATEX 100a for use in Zone 0,temperature class T4, for transferringhigh flammability liquids out of portablebarrels or containers. In addition,Hastelloy C is chemically resistant to mostof acids and alkalis, allowing the mostF 416 ExF 416-2 ExF 458F 458 ELF 458-1F 414F 457F 457 ELF 417F 417 ELuniversal use of this pump type.With the help of the performance chartsyou can compare the delivery ratesachieved by each pump model poweredby the various FLUX motors.Detailed motor data are shown on pages21 to 31.the delivery rate will be approx. 70 l/min.Depending on the motor type a 200 lbarrel can be emptied within 3–4minutes.The delivery rates shown in the performance charts are obtained at the outletconnection of the pump.Motor FBM 4000 Ex12Detailed motor data see pages 21 to 31.F 430 HC-40/38hose (of approx. 2 m) and a hand tap,F 430 AL-41/38When using the pump with a dischargeMotor F 416 Ex, F 416-1 Exor F 416-2 ExMotor F 417 or F 417 EL

BARREL PUMP (TUBE SET) IN ALUMINIUM ALLOY, THREAD ON OUTLET G 1 1/4 A (BSP 1 1/4” MALE), WITHOUT MOTORF 430 AL-41/38Type/CurveF 430 AL-41/37 ZF 430 AL-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in NBRMaterialshaft in stainless steel 316 Ti, seal in NBR, impellor in ETFEmax.temperature120 C (for short periods)outer Ø41 mm41 mm50 mmPart No./WeightImmersion length700 mm430 10 107/1,2 kg430 10 407/1,2 kg430 10 307/1,5 kgImmersion length 1000 mm430 10 110/1,5 kg430 10 410/1,5 kg430 10 310/1,8 kgImmersion length 1200 mm430 10 112/1,7 kg430 10 412/1,7 kg430 10 312/2,1 kgAccessoriesHose connection complete with nut G 11/4DN 19 Part No. 959 04 050DN 25 Part No. 959 04 039Pump models in immersion length of 200 – 2000 mm (in steps of 100 mm) on request.BARREL PUMP (TUBE SET) IN HASTELLOY C, THREAD ON OUTLET G 1 1/4 A (BSP 1 1/4” MALE), WITHOUT MOTORF 430 HC-40/38Type/CurveVersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FFKMMaterialshaft in Hastelloy C, seal in FFKM, impellor in ETFEmax.temperature120 Couter Ø40 mmPart No./WeightImmersion length700 mm430 30 107/2,3 kgImmersion length 1000 mm430 30 110/3,0 kgImmersion length 1200 mm430 30 112/3,5 kgAccessoriesHose connection complete with nut G 11/4DN 25 Part No. 959 04 043Other immersion lengths on request.This pump version will achieveThis pump version will achieveMax. viscosity per pump and motor,a higher delivery rate!a higher delivery head!please see pages 32 and 33.Motor F 457 or F 457 ELMotor F 458, F 458 EL, F460 Exor F 460 Ex ELMotor F 458-1 or F 460-1 ExValues 10 % with water (20 C) and a voltage of 230 Volt.13

FLUX BARREL PUMPS IN POLYPROPYLENEFLUX barrel pumps in polypropylene areused for both, chemically aggressive andlow flammability liquids such as acidsF 417F 417 ELand alkalis, together with most thin andF 457F 457 ELneutral liquids.With the help of the performance chartsyou can compare the delivery ratesachieved by each pump model poweredby the various FLUX motors.Detailed motor data are shown on pagesF 458F 458 ELF 458-121 to 31.F 414When using the pump with a dischargehose (of approx. 2 m) and a hand tap,the delivery rate will be approx. 70 l/min.Depending on the motor type a 200 lbarrel can be emptied within 3–4minutes.The delivery rates shown in the performance charts are obtained at the outletSpecial version for horizontal use onrequest.F 430 PP-40/33connection of the pump.F 460 ExF 460 Ex ELF 460-1 ExFBM 4000 ExF 416 ExThis pump version will achieveThis pump version will achieveMax. viscosity per pump and motor,a higher delivery rate!a higher delivery head!please see pages 32 and 33.Motor FBM 4000 Ex14F 416-2 ExDetailed motor data see pages 21 to 31.Motor F 416 Ex, F 416-1 Exor F 416-2 ExMotor F 417 or F 417 EL

BARREL PUMP (PUMP TUBE SET) IN POLYPROPYLENE, THREAD ON OUTLET G 1 1/4 A (BSP 1 1/4”MALE), WITHOUT MOTORTyp e/CurveF 424 PP-41/36F 424 PP-41/35 ZF 424 PP-50/38F 424 PP-50/43 ZVersionSeal typesealless within the liquid sectionMaterialshaft in Hastelloy C, impellor in ETFE, o-ring in FKMmax. temperature50 Couter Ø40 mm (foot piece 41 mm) 40 mm (foot piece 41 mm) 50 mm50 mmPart No./WeightImmersion length700 mm424 40 007/0,8 kg424 40 107/0,8 kg424 40 207/0,9 kg424 40 307/0,9 kgImmersion length 1000 mm424 40 010/1,0 kg424 40 110/1,0 kg424 40 210/1,3 kg424 40 310/1,3 kgImmersion length 1200 mm424 40 012/1,2 kg424 40 112/1,2 kg424 40 212/1,6 kg424 40 312/1,6 kgTyp e/CurveF 425 PP-50/34Version99,98 % barrel emptyingF 426 PP-50/33Mixing pumpSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impellor in ETFEmax. temperature50 Couter Ø50 mm50 mmPart No./WeightImmersion length700 mm425 40 048/1,6 kg-Immersion length 1000 mm425 40 051/2,0 kg426 40 001/1,8 kgImmersion length 1200 mm425 40 053/2,3 kg426 40 002/2,1 kgTyp e/CurveF 430 PP-40/33F 430 PP-40/33 ZF 430 PP-50/43 ZF 430 PP-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impellor in ETFEmax. temperature50 Couter Ø40 mm40 mm50 mm50 mm700 mm430 40 107/1,1 kg430 40 407/1,1 kg430 40 207/1,1 kg430 40 307/1,1 kgImmersion length 1000 mm430 40 110/1,4 kg430 40 410/1,4 kg430 40 210/1,5 kg430 40 310/1,5 kgImmersion length 1200 mm430 40 112/1,6 kg430 40 412/1,6 kg430 40 212/1,7 kg430 40 312/1,7 kgPart No./WeightImmersion lengthAccessories1Hose connection complete with nut G 1 /4DN 19 Part No. 959 04 053DN 25 Part No. 959 04 052Pump models in immersion length of 200 – 3000 mm (in steps of 100 mm) on request.Motor F 457 or F 457 ELMotor F 458, F 458 EL, F460 Exor F 460 Ex ELMotor F 458-1 or F 460-1 ExValues 10 % with water (20 C) and a voltage of 230 Volt.15

FLUX BARREL PUMPS IN POLYVINYLIDENFLUORIDEFLUX barrel pumps in polyvinylidenfluoride are used for both, chemicallyaggressive and low flammability liquidsF 417F 417 ELsuch as acids and alkalis, together withF 457F 457 ELmost thin and neutral liquids.With the help of the performance chartsyou can compare the delivery ratesachieved by each pump model poweredby the various FLUX motors.Detailed motor data are shown on pagesF 458F 458 ELF 458-121 to 31.F 414When using the pump with a dischargehose (of approx. 2 m) and a hand tap,the delivery rate will be approx. 70 l/min.Depending on the motor type a 200 lbarrel can be emptied within 3–4The delivery rates shown in the performance charts are obtained at the outletconnection of the pump.F 424 PVDF-41/36minutes.F 460 ExF 460 Ex ELF 460-1 ExFBM 4000 ExF 416 ExThis pump version will achieveThis pump version will achieveMax. viscosity per pump and motor,a higher delivery rate!a higher delivery head!please see pages 32 and 33.Motor FBM 4000 Ex16F 416-2 ExDetailed motor data see pages 21 to 31.Motor F 416 Ex, F 416-1 Exor F 416-2 ExMotor F 417 or F 417 EL

BARREL PUMP (TUBE SET) IN POLYVINYLIDENFLUORIDE, THREAD ON OUTLET G 1 1/4 A (BSP 1 1/4” MALE), WITHOUT MOTORTyp e/CurveF 424 PVDF-41/36F 424 PVDF-41/35 ZF 424 PVDF-50/38VersionSeal typesealless within the liquid sectionMaterialshaft in Hastelloy C, impellor in ETFE, o-ring in FKMmax. temperature100 Couter Ø40 mm (foot piece 41 mm)40 mm (foot piece 41 mm)50 mmPart No./WeightImmersion length700 mm424 60 007/1,1 kg424 60 107/1,1 kg424 60 207/1,4 kgImmersion length 1000 mm424 60 010/1,4 kg424 60 110/1,4 kg424 60 210/1,9 kgImmersion length 1200 mm424 60 012/1,6 kg424 60 112/1,6 kg424 60 212/2,2 kgTyp e/CurveF 430 PVDF-40/33F 430 PVDF-40/33 ZF 430 PVDF-50/43 ZF 430 PVDF-50/38VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impellor in ETFEmax. temperature100 Couter Ø40 mm40 mm50 mm50 mmPart No./WeightImmersion length700 mm430 60 107/1,4 kg430 60 407/1,4 kg430 60 207/1,7 kg430 60 307/1,7 kgImmersion length 1000 mm430 60 110/1,7 kg430 60 410/1,7 kg430 60 210/2,1 kg430 60 310/2,1 kgImmersion length 1200 mm430 60 112/2,0 kg430 60 412/2,0 kg430 60 212/2,5 kgAccessoriesHose connection with nut G 11/4DN 19 Part No. 959 04 101430 60 312/2,5 kgDN 25 Part No. 959 04 102Pump models in immersion length of 200 – 3000 mm (in steps of 100 mm) on request.Motor F 457 or F 457 ELMotor F 458, F 458 EL, F460 Exor F 460 Ex ELMotor F 458-1 or F 460-1 ExValues 10 % with water (20 C) and a voltage of 230 Volt.17

FLUX CONTAINERPUMP IN POLYPROPYLENEThe powerful, extremely lightweight and easyto-handle solution for transferring corrosiveacids and alkalis and almost every thin, lowflammability liquid out of larger containers:FLUX container pump type F 430 PP-100/50in polypropylene. Especially designed forF 457emptying 1000-L-Containers, this pump providesthe high safety and ease of handling you doappreciate on FLUX barrel pumps.The use of this pump allows to dispense withfloor drains, minimizing leakage risks andeliminating residual liquid within suction pipesand subsequent handling cost. A compressiongland or a vapour-proof gland always securesF 458-1the pump in a vertical position within the domeof the container.With the help of the performance chart you cancompare the delivery rates achieved by thecontainer pump powered by motors type F 457,F 458-1 or F 414. Detailed motor date areshown on pages 21 – 31.F 414Depending on the motor type, this pump willand a maximum delivery head of 32 m liquidcolumn in transferring liquids up to a maximumviscosity of 150 mPas (cP).FLUX Container PumpF 430 PP-100/50in combination with1 Commutator motor2 Three-phase gearmotorType F 457/F 458-1Type F 414Detailed motor datasee pages 21 to 3118Values 10 % with water (20 C) and a voltage of 230 Volt.F 430 PP-100/50achieve a maximum delivery rate of 105 l/min

CONTAINER PUMP (TUBE SET) IN POLYPROPYLENE, THREAD ON OUTLET G 1 / A, WITHOUT MOTOR1 4TypeF 430 PP-100/50VersionSeal typemechanical seal in ceramic oxide, PTFE/carbon, o-rings in FKMMaterialshaft in Hastelloy C, seal in FKM, impellor in polypropylenemax. temperature50 Couter Ø100 mmPart No./WeightImmersion length 1000 mm430 40 510/2,0 kgImmersion length 1200 mm430 40 512/2,2 kgImmersion length 1500 mm430 40 515/2,5 kgAccessoriesHose connection with nut G 11/4DN 25 Part No. 959 04 052DN 32 Part No. 959 04 054Accessories for fixing the pump onto the containerPart No.Screw cap DN 150001 14 063Screw cap DN 225001 14 064in connection with FLUX vapour-proof gland, consisting of:Valve part (PP) Ø 50 mm001 14 243Threaded ring (PP) G 2001 14 238Dimensions in mmabImmersion length 1000 mm10221097Immersion length 1200 mm12221297Immersion length 1500 mm1522159719

FLUX QUICK ACTION COUPLING SSK 400FLUX Quick Action Coupling Type SSK 400suits all FLUX barrel and container pumpsType F 424, F 425, F 426, F 427 and F 430and allows a quick assembly/disassemblyof pump and motor within a few secondsonly.This allows the use of several pump tubesets with one drive motor only.The quick action coupling SSK 400 consistsof a clamping element which is mountedonto the pump tube set and a threaded ringwhich is screwed onto the drive motor.TypePart No.consisting of threaded ring (motor side) andclamping element (pump side)001 10 802Threaded ringto be screwed onto the drive motor001 10 800Clamping elementto be mounted onto the pump tube set001 10 804Quick Action CouplingSSK 400 completeor as individual parts:20

FLUX BRUSHLESS MOTOR FBM 4000 EXBarrel and Container Pumps are used in almost every sectorof the processing and manufacturing industries.Initially designed for decanting and transfer operations ofdiffering liquids from barrels and containers, current productiontime scales are now requiring these pumps to be used onapplications with extended run times and frequent stoppingand starting.NEWThese, more ardous uses, are exactly the applications the newbrushless motor Type FBM 4000 Ex has been designed for.For either continuous or intermittent use, or even precisedispensing operations: the new brushless motor is ideally suited.The brushless motor Type FBM 4000 Ex is featuring a compactdesign, a robust double shell housing in aluminium and a verylow noise level. The explosion-proof motor is tested and certifiedaccording to the latest Directive 94/9/EC-ATEX 100a.EC-Type-Examination Certificate PTB 03 ATEX 1042.FBM 4000 ExThe combined on/off switch and easy to use speed controllerallow precise dispensing operations.Electronic monitoring of speed, voltage and temperature.A no-volt release safety circuit monitors the power and preventsunintentional re-start of the pump. This feature ensures additionalsafety for the user.Due to negligible wear, the brushless motor design guaranteeslowest cost of ownership, even with continuous use.Brushless motor, explosion-proof to II 2 G EEx de IIC T6,protection class I.Jet-proof according to IP 55.With power supply cable, 5 m long,with safety plug (not explosion-proof).BRUSHLESS MOTOR,EXPLOSION-PROOF, CERTIFIED ACCORDING TOTypCapacityVoltageDIRECTIVE 94/9/EC – 100aFrequencyWeightPart No.Versionwith no voltrelease safetycircuitFBM 4000 Ex600 W230 V50-60 Hz6,2 kg400 01 000Accessories see page 23.21

FLUX COMMUTATOR MOTOR F 460 EXINDETAILExplosion-proof commutator motor Type F 460 Ex featuringa compact design, a robust double shell housing in aluminiumand a very low noise level. Tested and certified according toDirective 94/9/EC-ATEX 100a.EC-Type-Examination Certificate PTB 97 ATEX 1035.An improved ventilation system provides optimal coolingand ensures an extended service life.Additional safety by an integral no-volt release to prevent fromany unintentional re-starting after a voltage discontinuity.Commutator motor, explosion-proof to II 2 G EEx de IIC T6,protection class I in 230, 240 or 110 Volt,protection class III in 42, 24 or 12 Volt.Jet-proof according to IP 55.With power supply cable, 5 m long. 230, 240 and 110 Voltversion with safety plug (not explosion-proof).F 460 Ex (pict.)F 460 Ex EL42, 24 and 12 Volt version without plug.230 Volt version approved to VDE, GS and SEV standards.Type F 460 Ex EL, 230 Volt, with infinitely variable speed controlincluded in the switch knob for an easy control of the deliveryrate.The commutator motor Type F 460-1 Ex is identical with Type F 460 Ex,but has a considerably hi

FLUX container pump (pump tube set) in polypropylene (PP) in detail, together with performance chart FLUX quick action coupling to suit all FLUX barrel and container pumps FLUX motor data in detail Summary of FLUX motor - pump combination Outline of FLUX barrel and container pumps with accessories Dimensions of FLUX barrel pumps and drive .