Transcription

Rotronic’s UniversalMonitoring System: RMS

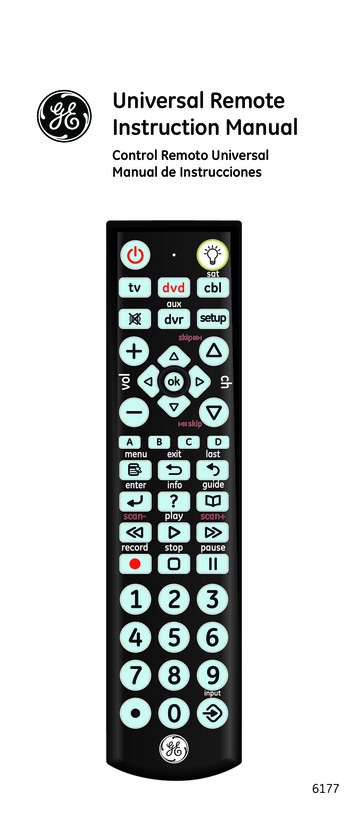

RMS – ROTRONIC MONITORING SYSTEMHigh quality standards in production and storage necessitate a comprehensive monitoring system that delivers variousmeasured data reliably. The adaptive RMS Rotronic Monitoring System is the perfect solution for a variety of applications.RMS – For Every ApplicationThe Rotronic Monitoring System is a modular system of hardware elements and a serversoftware. It guarantees maximum flexibility at installation time, and ensures excellentavailability of the data during operation. The data loggers record all measurements byRotronic and third-party sensors and transmit them to the database. It stores all information and makes it available to all users, regardless of whether they access the database by PC, Mac, tablet or smart phone.RMS – For Big and SmallThe RMS is ideal for both large monitoring systems in international corporations andfor simple small applications, for which Rotronic makes the database available as cloudaccount.RMS – The One-Stop SolutionRotronic does not only supply the individual components such as the instruments andsoftware for the monitoring system. We also offer professional advice, installation,commissioning and maintenance of the RMS during operation.Main Features– GMP/GLP/GDP compatibility– FDA 21 CFR Part 11– PDF report with chart and statistics– Alarming by voice call, SMS or email– Platform-independent– Suitable for smart phones and tabletsContents2RMS – Rotronic Monitoring System2Data Flow3Monitoring Software4–5LAN and Wireless System6–7RMS Converter / RMS Probes8–9Data Security / Data Integrity / FDA Conformity10 – 11RMS Applications12 – 13RMS Service14 – 15Rotronic’s Universal Monitoring System: RMS

DATA FLOWInput TransducersRotronic probes or other input transducerssuch as cameras or third-party sensorscan be read out by the data loggers. Inthis way the RMS monitors a variety ofparameters such as humidity, temperature, dew point, door contacts, particlesand many more.mAVData LoggerThe data logger stores all measured dataand sends it to the database. Should theconnection be lost, the logger stores thedata intermediately to protect data integrity and fills up the data gaps when theconnection has been restored.Software / DatabaseThe database covers the complete monitoring system. It contains all the measuredvalues of the system and saves all actions.The server software alerts the relevantusers in the case of problems and managesthe user-specific access rights.Output SizeThe database can be accessed with smart phones, tables and all PCs with a webbrowser. Visualization and alarming aretherefore possible worldwide and on allcommon platforms.Rotronic’s Universal Monitoring System: RMS3

MONITORING SOFTWAREThe RMS Server Software fulfills all requirements for server-based monitoring. The software is linked to a database that storesall the measured data and actions of the system. The data can be accessed from anywhere in the world via all common platformsas long as an internet connection is available.MenuChartShows all parameters graphically andnumerically.TableEnables sorting and filtering of all inputvariables available in the system.LayoutVisualizes which variable is measuredwhere and its state.DashboardOffers the individual user the possibilityto show the most important parametersfor him in one view.EventsAlarms, warnings and system messagesare shown here clearly and can be acknow ledged directly.ToolsHere the user can generate PDF reports,calibrate/adjust measuring points andmanage the complete system.Data History Always AvailableCompatible withAll PlatformsThe database allows access to all historical data at any time, thereby ensuring trace-Regardless of manufacturer or hardware,ability according to FDA and GMP. This data can be put together into a complete PDFthe software can run on all systems withreport quickly and easily.a web browser. The user can thereforeaccess it with all devices.4Rotronic’s Universal Monitoring System: RMS

AlarmsWhether by voice call, email, SMS or switching of an alarm relay: the RMS offers clearalarm functions and records all events such as error messages, warnings or systemAlarmingmessages in the database.Validation at the Touch of a ButtonThe RMS Server Software enables validation at the touch of a button. The systemSmart PhoneTablet PCchecks the data integrity automatically by self test in that it switches all input modulesData LoggerDB / Server SoftwareData Centerinto their various states and checks the alarms that are meant to be triggered. Thesoftware then generates a validation report on the complete system.Easy User ManagementSNMP / HTTPOPCUserAccountThe intelligent user management function makes it possible to assign different rightsto every user on the basis of data groups. For example, the same user can have onlyread rights in data group A, while he also has write rights in data group B.RMS Software Products Data archivingAudit trailCalibration/AdjustmentValidationMeasuring point alarm Alarm schemeExclusive Professional Dashboard viewAlarm table Layout viewEnterprise SmallChart & table viewFreeBasicVersionRMS Cloud(SaaS – Software as a Service)EnterpriseRMS Server SoftwareProfessionalType 40200200 Users (freely extendable)25101251010Devices or measuring points(freely extendable)104010021040100100Storage (freely extendable) 6 months6 months6 months Rotronic’s Universal Monitoring System: RMS5

LAN AND WIRELESS SYSTEMAll RMS components come with a LAN or wireless interface. They are linked to each other in an Ethernet network or send theirdata to the data center via a gateway. In this way every module transmits its data to the RMS database. It must therefore beensured by way of network connections that the RMS modules can reach the server with the Server Software.Display ModuleThe display module can show any values from the RMS network.Humidity, temperature and switch states can be configured persoftware.Standard LoggerRecords the measured data of the digital HygroClip HCD or otherRMS probes. Stored in the ring memory, the data are then sentto the server software.Output ModuleProvides two analog voltage or current outputs or is also available as variant with two solid-state relays in order, for example,to switch alarm lamps.Input ModuleRecords voltage or current signals from analog devices such asparticle counters, flow transmitters or CO2 probes. For example:– AF1 transmitter (airflow)– CO2 transmitter (CO2)– PF4 transmitter (differential pressure)Temperature LoggersThe loggers can be equipped with various temperature sensors(NTC, Pt100, Pt1000 or K-element). This offers highest flexibilityin use.Mini LoggerA temperature logger with integrated or remote NTC sensor.Instead of a temperature sensor, it is also available with a switchinput in order, for example, to monitor door contacts.GatewayThe gateway is the connecting element between Ethernet andwireless network and forwards the data flow from the loggers tothe data center.Data Center6Rotronic’s Universal Monitoring System: RMS

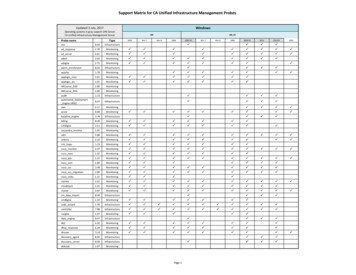

Output ParametersParametersLAN InterfaceWireless InterfaceData Memory (Points)BatteryPower over Ethernet (PoE)Ext. Power Supply 24 VDIN Rail Housing IP20Wall-Mounted Housing IP65Product OverviewData loggerRMS-LOG 40’000 10’000 %RH & C CdpTemperature mini data loggerRMS-MLOG-868 CAnalog input moduleRMS-ADC 40’000 mA / V On-Off 10’000 On-Off mA / V LuxDigital input moduleRMS-DIDigital mini loggerRMS-MDI-868Analog mini loggerRMS-MADC-868Light mini loggerRMS-MLOG-LGT-868Relay moduleRMS-DO On-Off DisplayDisplay moduleRMS-D Rotronic’s Universal Monitoring System: RMS7

RMS CONVERTERIntegrate Third-Party Devices with the RMS ConverterThe RMS converter allows integration of digital third-party devices via an Ethernet interface. The hardware collects the data of allthird-party components and, if necessary, controls them. In this way Rotronic devices from existing networks as well as web camsor third-party devices with public protocol can be integrated. Our customers are therefore able to implement software extensionseasily on a project-specific basis. The only requirement is that the devices have an Ethernet interface.Data IntegrityThe RMS converter stores the collected data internally so that the data are safe in theevent of an interruption in communication with the database. When the network connection has been restored, the data are synchronized automatically with the database.RMS Converter as GatewayA simple extension with a USB dongleturns the RMS converter into a wirelessgateway for RMS wireless data loggers –and into a cost-effective solution for theuser.Data CenterSupported ProtocolsDevices Already Supported– RoASCII– Rotronic HygroFlex transmitters– HTTP– Rotronic HygroLog data loggers– Customer-specific extension– Rotronic HL-RC wireless data loggers– Rotronic differential pressuretransmitters– Rotronic clean room panelOutput Devices8Rotronic’s Universal Monitoring System: RMS

RMS PROBESChoice of Digital RMS ProbesThe digital RMS probes have been developed in line with the latest art of engineering. With minimal current consumption, theymeasure environmental conditions within a few milliseconds and boast high accuracy. The new probe generation therefore fulfillsthe requirements for long battery life and quick response times during measurement – and this without any loss in Rotronic's renownedFilterResponse TimeMaterialParameters-40 85 CHT-1PC, 4015 sPC%RH &HCD-S%RH0 100 %RHPt1000µmNo filterRange 0.8at 23 C 5 CStandard probeAccuracySensorProbe TypesMeasurementmeasurement accuracy. C 0.1 CIndustrial probe with remote sensor 0.8-100 200 CHT-1HCD-IC (2 m, 5 m cable), PPS%RH0 100 %RHPt100015 sPPS%RH & C 0.1 CIndustrial probe with remote sensor 0.8-100 200 CHT-1HCD-IM (2 m, 5 m cable), metal%RH0 100 %RHPt1000-200.25 CNTCNo filter15 sSteel%RH &1.4301 CStainless C 0.1 CT10-0001N/AN/AN/AsteelT10-0002N/A-80.200 CNTCN/AN/AStainless CsteelT10-0003N/A-50.200 CNTCN/AN/AStainless CsteelDC-0001N/A-20.70 CSwitchN/AN/APCRotronic’s Universal Monitoring System: RMSOn-Off9

DATA SECURITY/DATA INTEGRITY/FDA CONFORMITYData security, data integrity, data availability: these three terms play a central role in monitoring systems. The RMS scores in allthese fields with convincing results.Data SecurityFDA/GMP RequirementsData security means the data cannot be viewed by unauthorized persons or stolen.Regulators in the pharmaceutical andThis is achieved through encryption during transfer and storage.food industries demand that all relevantevents are recorded such that they areclear and traceable. This is achievedthrough electronic marking of all calibration measurements and verification processes. The so-called “electronic recording” requires unique identification ofcertificates. This means that every calibration certificate with date and inspection stamp must be traceable such thatthe correctness of the calibration chaincan be verified.Audit TrailWhen a monitoring system is commissioned, it is calibrated and validated. Inthis way the operator assures his qualitydepartment that the system works correctly. During subsequent operation, all10Data Security in RMSrelevant changes must be recorded inIf wanted by the customer, the monitoring system offers encryption of the data duringfull. The audit trail guarantees recordingtransfer. This means the data can neither be tapped nor manipulated by so-called retryof all changes in the system such as, forattacks. The security of the stored database is ensured in RMS by the IT structure. Theexample, change in measurement probes,Rotronic cloud is protected by certified IT data centers. If the database is located in theuser activities, battery change, etc. Thiscustomer’s server center, the customer defines the security infrastructure. Rotronicin turn ensures that all events can bethen offers support in IT expertise.tracked at a later point in time.Rotronic’s Universal Monitoring System: RMS

Data AvailabilityData IntegrityData availability usually stands in contradiction to data securityEnsuring data integrity means guaranteeing secure transmissionbecause secure data are difficult to access. The user must authen-and storage. A measured value may not change suddenly duringticate himself and use secure connections or verified platforms.transmission because of disruptions. Data transmission andNevertheless, the trend is clearly moving towards worldwidestorage must therefore be safe from manipulation. This is achieveddata accessibility allowing platform-independent viewing andwith CRC checksums and intermediate storage during dataevaluation.transmission. In this way, faulty data communication is recognized and the data stored in the buffer memory are sent againuntil the transmission has been finished.Data Integrity in RMSAll data in RMS are sent with CRC checksums and confirmed bythe recipient after receipt. Faulty data transmission is thus ruledout. Should the data not arrive at the recipient, they are storedintermediately by the logger and can then be transmitted at alater point in time when the connection has been restored.Availability of Data CentersThanks to the server database and Server Software, very highavailability of the data is already implemented in the basic concept of the RMS. The data can be viewed without problem fromanywhere in the world with all conventional devices. Security isguaranteed by user rights and authentication.Rotronic’s Universal Monitoring System: RMS11

RMS APPLICATIONSYou Need a Universal and Turnkey Monitoring Solution?With its RMS, Rotronic offers a complete solution for monitoring systems. Our team supports the project from beginning to endfrom stipulation of the user requirement specifications (URS) and installation of the system to servicing of all measuring pointsand their regular calibration.Definition of URS(User Requirement Specifications)The most important phases in RMS projects:– Definition of the URS and clarification of technical implementation. The main task in this phase is to define additional requirements and to prioritize them.Project Planning(Time/Costs/Software Functions)– A subsequent demo installation offers the possibility of veri fying implementation directly and making detailed adaptations. The engineering team stipulates the customer requirements in detail so that the customer can check the correctnessof implementation.Standard Price Quotation– Following acceptance of the demo installation, the final system is installed, calibrated and commissioned. The softwareis also installed and configured. In the last step, all measuring points are calibrated.On-Site Demo Installation– Depending on the project, the complete monitoring system isthen validated. This is complex and requires checking anddocumentation of all possible system states.– The system is then serviced by Rotronic in subsequent opera-Final Offertion. This includes regular calibration of all measuring pointsby our after-sales team. It provides on-site support in the eventof faults and ensures trouble-free operation.Verification by the CustomerInstallation / CommissioningValidation12Rotronic’s Universal Monitoring System: RMS

You Use HW4 Successfully and Need an Update?With RMS, Rotronic offers an easy possibility to update current HW4 monitoringsystems to the latest state of the art and to adapt them for future extensions. It is notonly inexpensive but also very easy to update HW4 to RMS for a complete system.You Have Your Own Systemand Would Like to ConnectRMS Devices?All RMS devices can be integrated intothird-party systems such as building man-RMS Converter for Integration of Ethernet Devicesagement systems without problem. To thisThe RMS converter makes it possible to integrate all products with an Ethernet interfaceend, Rotronic has equipped all productsfrom HW4 systems into RMS directly. The RMS converter collects all data from the devicesby default with the standard MODBUSand stores their values. The data are then forwarded to the server by the RMS software.protocol. The digital HygroClips can beread out directly per MODBUS-RTU. ThisInput Modules for Integration of Analog Devicesis interesting for systems in which powerDevices that do not have an Ethernet interface must be integrated into the RMS systemconsumption must be kept to a minimum.via the analog input modules. The analog input modules digitalize the analog signalIn systems with Ethernet, data loggersand send the date to the RMS software per Ethernet interface. The software upgrade toand gateways can be addressed directlyRMS turns the monitoring system into a server-client system, making it more flexiblevia MODBUS-TCP.and compliant with the latest state of the art. Users can access the monitoring systemfrom iOS devices, Linux platforms, Windows systems or Android devices, as a result ofwhich they are kept up to date from anywhere about the state of the monitoring system.You Want to Use anExternal IT Infrastructure?Not all systems are suitable for installationof the software and database on a localserver. For small enterprises such as pharmacies it is often far easier to outsourcethe IT infrastructure. For this, Rotronicoffers accounts in the Rotronic Cloud.Rotronic provides the database and all thecustomer needs to do is install the deviceslocally and configure the account according to his requirements. This simplifiesthe complete commissioning processsignificantly.Rotronic’s Universal Monitoring System: RMS13

RMS SERVICESCalibration and AdjustmentIn spite of the almost legendary long-term stability of Rotronic sensors, we advise our customers to calibrate their probes regularly.Calibration once a year normally suffices. However, more frequent calibration can be necessary if the probes are used in polluted/contaminated atmospheres.Humidity and temperature measuring instruments are precision instruments that must be serviced regularly to maintain reliability.Measurement errors can cause substantial damage to products during production and storage. If the last calibration carried out byyou is long in the past, we recommend you attend one of our calibration seminars. In one day we refresh your knowledge and carryout practical calibrations with you.What Are the Calibration Options?We can calibrate your instruments both on your premises or in our laboratory– or you calibrate the instruments yourself:1. Calibration in Rotronic laboratory– RAG factory adjustment certificate (ISO 9001 standard)– SCS certificate (Swiss Calibration Standard, accredited laboratoryProject PlanningISO/IEC 17025)2. We come to you– HygroGen humidity and temperature generator– Calibration mobile3. You calibrate yourself– Rotronic calibration device and SCS-certified humidity standards– SCS-certified reference probes (reference measurement)– HygroGenProject PlanningCalibration MobileWe support you from planning to realization of your system. This ensuresoptimal design for your processing unit. The uniqueness of your applicationcan necessitate a multitude of function-specific settings and measurementsystems. Rotronic is one of the leading suppliers in the world for humidity andtemperature measurement equipment – profit from our know-how!Validation/QualificationGlobal companies are increasingly subject to obligatory international regulations. For example, manufacturers wishing to deliver pharmaceutical productsor foods to the USA must fulfill the requirements of the FDA1. Another wellknown code is GAMP2, which, although it is not legally binding, is an acknow Validation14ledged standard for validation.Rotronic’s Universal Monitoring System: RMS

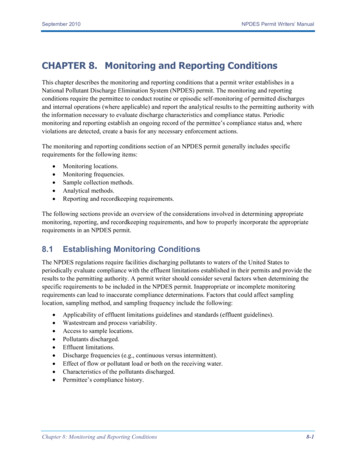

Validation includes the provision of documented evidence thatRisk Management / Design ReviewChange ManagementConfiguration Managementa system was planned and produced according to extremelystrict quality guidelines, is tested against specifications and hasbeen operated in a qualified manner since it was introduced.ValidationManagementValidation ReportMissing information and poorly specified or inadequately testedsystems represent a risk and can lead to high maintenance costsand losses in productivity. Validation by a computer-aided system(CSV3)is therefore critical for legal and business reasons. ThePerformanceQualification (PQ)User RequirementsSpecification (URS)business reasons are also valid for fields not subject to speciallegal ication (OQ)Our products, including software, conform to specific FDArequirements, are manufactured according to GAMP and provideSystem ConfigurationSpecificationa path to validation.FDA1:Food and Drug AdministrationGAMP2 :Good Automated Manufacturing PracticeCSV3:Computer System ValidationInstallationQualification (IQ)Implementation(Configuration)Humidity and Temperature MappingIncorrect temperature or humidity control can result inMapping by Rotronic Comprises:expensive damage to products. In the case of climate– Analysis of the requirements and definition of the measuringdeviations, therefore, it is necessary to react immediately.However, before an FDA-compliant system can be installed, it isfirst necessary to investigate where and how many measuringpoints– Placement/Installation of the data loggers with traceablecertificatespoints should be set up to monitor the production or storage– Continuous recording of the climatic conditionsrooms and cabinets. This is done with the help of a temperature– Evaluation and analysis of the recorded dataand humidity mapping procedure. It provides information on– Preparation of GMP-compliant documentationhow many different climate zones (temperature gradients) there– Recommendations for optimization from Rotronicare in the rooms. Using the measured data, it is possible todefine the optimum storage positions for products or even toYour Benefits:initiate changes in the room climate! Mapping also takes influ-– Exact data on room climateencing factors such as direct sunlight, air conditioners, insulation,– FDA conformityheat sources and outdoor temperature into consideration,– Knowledge of possible weak pointsresulting in recommendations on how to optimize conditions ifapplicable. Mapping is typically performed at very hot and veryYour Contact:cold times of the year and takes about 1 to 2 weeks. A generous– rms-support@rotronic.chMnumber of measuring points is used to ensure that every zone iscovered!We recommend renewed mapping if a production or storagearea is modified or if there are other significant changes to theroom.Rotronic’s Universal Monitoring System: RMS15

ROTRONIC WORLDWIDERotronic is present in more than 40 countries worldwide. You can find a complete list of all our partners atwww.rotronic.comRotronic International16SWITZERLANDGERMANYFR ANCEITALYROTRONIC AGGrindelstrasse 6CH-8303 BassersdorfP: 41 44 838 11 44F: 41 44 838 14 83www.rotronic.chROTRONIC Messgeräte GmbHEinsteinstrasse 17– 23D-76275 EttlingenP: 49 7243 383 250F: 49 7243 383 260www.rotronic.deROTRONIC Sarl10, rue Graham BellBatiment H – lot 477600 Bussy Saint GeorgesP: 33 1 60 95 07 10F: 33 1 60 17 12 56www.rotronic.frROTRONIC Italia srlVia Repubblica di San Marino 1I-20157 MilanoP: 39 02 39 00 71 90F: 39 02 33 27 62 99www.rotronic.itUKUSACANADASINGAPOREROTRONIC Instruments UK Ltd.Crompton Fields, Crompton WayCrawley, West Sussex RH10 9EEP: 44 1293 571 000F: 44 1293 571 008www.rotronic.co.ukROTRONIC Instrument Corp.Suite 150, 135 Engineers Road,Hauppauge, NY 11788P: 1 631 427 3898F: 1 631 427 3902www.rotronic-usa.comROTRONIC Canada Inc.236 Pritchard Rd, Unit 204Hamilton, ON, CanadaL8W 3P7P: 1 905 754 5164F: 1 905 383 5593www.rotronic.caROTRONIC Instrument PTE Ltd.1003 Bukit Merah Central#06-31 Inno CentreSingapore 159836P: 65 6376 2107F: 65 6376 4439www.rotronic.sgCHINAJAPANROTRONIC Shanghai Rep. Office2B, Zao Fong Universe BuildingNo. 1800 Zhong Shan West RoadShanghai 200233, ChinaP: 86 40 0816 2018F: 86 10 8225 4374www.rotronic.cnROTRONIC Japanc/o Michell Japan KKMusashino Center Building1-19-18 Nakacho, MusashinoTokyo 180-0006P: 81 422 502 600www.rotronic.com5001E/2017-09Rotronic Partners

data to the data center via a gateway. In this way every module transmits its data to the RMS database. It must therefore be ensured by way of network connections that the RMS modules can reach the server with the Server Software. Display Module The display module can show any values from the RMS network.