Transcription

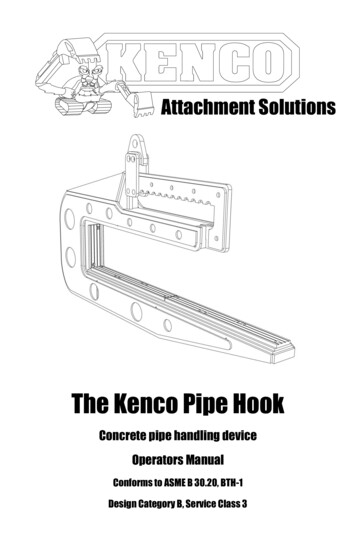

Attachment SolutionsThe Kenco Pipe HookConcrete pipe handling deviceOperators ManualConforms to ASME B 30.20, BTH-1Design Category B, Service Class 3

TABLE OF CONTENTSSection I.General Information . . 1Section II.Safety . .Section III.Identification of Major Components . 3Section IV.Setup . . 4Section V.Operation . . 5Section VI.Maintenance . 8Section VII.Inspection Criteria . 9Section VIII.Parts/Drawings . 11Section IX.Available Options . .17Section X.Warranty .17RECORD INFORMATION HERE FOR REFERENCEMODELBODY SERIAL NUMBERNotes:1

Section I. General InformationMay we take this opportunity to thank you for purchasing theKENCO Pipe Hook concrete pipe handling system. The Pipe HookSystem provides the ultimate in below the hook concrete pipeversatility. The Pipe Hook is quality engineered to provide years oftrouble free, low maintenance performance. Please read and fullyunderstand this manual and any additional attacheddocumentation before attempting to setup, operate or maintainthe Pipe Hook system.This manual should be made available to all persons whomay use or maintain the Pipe Hook system. For additionalinformation, please feel free to contact the service department atKenco at 1-800-653-6069Section II. SafetyA. General1.Safety practices described in this manual are intended as guidelinesfor safe operation under most conditions and are supplementary toany and all rules and/or laws governing any aspect of the KENCOPipe Hook operation that are in force in your area.2.Before operating the KENCO Pipe Hook, you should have aclear understanding of said laws and regulations to ensurecompliance.3.Throughout this manual there are parts tagged with one ormore of the following safety warnings. Particular care mustbe exercised with regard to these statements.1KENCO Pipe Hook Operation Manual

!DANGERThis warning is used where there is a high probabilityof death or serious injury if the instructions are notfollowed correctly.! WARNINGThis warning is used where there is a possibility ofinjury to yourself or others if the instructions are notfollowed correctly.! CAUTIONThis warning is used where there is a possibility ofdamage to the machine if the instructions are notfollowed correctly.B. Personal Safety1. Wear appropriate protective clothing and related safetyequipment including protective glasses, hardhat, gloves,protective shoes, hearing protection, and any otherequipment/devices dictated by job conditions.2. Do not wear loose clothing, jewelry, or hairstyles that couldbecome entangled in the KENCO Pipe Hook or rigginghardware.3. Keep hands, fee, and any other appendages clear of the PipeHook while in operation2KENCO Pipe Hook Operation Manual

C. Operation Safety1. DO NOT ATTEMPT TO OPERATE OR PERFORMMAINTENANCE ON THE PIPE HOOK UNTILREADING AND FULLY UNDERSTANDING THISMANUAL2. MAINTAIN SAFE DISTANCE FROM LOAD - NEVERALLOW PIPE HOOK OR LOAD TO PASS OVER ANYPART OF A PERSON.3. DO NOT USE A KENCO PIPE HOOK THAT HASBEEN ALTERED ACCIDENTALLY ORINTENTIONALLY, IN ANY WAY WITHOUTINSPECTION BY QUALIFIED PERSONNEL.4. DO NOT USE A KENCO PIPE HOOK FOR ANY TASKOTHER THAN THE INTENDED PURPOSE OF THEDESIGN.3KENCO Pipe Hook Operation Manual

Section III. Identification of Major ComponentsADJUSTABLELEVELERHORIZONTALPADVERTICAL PADPADBOLTS4KENCO Pipe Hook Operation Manual

Section IV. SetupA. Check The Pipe Hook for any signs of damage incurred duringshipping.B. Record model and serial #of assembly and components.C. Check that all pad bolts are tight.D. Check that all identification and warning labels are present.E. Attach Pipe Hook to hoist.1. Use as few rigging components (shackles, slings, chain,etc.) as possible.2. ALL RIGGING COMPONENTS MUST HAVE AWORKING LOAD LIMIT THAT IS EQUAL TO ORGREATER THAN THE COMBINED WEIGHT OFINTENDED LOAD PLUS THE PIPE HOOK.3. UNDER NO CIRCUMSTANCES SHOULD ANYCOMPONENT USED AS RIGGING TO THE PIPEHOOK BE OF A RATED CAPACITY LESS THANTHAT OF THE PIPE HOOK.4. DO NOT RIG UNPROTECTED NYLON SLINGS ORWIRE ROPE DIRECTLY THROUGH LIFT BAIL.5. IF USING EQUIPMENT OTHER THAN A CRANE:USE RIGGING OF SUFFICIENT LENGTH TOPREVENT CONTACT BETWEEN PIPE HOOK ANDEQUIPMENT.5KENCO Pipe Hook Operation Manual

Section V. Operation!DANGER!DANGER!DANGERBefore attempting to use the pipe hook deviceALWAYS perform a test lift on the intended object(s)to confirm proper operation. DO NOT use a pipehook to handle objects beyond the rated capacity orrange.Manipulation of the Pipe Hook by ground personnelfor the purpose of alignment with load shall only bedone with Pipe Hook suspended above the wall.KEEP ALL HANDS AWAY FROM Pipe HookDURING OPERATION.Surfaces of the load that come into contact with thegripping surfaces must be free of any foreignmaterial or coating that could compromise the grip.A. Operation1. Ensure that the Pipe Hook’s capacity and range areappropriate to the pipe to be handled.2. Ensure pads are clean and free of debris or contamination.3. Position Pipe Hook inside pipe by ensuring VERTICALPAD is contacting end of pipe while taking care not todamage pipe.4. Ensure that all persons are clear of Pipe Hook and pipe.5. Lower Pipe Hook onto center of pipe and slide theADJUSTABLE LEVELER to the appropriate slot for thepipe being lifted.6. Raise Pipe Hook and load in a smooth motion, do not“jerk”.7. Deposit at desired location8. Lower Pipe Hook onto center of pipe and slide theADJUSTABLE LEVELER to its furthest back position andremove Pipe Hook.6KENCO Pipe Hook Operation Manual

Tip: The majority of wear on the Pipe Hook will result from shockloading, impacting, and poor alignment of the Pipe Hook with theload. Minimizing these incidents will greatly extend the life of the PipeHook and consumables.B. AVOID JARRING, WEINGING, AND OTHERWISEUNNECESSARY MANIPULATION OF THE LOAD.C. AVOID HANDLING OF LOADS OFF CENTER.D. DO NOT USE THE PIPE HOOK TO PICK MULTIPLESOF ITEMS IN A SINGLE PICK.E. OBSERVE ALL SAFETY PRACTICES ASSOCIATEDWITH OPERATION OF HOIST MACHINERY.F.DO NOT USE PIPE HOOK TO DRAG LOADS.G. DO NOT ALLOW LOAD TO CONTACT ANYSURFACE/OBJECT WHILE BEING HANDLED.7KENCO Pipe Hook Operation Manual

Section VI.MaintenanceA.1.2.3.4.5.6.Daily:Visually inspect Pipe Hook for signs of stress and wear.Check that bolts and nuts are snug.Ensure free movement of all components.Ensure that all warning labels are present and readable.Lubricate all moving mechanisms with penetrating OIL.LUBRICATE ACTUATOR WITH LIGHTPENETRATING OIL ONLY (WD40 )7. For Pads:a. Check that all pad mounting bolts and nuts are tight.b. Ensure that pad material is sound, and not de-laminatedfrom backing plates.c. Ensure that pad mounting bolts heads are min.3/32’’below the surface of the pad. (see ill.)d. Ensure pads are clean and free of any foreign material orsubstance.BACKING PLATEPAD MOUNTINGCHANNEL OR ANGLEPADmin. 3/32’’8KENCO Pipe Hook Operation Manual

B. Annually*1. Remove pivot bolts and washers, coat with grease.2. Inspect holes, pins, bolts etc. for wear. See sect VII forcriteria.* Frequency depends on usage, environmental conditions, etc.Section VII.Inspection CriteriaTHE PIPE HOOK UNIT AND ALL OF ITS ASSOCIATEDCOMPONENTS SHALL BE REMOVED FROM SERVICEAND TAGGED APPROPRIATELY UNTILRECERTIFICATION BY A QUALIFIED INDIVIDUAL INANY OF THE FOLLOWING CONDITIONS:A. General1.2.3.4.Cracking in any component or member.Cracking in any weld.Visible distortion in any member.Visible distortion in any Bolt/Pin/Shaft.9KENCO Pipe Hook Operation Manual

B. Specific1. Lift Baila. The lift bail shall be replaced if a 20% loss in crosssectional area from the original member(s) can bedemonstrated. Note: cross section of welds,“mushroomed” wear faces, and burrs are notaccounted for as cross-sectional area. (see ill.)2. Holesa. Any members through which bolted or pinnedconnections pass shall be replaced if a 10% loss in crosssectional area from the original member(s) can bedemonstrated. Note: cross section of welds,“mushroomed” wear faces, and burrs are not accountedfor as cross-sectional area.3. Pins/Boltsa. Any visible deformation of a pin, shaft or bolt shallrequire replacement of that part.10KENCO Pipe Hook Operation Manual

Section VIII. Parts/Drawings11KENCO Pipe Hook Operation Manual

DANGER22DO NOT STAND UNDER OR NEARWHILE MACHINE IS OPERATINGKENCO CORPORATION877-4ATTACH23MODELWT.USAGE24THIS LIFTER IS DESIGNED TO ASME BTH-1CAPACITYDESIGN CATEGORYSERVICE CLASSSERIAL NO.12KENCO Pipe Hook Operation Manual

WARNING!DO NOT exceed the rated loadcapacity of the lifter.DO NOT attempt to operate amalfunctioning or damagedunit.25DO NOT allow unit or load to passover any part of a person.DO NOT leave a suspended loadunattended.DO NOT remove or obscure anylabels or markings.DO NOT operate or service withoutfirst having read andunderstood the operatingmanual.DO NOT lift loads higher thannecessary.DO NOT alter or modify thisequipment.!WARNINGDO NOT use ses.operator’smanual before2626using this equipment.DO NOT lift unbalanced loads.Failure to follow operatingDO NOT allow loadto contactand maintenanceproceduresothercould result in death orobjects whilesuspended.INSPECT LIFTER PRIOR TOEACH USE.13KENCO Pipe Hook Operation Manual

27 (ex.)NOQTY NAME11LIFT BALE ASSEMBLY22LIFT BALE BOLT32LIFT BAIL NUT414X13 PAD59PAD BOLT622-272#4X36 PADID& SAFETY TAGS14KENCO Pipe Hook Operation Manual

Section X. WarrantyA. Policy1. KENCO Corporation (KENCO) warrants the KENCOPipe Hook lifting device (not including consumable items)sold by KENCO to be free from proven defects in materialand workmanship for a period of six (6) months from thedelivery date to the original customer.2. Warranty is limited to replacement of parts and/orassemblies, which upon inspection by KENCO aredeemed to be defective in material, workmanship, or both.3. Warranty shall not extend to products that have beenaltered or repaired in any way without the express writtenconsent of KENCO.4. Warranty shall not extend to any product that has beenmisused, abused, or improperly applied or any defectresulting thereof.5. Defects and corrosion that are the result of improperstorage and/or maintenance are not warrantable.6. Wear items such as Pins or Lifting bails etc. are notconsidered for warranty claims.15KENCO Pipe Hook Operation Manual

B. Disclaimer1. THIS WARRANTY IS EXCLUSIVE AND IN LIEW OFALL OTHER REPRESENTATIONS ANDWARRANTIES EXPRESSED OR IMPLIED, ANDKENCO EXPLICITLY DISCLAIMS AND EXCLUDESANY IMPLIED WARRANTY OFMERCHANTABILITY FOR A PARTICULARPURPOSE. IN NO EVENT SHALL THE END USERBE ENTITLED TO ANY CONSEQUENTIAL,INCIDENTAL OR CONTINGENT DAMAGES OF ANYKIND ARISING OUT OF BREACH OF CONTRACT,WARRANTY (INCLUDING NEGLIGENCE ANDSTRICT LIABILITY) OR OTHER THEORIES OF LAW,WITH RESPECT TO PRODUCTS SOLD ORSERVICES RENDERED BY KENCO, OR ANYUNDERTAKINGS, ACTS OR OMISSIONS RELATINGTHERETO.16KENCO Pipe Hook Operation Manual

24 THIS LIFTER IS DESIGNED TO ASME BTH-1 DESIGN CATEGORY SERVICE CLASS. 13 KENCO Pipe Hook Operation Manual Read and understand RSHUDWRU¶VP DQXDOEHIRUH using this equipment. Failure to follow operating and maintenance procedures could result in death or ! WARNING 26 DO NOT exceed the rated load capacity of the lifter. DO NOT attempt to operate a malfunctioning