Transcription

Maximizing the Value ofNovartis' GMP PI Systemwith the EnterpriseAgreement: San Carlos SiteCase StudyPresented by Serge de GrandpréHervé Bajolle Copyright 2015 OSIsoft, LLC

Disclaimer"The information contained in this presentation belongs or has beenlicensed to Novartis and/or its affiliates. Novartis does not make andexpressly disclaims: (a) any representation or warranty (express orimplied) with respect to the information shown in this presentation; and(b) any liability relating to the accuracy, fitness for any purpose orcompleteness of the information. The views and opinions expressed inthis presentation are those of the author and do not necessarily reflectthe official policy or position of Novartis or any of its officers.”22

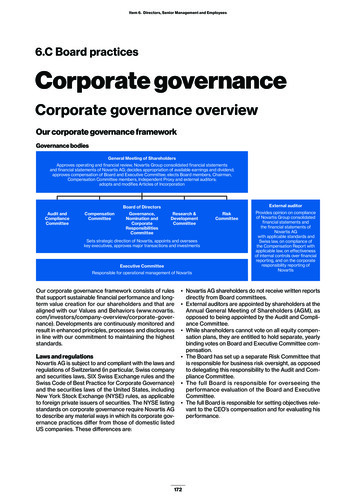

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI System Upgrade ProjectBusiness and Operational Value AchievedFuture Plans33

Global Pharmaceutical CompanyHeadquartered in Switzerland2014 Net Sales: 58 billion USDThree Main Divisions:41. Pharma2. Sandoz3. Alcon(brandedproducts)(generics)(visioncare)4

pharma ellsbranded medicines s yrespiratoryrheumatologytransplantationThere are Manufacturing Sites in over adozen countries55

San Carlos, California SiteHome of TOBI Podhaler Novartis acquired the pulmonary business ofNektar (San Carlos) in 2009 TOBI Podhaler was approved by the FDA in 2013 Approved for use in 68 countries Helps prevent chronic lung infections for cysticfibrosis patients66

San Carlos, California SiteManufacturing Capabilities 6 Spray Drying Systems 4 Filling Systems Clean Utilities and General Building UtilitiesSpray Dryer7Powder (PulmoSphereTM)R&D, Clinical & CommercialManufacturing ActivitiesFilled Capsule7

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI Upgrade ProjectBusiness and Operational Value AchievedFuture Plans88

Novartis and OSIsoft / EA Contract Need to leverage on edge technology and trustable partners toaccomplish the High Quality Manufacturing required in PharmaNovartis recognized OSIsoft/PI System from the very beginning, asreference company/product for their stringent requirementsSince 1999 the PI System has been used in Novartis and graduallythe PI Server has replaced all legacy HistoriansIn 2006 OSIsoft became the Pharma preferred supplier for 4 sitesfor 3 yearsIn 2013 the Enterprise Agreement (EA) with OSIsoft was signed Copyright 2015 OSIsoft, LLC9

Special Aspects of an EAUnlimitedFutureProofOptimizedEAPerpetualAll futureGlobalPriced by yourLicenseinterfacesExpertsmetricsUnlimitedAll futureBest practices All-inclusiveassistanceversionsBenchmarking pricingAll-inclusiveNimbleNo surprisesPartnerscalabilitytrainingDynamic, continuous improvement.One, and done. Copyright 2015 OSIsoft, LLC10

Enterprise ServicesUnder an executed Enterprise Agreement, customers have accessto a cumulative knowledge base built upon 30 years as an industry leader.Available services include:Enterprise AgreementAccess toCenter of twareUpgradesAssetMonitoringExtranet Copyright 2015 OSIsoft, LLC11

EA Goals MethodologySpecific objectives include who will be targeted and what will beaccomplished.Measurable objectives include how much change is expected,specifically enough that achievement of the objective can bemeasured through counting or documenting change.Achievable objectives can be realistically accomplished givenNovartis Pharma existing resources and constraints.Realistic objectives address the scope of the problem andpropose reasonable steps for achievement.Time-phased objectives provide a timeline indicating when theobjective will be met. Copyright 2015 OSIsoft, LLC12

NOVARTIS EA ObjectivesEA ObjectiveValueTimelineEnterprise Agreement SuccessCapture and clearly articulate the success of the EnterpriseAgreement program2Q 2018Value of the Global RolloutClearly articulate the value and benefits of the enterpriseinfrastructure to each global site.1Q 2016Deployment and Rollout PlanningDevelop a rollout plan that addresses the structure for therollout and support model1Q 2015Technology and Interface DesignDevelop a robust, highly available infrastructure1Q 2016Data Model DesignSupport critical manufacturing, continuous operations andwithout the reasonable loss of data1Q 2016MES Integration DesignDesign and integrate MES and PI to reduce and simplify thedata integration4Q 2015Continued Process Verification (CPV)The ability to verify the stability and capability of theproduction process.2Q 2016Process Analytical Technology (PAT)Provide timely data, identify weak points and preventprocess deviations4Q 2015Operational Solution CasesDevelop potential enterprise value areas that Novartis canrealize.1Q 2016 Copyright 2015 OSIsoft, LLC13

Progress to Date Copyright 2015 OSIsoft, LLC14

Novartis PI System Roll Out PlanSiteAssessmentInstallation ScheduledInstallation CompleteNovartis GrimsbyDoneDoneDoneNovartis ChemOps SwitzerlandIn ProgressNovartis TRD SwitzerlandIn ProgressNovartis HuningueDoneDoneDoneNovartis PharmOPS SteinDoneDoneDoneNovartis Singapore PharmaOpsDoneDoneDoneNovartis NSPM BiopharmOps SingaporeDoneDoneDoneNovartis San CarlosDoneDoneDoneNovartis Farmaceutica, Barbera del VallésIn ProgressNovartis Pharma Germany WehrIn ProgressNovartis RingaskiddyNovartis Urunleri PharmOps Kurtkoy Copyright 2015 OSIsoft, LLC15

San Carlos PI System Use Case Introduction San Carlos joined the EA on January 2014 It was selected for rolling out the PI System in adherence with theglobal standardization process defined in the HQ San Carlos started very soon to work in a very cooperative way withEPM, COE, FSE and TS We executed rollout per phases managing the project with a verymethodological approach The overall goal of the rollout was to address the businesschallenges that the San Carlos site was presenting to the projectteam Copyright 2015 OSIsoft, LLC16

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI System Upgrade ProjectBusiness and Operational Value AchievedFuture Plans1717

San Carlos SiteBusiness ChallengeSan Carlos Business Challenge:1) Need bigger and better PI System (site expansion)2) Need to Align with Novartis Automation StrategyNovartis Automation Strategy:It’s All About The Data“The rightinformation, forthe right user, atthe right ta18

The Novartis Automation StrategyThe Four Business Drivers Is my process in control ? How can I improve my process ? What is the yield ? Why are machines stopping ? Product transfer across sites Visibility of supply chainTech. R&D toCommercial2.Productivity4. 3.Flexibility IntegratedEnvironment Systems are integrated Data flows from ERP to shop floorand vice versaBusinessPlanning andLogistics SystemsLevel4 4LevelBusiness Process Information NetworkManufacturingManufacturingOperations andManagmentControlSystemsLevel 3InformationManagement SystemERP anAlarmsOperations Information NetworkProductionLevel onMgmtProcess tworkLevel 1EquipmentSupply Chain19Discrete DeviceEquipmentI/O andElements SensorsProcess DeviceProcessDeviceDiscrete ManufacturingLevelLevel00Continuous/ Batch Manufacturing19

The Novartis Automation StrategyThe Workcenter of the FutureObjectives1. “Lights out” Manufacturing High visibility of process without entering the room2. Paperless Manufacturing MES3. User Cockpits 20Information needed to drive the operation20

The Novartis Automation StrategySimplified Architecture: The PI System as the Central Data LayerERPCentral Data Layer forall the data coming fromthe shop floorCAPALIMSMESSerializationMVDASome data is written down to the equipment too(Initialization, NON-real-time-control)PI System Real-time data infrastructureScada 1Scada 2Scada 3Scada 4PLC 1PLC 2PLC 3PLC 421PAT 1IPC 1IPC 2InstrumentPAT 2InstrumentBMSControllers21

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI System Upgrade ProjectBusiness and Operational Value AchievedFuture Plans2222

The San Carlos PI System Upgrade ProjectProject Objectives1. Improve PI System robustness and data access»»Existing PI System had no PI Collective, no mPI, no AF, no PI CoresightPI DataLink and PI ProcessBook are behind firewall2. Lay the foundation for Novartis data infrastructure for future MES»23San Carlos equipment was already networked, with remote access capability23

The San Carlos PI System Upgrade ProjectHigh-Level Project Strategyo Rollout the “latest & greatest” PI System softwareo Rollout the OSIsoft/Novartis standard PI System architectureo Leverage EA for preparation, s/w installation, and basic s/w config.2424

The San Carlos PI System Upgrade ProjectProject Scope1. Install following applications:»»»»»»»»PI CollectiveAsset Framework (AF)PI CoresightManaged PINotificationsEvent Frames (EF)PI ProcessBook and PI DataLinkOPC interfaces and OPC ServersExisting system must keeprunning while new system isbeing implemented2. Migrate data from old PI Server3. Document and Qualify System2525

The San Carlos PI System Upgrade ProjectTechnical Project Strategy Use VM’s (HA) for all servers and interface nodes Build separate system in parallel with existing one Have OSIsoft engineers perform remote installation 26Using Bomgar sessions in presence of System AdminExecute project internally, except for one validation contractor26

The San Carlos PI System Upgrade ProjectSan Carlos System ArchitectureNovartis Standard PI Architecture(developed with OSIsoft COE)Tag Count: 7,000 tagsInterface Nodes run only PI OPC Interfaceand OPC Server (which talks to A-B PLCs)2727

The San Carlos PI System Upgrade ProjectProject Noteworthy Highlights28 Remote installation worked very well (but took slightly longer) Use of VMs allowed quick turnaround for changes28

The San Carlos PI System Upgrade ProjectProject Noteworthy Highlights (cont’d) Minor issue during Data Migration: Lost the newly created interface health tags, Notification & EF history tagsHad to be re-created Qualification went very well»» 29Risk-based approach for Quality-Critical tagsSome Non-Quality-Critical functionality (eg Notifications) was not OQ’dProject Completed in 8 months29

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI System Upgrade ProjectBusiness and Operational Value AchievedFuture Plans3030

The San Carlos PI System Upgrade ProjectBusiness Value Achieved San Carlos is the first site to rollout standard architecture with latest software Architectural foundation is laid out for ‘Workcenter of the Future’ Project direct costs were very low 31Realizing EA Value:Most of it covered by EA, or done by internal staff31

The San Carlos PI System Upgrade ProjectOperational Value Achieved PI Coresight dramatically improves access to data»»»»32Application available on business networkUsers can browse AF Elements to find dataCan teach a new user in 5 minutesNo more data request to Automation Engineers!32

The San Carlos PI System Upgrade ProjectOperational Value Achieved (cont’d) Users are using PI Coresight iPhone appoo33Facilities team can check status of utilities (water, steam, etc)Engineers & Management can check status of manuf. equip.33

The San Carlos PI System Upgrade ProjectOperational Value Achieved (cont’d)34 ‘Managed PI’ frees up internal resources Implemented a risk-based approach to managing Quality-Criticaltags vs. Non-Quality-Critical tags34

OSIsoft UC 2015San Carlos Case StudyThe Novartis Company and the San Carlos Site at a GlanceOSIsoft/Novartis Enterprise AgreementBusiness ChallengeSan Carlos PI System Upgrade ProjectBusiness and Operational Value AchievedPlans for the Future3535

The San Carlos PI SystemPlans for the Future Store data from BAS and from three remaining Process Units inPI Server3636

The San Carlos PI SystemPlans for the Future Monitor QC Equip. with PI ProcessBook and NotificationsWill use templates from‘Monitoring & AlarmingSystem’ developed atSingapore site3737

The San Carlos PI SystemPlans for the Future (cont’d) Create dashboard showing the status of every major equipment on site Use Event Frames to analyze/compare Spray Dryer batches3838

Maximizing the Value of Novartis' GMP PI System with theEnterprise Agreement: San Carlos Site Case Study“We fully leveraged the EA to upgradethe San Carlos Site PI System. Theproject was extremely successful, andwe are now well-positioned toimplement the rest of the NovartisAutomation Strategy”Serge de GrandpréNovartis Pharmaceuticals Corp.Business ChallengesA.Need bigger and better PI Systemdue to site expansionB.Need to align with NovartisAutomation StrategyC.SolutionA.Leverage EA for software andinstallation services to upgradeaging PI SystemB.Implement new state-of-the-art androbust PI System, and migratehistorical dataC.Use PI Coresight to improve accessto dataUsers find it difficult to access PI dataResults and BenefitsA.Extremely successful implementation(fast and with no issues)B.Productivity is increased as users havemuch easier access to data to makeGMP decisionsC.Foundation is laid out to implementMES (part of ‘The Workcenter of theFuture’ initiative). Copyright 2015 OSIsoft, LLC3

Serge de GrandpreHerve Bajolle /Vito Ruggieriserge.de i@osisoft.comSr. Engineer,Automation & ControlsCenter of Excellence Engineer/ Enterprise Program ManagerNovartisPharmaceuticals Corp.OSIsoft Copyright 2015 OSIsoft, LLC40

QuestionsPlease wait for the microphonebefore asking your questionsState yourname & company Copyright 2015 OSIsoft, LLC41

Copyright 2015 OSIsoft, LLC

Using Bomgar sessions in presence of System Admin Execute project internally, except for one validation contractor 26 . . tags vs. Non-Quality-Critical tags 34 . OSIsoft UC 2015 San Carlos Case Study The Novartis Company and the San Carlos Site at a Glance Plans for the Future