Transcription

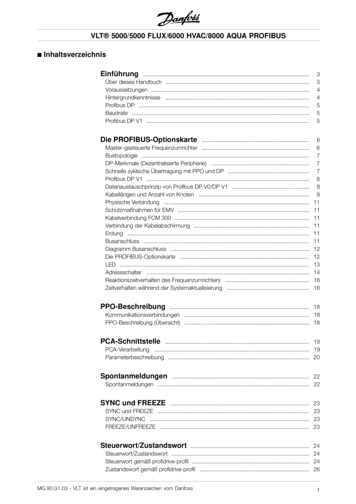

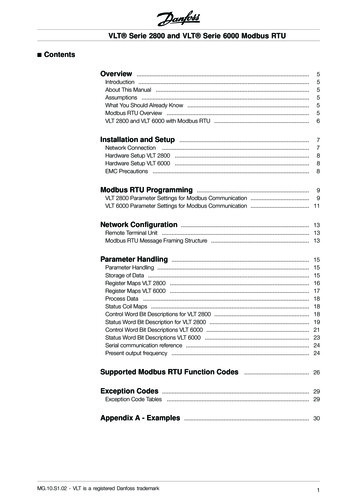

VLT Serie 2800 and VLT Serie 6000 Modbus RTUåContentsOverview5555556Installation and Setup77888.Introduction .About This Manual .Assumptions .What You Should Already Know .Modbus RTU Overview .VLT 2800 and VLT 6000 with Modbus RTU .Network Connection .Hardware Setup VLT 2800 .Hardware Setup VLT 6000 .EMC Precautions .Modbus RTU Programming. 9VLT 2800 Parameter Settings for Modbus Communication . 9VLT 6000 Parameter Settings for Modbus Communication . 11Network Configuration. 13Remote Terminal Unit . 13Modbus RTU Message Framing Structure . 13Parameter Handling.Parameter Handling .Storage of Data .Register Maps VLT 2800 .Register Maps VLT 6000 .Process Data .Status Coil Maps .Control Word Bit Descriptions for VLT 2800 .Status Word Bit Description for VLT 2800 .Control Word Bit Descriptions VLT 6000 .Status Word Bit Descriptions VLT 6000 .Serial communication reference .Present output frequency .Supported Modbus RTU Function Codes15151516171818181921232424. 26Exception Codes. 29Exception Code Tables . 29Appendix A - ExamplesMG.10.S1.02 - VLT is a registered Danfoss trademark. 301

VLT Serie 2800 and VLT Serie 6000 Modbus RTUVLT 2800 Series195NA009.17å Software Version VLT 2800 and VLT 6000Operating instructionsSoftware version: 2.8xVLT 6000 HVAC175ZA691.13These operating instructions can be used for all VLT 2800Series frequency converters with software version 2.8x.The software version number can be seen from parameter640 Software version no.Operating InstructionsSoftware version: 2.6xThese Operating Instructions can be used for all VLT 6000HVAC frequency converters with software version 2.6x.The software version number can be seen from parameter624.2MG.10.S1.02 - VLT is a registered Danfoss trademark

å High Voltage WarningRotating shafts and electrical equipmentcan be hazardous. Therefore, it is stronglyrecommended that all electrical workconform to National Electrical Code (NEC) and all localregulations. Installation, start-up and maintenanceshould be performed only by qualified personnel.Motor control equipment and electronic controls areconnected to hazardous line voltages. When servicingå Warnings Against Unintended Start1. While the frequency converter is connectedto the AC line, the motor can be brought toa stop by means of external switch closures,serial bus commands or references. If personalsafety considerations make it necessary toensure that no unintended start occurs, thesestops are not sufficient.2. During programming of parameters, the motormay start. Be certain that no one is in thefrequency converters and electronic controls, there willbe exposed components at or above line potential.Extreme care should be taken to protect against shock.Stand on an insulating pad and make it a habit to useonly one hand when checking components. Alwayswork with another person in case of an emergency.Disconnect power whenever possible to check controlsor to perform maintenance. Be sure equipment isproperly grounded. Wear safety glasses wheneverworking on electric control or rotating equipment.area of the motor or frequency converter drivenequipment when changing parameters3. A motor that has been stopped may startunexpectedly if faults occur in the electronicsof the frequency converter, or if an overload, afault in the supply AC line or a fault in the motorconnection or other fault clears.4. If the "Local/Hand" key is activated, the motorcan only be brought to a stop by means of the"Stop/Off" key or an external safety interlock.å Electrostatic discharge (ESD)Electronic components are sensitive toelectrostatic discharge (ESD). ESD canreduce performance or destroy sensitiveelectronic components. Follow proper ESD proceduresduring installation or servicing to prevent damage.Warning:It can be extremely dangerous to touch the electrical partseven when the mains supply has been disconnected.Also ensure that other voltage inputs are disconnectedfrom load sharing through the DC bus.Wait at least 4 minutes after the input power has beenremoved before servicing the drive.195NA139.10VLT 2800MG.10.S1.02 - VLT is a registered Danfoss trademark3Safety - ModbusRTUVLT Serie 2800 and VLT Serie 6000 Modbus RTU

Warning:Touching the electrical parts may be fatal - even after the equipmenthas been disconnected from mains.Using VLT 6002 - 6005, 200-240 V: Wait at least 4 minutesUsing VLT 6006 - 6062, 200-240 V: Wait at least 15 minutesUsing VLT 6002 - 6005, 380-460 V: Wait at least 4 minutesUsing VLT 6006 - 6072, 380-460 V: Wait at least 15 minutesUsing VLT 6102 - 6352, 380-460 V: Wait at least 20 minutesUsing VLT 6400 - 6550, 380-460 V: Wait at least 15 minutesUsing VLT 6002 - 6006, 525-600 V: Wait at least 4 minutesUsing VLT 6008 - 6027, 525-600 V: Wait at least 15 minutesUsing VLT 6032 - 6275, 525-600 V: Wait at least 30 minutesVLT 60004MG.10.S1.02 - VLT is a registered Danfoss trademark175HA490.11VLT Serie 2800 and VLT Serie 6000 Modbus RTU

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå OverviewFor specific information on installation and operationof the frequency converter, refer to the VLT 2800Operating Instructions, MG.28.AX.YY / VLT 6000Operating Instructions, MG.60.AX.YY.å About This ManualThese operating instructions are intended to be used forboth instruction and reference. It only briefly touches onthe basics of the Modbus protocol whenever necessaryto gain an understanding of the Modbus RTU.These operating instructions are also intended toserve as a guideline when you specify and optimizeyour communication system. Even if you are anexperienced Modbus programmer, it is suggestedthat you read these operating instructions in itsentirety before you start programming since importantinformation can be found in all sections.å AssumptionsThese operating instructions assume that you havea controller that supports the interfaces in thisdocument and that all the requirements stipulated inthe controller, as well as the frequency converter, arestrictly observed, along with all limitations therein.reported. It establishes a common format for thelayout and contents of message fields.During communications on a Modbus RTU network,the protocol determines how each controller will knowits device address, recognize a message addressedto it, determine the kind of action to be taken, andextract any data or other information contained inthe message. If a reply is required, the controller willconstruct the reply message and send it.Controllers communicate using a master-slavetechnique in which only one device (the master) caninitiate transactions (called queries). The other devices(slaves) respond by supplying the requested data to themaster, or by taking the action requested in the query.The master can address individual slaves, or caninitiate a broadcast message to all slaves. Slavesreturn a message (called a response) to queries thatare addressed to them individually. Responses are notreturned to broadcast queries from the master.The Modbus RTU protocol establishes the formatfor the master’s query by placing into it the device(or broadcast) address, a function code definingthe requested action, any data to be sent, and anerror-checking field. The slave’s response messageis also constructed using Modbus protocol. Itcontains fields confirming the action taken, any datato be returned, and an error-checking field. If anerror occurred in receipt of the message, or if theslave is unable to perform the requested action,the slave will construct an error message and sendit in response or a timeout will occur.å What You Should Already KnowThe Modbus RTU is designed to communicate with anycontroller that supports the interfaces defined in thisdocument. It is assumed that you have full knowledgeof the capabilities and limitations of the controller.å Modbus RTU OverviewModbus RTU (Remote Terminal Unit) protocol definesa message structure that controllers will recognizeand use, regardless of the type of physical networksover which they communicate. It describes theprocess a controller uses to request access to anotherdevice, how it will respond to requests from theother devices, and how errors will be detected andMG.10.S1.02 - VLT is a registered Danfoss trademark5Overviewå IntroductionThese operating instructions provide comprehensiveinstructions on the installation and set up of the ModbusRTU for the VLT 2800 and the VLT 6000 FrequencyConverter to communicate over a Modbus network.

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå VLT 2800 and VLT 6000 with Modbus RTUThe frequency converter communicates in ModbusRTU format over an EIA-485 (formerly RS-485)network. Modbus RTU allows access to the frequencyconverter’s Control Word and Bus Reference.The Control Word allows the Modbus master to controlseveral important functions of the frequency converter: Start Stop the frequency converter in several ways:Coast stopQuick stopDC Brake stopNormal (ramp) stop Reset after a fault trip Run at a variety of preset speeds Run in reverse Change the active setup Control the frequency converter’s two built-in relaysThe Bus Reference is commonly used for speed control.It is also possible to access the parameters, readtheir values, and, where possible, write values tothem. This permits a range of control possibilities,including controlling the frequency converter’s setpointwhen its internal PID controller is used.6MG.10.S1.02 - VLT is a registered Danfoss trademark

VLT Serie 2800 and VLT Serie 6000 Modbus RTUand SetupModbus RTU is a transmission protocol developed forprocess control systems. The Modbus standard doesnot specify the physical interface for the protocol i.e.a number of different interfaces can be chosen.The Modbus RTU protocol is based on the build-inRS-485 (EIA-485) interface.RS-485 is a two-wire bus-interface that allowsmulti-drop network topology i.e. nodes canbe connected as a bus, or via drop cablesfrom a common trunk line.A total number of 32 nodes can be connected toone Modbus RTU network segment, and a total of247 nodes in a network are supported.Network segments are divided with repeaters.Please note that each repeater counts for a nodein each segment it’s installed.Every node connected to the same network must havean unique nodes address, across all segments.Every segment must be terminated in both ends, eitherwith the termination switches (switch 2 & 3) of the VLT6000 or with a biased termination resistor network.For bus-cabling always use cable of screenedtwisted pair type (STP), and make sure to followgood common installation practice.Make sure the screen of the Modbus RTU cable mustalways be connected to ground at all nodes.It is very important to have a low impedance groundconnection of the screen, also at high frequencies.This can be obtained by connecting a large surfaceof the screen to ground, for example by means ofa cable clamp or a conductive cable gland.Particularly in installation where there is longcable lengths, it can be necessary to applypotential equalizing cables to ensure same groundpotential throughout the network.To prevent impedance mismatch, always use cableof same type across the entire network.When connecting a motor to the frequency converter,make sure always to use screened motor cable.Adress range:1 - 247Baud Rate:300 - 9600 bpsCable:Screened twisted pair (STP)Impedance: 120 OhmCable length:Max. 1200 m (including drop lines)Max. 500 m station-to-stationInstallation andSetupå Installationå Network ConnectionConnect the frequency converter to the Modbus RTU inaccordance with the following procedure (see Figure 1).1. Connect signal wires to terminal 68 (P ) andterminal 69 (N-) on main control board ofthe frequency converter.2. The shield of the cable must be connectedto the cable clamps.NB!:It is recommended to use shielded, twisted-paircables to reduce noise between conductors.Figure 1 Network Terminal ConnectionMG.10.S1.02 - VLT is a registered Danfoss trademark7

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå Hardware Setup VLT 2800The VLT 2800 control card does not have build-intermination network for RS 485. To terminate with theå Hardware Setup VLT 6000A terminator dip switch on the main control boardof the frequency converter is used to terminate theModbus RTU bus. The switch positions shownin Figure 2 demonstrate the factory setting. Table1 lists the switch functions and settings requiredfor Modbus RTU operation.correct impedance in the network the following resistorsshould be applied at the first and the last station.Figure 2 Terminator Switch Factory SettingNB!:Factory setting for DIP Switch is on.Table 1 Terminator Switch Functions and Modbus RTUSwitchSettingSwitches 2 & 3 Used for terminating an RS-485 interface. On first and last devices in a multiple devicenetwork, or on the only device in a single device network, switches 2 and 3 must be ON.On all other devices in a multiple device network, 2 and 3 must be OFF.NB!:Terminator switch positions must be setcorrectly in accordance with Table 1 for properModbus RTU serial communication.å EMC PrecautionsThe following EMC precautions are recommendedin order to achieve interference-free operationof the Modbus RTU network.NB!:Relevant national and local regulations,for example regarding protective earthconnection, must be observed.8The Modbus RTU communication cable must bekept away from motor and brake resistor cables toavoid coupling of high frequency noise from onecable to the other. Normally a distance of 200 mm (8inches) is sufficient, but it is generally recommendedto keep the greatest possible distance between thecables, especially where cables run in parallel overlong distances. If the Modbus RTU cable has tocross a motor and brake resistor cable they mustcross each other at an angle of 90 degrees.MG.10.S1.02 - VLT is a registered Danfoss trademark

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå VLT 2800 Parameter Settings for ModbusCommunicationUsing the Modbus RTU Protocol requires settingof the below listed parameters.Function:This parameter is for programming the speed at whichdata is transmitted via the serial port. Baud rate isdefined as the number of bits transmitted per second.NB!:Please make sure that par. 512 TelegramProfile is set to FC PROTOCOL.Description of choice:The frequency converter’s transmission speedmust be set at a value corresponding to thetransmission speed of the master.Parameter 501 Baudrate cannot be selected via theserial port, but must be preset via the operating unit.See the VLT 2800 Operating InstructionsMG.28.AX.YY for details on selecting and changingparameter values, if necessary.561 Protocol(PROTOCOL) Factory settingValue:jFC protocol (FC PROTOCOL)Metasys N2 (METASYS N2)MODBUS RTU (MODBUS RTU)500 Address(BUS ADDRESS)j 1Description of choice:j 1570 Modbus parity and message framing(M.BUS PAR./FRAME)Description of choice:The individual frequency converter must beallocated a unique address.If the number of units connected (frequency converters master) is higher than 31, a repeater must be used.Parameter 500 Address cannot be selected via the serialcommunication, but must be preset via the control unit.Value:(EVEN/1 STOPBIT)(ODD/1 STOPBIT)j (NO PARITY/1 STOPBIT)(NO PARITY/2 STOPBIT)[0][1][2][3]Function:This parameter sets up the drive’s Modbus RTUinterface to communicate properly with the mastercontroller. The parity (EVEN, ODD, or NO PARITY) mustbe set to match the setting of the master controller.Description of choice:501 Baudrate(BAUDRATE)MG.10.S1.02 - VLT is a registered Danfoss trademarkSelect the required control word protocol.j 1Function:This parameter allows the allocation of anaddress to each frequency converter in a serialcommunication network.Value:300 Baud (300 BAUD)600 Baud (600 BAUD)1200 Baud (1200 BAUD)2400 Baud (2400 BAUD)4800 Baud (4800 BAUD)j9600 Baud (9600 BAUD)Function:There is a choice of three different protocols.[0][1][2][3][4][5]Select the parity that matches the setting for theModbus master controller. Even or odd parity issometimes used to allow a transmitted word to bechecked for errors. Because Modbus RTU usesthe more efficient CRC (Cyclic Redundancy Check)method of checking for errors, parity checking isseldom used in Modbus RTU networks.9Modbus RTUProgrammingValue:Parameter 500 Protocol FC protolkol [0]0 - 247Parameter 500 Protocol Metasys N2 [1]1 - 255Parameter 500 Protocol MODBUS RTU [3]1 - 247[1][2][3]

VLT Serie 2800 and VLT Serie 6000 Modbus RTU571Modbus communications timeout(M.BUS COM.TIME.)Value:10 ms - 2000 msj 100 msFunction:This parameter determines the maximum amountof time that the drive’s Modbus RTU will waitbetween characters that are sent by the mastercontroller. When this amount of time expires, thedrive’s Modbus RTU interface will assume that ithas received the entire message.Description of choice:Generally, the value of 100 ms is sufficient for ModbusRTU networks, although some Modbus RTU networksmay operate on a timeout value as short as 35 ms.If this value is set too short, the drive’s Modbus RTUinterface may miss a part of the message. Since theCRC check will not be valid, the drive will ignore themessage. The resulting retransmissions of messageswill slow communications on the network.If this value is set too long, the drive will wait longerthan necessary to determine that the message iscompleted. This will delay the drive’s response to themessage and possibly cause the master controller totime out. The resulting retransmissions of messageswill slow communications on the network.10MG.10.S1.02 - VLT is a registered Danfoss trademark

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå VLT 6000 Parameter Settings for ModbusCommunicationUsing the Modbus RTU Protocol requires settingof the below listed parameters.See the VLT 6000 Operating InstructionsMG.60.AX.YY for details on selecting and changingparameter values, if necessary.cannot be chosen via serial communication, butmust be set via the LCP control unit.570 Modbus parity and message framing(M.BUS PAR./FRAME)Value:(EVEN/1 STOPBIT)(ODD/1 STOPBIT)j (NO PARITY/1 STOPBIT)(NO PARITY/2 STOPBIT)500Protocol(PROTOCOL)Value:jFC protocol (FC PROTOKOL)Metasys N2 (METASYS N2)Landis/Staefa Apogee FLN (LS FLN)Modbus RTU (MODBUS RTU)[0][1][2][3]Function:There is a choice of four different protocols.Description of choice:Select the required control word protocol.501 Address(ADRESSE)Value:Parameter0 - 126Parameter1 - 255Parameter0 - 98Parameter1 - 247j 1500 Protocol Metasys N2 [1]j 1500 Protocol LS FLN [2]j 1500 Protocol MODBUS RTU [3]Description of choice:The individual frequency converter must begiven a unique address.If the number of units connected (frequencyconverters master) exceeds 31, an amplifier(repeater) must be used.Parameter 501 AddressMG.10.S1.02 - VLT is a registered Danfoss trademarkDescription of choice:Select the parity that matches the setting for theModbus master controller. Even or odd parity issometimes used to allow a transmitted word to bechecked for errors. Because Modbus RTU usesthe more efficient CRC (Cyclic Redundancy Check)method of checking for errors, parity checking isseldom used in Modbus RTU networks.571500 Protocol FC protolkol [0]Function:In this parameter it is possible to allocate anaddress in a serial communication network toeach frequency converter.Function:This parameter sets up the drive’s Modbus RTUinterface to communicate properly with the mastercontroller. The parity (EVEN, ODD, or NO PARITY) mustbe set to match the setting of the master controller.j 1Modbus communications timeout(M.BUS COM.TIME.)Value:10 ms - 2000 msj 100 msFunction:This parameter determines the maximum amountof time that the drive’s Modbus RTU will waitbetween characters that are sent by the mastercontroller. When this amount of time expires, thedrive’s Modbus RTU interface will assume that ithas received the entire message.Modbus RTUProgramming Factory setting[0][1][2][3]Description of choice:Generally, the value of 100 ms is sufficient for ModbusRTU networks, although some Modbus RTU networksmay operate on a timeout value as short as 35 ms.If this value is set too short, the drive’s Modbus RTUinterface may miss a part of the message. Since theCRC check will not be valid, the drive will ignore themessage. The resulting retransmissions of messageswill slow communications on the network.11

VLT Serie 2800 and VLT Serie 6000 Modbus RTUIf this value is set too long, the drive will wait longerthan necessary to determine that the message iscompleted. This will delay the drive’s response to themessage and possibly cause the master controller totime out. The resulting retransmissions of messageswill slow communications on the network.12MG.10.S1.02 - VLT is a registered Danfoss trademark

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå NetworkConfigurationå Remote Terminal UnitThe controllers are setup to communicate on theModbus network using RTU (Remote TerminalUnit) mode, with each 8-bit byte in a messagecontains two 4-bit hexadecimal characters. Theformat for each byte is shown below.Coding System:8-bit binary, hexadecimal 0-9, A-FTwo hexadecimal characters contained ineach 8-bit field of the messageBits Per Byte:1 start bit8 data bits, least significant bit sent first1 bit for even/odd parity; no bit for no parity1 stop bit if parity is used; 2 bits if no parityError Check Field:Start bitData bitCyclical Redundancy Check (CRC)Stop/Stopparityå Modbus RTU Message Framing StructureA Modbus RTU message is placed by the transmittingdevice into a frame with a known beginning andending point. This allows receiving devices to beginat the start of the message, read the address portion,determine which device is addressed (or all devices,if the message is broadcast), and to know whenthe message is completed. Partial messages aredetected and errors set as a result.monitor the network bus continuously, including ‘silent’intervals. When the first field (the address field) isreceived, each frequency converter or device decodesit to determine whether it is the addressed device.Modbus RTU messages addressed to zero arebroadcast messages. No response is permittedon broadcast messages.A typical message frame is shown below.The allowable characters transmitted for all fieldsare hexadecimal 00 to FF. The frequency converterAddress8 BitsFunctionDataCRC Check8 Bitsn x 8 bits16 BitsTypical Modbus RTU Message Structureå Start/Stop FieldMessages start with a silent interval of at least 3.5character times. This is implemented as a multiple ofcharacter times at the selected network baud rate(shown as Start T1-T2-T3-T4). The first field thentransmitted is the device address. Following the lasttransmitted character, a similar interval of at least 3.5character times marks the end of the message. Anew message can begin after this interval.EndT1-T2-T3-T4frame, the receiving device flushes the incompletemessage and assumes that the next byte will bethe address field of a new message.Similarly, if a new message begins earlier that 3.5character times following a previous message, thereceiving device will consider it a continuation of theprevious message. This will cause a timeout (noresponse from the slave), since the value in the finalCRC field is not valid for the combined messages.NetworkConfigurationStartT1-T2-T3-T4The entire message frame must be transmitted as acontinuous stream. If a silent interval of more than1.5 character times occurs before completion of theMG.10.S1.02 - VLT is a registered Danfoss trademark13

VLT Serie 2800 and VLT Serie 6000 Modbus RTUå Address FieldThe address field of a message frame contains 8 bits.Valid slave device addresses are in the range of 0 –247 decimal. The individual slave devices are assignedaddresses in the range of 1 – 247. (0 is reserved forbroadcast mode, which all slaves recognize.) A masteraddresses a slave by placing the slave address in theaddress field of the message. When the slave sends itsresponse, it places its own address in this address fieldto let the master know which slave is responding.receiving device recalculates a CRC during receipt ofthe message and compares the calculated value tothe actual value received in the CRC field. If the twovalues are not equal, a bus timeout results.The error checking field contains a 16-bit binaryvalue implemented as two 8-bit bytes. When this isdone, the low-order byte of the field is appended first,followed by the high-order byte. The CRC high-orderbyte is the last byte sent in the message.å Coil/Register Addressingå Function FieldAll data addresses in Modbus messages are referencedThe function field of a message frame contains 8 bits.to zero. The first occurrence of a data item isValid codes are in the range of 1-FF. (See sectionaddressed as item number zero. For example:Modbus RTU Function Codes.) When a message issent from a master to a slave device, the function codeThe coil known as ‘coil 1’ in a programmable controllerfield tells the slave what kind of action to perform.is addressed as coil 0000 in the data addressfield of a Modbus message. Coil 127 decimal isWhen the slave responds to the master, it uses theaddressed as coil 007EHEX (126 decimal).function code field to indicate either a normal (error-free)response, or that some kind of error occurred (calledan exception response). For a normal response, theslave simply echoes the original function code. Foran exception response, the slave returns a codethat is equivalent to the original function code withits most-significant bit set to a logic 1. In addition,the slave places a unique code into the data fieldof the response message. This tells the masterwhat kind of error occurred, or the reason for theexception. See the chapter Exception Codes inthese operating instructions for definitions.Holding register 40001 is addressed as register0000 in the data address field of the message.The function code field already specifies a ‘holdingregister’ operation. Therefore, the ‘4XXXX’ referenceis implicit. Holding register 40108 is addressedas register 006BHEX (107 decimal).å Data FieldThe data field is constructed using sets of twohexadecimal digits, in the range of 00 to FFhexadecimal. These are made from one RTU character.The data field of messages sent from a master to slavedevice contains additional information which the slavemust use to take the action defined by the functioncode. This can include items like coil or registeraddresses, the quantity of items to be handled, andthe count of actual data bytes in the field.å CRC Check FieldMessages include an error-checking field that is basedon a cyclical redundancy check (CRC) method. TheCRC field checks the contents of the entire message. Itis applied regardless of any parity check method usedfor the individual characters of the message. The CRCvalue is calculated by the transmitting device, whichappends the CRC as the last field in the message. The14MG.10.S1.02 - VLT is a registered Danfoss trademark

VLT Serie 2800 and VLT Serie 6000 Modbus RTUHandlingå Parameter HandlingPNU (Parameter Number) is translated from theregister address contained in the Modbus read/writemessage. The parameter number is trans

VLT 6000 HVAC 175ZA691.13 Operating Instructions Software version: 2.6x These Operating Instructions can be used for all VLT 6000 HVAC frequency converters with software version 2.6x. The software version number can be seen from parameter 624. 2 MG.10.S1.02 - VLT is a registered Danfoss trademark.