Transcription

MAKING MODERN LIVING POSSIBLEDanfoss VLT DrivesVLT Product Catalogue50%Energy savingSpeed control of fans andpumps can in many cases leadto significant energy savings.www.danfoss.com/drives

VLT Decentral Drive FCD 302A single drive concept that covers the entire spectrumof drives applications – a major benefit in commissioning, operating and maintaining the equipment. VLT AutomationDrive comes in a standard version (FC 301)and an advanced high dynamic version (FC 302) withadditional functionalities, asynchronous and PM motorcontrol.The new generation of decentral drives based on theVLT AutomationDrive FC 302 platform. It combines thekey features of both products in a completely re-designed enclosure, made for best fit on direct machinemounting.PAGE 26VLT AutomationDriveVLT Decentral Drive FCD 300The VLT HVAC Drive is a dedicated, globally supporteddrive that combines flexibility and efficiency in a package designed to minimize total system and lifecyclecosts in HVAC applications. Designed to provide thehighest effi ciency solution with both asynchronous andpermanent magnet motors from all major suppliers, theVLT HVAC drive is the leading drive for heating, ventilation and air conditioning systems.A complete frequency converter designed for decentralmounting. It can be mounted on the machine/wall –close to the motor. The decentral design eliminates theneed for space-consuming control cabinets and theneed for long screened motor cables is significantlyreduced.PAGE 28VLT HVAC DriveVLT DriveMotor FCP 106Specially designed for the needs of refrigeration applications covering compressors, evaporators, condensers,pumps and cooling towers. Efficiently runs compressors,fans and pumps. Setup of the drive is made easy by thebuilt-in setup guide, that helps the installer programthe drive effectively & efficiently thus improving peopleproductivity and processes performance.With a wide range of standard integrated pump and fanfeatures, the VLT DriveMotor FCP 106 can provideefficient control of motors in the 0.55 – 7.5 kW range.By mounting the drive directly on the motor, owners arefree to choose their own motor manufacturer and designthe optimal system for their application.PAGE 30VLT Refrigeration DriveVLT DriveMotor FCM 106The perfect match for pumps and blowers in modernwater and wastewater systems, offering advancedapplication protective features. Available with cascadecontrol of up to 8 pumps in fixed speed mode or master/follower mode.With a wide range of standard, integrated pump and fanfeatures, the VLT DriveMotor FCM 106 is a highlydedicated, space saving motor and control solution inthe 0.55-7.5 kW range.The drive is delivered from the factory attached to eithera standard induction motor or a size optimizedpermanent magnet motor.PAGE 32VLT AQUA DriveVLT DriveMotor FCM 300Ideal solution for rope and hydraulic elevators. The driveis designed to meet the comfort requirements. Highefficiency and motor independent-concept help usdifferentiate from competitors.Integrated drive-motor solution which combines a VLT frequency converter and a high standard qualityinduction motor in a single product. The frequencyconverter is attached in place of the motor terminal boxand it is no higher than the standard terminal box – norwider or longer than the motor.PAGE 34VLT Lift DriveVLT 2800 SeriesVLT OneGearDrive A multi purpose drive offering a perfect match betweenprice and performance for industrial applications up to18,5 kW.A highly efficient permanent-magnet three-phasesynchronous motor coupled to an optimised bevel gearbox. As part of the Danfoss VLT FlexConcept the VLT OneGearDrive is an energy-efficient drive system thathelps to optimise plant productivity and reduce energycosts.PAGE 36PAGE 22PAGE 20PAGE 16PAGE 13PAGE 10PAGE 6Contents4A compact general purpose drive for AC motors up to22 kW. It performs perfectly even in complex applicationset-ups and optimises energy efficiency and operation.PAGE 38PAGE 24VLT Micro DriveVLT Integrated Servo Drive SystemISD 410A high performance Integrated Servo Drive systembased on PM motor technology. The motion control isintegrated in the drive. The communication bus is CAN. Itis a system for applications with a variable number ofaxis and it allows flexible machine structure within food& beverage and packaging.

Common mode filters are placed between the frequencyconverter and the motor. They are nano-crystalline coresthat mitigate high frequency noise in the motor cable(shielded or unshielded) and reduce bearing currents inthe motor.PAGE 54VLT Common Mode FiltersA total motor-starting solution with advanced start, stopand protection features, Adaptive Acceleration Control,inside delta connection, 4 line graphical display andmultiple programming setup menus.VLT Sine-Wave FiltersA compact and cost effective soft starter range for applications where direct-on-line starting is undesirable.MCD 200 is, because of its size and functionality, a goodalternative to other reduced voltage starting methodssuch as star/delta starters.Sine-Wave filters are placed between the frequencyconverter and the motor. They are differential-modelow-pass filters that suppress the switching frequencycomponent from the frequency converter and smoothout the phase-to-phase output voltage of the frequencyconverter to make it sinusoidal. This reduces the motorinsulation stress, bearing currents and eliminates theswitching acoustic noise from the motor.PAGE 56VLT Compact Starter MCD 200VLT Soft Start Controller MCD 100VLT dU/dt FiltersA cost effective and extremely compact soft starter forAC motors from 1.1 – 11 kW. Due to a unique semiconductor design it is a true “fit and forget” product.dU/dt filters are placed between the frequency converterand the motor. They are differential-mode low-pass filtersthat reduce motor terminal phase-to-phase peak voltagespikes and reduce the rise time to a level that lowers thestress on the insulation of motor windings. dU/dt filtersare smaller, weigh less and have a lower price comparedto Sine-Wave filters.PAGE 58PAGE 40PAGE 42PAGE 44VLT Soft Starter MCD 500PAGE 60Meets the toughest harmonic requirements under allload/grid conditions. The Danfoss VLT Low harmonicdrive is the first solution combining an active filter and adrive in one package. The VLT Low harmonic drivecontinuously regulates harmonic suppression accordingto the load and grid conditions without affecting theconnected motor.VLT Motion Control ToolMCT 10The VLT Motion Control Tool MCT 10 is the perfect toolto handle all drive-related data. The tool is useful in allphases of your project: programming, commissioning,daily use and even useful for service and maintenancepurposes. During commissioning a project can be prepared offline in advance and uploaded when the systemis online.VLT Motion Control Tool MCT 31A robust and cost effective harmonic solution for thehigher power range. The Danfoss 12-pulse VLT driveoffers reduced harmonics for demanding industryapplications above 250 kW. The 12-pulse VLT drive isa high efficiency variable frequency converter which isbuilt to the same modular design as the popular 6-pulseVLT drives.With VLT Motion Control Tool MCT 31, you candetermine whether harmonics will be an issue in yourinstallation as a consequence of nonlinear load. MCT 31estimates the benefits of adding various harmonicmitigation solutions from the Danfoss product portfolioand calculates system harmonic distortion.PAGE 6212-pulse VLT driveVLT Energy BoxA flexible and adaptable solution for central or decentral harmonic mitigation. Danfoss Advanced ActiveFilters can compensate for individual VLT drives as acompact integrated solution or can be installed as acompact stand-alone solution at a point of common coupling, compensating for multiple loads simultaneously.Danfoss Active Filters can operate at medium voltagelevel by means of a step-down transformer.With the VLT Energy Box Software you can early in theproject estimate the energy savings. Later you can easilycompare your estimations with the actual energy savingsand carbon footprint reduction using the trend andenergy data stored in your drive.VLT Advanced Harmonic FilterAHF 005/010The Danfoss Advanced Harmonic Filters have beenspecially designed to match the Danfoss frequency converters. The solution is available in two variants, AHF 005and AHF 010, connected in front of a Danfoss frequencyconverter, the harmonic current distortion generatedback to the mains is reduced to 5% and 10% Total Harmonic Current Distortion at full load.PAGE 64VLT Advanced Active Filter AAF 006VLT Service – Your wayPAGE 66PAGE 52PAGE 50PAGE 48PAGE 46VLT Low Harmonic DriveDrivePro is an efficient productivity programme tailored to meet your specific needs. Allthe necessary VLT Service facilities are at yourdisposal, which will minimize downtime andincrease productivity at your factory.5

VLT AutomationDriveThe premier, globally supported drive concept for exceptional control of motor driven applications.Designed for variable speed control of all asynchronous motors andpermanent magnet motors, on any industrial machine or production line, aVLT AutomationDrive helps its ownersave energy, increase flexibility, andoptimize processes.Flexible and expandableBuilt on a flexible, modular designconcept the AutomationDrive ispacked with standard, industryfeatures out of the box. These can beexpanded with plug-and-play optionswith additional features, positioningcontrol, fieldbuses, safety functionssuch as STO, SS1, SLS, SMS and SSM,motor protection and more.Robust and safeVLT AutomationDrives are provenperformers in all industrial environments and grid voltages, including690V. Enclosures are available upto IP 66 (depending on model), andintegrated DC chokes and RFI filtersin all models protect installations byminimizing harmonic distortion andelectromagnetic interferences. Alldrives are fully tested at the factorybefore they are shipped.6FeatureBenefitReliableAmbient temperature 50 C without deratingAvailable in IP 00, 20, 21, 54, 55and 66 enclosuresResistant to wear and tearBack-channel cooling for frame D, E and FUser-friendlyPlug-and-Play technologyAwarded control panelIntuitive VLT interfacePluggable cage clamp connectorsExchangeable languagesIntelligentIntelligent warning systemsSmart Logic ControlAdvanced plug-in featuresMaximum uptimeLess need for cooling or oversizingSafe stopSTO: Safe Torque Off (IEC 61800-5-2)Intelligent heat managementEasy to set up and operate via theuser-friendly graphical control panel,a VLT AutomationDrive only requireslittle maintenance once in operation.The result is an market leading controlsolution that provides a fast return oninvestment and a highly competitivecost of ownership.Enclosures for all environmentsLow lifetime costProlonged lifetime of electronicsSaves commissioning and operating costEasy upgrade and changeoverUser-friendlySaves timeEasy connectionUser-friendlyWarning before controlled stopReduces need for PLC capacityEasy commissioningSafety cat. 3, PL d (ISO 13849-1),Stop cat. 0 (EN 60204-1)SIL 2 (IEC 61508)SIL CL 2 (IEC 62061)Intelligent heat managementPower range3 x 200 – 240 V . 0.25 – 37 kW3 x 380 – 480/500 V. 0.37 – 800 kW3 x 525 – 600 V .0.75 kW – 75 kW3 x 525 – 690 V . 1.1 kW – 1.2 MWNormal overload .1.5 kW – 1.4 MW

Fieldbus options VLT PROFIBUS DP MCA 101 VLT DeviceNet MCA 104 VLT CanOpen MCA 105 VLT Profibus Converter MCA 113 VLT Profibus Converter MCA 114 VLT PROFINET MCA 120 VLT Ethernet/IP MCA 121 VLT Modbus TCP MCA 122 VLT POWERLINK MCA 123 VLT EtherCAT MCA 124 VLT DeviceNet Converter MCA 194SpecificationsI/O and feedback options VLT General Purpose I/O MCB 101 VLT Encoder Input MCB 102 VLT Resolver Input MCB 103 VLT Relay Card MCB 105 VLT 24 V External Supply MCB 107 VLT Extended Relay Card MCB 113 VLT Sensor Input MCB 114Switching on outputRamp timesNote: 160% current can be provided for 1 minute.Higher overload rating is achieved by oversizing the drive.Safety options VLT Safe PLC I/O MCB 108 VLT PTC Thermistor Card MCB 112 VLT Safe Option MCB 140 Series VLT Safe Option MCB 150 SerieMotion Control Options VLT Motion Control OptionMCO 305 VLT Synchronizing ControllerMCO 350 VLT Position Controller MCO 351 VLT Center Winder MCO 352Power options VLT Brake resistors MCE 101 VLT Sine-Wave Filters MCC 101 VLT dU/dt Filters MCC 102 VLT Common Mode Filter MCC 105 VLT Advanced Harmonic FiltersAHF 005/010Other accessories IP 21/NEMA 1 Kit(convert IP 20 to IP 21) PROFIBUS adapter Sub-D9 Connector Decoupling plate forfieldbus cables USB connection cable to PC Panel Through option LCP panel mounting kit Mounting brackets Mains disconnect option USB Extension Interbus gateway MCA 110 Option Adapter RCMB20/RCMB35 Leakage CurrentMonitor ModuleMains supply (L1, L2, L3)Supply voltageSupply frequencyTrue Power Factor (λ)Displacement Power Factor (cos φ) near unitySwitching on input supply L1, L2, L3Output data (U, V, W)Output voltageOutput frequency200 – 240 V 10%FC 301: 380 – 480 V 10%FC 302: 380 – 500 V 10%, 525 – 600 V 10%525 – 690 V 10%50/60 Hz0.92 nominal at rated load( 0.98)Maximum 2 times/min.0 –100% of supply voltageFC 301: 0.2 – 590 Hz (0.25 – 75 kW)FC 302: 0 – 590 Hz (0.25 – 75 kW)0 – 590 Hz (90 – 1200 kW)0 – 300 Hz (Flux mode)Unlimited1–3600 sec.Digital inputsProgrammable digital inputsFC 301: 4 (5) / FC 302: 4 (6)LogicPNP or NPNVoltage level0 – 24 VDCNote: One/two digital inputs can be programmed as digital output for FC 301/FC 302.Analogue inputAnalogue inputsModesCurrent level2Voltage or currentFC 301: 0 to 10 VFC 302: -10 to 10 V (scaleable)0/4 to 20 mA (scaleable)Pulse/encoder inputsProgrammable pulse/encoder inputsVoltage levelFC 301: 1 / FC 302: 20 – 24 V DC (PNP positive logic)Digital output*Programmable digital/pulse outputsVoltage level at digital/frequency outputFC 301: 1 / FC 302: 20 – 24 VAnalogue output*Programmable analogue outputsCurrent range10/4 – 20 mARelay outputs*Programmable relay outputsFC 301: 1 / FC 302: 2Voltage levelCable lengthsFC 301: 50 m / FC 302: 150 m(screened/armoured)FC 301: 75 m / FC 302: 300 m(unscreened/unarmoured)*More analogue and digital inputs/outputs can be added with options.Max. motor cable lengthsBrake chopper (IGBT) optionLimits the load on the intermediatecircuit in the case the motor acts as agenerator.High power options Emergency stop with Safety Relay Safety Stop with Safety Relay RFI Filters NAMUR terminals Residual Current Device Insulation Resistance Monitor Mains shielding Regen terminalsPlease see the VLT High Power DriveSelection Guide for the complete range ofoptions.7

VLT AutomationDrive – continuedCurrent and power C1C1C2C2C2D1h/ D1h/D3h D5h/ D5h/D6h 1530B4C3C4B1B1B1B2B2B2C1C1C1C2C2C2B4C3C4A4/A5D2h/ D2h/D4h D7h/ D7h/D8h D8hE2E1E1Consult factory* For selection of A1 see enclosure types in the code position 4 (FC 301 only)IP 00/Chassis8IP 20/ChassisIP 21/Type 1With upgrade kit –available in US onlyIP 54/Type 12IP 55/Type 12A4/A5A2A4/A5A25.57.5111518.5223037455575B3IP 66101316243237.544617390106147IP 551.21.62.12.73.44.86.3IP 541.31.82.434.15.67.2IP 211.21.62.12.73.44.86.3IP 201.31.82.434.15.67.2IP 00 440 VF1/F3A5 440 VF2/F4A5 440 VA1*/A2A3 440 VF1/F3A3A2Amp. NOF2/F4A2Amp. HOA1*/A224.230.846.259.474.888115143IP 66NO1.82.43.54.66.67.510.612.516.7A4/A5HOIP 55NO0.250.370.550.751.11.52.233.74.0IP 21HOT4/T5 380 – 480/500 P560P630P710P800P900P1M0P1M2P1M4P1M6A1*/A2FC 300Amp.IP 20T2 200 – 240 VkWIP 66/NEMA 4X

2836435465871051376.191122273441526283100131A3 A3 A5 A5A3 A3 A5 A5B3B4C3C4B1B1B1B2B2B2C1C1C1C2C2 70630730850945106012601415IP 344IP 0IP 541.62.23.24.5IP 212.12.73.94.9IP 20690 VIP 00550 VA3 A3A3 A3B4C3B2B2C2C2D1h/ D1h/D3h D5h/ D5h/D6h D6hD4D2h/ D2h/D4h D7h/ D7h/D8h 00120014001.72.42.73.94.9690 2.62.94.15.2Amp. NO550 VF1/F30.250.370.550.751.11.52.233.74.0IP 66 550 V 550 V 550 V 550 VIP 55NOT7 525 – 690 VAmp. 0P560P630P710P800P900P1M0P1M2HOAmp. NOIP 21FC 300Amp. HOIP2 0T6 525 – 600 VkWF122801400607F222801804607Dimensions [mm]A1H 200W 75D 207H W A2 A3 A4 A5 B1 B2268390 420 480 65090 130 200242205175 20026037590 130B3399165249475165B4 C1 C2 C3 C4 D1h D2h D3h D4h D5h D6h D7h D8h520 680 770 550 660 901 1107 909 1122 1324 1665 1978 2284230 308 370 308 370 325 420 250 350325420242 310 335333378375381384 402670755 950255329 607Note: H and W dimensions are with back-plate. H and W are with IP upgrade kit. D dimensions are without option. A or B for A2 and A3.9

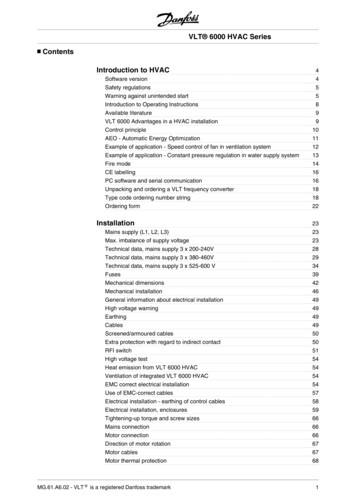

VLT HVAC DriveThe VLT HVAC Drive series is available in a wide power range designedfor all HVAC applications. An advanced drive built on HVAC dedication.The VLT HVAC Drive is a full-featured,HVAC dedicated drive with built-inintelligence. Every VLT HVAC Drive isbased on 25 years of experience andinnovation.The VLT HVAC Drive has a vast number of functions developed to meetthe diverse needs of the HVAC business. Easy to use, all models followthe same basic design and operatingprinciple. Once you know one, youknow them all.It is the perfect match for pumps,fans and compressors in modernbuildings that are fitted withincreasingly sophisticated solutions.Product range3 x 200 – 240 V . 1.1 – 45 kW3 x 380 – 480 V .1.1 – 1000 kW3 x 525 – 600 V . 1.1 – 90 kW3 x 525 – 690 V . 1.1 – 1400 kWWith 110% over load torqueAvailable enclosure ratingsIP 00 .335 – 630 kWIP 20 .1.1 – 400 kWIP 21 (Type 1).1.1 – 1400 kWIP 54 (Type 12) . 75 – 1400 kWIP 55 (Type 12) . 1.1 – 90 kWIP 66 (NEMA 4X indoor) . 1.1 – 90 kWOptional coating providing extra protectionfor aggressive environments.10FeatureAll built-in – low investmentModular product concept and a widerange of optionsDedicated HVAC I/O functionality fortemperature sensors etc.Decentral I/O control via serial communicationBenefitLow initial investment – max. flexibility,later upgrade possibleExternal conversion savedReduced wiring costs, and externalcontroller I/O savedWide range of HVAC protocols for BMSLess extra gateway solutions neededcontroller connectivity4 x auto tuned PID’sNo external PID controller neededSmart Logic ControllerOften makes PLC unnecessaryReal Time ClockEnables daily and weekly settingsIntegrated fan, pump and compressorSaves external control and conversionfunctionality i.e.equipmentFire Override Mode, Dry run DetectionProtects equipment and saves energyConstant Torque etc.Back-channel cooling for frame D, E and F frameProlonged lifetime of electronicsSave energy – less operation costAutomatic Energy Optimizer function,Saves 5 – 15% energyadvanced versionAdvanced energy monitoringOverview on energy consumptionEnergy saving functions i.e. flow compensation,Saves energysleep mode etc.Unequalled robustness – maximum uptimeRobust single enclosureMaintenance-freeUnique cooling concept with no ambient air flow Problem-free operation in harshover electronicsenvironmentsMax ambient temp. 50 C without deratingNo external cooling or oversize necessaryUser-friendly – save commissioning and operating costSmart startQuick and precise start-upAwarded graphical display, 27 languagesEffective commissioning and operationUSB plug and play connectionEasy to use PC software toolsGlobal HVAC support organisationLocal service – globallyBuilt-in DC coils and RFI filters – no EMC concernsIntegrated DC link harmonic filtersSmall power cables. Meets EN 61000-3-12Meets EN 55011 Class B, A1 or A2 andIntegrated EMC filtersIEC61800-3 Category C1, C2 and C3

Application optionsA wide range of integrated HVACoptions can be fitted in the drive:SpecificationsMains supply (L1, L2, L3)Supply frequencyDisplacement Power Factor (cos φ) near unitySwitching on input supply L1, L2, L3200–240 V 10%380–480 V 10%525–600 V 10%525–690 V 10%50/60 Hz( 0.98)1–2 times/min.Output data (U, V, W)Output voltageSwitching on outputRamp timesOutput frequency0 –100% of supply voltageUnlimited1–3600 sec.0–590 HzSupply voltageVLT General Purpose I/O MCB 1013 digital inputs, 2 digital outputs,1 analogue current output,2 analogue voltage inputs.VLT Relay Card MCB 105Adds 3 relay outputsVLT Analog I/O MCB 1093 PT1000/Ni1000 inputs, 3 analoguevoltage outputs and back-up powerfor Real-Time Clock.VLT 24 V External Supply MCB 10724 V DC external supply can be connected to supply, control and optioncards.Sensor input cardSensor input card for motor protection with 2 or 3 PT100 or PT1000inputs (VLT Sensor Input MCB 114).Brake chopper (IGBT) optionConnected to an external brakeresistor, the built-in brake chopperlimits the load on the intermediatecircuit in the case the motor acts as agenerator.Power optionsA wide range of external power optionsare available for VLT HVAC Drive incritical networks or applications: Advanced Harmonic Filters:For critical demands on harmonicdistortion dU/dt filters: For special demandson motor isolation protection Sine-Wave filtersDigital inputsProgrammable digital inputsLogicVoltage level* 2 can be used as digital outputsPulse inputsProgrammable pulse inputsVoltage levelPulse input accuracy* Utilize some of the digital inputsAnalogue inputAnalogue inputsModesVoltage levelCurrent levelRelay outputsProgrammable relay outputs2 (240 VAC, 2 A and 400 VAC, 2 A)Fieldbus communicationStandard built-in:FC ProtocolN2 MetasysModbus RTUBACnet embeddedHigh power options 2Voltage or current0 V to 10 V (scaleable)0/4 to 20 mA (scaleable)10/4 – 20 mA 2*0–24 VDC (PNP positive logic)(0.1–110 kHz)Analogue outputProgrammable analogue outputsCurrent range at analogue outputHVAC PC software toolsVLT Motion Control Tool MCT 10:Ideal for commissioningand servicing the driveVLT Energy Box: Comprehensiveenergy analysis tool. Energy consumption with and w/o drive canbe calculated (drive payback time).Online function for accessing drivesenergy log.VLT Motion Control Tool MCT 31:Harmonics calculations tool6*PNP or NPN0 – 24 VDC Optional:VLT LonWorks MCA 108VLT BACnet MCA 109VLT DeviceNet MCA 104VLT PROFIBUS DP MCA 101VLT PROFINET MCA 120VLT EtherNet/IP MCA 121VLT Modbus TCP MCA 122IEC Emergency stop withSafety RelaySafety Stop with Safety RelayRFI FiltersNAMUR terminalsRCDIRMMains shieldingRegen terminalsPlease see the VLT High Power Drive Selection Guidefor the complete range of options.11

VLT HVAC Drive – continuedCurrent and power ratingsT6 525 – 600 VA2A2212260315395480588190240302361443535D1h/ D1h/D3h D5h/ D5h/D6h D6h658745800880990112012601460590678 E273078089010501160138017201530A4/A5A3A3A5 A5B3B1B1 B1B4C3C4B2B2 B2C1C1 C1C2C2 526283100131A3 A3 A5 A5B3 B1 B1 B1B4C3B2 B2 B2C1 C1 C1C4 C2 C2 15IP 66IP 55IP 54IP 21550 V 690 VIP 20IP 66A3 A3 A5 A5D2h/ D2h/D4h D7h/ D7h/D8h D8hE1IP 55IP 21IP 55IP 66A4/A5A4/A5IP 54IP 21IP C3B2B2C2C2D1h/ D1h/D3h D5h/ D5h/D6h D6hD2h/ D2h/D4h D7h/ D7h/D8h D8hE1F2/ F4F2/ F4E1E1F1/F3C4 C2 C2 C2A22.62.94.15.2F2/F4C1 C1 C1101316243237.544617390106147177A2 550 V 550 VF1/F3C3B2 B2 B22.73.44.86.3F2/F4B434.15.67.2Amp.F1/F3B3 B1 B1 B1 440 V 440 VF1/F324.230.846.259.474.888115143170A4/A56.67.5 A2 A210.612.5A3 A3 A5 0P630P710P800P900P1M0P1M2P1M4IP 00IP 66IP 55IP 21IP 20FC 102 kWT7 525 – 690 VAmp.IP 00T4 380 – 480 VAmp.IP 20T2 200 – 240 V* @ 690 VIP 00/ChassisIP 20/ChassisIP 21/Type 1With upgrade kit –available in US onlyIP 54/Type 12IP 55/Type 12IP 66/NEMA 4XDimensions [mm]A2 A3 A4 A5 B1 B2H268390 420 480 650W 90 130 200242D205175 200260H 375W 90 130B3399165249475165B4 C1 C2 C3 C4 D1h D2h D3h D4h D5h D6h D7h D8h520 680 770 550 660 901 1107 909 1122 1324 1665 1978 2284230 308 370 308 370 325 420 250 350325420242 310 335333378375381384 402670755 950255329 391E12000600494E21547585498F122801400607Note: H and W dimensions are with back-plate. H and W are with IP upgrade kit. D dimensions are without option. A or B for A2 and A3.12F222801804607F322801997607F422802401607

VLT Refrigeration DriveDedicatedto refrigeration applicationSpecially designed for the needs ofrefrigeration applications, but alsocapable of running pump and fanapplications.Regardless if you want to operate compressors, pumps or fans, the VLT Refrigeration Drive FC 103provides you the possibility to save energy and extend the lifetime of the components.Speed control provides many benefitsin all motor driven parts of refrigeration applications. The VLT Refrigeration Drive moves the user in theposition to profit from this in a verysimple way by saving energy andprolonging lifetime of essentialequipment.One drive for allThe VLT Refrigeration Drive FC 103covers a power range between1.1-315 kW. Available in a variety ofprotection classes the drive suits theneeds of pump, fan and compressorapplications. Every application andpower size can be operated andprogrammed with the same commonuser interface.Easy commissioningThe VLT Refrigeration Drive FC 103offers a setup Wizard, using commonrefrigeration terms rather thancomputer language, making installation quick and easy for servicetechnicians and installers.The wizard menu also supports thecommissioning engineers if theyencounter any problems. The menuwill help the engineer troubleshootand offer solutions to get the driveup and running again if there is aproblem.FeatureBenefitRobust single enclosureProtection classes IP 20/21/55/66Coated electronics (class 3C2 or 3C3)Maintenance freeFits every applicationWithstands challenging environmentsMax. ambient temp. 50 C without deratingNo external cooling or oversize necessarySoftware featuresSleep modeThermostat/Pressostat functionFieldbus (AKD LON, Modbus RTU )Velocity-to-flow conversionDay/Night ControlAdvanced energy monitoringPressure to temperature conversionCompressor featuresHigh starting torquePO optimizationInjection on/offDischarge temperature monitorPack controllerNeutral zone controllerPump featuresPump cascade controllerDry pump protection and end of curveFlow compensationFan featuresBroken belt detectionOperate induction motors in parallelAutomatic Energy Optimizer AEO functionNo EMC concernsIntegrated DC link harmonic filtersIntegrated EMC filtersBenefitsOptimum system efficiencySystem protectionOpen for all kind of controllersSaves costsReduces wear and energy consumptionOverview of energy consumptionSaves costsBenefitsOperates all types of compressorOptimum system efficiencyImproves refrigeration processesProtects the compressorSaves energy and reduce maintenanceHandling of unsymmetrical zonesBenefitsSaves energy and reduce maintenanceProtects the pumpSaves energyBenefitsProtects the systemReduces investment costSaves energyBenefitsLow harmonic load on mainsNo external filters required13

VLT Refrigeration Drive – continuedProduct range3 x 200 – 240 V . 1.1 – 45 kW3 x 380 – 480 V .1.1 – 315 kW3 x 525 – 600 V . 1.1 – 90 kWSpecificationsMains supply (L1, L2, L3)Supply frequencyDisplacement Power Factor (cos φ)Switching on input supply L1, L2, L3200 – 240 V 10%380 – 480 V 10%525 – 600 V 10%50/60 HzNear unity ( 0.98)1-2 times/min.Output data (U, V, W)Output voltageSwitching on outputRamp timesOutput frequency0 –100% of supply voltageUnlimited1 – 3600 sec.0 – 590 HzSupply voltageWith 110% overload torqueAvailable enclosure ratingsIP 20 (NEMA 1).1.1 – 315 kWIP 21 (NEMA 1).1.1 – 315 kWIP 54 (NEMA 12) .110 – 315 kWIP 55 (NEMA 12) . 1.1 – 90 kWIP 66 (NEMA 4X) . 1.1 – 90 kWStandard coating providing extra protection foraggressive environments.OptionsA wide range of VLT RefrigerationDrive FC 103 options are availablemounted and tested from the factoryor as plug-and-play options for laterupgrades.VLT General purpose I/O MCB 1013 digital inputs, 2 digital outputs,1 analogue current output,2 analog

box. As part of the Danfoss VLT FlexConcept the VLT OneGearDrive is an energy-effi cient drive system that helps to optimise plant productivity and reduce energy costs. VLT DriveMotor FCM 300 Integrated drive-motor solution which combines a VLT frequency converter and a high standard quality induction motor in a single product.