Transcription

LonWorks FTP Option Cardfor TEIOperating InstructionsSoftware version: 2.5xThese Operating Instructions can be used for all VLT 6000HVAC frequency converters with software version 2.5x.The software version number can be seen from parameter624.175Z6910.10VLT 6000 HVAC

VLT 6000 HVAC TEI! DANGERRotating shafts and electrical equipment canbe hazardous. Therefore, it is stronglyrecommended that all electrical work conformto the National Electrical Code (NEC) and alllocal regulations. Installation, start-up andmaintenance should be performed only byqualified personnel.Factory recommended procedures, included in this manual,should be followed. Always disconnect electrical power beforeworking on the unit.Although shaft couplings or belt drives are generally notfurnished by the manufacturer, rotating shafts, couplings andbelts must be protected with securely mounted metal guardsthat are of sufficient thickness to provide protection againstflying particles such as keys, bolts and coupling parts. Evenwhen the motor is stopped, it should be considered “alive”as long as its controller is energized. Automatic circuits maystart the motor at any time. Keep hands away from the outputshaft until the motor has completely stopped and power isdisconnected from the controller.Motor control equipment and electronic controls areconnected to hazardous line voltages. When servicing drivesand electronic controls, there will be exposed componentsat or above line potential. Extreme care should be taken toprotect against shock. Stand on an insulating pad and makeit a habit to use only one hand when checking components.Always work with another person in case of an emergency.Disconnect power whenever possible to check controls orto perform maintenance. Be sure equipment is properlygrounded. Wear safety glasses whenever working on electriccontrol or rotating equipment.does not disconnect the equipment from the AC line andis not to be used as a safety switch.3. Correct protective grounding of the equipment must beestablished. The user must be protected against supplyvoltage and the motor must be protected againstoverload in accordance with applicable national and localregulations.4. Ground currents are higher than 3 mA.Warnings Against UnintendedStart1. While the drive is connected to the AC line, the motorcan be brought to a stop by means of external switchclosures, serial bus commands or references. If personalsafety considerations make it necessary to ensure thatno unintended start occurs, these stops are not sufficient.2. During programming of parameters, the motor may start.Be certain that no one is in the area of the motor ordriven equipment when changing parameters.3. A motor that has been stopped may start unexpectedlyif faults occur in the electronics of the drive, or if anoverload, a fault in the supply AC line or a fault in themotor connection or other fault clears.4. If the “Local/Hand” key is activated, the motor can onlybe brought to a stop by means of the “Stop/Off” key oran external safety interlock.NOTE:It is responsibility of user or person installingdrive to provide proper grounding and branchcircuit protection for incoming power andmotor overload according to National ElectricalCode (NEC) and local codes.The Electronic Thermal Relay (ETR) is UL listed. VLTs provideClass 20 motor overload protection in accordance with theNEC in single motor applications, when VLT 6000/8000parameter 117 (VLT 5000 parameter 128) is set for ETR Trip 11. The drive must be disconnected from the AC line beforeand parameter 105 is set for rated motor (nameplate) current.any service work is done.2. The “Stop/Off” key on the local control panel of the driveSafety Guidelines! DANGERTouching electrical parts may be fatal – even after equipment has beendisconnected from AC line. To be sure that capacitors have fully discharged, wait 14 minutes after power has been removed before touchingany internal component.2MG.60.R1.02 - VLT is a registered Danfoss trademark

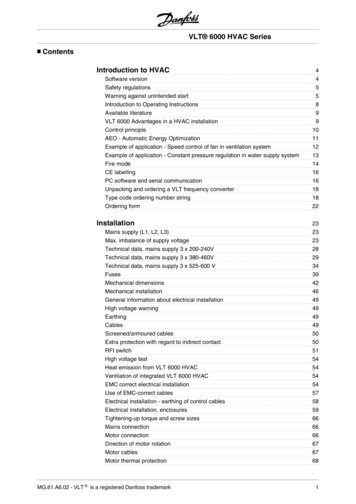

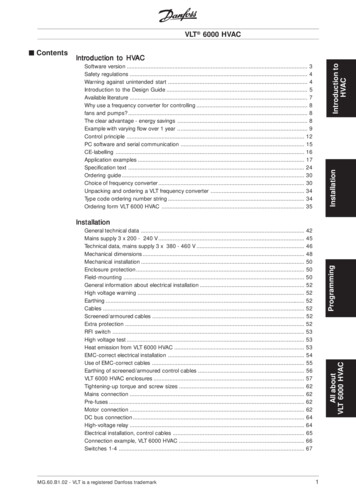

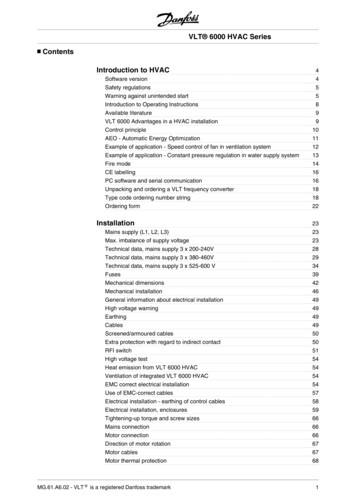

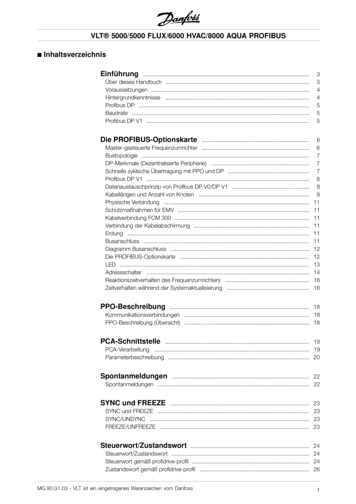

VLT 6000 HVAC TEITable of ContentsOverviewIntroduction .About This Manual .Assumptions .What You Should Already Know .References .LonWorks Overview .LON Concept .Applications .VLT LonWorks Option Card .Node Arrangements .Message Passing .Collision Detection .Network Management .Routers and Bridges .55555666777889InstallationWiring Installation . 10Card Installation . 10Tools Required . 10VLT LonWorks Option Card.11Installation Instructions . 12Network Initialization of LonWorks Option Card . 19Resource files . 19Free Topology Network ConfigurationFree Topology Network Configuration .Network Termination Option .Terminator and Service Switch Locations .System Performance .System Specifications .Transmission Specifications .Free Topology Specifications .Doubly-terminated Bus Topology Specifications .2021212222222222Diagnostic LEDsLonWorks Card Diagnostic LEDs .Status LED .Service LED .Service LED Patterns and Descriptions .MG.60.R1.02 - VLT is a registered Danfoss trademark232323243

VLT 6000 HVAC TEIInterface/Network VariablesNetwork Drive Control Input .Drive Feedback to Network .Drive Status Bit Definitions .Network Timer Functions .VLT Parameter Access .Parameter Access Error Codes .Parameter Access Command and Response Examples .Standard Object Support .Alarm Descriptions .252931323334343637ParametersParameter List . 38Parameter Description . 384MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEIIntroductionThis manual provides comprehensiveinstructions on the installation and set up ofthe LonWorks Option Card for the VLT 6000Frequency Converter to communicate over aLonWorks network.For specific information on installation andoperation of the frequency converter, refer tothe VLT 6000 Operating Instructions and DesignGuide.Portions of this manual are printed with theAbout ThisManualThis manual is intended to be used for bothinstruction and reference. It only brieflytouches on the basics of the LonWorksprotocol whenever it is necessary for gainingan understanding of the LonWorks profile fordrives and the LonWorks Option Card for thefrequency converter.permission of the Echelon Corporation and theNational Electrical Contractors Association ofthe USA (NECA).Echelon , LonTalk , Neuron and LonWorks are registered trademarks of the EchelonCorporation. VLT is a registered trademarkof Danfoss Inc.communication system. Even if you are anexperienced LonWorks programmer, wesuggest that you read this manual in its entiretybefore you start programming, since importantinformation can be found in all sections.This manual is also intended to serve as aguideline when you specify and optimize yourAssumptionsThis manual assumes that you have acontroller node that supports the interfacesin this document and that all the requirementsstipulated in the controller node, as well as thefrequency converter, are strictly observed alongwith all limitations therein.What YouShouldAlready KnowThe Danfoss LonWorks Option Card isdesigned to communicate with any controllernode that supports the interfaces defined inthis document. It is assumed that you havefull knowledge of the capabilities andlimitations of the controller node.ReferencesLonMaker for Windows User's Guide.VLT 6000 Installation, Operation andInstruction Manual(Referred to as the VLT Instruction Manual inthis document.)MG.60.R1.02 - VLT is a registered Danfoss trademark5

VLT 6000 HVAC TEILonWorksOverviewLonWorks is both an existing standard andhardware developed by Echelon Corporation.Echelon's stated goal is to establish a commodity solution to the presently dauntingproblems of designing and building controlnetworks.The result is LonMark Interoperability whichmakes it possible for independent networkdevices to operate together over aLonWorks network. The LonMark programwas developed to address interoperabilityissues. As a result, the LonMarkInteroperability Association Task Groups(LonUsers Groups) were developed. Thetask groups determine that each device onthe network has an object definition, createLONConceptThe LonWorks communications structure issimilar to that of a local area network (LAN)in that messages are continually exchangedbetween a number of processors. ALonWorks system is a determined localoperating network (LON). LON technologyoffers a means for integrating variousdistributed systems that perform sensing,monitoring, control, and other automatedfunctions. A LON allows these intelligentdevices to communicate with one anotherthrough an assortment of communicationsmedia using a standard protocol.standards and models to be used by particularapplications and create a common platformfor presenting data. A standard networkvariable type (SNVT) facilitates interoperabilityby providing a well defined interface forcommunication between devices made bydifferent manufacturers. The VLT FrequencyConverter supports the node object andcontroller standard object definitions ofLonMark Interoperability.Customers are currently using LonWorks forprocess control, building automation, motorcontrol, elevator operation, life safetysystems, power and HVAC distribution andsimilar intelligent building applications.network devices can communicate directlywith one another without need for a centralcontrol system. A LON is designed to movesense and control messages which aretypically very short and which containcommands and status information thattrigger actions. LON performance is viewedin terms of transactions completed persecond and response time. Control systemsdo not need vast amounts of data, but theydo demand that the messages they sendand receive are absolutely correct. The criticalfactor in LON technology is the assuranceof correct signal transmission and verification.LON technology supports distributed, peerto-peer communications. That is, individualApplicationsAn important LonWorks benefit is thenetwork’s ability to communicate acrossdifferent types of transmission media. TheNEURON chip is the heart of the LonWorkssystem. The N EURON chip's communication port allows for the use oftransceivers for other media (such as coaxand fiber optic) to meet special needs.LonWorks control devices are called nodes.Physically, each node consists of a NEURONchip and a transceiver. With proper design,the nodes become building blocks that can6be applied to control a variety of tasks, suchas lighting or ventilating, integrating a varietyof communications media.The tasks which the nodes perform aredetermined by how they have beenconnected and configured. Becausehardware design, software design, andnetwork design may be independent in aLonWorks-based system, a node’s functioncan be programmed to accommodate thenetworks in which it will be used.MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEIVLT LonWorks The Danfoss VLT LonWorks option card iscomprised of a control card with a NEURONOption Cardchip and a memory card. When installed intothe VLT frequency converter, the unit enablesthe drive to communicate with other deviceson the LON. The VLT drive is designed toprovide precision control of standard inductionelectrical motors. The drive receives threereference signals along with start/stop and resetcommands from the network. The drive alsoreceives a 16-bit control word that providesfull operational control of the drive. (SeeNetwork Drive Control Input for additionaldetails.)In response, the drive provides 16 outputnetwork variables containing important driveand motor data. (See Drive Feedback toNetwork.) Output to the network includesdrive status, current, voltage, motor andinverter thermal status, and alarms andwarnings.NodeArrangementsLonWorks nodes can be addressed eitherindividually or in groups. A group can containup to 64 nodes, and one LonWorks networkcan support 255 groups. Furthermore, anynode can be part of 15 different groups. Asubnet, very similar to a group, can contain127 nodes. A domain is the largestarrangement of nodes with a single domainable to handle 255 subnets. Thus a domaincan handle 32,385 separate nodes. A singlenode may be connected to no more than twodomains.The group structure has the advantage ofallowing a number of nodes to be reached atonly one address. This method reduces theMessagePassingThere are a number of trade-offs betweennetwork efficiency, response time, security,and reliability. Generally, LonWorks defaults tothe greatest degree of safety and verificationfor all communications over the LON network.The LonTalk protocol, built into the chips, isthe operating system that coordinates theLonWorks system. It offers four basic typesof message service.MG.60.R1.02 - VLT is a registered Danfoss trademarkLonWorks supports many different types oftransmission media. A LonWorks networkphysical layer option can be transformercoupled twisted pair (78 kbps and 1.25Mbps), free topology, link power, power line,RF, RS-485, fiber optic, coaxial, or infrared.The VLT LonWorks option supports fourtransmission media with three versions of theVLT LonWorks option card. The VLTLonWorks option card versions are:1. Free topology, which also operates ona link power network.2. 78 kbps transformer coupled twistedpair.3. 1.25 Mbps transformer coupled twistedpair.A router is required to interface to a LonWorksnetwork when not supported by one of thethree option card versions.record keeping inside each chip to a minimum,allowing faster operation. However, highefficiency individual addressing can be doneat all levels of a LonWorks system. Theaddress table of a node contains entries forthe group type and size and tells the nodehow many acknowledgments to expect whenit sends a message. It also tells the NEURONchip which domain to use and the node groupmember number, which identifies anacknowledgment as coming from the node.The address also contains a transmit timer, arepeat timer, a retry counter, a receive timer,and the group ID.The most reliable service is acknowledged (orend-to-end acknowledged service), where amessage is sent to a node or group of nodesand individual acknowledgments are expected from each receiver. If anacknowledgment is not received from all destinations, the sender times out and re-triesthe transaction. The number of retries andtime-out duration are both selectable. Ac-7

VLT 6000 HVAC TEIMessagePassing(continued)knowledgments are generated by the networkhost processor without intervention of the application. Transaction IDs are used to keeptrack of messages and acknowledgments sothat the application does not receive duplicate messages.An equally reliable service is request/response,where a message is sent to a node or groupof nodes and individual responses are expected from each receiver. Incomingmessages are processed by the applicationon the receiving side before a response isgenerated. The same retry and time-out options are available as with acknowledgedservice. Responses may include data, so thatthis service is particularly suitable for remoteprocedure call or client/server applications.Next in reliability is unacknowledged repeated.Messages are sent multiple times to a nodeor a group of nodes with no responseexpected. This service is typically used whenbroadcasting to large groups of nodes whentraffic generated by all the responses wouldoverload the network.The final method in reliability is unacknowledged, where a message is sent onceto a node or group of nodes and no responseis expected. This option is typically used whenthe highest performance is required, networkbandwidth is limited, and the application isnot sensitive to the loss of a message.CollisionDetectionThe LonTalk protocol uses a unique collisionavoidance algorithm which allows anoverloaded channel to carry near to itsmaximum capacity, rather than reducing itsthroughput due to excessive collisionsbetween messages. When using acommunications medium that supportscollision detection, such as twisted pair, theLonTalk protocol can optionally canceltransmission of a packet as soon as a collisionis detected by the transceiver. This optionallows the node to immediately retransmit anypacket that has been damaged by a collision.Without collision detection, the node wouldwait the duration of the retry time to noticethat no acknowledgment was received. At thattime it would retransmit the packet, assumingacknowledge or request/response service.For unacknowledged service, an undetectedcollision means that the packet is not receivedand no retry is attempted.NetworkManagementDepending on the level of a given application,a LonWorks network may or may not requirethe use of a network management node. Anetwork management node performsmanagement functions, such as: Find unconfigured nodes anddownload their network addresses. Stop, start, and reset nodeapplications. Access node communication statistics. Configure routers and bridges. Download new applications programs. Extract the topology of a runningnetwork.8MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEIRouters andBridgesA router (or bridge) is a special node thatconsists of two connected NEURON chips, eachconnected to a separate channel (see figurebelow). Routers and bridges pass packetsback and forth between these channels. Thereare four types of routers. A repeater is thesimplest form of router, simply forwarding allpackets between the two channels. A bridgesimply forwards all packets which match itsdomains between the two channels. Using abridge or repeater, a subnet can exist acrossmultiple channels. A learning router monitorsthe network traffic and learns the networktopology at the domain/subnet level. Thelearning router then uses its knowledge toselectively route packets between channels.Like a learning router, a configured routerselectively routes packets between channelsby consulting internal routing tables. Unlike alearning router, the contents of the internalrouting tables are specified using networkmanagement commands.Initially, each router sets its internal routing tablesto indicate that all subnets could lie on either sideof the router. Suppose that node 6, in the figurebelow, generates a message bound for node 2.Learning router 1 initially picks up the message.It examines the source subnet field of themessage and notes in its internal routing tablesthat subnet 2 lies below it. The router thencompares the source and destination subnet IDsand, since they are different, the message ispassed on. Meanwhile, learning router 2 alsopasses the message on, making an appropriatenotation in its internal routing tables regarding thelocation of subnet 2.Suppose now that node 2 generates anacknowledgment. This acknowledgment ispicked up by learning router 1, which now notesthe location of subnet 1. Learning router 1examines its internal routing tables, and, notingthat subnet 2 lies below, passes the messageon. When the message appears on subnet 2, itis noted by both node 6 (the destination) andlearning router 2. Learning router 2 does not passit on but merely notes that subnet 1, like subnet2, lies somewhere above. Learning router 2 willnot learn of the existence or location of subnet 3until a message is originated from there. Subnetscannot cross routers. While bridges andrepeaters allow subnets to span multiplechannels, the two sides of a router must belongto separate subnets. Since routers are selectiveabout the packets they forward to each channel,the total capacity of a system can be increasedin terms of nodes and connections.Channel1234RLearningRouter 1ChannelSubnet 1LearningRouter 2R5678ChannelSubnet 29101112Subnet 3Learning RoutersSource: Echelon Corp.MG.60.R1.02 - VLT is a registered Danfoss trademark9

VLT 6000 HVAC TEIWiringInstallationW iringThe frequency converter generates a carrierfrequency with a pulse frequency between 3kHz and 14 kHz. This results in radiatedfrequency noise from the motor cables. It isvery important that the LonWorks cable beisolated as much as possible from the driveoutput cabling to the motor. Use shielded wirerather than twisted-pair. Do not run LonWorkscabling and motor cables in parallel or in closeproximity to one another. Ensure that the driveis properly grounded.CardInstallationThe following section describes the installationprocedures for the LonWorks option card (seefollowing illustration). For additional informationon installation and operation of the VLTfrequency converter, refer to the VLT InstructionManual.! DANGERVLT frequency converter containsdangerous voltages whenconnected to line power. Afterdisconnecting from line, wait atleast 14 minutes before touchingany electrical com-ponents.! WARNINGOnly a competent electricianshould carry out electricalinstallation. Improper installationof motor or VLT can causeequipment failure, serious injuryor death. Follow this manual,National Electrical Code (USA)and local safety codes.ToolsRequired10! CAUTIONElectronic components of VLTfrequency converter are sensitiveto electrostatic dis-charge (ESD).ESD can reduce performance ordestroy sensitive electroniccomponents. Follow proper ESDprocedures during installation orservicing to prevent damage.! CAUTIONIt is responsibility of user orinstaller of VLT frequencyconverter to provide propergrounding and motor overloadand branch protection accordingto National Electrical Code (USA)and local codes.Flat-head screw driverTorx T-10 screw driverTorx T-20 screw driverMG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEILEDsService PinSwitch SW1TerminalConnectorTerminatorSwitchMounting (to MemoryBoard)Service PinSwitch SW3RibbonCableSocket(to ControlBoard)LonWorks Control BoardDriveMemoryRibbonCableSocket(to drivecontrolboard)Memory BoardVLT LonWorks Option Card(Free Topology Model)MG.60.R1.02 - VLT is a registered Danfoss trademark11

VLT 6000 HVAC TEIInstallation Instructions1. Access toControlCardCassetteIP20/NEMA 1 and Bookstyle Remove Local Control Panel (LCP) bypulling out from top of display (A) byhand. LCP connector on panel backwill disconnect. Remove protective cover by gentlyprying with a screw driver at notch (B)and lift cover out of guide pin fittings.(A)(B)IP54/NEMA 12 Open front panel of drive by looseningcaptive screws and swing open. Disconnect Local Control Panel (LCP)cable from drive control card.(A)2. DisconnectControlCardCassette Remove control wiring by unpluggingconnector terminals (A). Remove grounding clamps (B) byremoving two screws holding each inplace. Save screws for reassembly. Loosen two captive screws (C) securingcassette to chassis.(B)(C)12MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEI3. RemoveCassetteand RibbonCables Lift control card cassette from bottom. Unplug two ribbon cables (A) and (B)from control board. Unhinge cassette at top to remove.(A)(B)NOTERibbon cables will need to bereconnected to same connections from which removed.4. ChassisGroundConnectionsNOTEGround strips are used on 208 Vdrives of 22 kW (30 HP) or lessand on 460 V drives of 45 kW(60 HP) or less. For all otherdrives, go to step 6. Location of holes to mount groundingstrips can vary with drive configuration.When applicable, remove mountingscrews and washers located in chassisusing Torx T-20 screw driver and savefor reassembly. Otherwise, groundingstrips attach with screws and washersprovided, as shown in step 5.MG.60.R1.02 - VLT is a registered Danfoss trademark13

VLT 6000 HVAC TEI5. InstallChassisGroundConnections Align ground strips over screw holes.Strip with fewest contact points mountson cable side of chassis. Tabs ongrounding strips point toward outsideof chassis. Replace screws removed in step 4 andadd additional screws and washersprovided, as necessary. Tighten to0.9 Nm (8 in-lbs) using Torx T-20 screwdriver.GroundStrips6. InstallRibbonCablesbetweenOptionCards Attach ribbon cables betweenLonWorks control card and memorycard. Be sure exposed wire portion of ribboncable (A) is facing front of socket (B).Do not remove blue insulation coveringend of ribbon cable. Pull up collar (C) of ribbon cable socket,insert cable and push collar closed. Repeat procedure for all ribbon cables.(D)(E)IP20/NEMA 1 and IP54/NEMA 12 Remove terminal connector fromterminal block (D) and connect toterminal block (E) at this time for easeof access.14MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEI7. RemoveLCP CradleIP20/NEMA 1 and Bookstyle Carefully push in tabs at corners of LCPcradle to release clips. Pull out todisengage clips and lift cradle free.8. RibbonCableRouting Route ribbon cables from LonWorksmemory card through slot at side ofcontrol board cassette.9. InsertLonWorksCard Insert edge of LonWorks cards into slotin side of cassette and align screwholes.MG.60.R1.02 - VLT is a registered Danfoss trademark15

VLT 6000 HVAC TEI10. SecureLonWorksCard Secure LonWorks card with 3self-tapping screws and washersprovided using Torx T-10 screw driver.Tighten to 8 in-lbs (0.9 Nm).11. InstallRibbonCable onVLT ControlBoard Be sure not to twist or crimp ribboncables. Insert cables into correspondingsockets and fasten in accordance withdirections in step 5.12. InstallLCP CradleIP20/NEMA 1 and Bookstyle Insert cradle clips into holes in cassette. Push down on cradle to snap it intoplace.16MG.60.R1.02 - VLT is a registered Danfoss trademark

VLT 6000 HVAC TEI13. InstallSpringTensionClipIP20/NEMA 1 and IP54/NEMA 12 Spring tension clip (A) is used as a cablestrain relief and ground point forshielded cable. Insert clip through inner wall of chassisat slot provided. Compress spring into clip at outer wallof chassis.(A)14. InstallRibbonCables Connect ribbon cables. Connect control card cassette to hingeat top of drive and fit into chassis.NOTERibbon cables must be reconnected to same connections fromwhich removed.MG.60.R1.02 - VLT is a registered Danfoss trademark17

VLT 6000 HVAC TEI16. Plug inTerminalConnector(C) Fasten control card cassette byalternately tightening two captivescrews (A). Tighten to 0.9 Nm (8 in-lbs). Route control wires through clampfasteners (B) and secure clamps withtwo screws. Connect control terminals (C) by firmlypressing them into connectorreceptacles.(A)(B) Connect signal wire NET A to terminal79 and NET B to 80 of terminalconnector. (In free topology model,connections can be reversed.)79 80 6115. InstallControl CardCassetteShield 61NET B 80NET A 79IP20/NEMA 1 and IP54/NEMA 12 Plug network connector into terminalblock at side of control card cassette. Insert LonWorks cable between innerwall of chassis and spring tension clip.NOTEShielded cable is recommended.Ground shielded cable at springtension clip location or ground atcable clamp by removing cableinsulation at contact point. Do notuse connector terminal 61.Bookstyle Remove knockout from

MG.60.R1.02 - VLT is a registered Danfoss trademark 7 VLT 6000 HVAC TEI Message Passing Node Arrangements LonWorks nodes can be addressed either individually or in groups. A group can contain up to 64 nodes, and one LonWorks network can support 255 groups. Furthermore, any node can be part of 15 different groups. A subnet, very similar to a .