Transcription

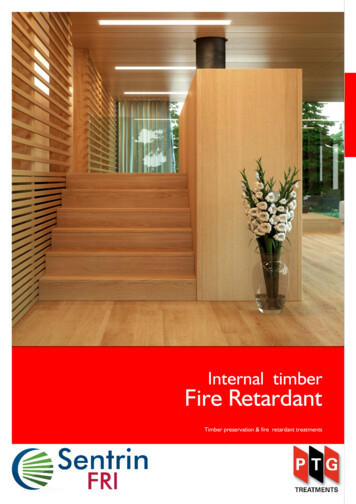

Internal timberFire RetardantTimber preservation & fire retardant treatments

Treated Timber SpecificationSentrin FRI fire retardant treated timber has been pressure impregnated with a humidity resistant, high temperature fireretardant formulation (Osmose FirePRO). It has been processed under ISO9001 controlled factory conditions to provideconfidence in performance and long lasting protection without further maintenance. Treated timber can meet therequirements of national Building Regulations where Euroclass B or C are required and will significantly reduce the spread offire, heat generation and smoke generation. These fire performance properties do not compromise critical engineeringproperties such as strength, durability, corrosivity and hygroscopicity.Flammability ClassificationsHow do I specify the correct treatment?Sentrin FRI treated wood products have been tested to BS ENEuroclassTransposition to BS47613501-1:2002; Fire classification of construction products andA1A2BCDbuilding elements. These ‘reaction to fire tests’ are used togenerate classifications of flammability which are commonlyspecified in building regulations. To specify the correct level ofprotection the following information is required:1. Timber species or plywood type and dimensions.2. Euroclass required (C or B).3. End use application (must be weather protected).Non-CombusibleVery limited combustibilityClass OClass 1Class 3What is the Service Life of the treated wood?Sentrin FRI treated wood products are designed to performContact us for assistance with detailed specification writing.for the life of the building or structure and require noSentrin FRI treated wood products meet the requirements ofmaintenance.HR (humidity resistant) and DI (dry internal) specifications. It isapproved by London Underground for use in construction andWhat is the appearance of the treated timber?maintenance projects. Certificate ID 1327 Osmose FirePRO.Treatment with fire retardant in general, does not alter theappearance of the timber or wood based panel. Some slightTypical applicationsdarkening may occur which will be dependent on the timberFor use in above ground interior applications where thespecies and the kiln drying process following treatment. Thererelative humidity does not exceed 85%. Sentrin FRI treatedmay also be some surface deposits which will not affect the firewood products can also be used externally when effectivelyperformance. Any deposits can be removed with a damp clothprotected from direct rainfall and weathering. Please contactor fine grade sandpaper.us regarding suitable external coatings which must beThe treatment process involves pressure impregnation with acorrectly maintained through the life of the building.warm liquid followed by at least 72 hours in a high temperatureOSB, MDF or other panel products produced from woodkiln. Consideration should be given as to whether the materialfibres or flakes are not suitable for pressure impregnationto be treated can withstand this process and we can providetreatment.advice.It is always recommended that representative samples areprocessed prior to full scale treatment.2

User GuideStorage of treated timberFollowing treatment kiln drying will reduce the moisture content to a level specified by the user and this should be as close to the inservice condition as possible. Treated timber is usually wrapped following drying to prevent weathering and re-wetting. Timbershould be protected from direct rain until installed. Extended outdoor exposure will downgrade the fire retardant properties.Re-working of treated timberWhere possible, treated wood should not be cut or otherwise reworked as this will expose untreated wood, reducing theeffectiveness of the flame retardant treatment. Rip-sawing, thicknessing and planing are not permitted. Light sanding with a fine gradesandpaper is acceptable and will not affect the fire retardant properties. Timber may be cross cut without the need for re-treatment.There are no limitations on the cutting of plywood. Refer to health & safety guidance if any re-working is to be carried out.HandlingTreated and dried wood poses the same hazards as untreated wood. Engineering controls and protective equipment should be usedto minimise airborne wood dust.Fixtures, fittings and gluingSentrin FRI treated wood is non-corrosive to metal fixtures and fittings. Where componentsare assembled and glued before treatment, a suitable waterproof adhesive should be used.Painting and stainingSentrin FRI treated wood can be painted using most standard coating systems. The user mustsatisfy themselves that the fire performance of a coating system does not compromise therequired fire performance of the timber. Advice should be sought from the coatingsmanufacturer. Samples should always be tested to ensure that the coating provides theintended result. Please contact us for further details.Treatment ProcessTreatment is carried out in high pressure autoclaves to penetrate fire retardant intothe timber to achive the required classification. Timber is loaded into the treatmentvessel and the door sealed. A vacuum is then created inside the to remove air fromthe timber. The vessel is flooded with fire retardant solution and high pressureapplied to penetrate into the timber. After the solution is removed a final vacuumis created to remove excess liquid. The liquid is returned to storage and there is nowaste generated from the process. The freshly treated timber is then heldundercover until it is drip dry before being kiln dried to its desired moisture content.Process times vary with the treatment specification but are typically between 90and 240 minutes.3

User GuideConfirmation of treatmentEvery consignment of treated timber is issued with a treatment certificate which confirms the fire retardant classification. This isan important document and may be required by a building regulator. Classification reports are available to be used in conjunctionwith the treatment certificate. If required, individual items can be stamped with the fire classification to aid identification.Quality AssuranceTreatment is carried out under controlled factory conditions.The process is ISO 9001 accredited and our productions centreshold Factory Production Control (FPC) certification and are WPA Benchmark FR approved. A computer controlled treatmentprocess ensures the correct retention of fire retardant to achieve the required classification. Sentrin FRI is an impregnated fireretardant and cannot be applied by hand, brush or spray. It provides a level of confidence in performance that may not beavailable with treatments applied on site or in uncontrolled conditions.How it worksWhen subjected to a fire, the protection technology reacts with the combustible gases and tars normally generated by untreatedwood, converting them to carbon dioxide and water. The layer of char formed on the surface insulates and retards the processof combustion reducing ignition, the rate of spread of flame, smoke propagation and the amount of heat released. This shouldprovide increased time for escaping from a building or structure.Construction Products Regulations and CE markingUK Building RegulationsUnder the EU Construction Products Regulation (CPR),The fire performance for all material that are to be used infrom 1 July 2013 a construction product will need to be CEbuildings, including wood and wood based panels are statedmarked and accompanied by a declaration of performancein Document B of the UK Building Regulations:if it is to be placed on the market in the EuropeanWall and ceiling linings are Class 1 Surface Spread of FlameEconomic Area and it is covered by either a harmonisedin accordance with BS476:Part 7 or Euroclass C inEuropean Product Standard or a European Technicalaccordance with BS EN13501.Assessment. It is the responsibility of the company orHigher risk areas, such as escape routes and staircases, andperson placing the product on the market for the first timeexternal cladding are Class 0 (BS476:Parts 6&7) orto ensure the CE mark is correct and accurate. PTGEuroclass B (BS EN13501).Treatments can supply the information required toThese standards relate to ‘reaction to fire’ of a material andcomplete a Declaration of Performance (DOP).not ‘fire resistance’ as in 30 or 60 minute specifications.4

Health Safety and EnvironmentalSentrin FRI fire retardant treated timber has been pressure treated with a waterbased humidity resistant (Type HR) fire retardant,Osmose FirePRO. Many of the health & safety recommendations are the same as those for working with untreated wood.Health & Safety Wear a dust mask, eye protection and gloves when working with wood. Treated wood should not be used where it may come into direct or indirect contact with drinking water. Do not use treated wood where the preservative may become a component of food, animal feed or beehives. Do not use treated wood for mulch. Wash exposed areas of skin following handling or working with treated timber. Launder heavily soiled clothes separately after working with treated timber.REACH StatementIn compliance with Article 33 of REACH: Sentrin FRI treated wood is an article which contains integral boric acid and it isconsidered that sufficient information is provided in this document to allow safe use of the article.Waste DisposalIndustrial Emissions DirectiveFurther informationSentrin FRI treated timber is notWood treatment facilities areFor further information on anyconsidered as hazardous waste.covered by EU Industrial Emissionsaspect of timber protection,Dispose of treated wood andDirective (IED) which promotescontact PTG Treatments. Ourwaste according to local authoritybest environmental techniques toliterature is constantly updated toregulation. Treated wood will notreduce and control the impact ofreflect regulatory changes. Thisreadily burn but can be disposed ofindustrial emissions. All PTGdocument is uncontrolled so pleasein commercial incinerators ortreatment centres comply with themake sure you have the latestlandfill to local regulations.requirements of the IED.version which can be downloadedfrom www.ptgtreatment.co.uk.5

Timber Preservation & fire retardant treatmentsContact UsTelephone 01777 709855Email info@ptgtreatments.co.ukWeb www.ptgtreatments.co.ukTreatment Centres Tilbury01375 858700tilbury@ptgtreatments.co.ukHull01482 329114hull@ptgtreatments.co.ukCumbernauld01236 720992cumbernauld@ptgtreatments.co.ukPerth01738 635521perth@ptgtreatments.co.uk

Sentrin FRI fire retardant treated timber has been pressure impregnated with a humidity resistant, high temperature fire retardant formulation (Osmose FirePRO). It has been processed under ISO9001 controlled factory conditions to provide . OSB, MDF or other panel products produced from wood fibres or flakes are not suitable for pressure .