Transcription

Grounding with Copper:Tinning vs. Non-tinningwww.copper.org

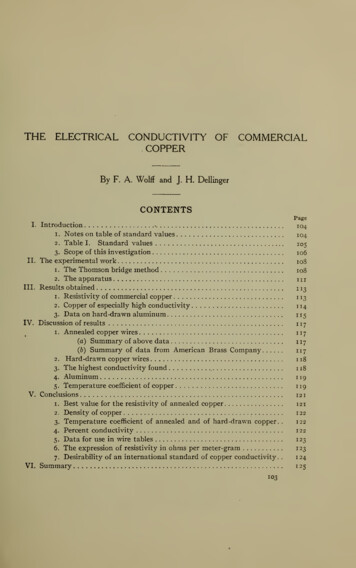

Grounding with Copper: Tinning vs. Non-tinningGeneralCopper and copper alloys are widely usedbecause they combine unique properties atan economical price. These include highthermal and electrical conductivity, ease ofmanufacture, high recyclability and goodcorrosion resistance. Copper, a noble metalthat occurs naturally in its elemental form, isalmost totally impervious to corrosion fromsoils found worldwide. But it would bemisleading to infer that copper will notcorrode.Fig. 1. Bare 4/0 AWG parallel copper conductorsare prepared for direct burial to form two ringgrounds around this wind-powered generatorbase. Soil analysis indicated that bare copper wasentirely appropriate at this site for direct burialwith no corrosion concerns.CorrosionGalvanic corrosion is an electrochemicalprocess whereby one metal corrodespreferentially to another whenever bothmetals are put in electrical contact andimmersed in an electrolyte. What issurprising to some is that soil or air can bean electrolyte.UndergroundCopper is the preferred metal for groundingconductors and electrodes. This is not onlydue to its high degree of connectivity, butalso its corrosion resistance. In most soils,copper electrodes outlast alternates such asgalvanized steel. However, there are certainconditions where tinning (coating with tin)the copper would be useful.The designer of a grounding systemtypically performs a soils analysis beforedesigning the grounding system. Soilaggressiveness and chemical compositionwill determine the appropriate steps to take.Fig. 2. Above-ground use of 4/0 AWG bare coppergrounding conductors for coax braids at acommunications facility. In this case, runoffconsiderations and corrosion were not issues andbare copper is perfectly suitable. Note the rich,brown color of the copper down-straps at left afterapproximately 10 years in service.

Fig. 3. Copper and galvanized steel are moresusceptible to corrosion where the pH of the soilexceeds 8. Soil analysis at this site (a dairypasture) indicated a large concentration oforganic acids. Stainless steel ground rods wereindicated, along with tinned 250 kcmil copperconductors. They were connected with a bronzefitting listed for that purpose, and coated withzinc-rich protective paint.Fig. 4. Bare copper can be directly attached torebar for concrete encasement. Note thatexothermic welding was utilized for this purpose.The concrete that will surround the rebar will actas a buffer, helping to prevent galvanic actionfrom the soil. (“Steel rebar embedded in concretehas approximately the same potential as copper,thus will not corrode” – IEEE Std. 142-1991)Fig. 5. In this instance, copper oxide runoff duringrain events is of no consequence. The copperoxide that will develop serves to protect theunderlying copper.When the chemical composition of the soilis unknown (in the absence of soil testing), itis the user’s choice to stipulate tinning orbare. In most cases, bare copper issufficient, although we recommendexceeding the rather minimal gaugerequirements of the NEC. 4/0 AWG or largeris commonly found in industrialenvironments.When soils are highly acidic, or alkaline, orsuspected of being so, backfill material suchas bentonite can greatly extend the life ofbare copper. Further, bentonite retainswater, thus can greatly increase contactarea with the soil, thus reducing groundingresistance. Carbon-based backfills oftencontain other contaminants, such as sulfurand other elements which are harmful tocopper and should be avoided.

Fig. 7. Tinned 4/0 copper conductor attached to agalvanized steel flange of a support column. Notethe high pressure compression fitting andprotective paint.Fig. 6. A chemical-filled electrode surrounded bybentonite backfill (the white slurry) to improveelectrical connectivity to the earth.Above-ground Outdoor ConstructionOutdoor air can act as an electrolytebecause it contains a variety of componentswhich can cause corrosion of any metal.Varying moisture levels, salt and othercontaminants are just a few. In overhead,outdoor construction, copper runoff cancause staining of pavement materials. It’sone reason why older overhead telephonewiring (before plastic coverings) was usuallytinned. In addition, copper runoff can bevery corrosive to galvanized steel supportstructures, even when not in direct contact.In such cases, tinning of the conductors isrecommended to prevent such conditions.“Precipitation run-off from copper andcopper alloys can attack galvanized parts(BS 6651:1999 and IEC 61024-1-2, section5.2); therefore, bare copper conductors orcopper bus bars shall not be installedabove galvanized steel, such as a tower,unless the steel is protected against theprecipitation run-off “ (IEC 61024-1-2,section 5.2, quoted in Motorola R56.)Lastly, for connection to the main groundingbus, or any connection point, considerconnectability. In a recent research projectconducted by Powertech Labs, copperconnections in mechanical connectorspassed thermal cycling tests under IEC61238-1, while the overwhelming majority ofaluminum connections largely did not pass,irrespective of preparation. uilding/for more information on this study.

Further Reading:The general information in this document is a limited look at the complex subject of corrosion,and further investigation is encouraged. The following sources contain additional information ongrounding and corrosion. IEEE Standard 142, “Green Book”, latest 07.html Standards and Guidelines for Communication Sites (Motorola 6 2005 manual.pdf Conditions Contributing to Underground Copper ction/underground.html Copper Applications in Power Qualitywww.copper.org/applications/electrical/pq

This publication has been prepared solely as resource material for the use of individuals involved in the specification, design, selection and installation ofelectrical systems. It has been compiled from information provided by one or more of the parties mentioned herein and other information sources CopperDevelopment Association Inc. (CDA) and/or the relevant parties believe to be competent. However, recognizing that each system must be designed and installedto meet the particular circumstances, CDA and the parties mentioned in this publication assume no responsibility or liability of any kind including direct orindirect damages in connection with this publication or its use by any person or organization, AND MAKE NO REPRESENTATIONS OR WARRANTIES OF ANY KINDRELATED TO ITS USE, ACCURACY, COMPLETENESS, UTILITY, AVAILABILITY OR DOCUMENTATION.www.copper.orgA6169 - XX/15

thus will not corrode” – IEEE Std. 142-1991) Fig. 5. In this instance, copper oxide runoff during rain events is of no consequence. The copper oxide that will develop serves to protect the underlying copper. When the chemical composition of the soil is unknown (in the absence of soil testing), it is the user’s choice to stipulate tinning or bare. In most cases, bare copper isFile Size: 316KBPage Count: 6