Transcription

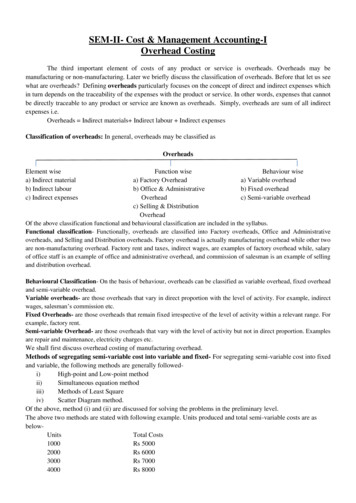

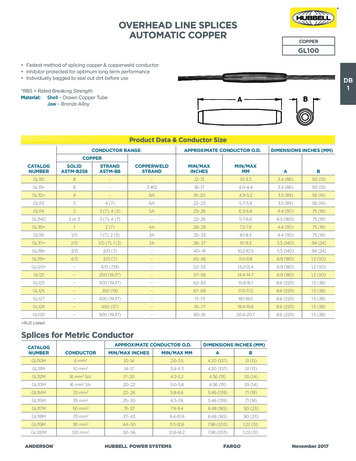

OVERHEAD LINE SPLICESAUTOMATIC COPPERCOPPERGL100 Fastest method of splicing copper & copperweld conductor Inhibitor protected for optimum long term performance Individually bagged to seal out dirt before useDB1*RBS Rated Breaking StrengthMaterial: Shell – Drawn Copper TubeJaw – Bronze AlloyProduct Data & Conductor SizeCONDUCTOR RANGEAPPROXIMATE CONDUCTOR O.D.DIMENSIONS INCHES ��.12-.133.1-3.33.4 (86).50 (13)GL111 6–3 #12.16-.174.0-4.43.4 (86).50 (13)GL112 4–8A.19-.204.9-5.23.5 (89).56 (14)GL11334 (7)6A.22-.235.7-5.93.5 (89).56 (14)GL11423 (7), 4 (3)5A.25-.266.3-6.64.4 (110).75 (19)GL11402 or 33 (7), 4 (7)–.22-.265.7-6.66.5 (160).75 (19)GL115 12 (7)4A.28-.297.2-7.44.4 (110).75 (19)GL1161/01 (7), 2 (3)3A.32-.338.1-8.34.4 (110).75 (19)GL117 2/01/0 (7), 1 (3)2A.36-.379.1-9.35.5 (140).94 (24)GL118 3/02/0 (7)–.40-.4110.2-10.55.5 (140).94 (24)GL119 4/03/0 (7)–.45-.4611.5-11.86.9 (180)1.2 (30)GL120 –4/0 (7,19)–.52-.5313.2-13.46.9 (180)1.2 (30)GL121–250 (19,37)–.57-.5814.4-14.76.9 (180)1.2 (30)GL123–300 (19,37)–.62-.6315.8-16.18.6 (220)1.5 (38)GL125–350 (19)–.67-.6817.0-17.28.6 (220)1.5 (38)GL127–400 (19,37)–.71-.7318.1-18.58.6 (220)1.5 (38)GL128–450 (37)–.76-.7719.4-19.68.6 (220)1.5 (38)GL130–500 (19,37)–.80-.8120.4-20.78.6 (220)1.5 (38) RUS ListedSplices for Metric ConductorAPPROXIMATE CONDUCTOR O.D.DIMENSIONS INCHES (MM)CATALOGNUMBERCONDUCTORMIN/MAX INCHESMIN/MAX MMABGL110M6 mm2.10-.142.6-3.54.20 (107).51 (13)GL111M10 mm2.14-.173.4-4.34.20 (107).51 (13)GL112M16mm2Sol.17-.204.2-5.24.36 (111).55 (14)GL113M16 mm2 Str.20-.225.0-5.84.36 (111).55 (14)GL114M25mm2.22-.265.8-6.65.46 (139).71 (18)GL115M35 mm2.25-.306.5-7.65.46 (139).71 (18)GL117M50mm2.31-.377.9-9.46.48 (165).90 (23)GL118M70 mm2.37-.439.4-10.96.48 (165).90 (23)GL119M95 mm2.44-.5011.3-12.67.98 (203)1.22 (31)GL120Mmm2.50-.5612.6-14.27.98 (203)1.22 (31)ANDERSON 120HUBBELL POWER SYSTEMSFARGO November 2017

OVERHEAD LINE SPLICESSUREFIT AUTOMATIC ALUMINUMALUMINUMGLSF400 ANSI C119.4, full tension, Class A connector (95% of conductorbreaking strength unless otherwise noted) Color coded funnel guides for easy identification Funnel guides deploy after full insertion Factory inhibitor protected Fastest method of splicing aluminum, aluminum alloy, and ACSRconductorDB2Material:Shell – High Strength Aluminum AlloyJaws – Aluminum AlloyInternal Components – Galvanized Steel and ThermoplasticProduct Data & Conductor SizeAPPROXIMATECONDUCTOR O.D.CONDUCTOR SIZEDIMENSIONS INCHES 4-24-24-2.220-.3205.59-8.13Red-Orange12 (305)1.0 (25)GLSF4076A1/0 - 2/01/0 - 2/01/0 - 2/0.355-.4709.02-11.94Yellow-Gray18 (460)1.4 (36)GLSF40983/0 - 4/03/0 - 4/03/0 - 4/0.450-.59511.43-15.11Pink-Black22 (560)1.7 (43)GLSF402A#2#2#2.225 - .2505.72 - 6.35Orange100.09GLSF406A1/01/01/0.355 - .4009.03 - 10.18Yellow131.1GLSF410266.8 (18/1)312.8*336.4.603-.66615.32-16.92Brown19 (480)1.7 (43)GLSF411336.4 (18/1)394.5*397.5, **336.4.659-.72416.74-18.42Green20 (510)1.8 (46)GLSF412397.5 (18/1)465.4*477.720-.79518.34-20.19Blue22 (560)2.0 (51)GLSF413477 (18/1)559.5*556.5, 500.780-.85819.81-21.79White24 (610)2.1 (54).879 - 1.04122.33 - 26.4426.762.5NaturalGLSF414556.5 (18/1) 795 (36/1)652.4, 740.8600 (37 str),795 (61 str)*Includes compact conductor of same size - ASTM-B400** Round onlyReleased Funnel GuideANDERSON HUBBELL POWER SYSTEMSFully Seated Funnel GuideFARGO November 2017

OVERHEAD LINE SPLICESSUREFIT AUTOMATIC CORROSIVE ENVIRONMENT ALUMINUMALUMINUMGLSF400 KR Designed SPECIFICALLY for high corrosive/problem environments Extensively tested, including Fault Current & Salt Spray. ANSI C119.4, full tension, Class A connector (95% of conductorbreaking strength unless otherwise noted) Sequence Tested: Salt Fog per ASTM G85, Current Cycle per ANSIC119.4, and Fault Current per IEEE837 Color coded end funnel guides for easy identification Funnel guides deploy after full insertion Fastest method of splicing aluminum, aluminum alloy, and ACSRconductor Special inhibitor blend for corrosive environments Stainless steel springs Stainless steel or plastic pilot cups Holes in shell & center stop for drainage & evaporationMaterial:DB3Shell – High Strength Aluminum AlloyJaws – Aluminum AlloyInternal Components – Stainless Steel and ThermoplasticProduct Data & Conductor SizeAPPROXIMATECONDUCTOR O.D.CONDUCTOR SIZECATALOGNUMBERACSRAAACASTM-B232 ASTM-B399DIMENSIONS INCHES 12 (305)1.0 (25)GLSF4076AKR1/0 - 2/01/0 - 2/01/0 - 2/0.355-.4709.02-11.94Yellow-Gray18 (460)1.4 (36)GLSF4098KR3/0 - 4/03/0 - 4/03/0 - 4/0.450-.59511.43-15.11Pink-Black22 (560)1.7 (43)GLSF402AKR#2#2#2.225 - .2505.72 - 6.35Orange100.09GLSF406AKR1/01/01/0.355 - .4009.03 - 10.18Yellow131.1GLSF410KR266.8 (18/1)312.8*336.4.603-.66615.32-16.92Brown19 (480)1.7 (43)GLSF411KR336.4 (18/1)394.5*397.5, **336.4.659-.72416.74-18.42Green20 (510)1.8 (46)GLSF412KR397.5 (18/1)465.4*477.720-.79518.34-20.19Blue22 (560)2.0 (51)GLSF413KR477 (18/1)559.5*556.5, 500.780-.85819.81-21.79White24 (610)2.1 (54).879 - 1.04122.33 - 26.4426.762.5NaturalGLSF414KR556.5 (18/1) 795 (36/1)652.4, 740.8600 (37 str),795 (61 str)*Includes compact conductor of same size - ASTM-B400Note: For conductors other than those listed, consult factory.Released Funnel GuideANDERSON HUBBELL POWER SYSTEMSFully Seated Funnel GuideFARGO November 2017

OVERHEAD LINE SPLICESAUTOMATIC ALUMINUMALUMINUMGL400 ANSI C119.4, Class 1, full tension connector (95% of conductorbreaking strength unless otherwise noted) ANSI C119.4, full tension, Class A connector (95% of conductorbreaking strength unless otherwise noted) Color coded end funnel guides for easy identification Factory inhibitor protected Fastest method of splicing aluminum, aluminum alloy and ACSRconductorDB4Material:Shell – High Strength Aluminum AlloyJaws – Aluminum AlloyProduct Data & Conductor SizeAPPROXIMATECONDUCTOR O.D.CONDUCTOR SIZECATALOGNUMBERACSRAAACASTM-B232 ASTM-B399DIMENSIONS INCHES ABGL4016-46-46-4.184-.2634.68-6.70Blue14 (360)1.0 (25)GL402A444.225-.2505.72-6.35Orange9 (230)0.9 (23)GL404A222.280-.3207.11-8.13Red12 (305)1.0 (25)GL4042A4-24-24-2.220-.3205.59-8.13Red- Orange12 (305)1.0 (25)GL406A1/01/01/0.355-.4009.02-10.16Yellow12 (305)1.1 4Yellow-Gray18 (460)1.4 (36)GL4072/02/02/0.400-.47010.16-11.94Gray18 (460)1.4 (36)GL4083/03/03/0.450-.53011.43-13.46Black20 (510)1.6 1Pink-Black22 (560)1.7 (43)GL409A4/04/04/0.505-.59512.83-15.11Pink17 (430)1.6 ural9 (230)1.2 (31)*Includes compact conductor of same size - ASTM-B400Note: For conductors other than those listed, consult factory.ANDERSON HUBBELL POWER SYSTEMSFARGO November 2017

OVERHEAD LINE SPLICESAUTOMATIC ALUMINUM(MULTIPLE LAYER STRAND CONDUCTORS)ALUMINUMGL400 Automatic for larger multiple layer stranded conductor used inprimary distribution and transmission ANSI C119.4, full tension, Class A connector (95% of conductorbreaking strength unless otherwise noted) Color coded end funnel guides for easy identification Factory inhibitor protected Fastest method of splicing aluminum, aluminum alloy and ACSRconductorMaterial:Shell – Seamless High Strength Aluminum AlloyJaws – High Strength Aluminum AlloyNote:For conductors other than those listed, consult factory.DB5Product Data & Conductor SizeMULTIPLE LAYER STRAND CONDUCTORS-KCMIL SIZESAPPROXIMATECONDUCTOR O.D.CONDUCTOR SIZEDIMENSIONS INCHES 8 (18/1)312.8*336.4.603-.66615.32-16.92Brown19 (480)1.7 (43)GL411336.4 20 (510)1.8 (46)GL412397.5 (18/1)465.4*477.720-.79518.29-20.19Blue22 (560)2.0 (51)GL413477 (18/1)559.5*556.5, 500.780-.85819.81-21.79White24 (610)2.1 (54)GLT1316A266.8 (26/7)––––Natural36 (916)2.2 (56)GLT1317B336.4 (26/7)––––Green22 (560)2.0 (51)GLT1319A477 (26/7)––––White36 (916)2.2 (56)GL1333A 556.5 (18/1)Consult Fargo636.840-.92021.34-23.37Natural15 (380)2.0 (51)GL1351A 556.5 (26/7)Consult Fargo652.8.927-.94023.55-23.88Natural16 (410)2.0 (51)GL1355A Consult FargoConsult Fargo700, 715.940-.97623.88-24.80Natural16 (410)2.0 (51)GL1385A Consult FargoConsult Fargo795.996-1.03125.30-26.19Natural16 (410)2.0 (51)GL1441A Consult FargoConsult Fargo9541.100-1.14027.94-28.96Red16 (410)2.0 (51)*Includes compact conductor of same size - ASTM-B400 Maximum design rating 10,000 lb./44.5 kN**Round onlyANDERSON HUBBELL POWER SYSTEMSFARGO November 2017

ALUMINUMGL*KROVERHEAD LINE SPLICESAUTOMATIC - CORROSIVE ENVIRONMENTALUMINUMDB6Conductor StrandsCorrosion Resistant Splice(KR) Designed SPECIFICALLY for high corrosive/problem environments Extensively tested, including Fault Current & Salt Spray. ANSI C119.4, Class 1, full tension connector (95% of conductorbreaking strength unless otherwise noted) ANSI C119.4 Class A, temperature rated connector Sequence Tested: Salt Fog per ASTM G85, Current Cycle per ANSIC119.4, and Fault Current per IEEE837 Color coded end funnel guides for easy identification Fastest method of splicing aluminum, aluminum alloy, and ACSRconductor Special inhibitor blend for corrosive environments Stainless springs Stainless or plastic pilot cups Holes in shell & center stop for drainage & evaporation Positive conductor insertion, look in the holesMaterial:Shell – Seamless High Strength Aluminum AlloyJaws – High Strength Aluminum AlloyInternal Components – Stainless Steel or PlasticAfter 2000 hours of Salt Fog, 1000hours of Heat Cycle, and ThreeRounds of Fault Current TestingProduct Data & Conductor SizeAPPROXIMATECONDUCTOR O.D.INCHES (MM)CONDUCTOR SIZE††DIMENSIONS,INCHES AKR#4#4#40.225 (5.72)0.250 (6.35)Orange9 (230)0.9 (23)GL404AKR#2#2#20.280 (7.11)0.320 (8.13)Red12 (305)1.0 (25)GL4042AKR#4 - #2#4 - #2#4 - #20.220 (5.59)0.320 (8.13)Red-Orange12.8 (325)1.0 (25)GL406AKR1/01/01/00.355 (9.02)0.400 (10.16)Yellow12 (305)1.1 (28)GL4076AKR1/0 - 2/01/0 - 2/01/0 - 2/00.355 (9.02)0.470 (11.94)Yellow-Gray18 (460)1.4 (36)GL407KR2/02/02/00.400 (10.16)0.470 (11.94)Gray18 (460)1.4 (36)GL408KR3/03/03/00.450 (11.43)0.530 (13.46)Black20 (510)1.6 (41)GL409AKR4/04/04/00.505 (12.83)0.595 (15.11)Pink17 (430)1.6 (41)GL410KR266.8 (18/1)312.8336.40.603 (15.32)0.666 (16.92)Brown19 (480)1.7 (43)GL411KR336.4 (18/1)394.5397.5, 336.4**0.659 (16.74)0.724 (18.39)Green20 (510)1.8 (46)GL412KR397.5 (18/1)465.44770.720 (18.29)0.795 (20.19)Blue22 (560)2.0 (51)GL413KR477 (18/1)559.5556.5, 5000.780 (19.81)0.858 (21.79)White24 (610)2.1 (54)GL1333AKR 556.5 (18/1)Consult Factory6360.840 (21.34)0.920 (23.37)Natural16.5 (420)2.0 (51)GL1351AKR 556.5 (27/7), 636 (18/1)Consult Factory652.80.927 (23.55)0.940 (23.88)Natural16 (410)2.0 (51)GL1355AKR Consult FactoryConsult Factory700, 7150.940 (23.88)0.976 (24.79)Natural16 (410)2.0 (51)GL1385AKR Consult FactoryConsult Factory7950.996 (25.30)1.031 (26.19)Natural16 (410)2.0 (51)GL1441AKR 795 (26/7)Consult Factory9541.100 (27.94)1.140 (28.96)Red16 (410)2.0 (51)†† Includes compact conductor of same size. Maximum design rating 10,000 lbs (44.5kN)** Round OnlyNote: For conductor other than those listed, consult factory.ANDERSON HUBBELL POWER SYSTEMSFARGO November 2017

OVERHEAD LINE SPLICESAUTOMATIC REDUCINGREDUCINGGL Allows easy splicing from one size conductor to another size conductor Allows utilities the option of not stocking old conductor that isn’tused anymore Splice provides full strength of the weaker of the two conductorsand a resistance lower than the equivalent conductor Same design philosophy and material as used in the copper andaluminum automatic splices.Material:DB7CopperCopperShell – Drawn Copper TubeJaws – Bronze AlloyAluminumShell – Aluminum AlloyJaws – Aluminum AlloyACSRProduct Data & Conductor SizeCOPPER REDUCING SPLICESCONDUCTOR SIZEDIMENSIONS INCHES (MM)LARGE ENDCATALOGNUMBERSOLIDGL150GL151GL152SMALL ENDSTRANDSOLIDSTRANDAB4–6346–4 (100).56 (14)–4 (100)344.56 (14)–4 (100).56 (14)GL153236–5 (130).75 (19)GL154234–5 (130).75 (19).75 (19)GL155126–5 (130)GL156124–5 (130).75 (19)GL15712345 (130).75 (19)GL15812235 (130).75 (19)GL1591/01345 (130).75 (19)GL1601/01235 (130).75 (19)GL1611/01125 (130).75 (19)GL1622/01/0346 (150).94 (24)GL1632/01/0236 (150).94 (24)GL1642/01/0126 (150).94 (24)GL1652/01/04–6 (150).94 (24)GL1662/01/01/016 (150).94 (24)GL1673/02/0346 (150).94 (24)GL1683/02/0236 (150).94 (24)GL1693/02/0126 (150).94 (24)GL1703/02/01/016 (150).94 (24)GL1713/02/02/01/06 (150).94 (24)GL1724/03/03/02/07.4 (190)1.3 (33)GL173–4/02/01/07.4 (190)1.3 (33)GL174–4/03/02/07.4 (190)1.3 (33)GL175–4/04/03/07.4 (190)1.3 (33)GL176–250–4/07.4 (190)1.3 (33)ACSR REDUCING SPLICESGL406A4042A1/04-212.1 (307)1.2 (30)GL412411397.5336.421 (530)2.0 (51)ANDERSON HUBBELL POWER SYSTEMSFARGO November 2017

OVERHEAD LINE SPLICES AUTOMATICBI-METAL (COPPER TO ALUMINUM)BI-METALGL Provide a permanent electrical and mechanical connection ofcopper to ACSR, aluminum or aluminum alloy conductors Factory loaded inhibitor to ensure long term corrosion freeperformance Individually bagged to seal out dirt before useDB8Material:Shell – Aluminum AlloyJaws on side – Aluminum AlloyJaws on copper side – Plated Bronze AlloyProduct Data & Conductor SizeCONDUCTOR RANGECOPPER ENDDIMENSIONS INCHES (MM)ALUMINUM 4–2/0 - 3/03/0 - 4/08.5 (220)1.3 (33)GL114185A23–1/01/0 - 2/08.5 (220)1.3 (33)GL114195A23–2/0 - 3/03/0 - 4/08.5 (220)1.3 (33)GL117018A2/01/0–1/02/08.5 (220)1.3 (33)GL118195A3/02/0–2/0 - 3/03/0 - 4/08.5 (220)1.3 (33)GL4042A116–2-42-42-49.4 (239)1.0 (25)GL4042A12462-42-42-49.4 (239)1.0 (25)GL4042A1

ANSI C119.4, full tension, Class A connector (95% of conductor breaking strength unless otherwise noted) Sequence Tested: Salt Fog per ASTM G85, Current Cycle per ANSI C119.4, and Fault Current per IEEE837 Color coded end funnel guides for easy identification